Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Previously, the farm used only conventional slope screens for their primary separation which removed the coarse material. The farm had to dredge their 200 acre-foot waste lagoon once a year.

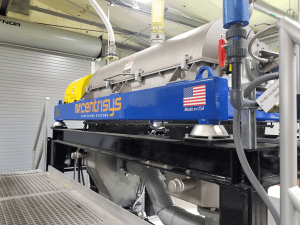

Bettencourt Dairy needed to process and meet their nutrient management plan when they added cross vents and vacuum trucks to move the manure from the barns. In 2018, they decided to add a Centrisys CS26-4DT dewatering centrifuge to remove the fines from the manure.

“We saw the Centrisys centrifuge as the only piece of equipment that was going to be able to get the solids out of our water,” Don Brand, Bettencourt Dairy Operations Manager of Equipment and Buildings. “The centrifuge seemed like the only piece of equipment that would be able to grow and expand with the operation.”

“The Centrisys centrifuge was the first piece of equipment that we bought for manure processing that worked from the beginning the exact way it was promised,” Brand said.

Centrisys/CNP supports global sustainability through its resource intensification portfolio with water and wastewater equipment and processes. Our systems are simple. They are designed to use less energy, less chemicals and less space. Centrisys is a U.S.A. manufacturer of dewatering centrifuges, sludge thickeners and also provides global service, repair and parts for all centrifuge brands. CNP, a division of Centrisys, designs and supplies nutrient recovery and biosolids treatment optimization systems.

For more information, please contact:

Centrisys/CNP

9586 58th Place

Kenosha, WI 53144

262-654-6006

Michele Whitfield or Jessie Jones

Email: marketing@centrisys-cnp.com

Website: www.centrisys-cnp.com

Centrisys/CNP has signed an exclusive U.S. distributor agreement with LIPP America Tank Systems, LLC for water, sludge and digester tanks. LIPP has a patented stainless steel digester system that allows digesters to be built on-site in less than two months. The short construction period and patented digester building system allow Centrisys/CNP to offer its clients cost-effective, high-quality digesters with a long life cycle. The LIPP product line compliments Centrisys/CNPs product portfolio by offering its customers solutions for resource intensification and resource recovery.

“Like Centrisys/CNP, LIPP is a highly innovative, privately-owned company. This partnership allows us to customize digesters and storage tanks with short delivery times and attractive costs,” said Gerhard Forstner, CNP President. “The distributor agreement enables Centrisys/CNP to retrofit even small wastewater treatment plants and convert them to resource recovery centers by recovering water, energy and nutrients.”

“We at LIPP America Tank Systems are honored and extremely excited to be a new partner with the Centrisys/CNP team,” said Al Lettinga, President/C.E.O. “We are confident that working together, we can make tremendous penetration within the municipal bioenergy and waste treatment market with our special LIPP double-fold tank technology. At LIPP America, as in the world markets, we stand out as a high quality and very unique tank technology. The LIPP double-fold and dual stainless plating system are a one-of-its-kind in the entire world market. Therefore, we are set apart against any liquid storage system in the market today.’

LIPP recently built a municipal anaerobic digester in Ohio and three more are currently being built in Michigan.

Centrisys/CNP supports global sustainability through its resource intensification portfolio with water and wastewater equipment and processes. Our systems are designed for simple operation using less energy, less space and fewer chemicals. Centrisys Corporation is a U.S.A. manufacturer of dewatering centrifuges, sludge thickeners and complete dewatering systems for municipal and industrial water and wastewater. Centrisys’ service department is a leader in global service, repair and parts for all centrifuge brands. CNP – Technology Water and Biosolids Corporation designs and supplies nutrient recovery and biosolids treatment optimization systems. CNPs key technologies are AirPrex® and CalPrex™, phosphorus recovery technologies that produce struvite and brushite fertilizers, and PONDUS, a Thermo-Chemical Hydrolysis Process (TCHP) which increases biogas production and digester capacity and reduces sludge volume and polymer consumption. CNP is a U.S. distributor for digester and storage tanks and hydrograv® adapt Variable Inlet System.

For more information, please contact:

Centrisys/CNP

9586 58th Place

Kenosha, WI 53144

262-654-6006

marketing@centrisys.com

www.centrisys-cnp.com

Market leader in sludge and industrial wastewater treatment equipment brings new ideas to market at major Chicago event

During the event, Centrisys personnel will conduct three in-booth presentations. On Monday, September 23 at 3 p.m., Centrisys/CNP shares an update on the first U.S. installation of a Passavant® hydrograv® adapt system that eliminates the need for clarifier systems. An in-booth demonstration unit will be on display. On Tuesday, September 24 at Noon, the company announces the CalPrex Pre-Digestion WRF project results and at 3 p.m., they talk about the recent THK installation updates.

The second session is on Wednesday, September 25 at 2 p.m. in Room S505A, where Menachem Tabanpour, CNP Vice President of Business Development, presents his paper, “High Efficiency Calcium Phosphate Recovery Technology at the Madison Metropolitan Sewerage District: Stability Metrics, Design Optimization and Performance.”

Stop by Booth 7708 and 7711 to learn more about the Centrisys/CNP technology.

For more information, please contact:

Centrisys/CNP

9586 58th Place

Kenosha, WI 53144

262-654-6006

marketing@centrisys.com

www.centrisys-cnp.com

Michele Whitfield or Jessie Jones

Note: Information taken from a discussion with Michael Kopper, the CEO and founder of Centrisys and Bill Fairbairn, Vice President and Building Expansion Manager at the company.

Expanded Building Area

Centrisys/CNP, Kenosha, Wisconsin today announced the completion of a 34,000 square-foot building expansion, including an upgrade of its balancing equipment with a first-of-its-kind centrifuge balancing bunker in the interior of the building.

The Centrisys/CNP Manufacturing and Service Campus, located in Kenosha, Wisconsin, consists of three buildings totaling 13,000 square feet. In 2016, it became apparent that the capital equipment manufacturing building was running out of workable space and needed an expansion. According to Kopper, “As the decision-making for the extension evolved, the addition of a next-generation balancing machine and bunker was logical. The safety of our employees, along with the assurance that every centrifuge we build and service is balanced correctly, was well worth the added expense.”

Because the balancing bunker is a first-of-its-kind solution, aimed at creating higher safety standards and increasing manufacturing productivity as well as efficiencies, a company committee was formed to design and build the bunker space and determine what equipment would work best.

According to Kopper, “We’ve been doing this type of work for a long time; centrifuge manufacturing and service have been our focus since the beginning. We had a thorough understanding of what we wanted and what the industry needed. Having enough workspace in a shop is important to eliminate errors during the manufacturing process. No one likes to work in a space that’s too crowded.” He added, “Underestimating the power of accurate balancing for a centrifuge is a big mistake. There is a tremendous cost to customers when a centrifuge is not in balance. High vibrations cause premature damage and wear to the centrifuge parts and structural components, creating higher repair costs and unnecessary process downtime.”

The HM7U has a full range of safety features for all protection classes. The bunker isolates the operator in a protected control area and includes video monitoring to see into the balancing areas without the employee needing to be in proximity to the running equipment. Cranes are installed overhead to place parts and components in the balancing cradles. Fairbairn concluded, “This set- up is something in which our team takes great pride, as it is world-class.”

Commenting on the future of Centrisys, Fairbairn said that the expansion changes were necessary and that the company’s growth “…has allowed us to build larger and greater numbers of centrifuges, along with different types of environmental process equipment. As the only US manufacturer of decanter centrifuges in all environmental dewatering and thickening applications, Kopper stated, “I believe we’ve set the bar high for improved safety, productivity and efficiency. These are all essential to the higher standards we’ve established in our industry.” He added, “I won’t compromise on any of these factors at a Centrisys facility. Our customers shouldn’t ever be required to compromise, either.”

For more information, please contact:

Centrisys/CNP

9586 58th Place

Kenosha, WI 53144

262-654-6006

marketing@centrisys.com

www.centrisys.com

Michele Whitfield or Jessie Jones

The PONDUS TCHP helps wastewater and sludge treatment facilities pursue a more sustainable future through a waste-to-value strategy

“Centrisys/CNP, through its licensing agreement to distribute PONDUS TCHP in North America, offers the market a more productive process alternative by replacing steam with safe caustic soda. The simplified system uses only a heat efficiency exchanger, progressive cavity pumps and a reactor with no moving parts,” said Seth Cutler, Frost & Sullivan’s principal consultant. “Through chemical reaction, the caustic soda breaks down cell membranes in the sludge as effective as steam. As a result, PONDUS TCHP offers operational simplicity avoids further personnel training and decreases the process carbon footprint.” ‘

TCHP reduces the volume of solids. This boosts the availability of digester capacity and the quality of outputs in biogas and solids. Biogas can be turned into heat, while the cake solids can be turned into fertilizer, soil amendments or nutrients. Thus, the product increases economic gains, economic care and offers a better future for communities.

“It is an honor that Frost & Sullivan gave us an award for PONDUS,” said Gerhard Fortner, CNP President. “The PONDUS process is a technology that just makes sense. It is simple to operate, cost-effective and safe for all sized plants.”

PONDUS originated in Germany and is currently used in six installations in Europe and one in China. Centrisys introduced PONDUS in North America through an agreement in 2015. The PONDUS process was integrated into the facility and fully functional in just 15 months.

Cutler further noted that this product can decrease the viscosity of thickened sludge up to 80%. This is important, as it permits 50% reductions in volume for anaerobic digesters and frees up more space. In addition, he pointed out that the produced sludge in the digesters is enhanced and can generate 30% more biogas, increasing value resource recovery. In addition, dewatering can result in improvements up to 5% in processing, while polymer consumption can shrink by 20% and eliminate foul odors in the facility.

The outstanding production and cost effectiveness gives Centrisys a huge advantage over traditional sludge treatment companies and position it for further growth.

Each year, Frost &Sullivan presents this award to a company that develops a product with innovative features and functionality that is gaining rapid market acceptance. The award recognizes the quality of the solution and the customer value enhancements it enables.

Centrisys/CNP will be at the WEF/IWA Residuals and Biosolids Conference in Fort Lauderdale, Florida from May 8-9 at booth 609. Zhongtian Li, CNP Technical Manager will give a presentation about PONDUS on May 9 at 2:30 pm.

About Centrisys/CNP

Centrisys/CNP supports global sustainability through its resource intensification portfolio with water and wastewater equipment and processes. Our systems are simple. They are designed to use less energy, less chemicals and less space. Centrisys is a U.S.A. manufacturer of dewatering centrifuges, sludge thickeners and also provides global service, repair and parts for all centrifuge brands. CNP, a division of Centrisys, designs and supplies nutrient recovery and biosolids treatment optimization systems.

About Frost & Sullivan

Frost & Sullivan, the Growth Partnership Company, works in collaboration with clients to leverage visionary innovation that addresses the global challenges and related growth opportunities that will make or break today’s market participants. For more than 50 years, we have been developing growth strategies for the global 1000, emerging businesses, the public sector, and the investment community.

For more information, please contact:

Centrisys/CNP

9586 58th Place

Kenosha, WI 53144

262-654-6006

marketing@centrisys.com

www.centrisys.com

From L to R: Salvation Army Kenosha Board Chairman Tim Leach; Salvation Army Kenosha Auxiliary Captain Marie Lewis; Receiving the award on behalf of the Centrisys/CNP employees Jan Mosele & Carlos Contreras; President of Celebrate Our Town Cindy Nicoletti; Kenosha County Sheriff David Beth; Mayor of Kenosha John Antaramian.

Centrisys/CNP, Kenosha, Wisconsin is proud to announce that they have been recognized for their charitable contributions by the Kenosha Salvation Army. Centrisys was awarded the 2019 Other’s Award Recipient in the category of “Resources Supporting Others.” Jim Andresen, the company’s COO said, “By May 2019, the Centrisys/CNP employees will have contributed over $15,000 to the Salvation Army and the company matches match all of our employees’ contributions dollar-for-dollar.”

Established in 2017, Centrisys Cares is the company’s charity. They support the Salvation Army through two programs, Youth Program and Recreation Program and the Disaster Relief Services. Every year in May, the company hands over checks to the Salvation Army for the two programs.

The award ceremony, entitled “2019 Other’s Luncheon,” was held March 9, 2019 at 12 pm at the Bristol Oaks Country Club. Each award recipient received two complimentary tickets. Centrisys was represented by Jan Mosele, marketing assistant and Carlos Contreras, the HR manager at the company. All the winners received a plaque and had their picture taken. Commenting on the award, Mosele said, “We were thrilled to accept this award on behalf of our generous employees at Centrisys Corporation. For the past 20 years, Centrisys has been very proud to call Kenosha home, so we knew we wanted to sponsor a local charity and selected the Salvation Army.” She concluded, “It is truly an honor to call the Salvation Army our partner in giving.”

Centrisys Corporation is a U.S.A. manufacturer of dewatering centrifuges, sludge thickeners and complete dewatering systems for municipal and industrial wastewater. The company’s focus is centrifuge equipment, including the award winning THK sludge thickener. Centrisys provides global service, repair and parts for all brands of centrifuges. CNP – Technology Water and Biosolids designs and supplies nutrient recovery and biosolids treatment optimization systems. CNP’s key technologies are: AirPrex® and CalPrex™, phosphorus recovery technologies, and PONDUS™, a Thermo-Chemical Hydrolysis Process (TCHP). CNP is a division of Centrisys Corporation.

For more information, please contact:

Centrisys/CNP

9586 58th Place

Kenosha, WI 53144

262-654-6006

marketing@centrisys.com

www.centrisys.com

One of Centrisys/CNP’s customers, the Kenosha Water Utility, received recognition as a “Utility of the Future Today” recipient.

The selection committee, consisting of six peer utility general managers/executives, had determined that the application submitted by the Kenosha Water Utility company met the criteria in the Activity Area of Partnering and Engagement.

Kenosha Water Utility attended the Utility of the Future Today Recognition ceremony. The reception took place at the 91st WEFTEC Conference and Exhibition, as part of the Utility Leaders Morning at the Earnest N. Morial Convention Center in New Orleans. This event took place on October 2nd, from 7:30 to 10:30 am. They received an outdoor flag and were presented with a certificate of recognition.

Centrisys Corporation is a U.S.A. manufacturer of dewatering centrifuges, sludge thickeners and complete dewatering systems for municipal and industrial wastewater. The company’s focus is centrifuge equipment, including the award winning THK sludge thickener. Centrisys provides global service, repair and parts for all brands of centrifuges. CNP – Technology Water and Biosolids designs and supplies nutrient recovery and biosolids treatment optimization systems. CNP’s key technologies are: AirPrex® and CalPrex™, phosphorus recovery technologies, and PONDUS™, a Thermo-Chemical Hydrolysis Process (TCHP). CNP is a division of Centrisys Corporation.

For more information, please contact:

Centrisys/CNP

9586 58th Place

Kenosha, WI 53144

262-654-6006

marketing@centrisys.com

www.centrisys.com

Centrisys/CNP, located in Kenosha, Wisconsin, is collaboratively working with the Milwaukee Metropolitan Sewerage District (Milwaukee, Wisconsin), the Metro Wastewater Reclamation District of Denver (Denver, Colorado), the Madison Metropolitan Sewerage District (Madison, Wisconsin) and the Massachusetts Water Reclamation Authority (Boston, Massachusetts).

Together, they will perform Tailored Collaborative Research (TCR), a program of The Water Research Foundation (WRF), to demonstrate phosphorus removal and recovery potential of the CalPrex™ process at the Madison Metropolitan Sewerage District from September to November.

The TCR will collect high-quality data from the CalPrex™ process and allow the participating utilities to evaluate high-rate phosphorus recovery prior to anaerobic digestion and its positive effects on operations and maintenance. This will help the utilities better meet stringent biosolids regulations and simultaneously mitigate operations and maintenance issues related to phosphorus levels in sludge. A peer review of the findings will be conducted and the results will be disseminated to industry professionals through the WRF LIFT Link platform.

Phosphorus (P) removal and recovery is one of the hottest topics in the wastewater biosolids industry today. Tightening regulations for both land applications and the sale of biosolids have water reclamation professionals eager to evaluate technologies that remove nuisance phosphorus from biosolids in a cost-effective and sustainable manner.

CNP – Technology Water and Biosolids designs and supplies nutrient recovery and biosolids treatment optimization systems. CNP’s key technologies are: AirPrex® and CalPrex™, phosphorus recovery technologies, and PONDUS™, a Thermo-Chemical Hydrolysis Process (TCHP). CNP is a division of Centrisys Corporation. Centrisys Corporation is a U.S.A. manufacturer of dewatering centrifuges, sludge thickeners and complete dewatering systems for municipal and industrial wastewater. The company’s focus is centrifuge equipment, including the award-winning THK sludge thickener. Centrisys provides global service, repair and parts for all brands of centrifuges.

For more information, please contact:

Centrisys/CNP

9586 58th Place

Kenosha, WI 53144

262-654-6006

Jessie Jones, Marketing Associate

Email: Jessie.jones@centrisys.us

Website: www.cnp-tec.com

With eight purchase orders in the last 3 months, the company’s sludge thickener has been used in several wastewater treatment facilities and wineries.

The basis of the THK design highlights what Centrisys is best known for – centrifuges. This sludge thickener is not a modified dewatering centrifuge, which is typically what happens when a conventional dewatering centrifuge is used for thickening sludge. The THK sludge thickener is designed and built specifically to thicken both primary and waste activated sludge using the fundamental principles of a centrifuge, DAFT and Rotary Drum Thickener.

According to Centrisys/ CNP’s CEO, Michael Kopper, “Equipment in this industry should last for decades. Those decision makers who understand the increasing importance of lower lifecycle costs and higher process efficiencies are clearly making the right choices for their plants and ultimately rate payers and our environment.”

Centrisys Corporation is a U.S.A. manufacturer of dewatering centrifuges, sludge thickeners and complete dewatering systems for municipal and industrial wastewater. The company’s focus is centrifuge equipment, including the award winning THK sludge thickener. Centrisys provides global service, repair and parts for all brands of centrifuges. CNP – Technology Water and Biosolids designs and supplies nutrient recovery and biosolids treatment optimization systems. CNP’s key technologies are: AirPrex® and CalPrex™, phosphorus recovery technologies, and PONDUS™, a Thermo-Chemical Hydrolysis Process (TCHP). CNP is a division of Centrisys Corporation.

For more information, please contact:

Centrisys Corporation

9586 58th Place

Kenosha, WI 53144

262-654-6006

Jessie Jones, Marketing Associate

Email: Jessie.jones@centrisys.us

Website: www.centrisys.com

Unlike fixed inlet structures for secondary clarifiers, the Passavant hydrograv adapt System consistently and continuously adjusts to current loading in a clarifier. If the loads are low, the hydrograv adapt automatically shifts the inlet elevation and opening height to a low position, introducing the mixed liquor below the sludge blanket. As the loads increase, the hydrograv adapt system shifts itself to a higher elevation and opening height, ensuring ideal hydraulic conditions for the operation of the secondary clarifiers and avoiding sludge overflow.

Benefits of the Passavant hydrograv adapt System include improved process stability of secondary clarification, a reduction of effluent suspended solids to usually less than 3 mg/L, improved particulate phosphorus removal, improved clarification capacity from hydraulic optimization and overall low maintenance requirements.

At WEFTEC 2018, Dr. Martin Armbruster, the Managing Director and founder of hydrograv GmbH and the inventor of the hydrograv adapt system, will co-present on the topic of “Stress Testing of a Secondary Clarifier with an Adaptive Inlet Structure.” His expertise in the field of clarifier CFD simulation includes optimization and practical engineering for more than 1,000 clarifiers in 200+ treatment plants worldwide. His experience in improving hydraulic efficiency of water management systems is based on 500+ hydrograv® with CFD simulations installations. The seminar will take place on Wednesday, October 3 at 1:50 p.m. in room 239.

Centrisys Corporation is a U.S.A. manufacturer of dewatering centrifuges, sludge thickeners and complete dewatering systems for municipal and industrial wastewater. The company’s focus is centrifuge equipment, including the award winning THK sludge thickener. Centrisys provides global service, repair and parts for all brands of centrifuges. CNP – Technology Water and Biosolids designs and supplies nutrient recovery and biosolids treatment optimization systems. CNP’s key technologies are: AirPrex® and CalPrex™, phosphorus recovery technologies, and PONDUS™, a Thermo-Chemical Hydrolysis Process (TCHP). CNP is a division of Centrisys Corporation.

For more information, please contact:

Centrisys Corporation

9586 58th Place

Kenosha, WI 53144

262-654-6006

Jessie Jones, Marketing Associate

Email: Jessie.jones@centrisys.us

Website: www.centrisys.com