Contact us today:

Author Archives: Bernard and Company

Grieve Corporation 2000°F Inert Atmosphere Heavy-Duty Box Furnace

The unit is equipped with a roof-mounted heat-resisting alloy recirculating fan, powered by a 1-HP motor with V-belt drive, motor-operated vertical lift door, 100 lb. capacity alloy loading cart with cast alloy roller rails, 3-1/2” diameter cast alloy rollers and a roller rail loading table with 4” diameter cast iron rollers.

This Grieve furnace also features inert atmosphere construction, consisting of a continuously welded outer shell, high temperature door gasket, sealed heater terminal boxes, inert atmosphere inlet, inert atmosphere outlet and inert atmosphere flowmeter.

Controls onboard No. 954 include a digital programming temperature controller, manual reset excess temperature controller with separate contactors, plus a strip chart recorder.

For more information, please contact: THE GRIEVE CORPORATION, Web: www.grievecorp.com.

Agency contact: Tim Daro, Bernard & Company

NEWS RELEASE: THE GRIEVE CORPORATION

DATE: December 21, 2009

New High-Performance, Compact Servo Motors for Demanding Motion Control

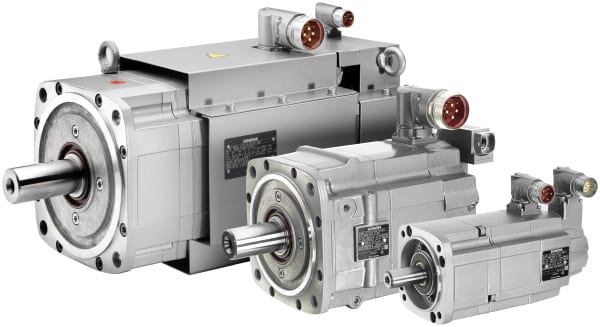

New Siemens 1FT7 servo motors, shown (l to r) in forced ventilation, water-cooled and air-cooled styles

Siemens introduces the 1FT7, a line of high-performance servo motors for such demanding motion control applications as machine tool CNC interpolation, production machine indexing control and more. Their use results in higher dynamic response, due to a 30% shorter design and 4x overload capacity versus 3x on the predecessor family of servos. Less downtime also results from the rigid vibration-insulated encoder mounting, which also enables the OEM or end user to exchange the encoder in the field in less than five minutes, without encoder alignment.

Design engineers have a choice in selecting this servo, as it is available in air-cooled, forced ventilation and water-cooled designs. The water-cooled design of the 1FT7 is provided with stainless steel piping in the stator.

Start-up and commissioning personnel will appreciate the Siemens electronic nameplate and digital encoder interface on this new servo, DRIVE CLiQ, as it simplifies start-up or replacement by not requiring all electronic data to be entered, as the DRIVE CLiQ cable recognizes all drive system components. With this feature, these motors become essentially plug-n-play devices. The drive recognizes the motor automatically and optimizes the parameterization accordingly. This digital encoder interface further allows users to route all their different encoder types along one signal cable.

High-resolution encoders, currently 22 bit, enable these servos to become highly precise motion control system components and these new high-dynamic 1FT7 motors also feature very low rotor inertia, thereby making them practical in applications where it was previously impossible to drive a servo. Such applications include sorters in the printing industry, which previously required mechanical cams but can now utilize electronic cams for better energy efficiency and less wear.

For a catalog or more information on these new servo motors, please contact:

SIEMENS INDUSTRY, INC.

GENERAL MOTION CONTROL

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/motioncontrol

Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communications

HAN-KWANG INTRODUCES FULLY AUTOMATIC TUBE CUTTING LASER SYSTEM

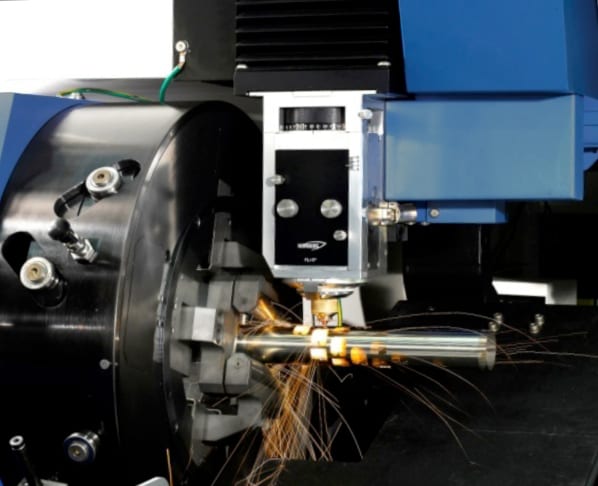

Han-Kwang USA announces immediate availability of its new Model TL 6015, a tube cutting laser system capable of handling 24’ long, 6.5” diameter workpieces up to 1/4” wall thickness in mild steel and 0.200” in stainless steel. Equipped with a powerful 2.5KW Panasonic laser and a versatile Siemens 840D CNC to control all functions of the machine, the TL 6015 can significantly increase the tube production in any department or shop, especially when used with Han-Kwang’s proprietary “Flex 3D” tube cutting software . The unit comprises an automatic bundle loading system with tube V-support, auto-centering rotary chucking system, laser cutting station and automatic parts removal station.

Maximum positioning speed on this new laser system is 4700 ipm for the X-

axis and 120 rpm for the rotary A-axis. Max acceleration rate is 1G, while the laser beam is precisely controlled by the unique Han-Kwang Auto Focus Control (AFC). This AFC technology allows the machine to automatically adjust the focal length of the cutting lens to accommodate variations in the materials being processed or changes in material feed, which eliminates the downtime normally associated with manual adjustments.

A new generation of sensing board in the S5 laser cutting head on the TL 6015 translates into faster cutting speeds on round, square or rectangular shapes.

In a recent design modification, the entire loading section of the machine has been enclosed, as depicted in the attached illustration.

For more information or to arrange a demonstration, please contact:

HAN-KWANG USA INC. Phone: 630-916-0200 Web: www.hankwang.com

Agency contact: Tim Daro Bernard & Company tdaro@bernardandcompany.com www.bernardandcompany.com

Continue reading

AME Offers Unique Locknut Design

Advanced Machine & Engineering Co., (AME) Rockford, IL provides its unique Spieth locknuts for accurate rotor positioning and reliable thrust bearing retentionon compressors, shafts, spindles and other industrial/commercial applications, in a unique engineering achievement.

In a compressor application, for example, the locknut can play a key role in establishing the clearance between the rotor and the compressor housing, where too little clearance causes seizure, while too much reduces compressor efficiency, due to leakage around the rotor body.

While the standard Spieth locknut configuration had considerable appeal for the application, several design refinements were deemed highly beneficial for this application. “We liked the positive locking feature without washers and keys, plus the locknut’s ability to support extreme thrust loads by providing full 360º contact around the thread flanks,” according to one application engineer contacted for this story.

Key features that led to one compressor manufacturer’s selection of the Spieth product from AME included:

- Square face to thread precision, for better bearing reliability and compressor efficiency, due to accurate rotor positioning

- Lock screw adjustment does not reduce end clearance or negatively impact reliability

- Absolutely no locknut movement in operation

- AME’s flexibility to cost-effectively customize the design for the application

- AME’s product quality and delivery performance record

The full circumference contact of the Spieth locknut was designed to ensure the locknut would not back off, even when subjected to extreme shock loads. It further aligns its contact face with either a zero runout or, as needed, it can be adjusted to suit the inaccuracies of the in-line connecting components, thus compensating for minor errors of parallelism due to the stack-up of mating parts. Uneven bearing loading is thus compensated and its impact minimized.

The basic design of the Spieth adjustable locknut involves two axially arranged radial grooves, one from the outside and one from the inside, which result in a diaphragm-like cross-section to give the locknut a predetermined axial elasticity. The internal groove divides the locknut into a clamping and a locking section. Depending on the nut size, multiple axially arranged socket head set screws are used to clamp the sections together. This eliminates the thread flank clearance between the rotor and the locknut, allowing for shockproof clamping.

In installing the locknuts, a consistent tool torque setting was found sufficient to achieve parallel locknut body and threads. Thus, the face of the thread flank and centerline of the shaft were always in ideal alignment. This was done to provide a square thrust collar for thrust bearing reliability and rotor positioning.

Other applications for Spieth locknuts typically include shaft and spindle retention on bearings, where displacement, axial preload and clearance issues are critical. The unique design of this locknut ensures no back-off, even when subjected to extreme shock loads. In machine tool and heavy equipment use, for example, spindle runout due to uneven bearing loads can be eliminated, due to the full 360º contact around thread flanks. Spieth heavy-duty locknuts can be used with needle and roller thrust bearings, plain thrust bearings or taper roller bearings on ballscrews, worm drives, bevel gears and other high-thrust carrying components.

For technical questions on this article, please contact Shane Hatfield (shane@ame.com) at AME.

Advanced Machine & Engineering Co., is a manufacturer located in Rockford, IL, serving the Machine Tool Industry with precision components and accessories, including spindle interface components, workholding devices, and, through our sister company, Hennig, machine enclosures, chip removal and filtration systems. The Fluid Power – Safety markets are served with cylinder rod locks and safety catcher devises; and the Production Saw market with our Amsaw carbide saw machines and Speedcut blade products. AME has manufacturing partners and customers around the world and across the U.S. To learn more, visit www.ame.com.

Hennig, Inc. design and produces custom machine protection and chip/coolant management products for state-of-the-art machine tools. Hennig products are designed to protect against corrosion, debris and common workplace contaminants. Manufacturing facilities located in the U.S., Germany, Brazil, India, Japan, China and South Korea. Repair centers are located in Machesney Park, IL; Chandler, OK; Livonia, MI; Blue Ash, OH; Mexico City, Mexico and Saltillo, Mexico. To learn more, visit www.hennigworldwide.com.

For more information, contact:

Tim Waterman

ADVANCED MACHINE & ENGINEERING CO.

2500 Latham St.

Rockford, IL 61103

Phone: 815-316-5277

Fax: 815-962-6483

E-mail: info@ame.com

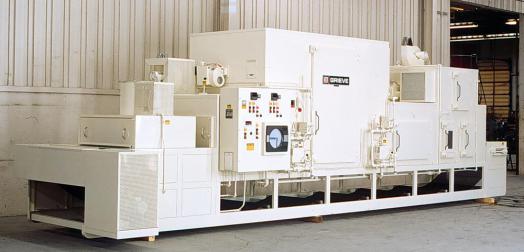

Grieve 500°F Electric Three-Zone Belt Conveyor Oven

No. 1018 is an electrically-heated, 500º F (~260ºC) three-zone belt conveyor oven from Grieve, currently used for drying ceramic parts. Workspace dimensions are 18” wide x 40’ deep x 18” high. 180 KW (60 KW per zone) are installed in Incoloy-sheathed tubular heating elements, while three 3-HP recirculating blowers (total 12,600 CFM) provide vertical downward airflow to the workload. The oven was split into three sections for shipment.

The unit contains a 12” wide, 1/2” stainless steel flat wire conveyor belt with 1/3-HP motor drive, variable from 2 to 30 inches per minute and has a 30” long open belt loading zone and a 60” long open unloading zone.

This Grieve conveyor oven features 4” insulated walls, aluminized steel exterior and Type 304, 2B finish stainless steel interior, three independent doors for access to the workspace, three 325 CFM powered forced exhausters and the unit was built to NEMA 12 electrical standards. It has disposable fresh air filters in each zone, including photohelic pressure gauges with alarms.

Controls onboard No. 1018 include SCR power controllers and independent recirculated airflow and temperature controls for each of three 162” insulated heat zones.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank Calabrese.

NEWS RELEASE: THE GRIEVE CORPORATION

DATE: November 23, 2009.

Agency contact: Tim Daro 847-934-4500

1450°F Electric Tempering Furnace from Grieve

No. 837 is a 1450OF electrically-heated tempering furnace from Grieve, currently used for pre-heating prior to welding and various post-welding heat treatments, at a customer’s facility.

Workspace dimensions of this furnace measure 60” wide x 60” deep x 60” high. 180KW installed in nickel chrome wire coils, supported by a stainless steel framework, provide heat to the load. A rear wall-mounted, heat-resisting alloy recirculating fan, powered by a 25-HP motor with V-belt drive and water-cooled bearings, is also on-board this unit.

8” thick insulated walls comprise 3” of 2300OF ceramic fiber and 5” block insulation, while 7” floor insulation is made from 5” of 2300OF firebrick and 2” of block insulation. No. 837 features an air-operated vertical lift door, as well as numerous safety and control components, including a programming and recording temperature recorder, SCR power controller, manual reset excess temperature controller with separate contactors and a recirculating blower airflow safety switch.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

750°F Class 100 Cleanroom Oven

No. 836 is a 750oF electrically-heated Class 100 cleanroom oven from Grieve, currently used to bake various coatings onto products at a customer’s facility.

No. 836 features a Type 304, 2B finish stainless steel interior with continuously backwelded seams, an exterior finished with white epoxy paint #4, brushed finish stainless steel door face and control panel face. The oven has 6” insulated walls and an aluminized exterior.

Additional equipment on this Grieve oven include a 30” x 24” x 6” thick stainless steel high temperature HEPA recirculating air filter, digital programming temperature controller, manual reset excess temperature controller with separate contactors, recirculating blower airflow safety switch and a 10” diameter circular chart recorder.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

500°F Electric Top-loading Oven

This Grieve top-loading oven features 4” insulated walls, aluminized steel interior and exterior, motor-operated rear-hinged door and compressed air manifold with eight connections. The unit meets NEMA 12 electrical standards, while the floor of the workspace is reinforced for 5000 lb. loading to support the customer’s fixtures.

Controls onboard No. 1007 include a digital programming temperature controller, 16-point strip chart recorder and tower light to indicate machine status.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

350°F Electric Tunnel Oven

This Grieve oven features 4” insulated walls, aluminized steel interior and exterior and a gravity roller conveyor with 1.9” diameter rollers on 6” centers. It also includes a 4’ long open loading zone, 19’ long insulated heat zone and 4’ long open uploading zone.

Additionally, controls on No. 1006 include a digital indicating temperature controller, manual reset excess temperature controller with separate control contactors, recirculating blower airflow safety switch and NEMA 12 control enclosure with fused disconnect.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

500°F Gas-heated Two-zone Conveyor Oven from Grieve

Grieve Corporation introduces No. 810, a 500°F gas-heated, two-zone belt conveyor oven, currently in use for curing aluminum pistons at a customer’s facility.

Workspace dimensions inside this unit measure 42” wide x 24’ deep x 15” high. The workloads travel atop a 36” wide, 1” x 1” high carbon steel flat wire conveyor belt with 1/4 HP motor drive, variable from 0.8 to 15 inches per minute, through an 18” long open loading zone; 36” long insulated heat zone with 2 HP, 2000 CFM recirculated airflow; 16” long insulated, unheated vestibule; 16’ long insulated heat zone with 10 HP, 12,500 CFM recirculated airflow; 12” long open zone; 36” long cooling zone and finally an 18” long open unloading zone.

350,000 BTU/HR are installed in modulating natural gas burners in each of the two heating zones on this Grieve conveyor oven. An aluminized steel exterior houses 4” insulated walls, Type 304 stainless steel interior with continuously welded seams in Zone One and aluminized steel interior in Zone Two.

A 16” diameter tubeaxial fan driven by a 3/4 HP motor pulls room air through the cooling zone.

All safety equipment required for gas heated equipment by IRI, FM and NFPA Standard 86 is on No. 810, including 325 CFM, 1/3 HP powered forced exhausters, airflow safety switches, hi/lo gas pressure switches, excess temperature controllers and electronic flame safeguard protection.

This unit also features doors at both ends of the workspace to contain heat, as well as pushbutton electric ignition for ease of operation and a recording thermometer. No. 810 was entirely designed, engineered, built and fully tested by Grieve.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP