Contact us today:

Author Archives: Bernard and Company

500°F Cleanroom Cabinet Oven

The unit has 4” insulated walls, aluminized steel exterior, type 304, 2B finish stainless steel interior with continuously backwelded seams, while the exterior is finished in white epoxy paint with a #4 brushed finish stainless steel door cover and control panel face. The oven is also equipped with double doors and positive latching door hardware.

A 1500 CFM, 2-HP recirculating blower provides horizontal airflow to the oven and two 30” x 24” x 6” thick stainless steel high temperature HEPA recirculating filters further purify the air. The ductwork is easily removable to expose filters for inspection or replacement.

Controls onboard No. 922 include a digital indicating temperature controller, manual reset excess temperature controller with separate contactors, recirculating blower airflow safety switch and solid state contactors.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

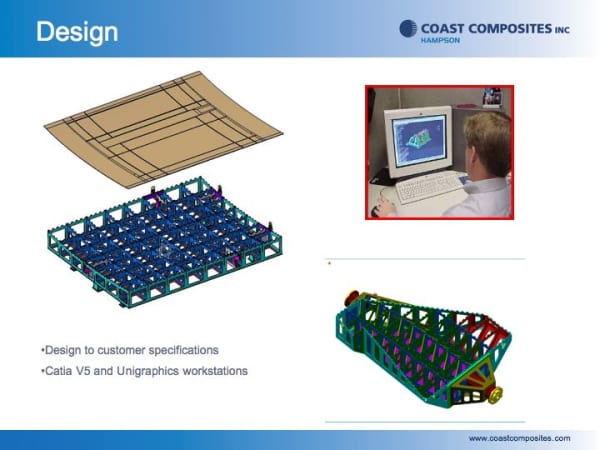

Coast Composites Achieves Higher Accuracies On Invar Tooling For Aerospace Structures

On the largest CNC mill at Coast, a German-built Handtmann five-axis machine that uses twin Siemens Sinumerik 840D numerical controls, the Siemens Volumetric Compensation System (VCS) acts in tandem with a proprietary temperature compensation system devised and implemented by Coast engineers. By combining these technologies with ongoing laser calibration, Coast achieves and maintains accuracies to +/- 0.003” on its longest runs. The Handtmann gantry mill can accommodate structures to 22’ wide x 75’ long x 84” high.

In operation, Siemens VCS factors all the machine kinematics of its various axes of motion, as well as pitch, yaw and roll, to precisely adjust the orientation of the tool tip to the workpiece. Simultaneously, the Coast temperature compensation system, developed over the company’s years in Invar tooling production for composite parts, further adjusts the machine’s accuracy to compensate the expansion of the machine and the workpiece for ambient temperature variations over a 24-hour period. While other companies in the industry typically

Invar tooling is the industry standard for composite lay-up, owing to its low coefficient of thermal expansion, but, as Coast President Paul Walsh explains, “While the material is a high nickel-iron alloy, which gives it great stability, the bottom line is you still get thermal growth over the long distance runs we process. The system we developed was the result of a lengthy analysis on all our long bed machine tools here.” Coast Composites runs the Handtmann mill at its Irvine facility, as well as Henri Liné five- and six-axis mills, plus SNK and Amura gantry and bridge mills. A 15-year-old Nicolas Correa five-axis gantry mill was recently retrofitted with a new Siemens CNC, motor and drives package, improving both its accuracy and speed, according to Walsh.

Coast Composites founder and current Director of Best Practices, Jerry Anthony, adds, “We knew the Siemens Volumetric Compensation System had substantial merit for our operation when it was first introduced to us, precisely because of the workpiece sizes we run and the corresponding thermal growth during machining, even on Invar tools. We had developed our temperature compensation system to adjust the go-to points from the control for real-time temperature on the machine and the workpiece. The data covered all aspects of our machining, from material composition to acceleration/deceleration mapping and the temperature variations over the largest pieces and longest machine cycles we had performed.” He notes that Coast

Expanding on the Coast Composites temperature compensation system, Anthony details the on-machine inspection of the workpiece and how the Siemens CNC is actually used to complete this process. “We have used laser tracking in tandem with our Valisys inspection software for some time now, having had a Siemens CNC engineer in Elk Grove Village, Illinois write the machine tool inspection interface software for us. In this way, we were and are now still able to use the power of the CNC to run real-time inspections and data analysis that have been extremely useful as an in-process inspection system for any tool manufactured by Coast.” He muses that the Coast system, “…essentially turns every machine tool here into its own CMM (coordinate measuring machine).” By developing this system at Coast Composites, Jerry Anthony concludes, the laser tracker is now used primarily for final checking, as the in-process monitoring produces what he suggests “…might be the highest accuracy machining standard in the aerospace industry.”

Walsh further comments on the evolution of composites in the commercial sector of the aerospace industry and at Coast. “Composites were only being used in non-critical applications but have now

On the massive Handtmann five-axis gantry mill, application engineering and training assistance were provided to Coast Composites by the machine tool builder’s local representative, Bryan Wilson of BD Technology, as well as personnel from the Siemens Aerospace Center of Competence.

Coast Composites is ISO 9001-2000 registered and AS-9100 Certified and holds numerous customer quality accreditations, including Boeing, Airbus, Northrop Grumman, Lockheed, Kawasaki, GKN and Mitsubishi, among others.

Coast Composites also builds tooling for the construction of such end products as satellite reflectors, used in the telecom and military markets.

HOW THIS MARRIAGE WORKS

In a typical long machining cycle on the very large parts produced at Coast, temperature variations in the workpiece material combine with the naturally occurring thermal expansion in the machine tool to create serious dimensional issues. This is true for whatever material is being run on the machine, even the Invar high nickel-iron alloy used extensively at Coast for producing composite lay-up tooling, fiber tape mandrels and other structures. While Invar has an extremely low coefficient of thermal expansion, the length of the machine cycle invariably (the word from which Invar got its name) results in sufficient thermal movement of the machine, which adversely affects the tool tip position.

In the Siemens VCS, the CNC compensates for 21 error factors of machine axes, pitch, yaw and roll. The true workpiece coordinates, rather than the programmed tool tip position, determine the actual cutting path. In conjunction with the highly advanced Siemens cutter path contouring, this compensation process results in a smoother finish on the part surface and a very high degree of machining accuracy.

In the Coast application, they have further enhanced this process by combining its proprietary temperature compensation system with the VCS inside the CNC to produce a highly accurate cutting path that takes into account the thermal expansion rates for the particular material being run as well as the machine itself.

The standard NC program assumes a 20ºC (68ºF) normal operating condition. This would be the norm for a CMM. The CNC incorporates the Coast temperature compensation system software, while the DNC runs the Valisys software, reading off the Renishaw touch probe data from the workpiece surface. Thus, the temperature compensation is within the machine control, resulting in real-time adjustments to the machine movement and an overall improved surface finish with superior accuracy, according to Anthony. “We have run enough material types and enough cycles to develop an

Siemens Aerospace Center of Competence engineers worked closely with the on-staff engineers at Coast Composites to consummate this marriage and, according to Anthony, the results have been beneficial for both parties.

“The relationship between the Siemens Aerospace Center of Competence and Coast Composites began seven years ago and has progressed to a true partnership, as the two companies have worked together consistently, merging advanced theoretical technologies with experiential knowledge. This has been and continues to be a very dynamic synergy between our companies. Siemens is proud to work with such a leader in the aerospace segment,” according to the Siemens account manager for Coast Composites.

For more information, please contact:

Coast Composites Inc. Tooling Division

Web: www.coastcomposites.com

Email: info@coastcomposites.com Attention: Jerry Anthony or Paul Walsh.

Siemens Industry, Inc. Drive Technologies — Motion Control (Machine Tool)

Aerospace Center of Competence Web: www.usa.siemens.com/cnc

Siemens Machine Tool Business

John Meyer

Manager, Marketing Communications

Siemens Industry, Inc.

(847) 640-1595

www.usa.siemens.com/cnc

SiemensMTBUMarCom.industry@siemens.com

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue reading350°F ELECTRIC BENCH OVEN FROM GRIEVE

This Grieve bench oven features 2” insulated walls, leg support stand, Type 304, 2B finish stainless steel interior and exterior of brushed #4 stainless steel. Two oven shelves are also included.

Since flammable solvents are handled in No. 991, a powered forced exhauster with powered forced airflow safety switch to shut down heat if there is an exhauster failure, as well as a purge timer to allow the oven to exhaust four volumes of fresh air prior to turning on the heat source are all onboard.

For more information, please contact: THE GRIEVE CORPORATION, Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank Calabrese.

Continue readingAdvanced Machine & Engineering Has Reasons To Breathe Easy

Using Stotz air gages to validate spindle interface components, this leading supplier keeps quality on highest levels; every part, every time

Stotz USA, LLC, is a leader in air gaging technology, products and quality gaging system integration. According to company president, Chris Koehn, Stotz has achieved that goal by a variety of means, not the least of which has been the loyalty of good customers, who appreciate the value Stotz products brings to theirs. One of those customers is also a longtime friend of Koehn’s and he can say that with complete honesty, because he worked there, long ago.

Advanced Machine & Engineering (AME) of Rockford, Illinois is a world player in high-quality machine tool spindle interface components. As part of the Goellner, Inc. Group, AME enjoys a reputation throughout the machine tool industry for manufacturing the finest power drawbars, spindle shafts, guide bushings, locknuts, hydraulic sleeves, expansion gibs and more. AME components, through their own branded products and those of their brother companies such as OTT Jakob, Spieth and Tschudin & Heid, as well as their “other brother” Hennig, itself a world leader in chip conveyor and machine protection systems, are found on nearly every major machine tool brand.

AME was a customer of Stotz before Chris Koehn ever came to work at the air gaging company. Today, these two market leaders maintain a great working relationship, for all the right reasons. AME demands the highest level of quality in their machining and finishing departments and Stotz air gaging systems facilitate the accomplishment of that goal, every day, according to AME Service Manager, Greg Hobbs. “Air gaging is the only technology we’ve found that’s accurate enough to check the machine tooling and especially the spindle tapers we produce here. That’s a fact. In the past, we’d use hard gages and we still use them, but only for certain OD checks. We’d blue up the tapers, insert them, give them a good twist and do our inspections. Way too much inconsistency. Today, with sophisticated HSK tooling, this method is too hit or miss to be reliable. Air gaging provides dead stops on the test stand and the documentation is unbeatable for validation on the straightness, surface finish and taper angles. Plus, the Stotz system allows us to upload all the data on every part, so we have our favorite word…documentation…for every part we produce.”

Hobbs also commented on the user-friendliness of the Stotz air column. When the program is first input into the column for a part in the AME grinding department, for example, the Stotz column essentially becomes a PLC, providing hard data via the Ethernet connections to the host data base. In this manner, every parameter of every part is documented and recorded. In a classic example of the law of unintended consequences, this process is not only used on the parts run, it’s also used for calibrating the AME machines, in a predictive maintenance function.

At AME, various testing of machined spindle interface and other components is performed both at the machines in the grinding department, in a temperature-controlled 72° environment, plus in the company’s totally environment-controlled in-house testing department, supervised by the company’s Director of Quality, Brad Patterson. He confirmed Greg Hobbs’ observation that numerous other technologies have been investigated over the years for quality checking at AME and that air gaging has been found to be the best and most reliable for this company’s applications, particularly ID dimensions and configuration. Patterson also observed, “The sophistication of the Stotz air column is unmatched in the industry. We get all the data required and we get it in exactly the fashion needed to support our customers. Repeatable results and elimination of error, every time. Plus, the set-up is much faster than on our laser mics, which can’t be used for ID measurement.” Patterson further noted that the replacement of the bluing technique, one he termed a “black art,” with air gaging has brought and keeps AME up to the most current industry standards for quality evaluation.

Typically, as AME’s Grinding Supervisor, Sam Schubert, explains, the finished product will rest for 24 hours of soaking, allowing the diameters to normalize. Though statistically predictable for most metal materials, thermal expansion can cause off-normal readings to occur. For checking certain bearing journals or spindle shafts, snap gages are set to accommodate size measurements down to the twenty millionths (0.000020”) range. The acceptable diameter tolerances for most AME products measured are in the 1-2 tenths (0.0001-0.0002”) range.

In cases where new masters are made for setting control values, those values are preset offline and programmed into the air column’s software, according to Greg Hobbs. Stotz typically performs this function for the customer in a remote manner over the Internet, through a proprietary IP address.

Among the many products finished in this grinding department are CAT/ISO 40 taper spindles, HSK test arbors, HSK grind quills, HSK steep taper milling tools and more. Often, older and worn spindle shafts are reverse engineered by AME for retrofits and reman’s. Even in these cases, air gaging is used to evaluate the finish process on the ID taper, as this versatile technology is easily adapted to such applications, according to AME personnel.

Sam Schubert expanded on the use of Stotz air gaging at AME.

“We have a full and very expensive inventory of hard gages with state-of-the-art indicators attached. But the air gages can do so much more. We use them for set-up on the grinding machines and they save us hours, every week. When you run the number of jobs we do here, that translates into substantial, additional work product and therefore more revenue for the company. In terms of reliability, some of the Stotz air gages we run here have been at AME since we began using the technology, nearly ten years ago now.” Schubert also noted the air gaging set-ups on the grinders dramatically reduce the time to first part in his department’s operation.

On one major spindle shaft project for an Asian machine tool builder, who was looking for a local source of supply in America, Schubert notes, AME was confronted with an unusually large quantity run, where tool degradation during the run would normally impact the production at some point. After an initial batch was produced, the machine builder claimed that everything but the taper was satisfactory. Quite surprised by this claim, AME checked all the documentation and determined that the customer’s test unit was actually out of spec, in a case where the error was repeated consistently and thus overlooked. In the end, the AME products were deemed better than perfect, in that instance.

As evidence of their commitment to this technology, Schubert notes that AME is now purchasing air gaging fixtures for all new customer applications. This quality spindle interface manufacturer aims to “keep breathing easy” in their process and product validation, as a result.

“Stotz has been a leader in gaging technology for almost 60 years. We are constantly striving to improve our designs and develop new products to solidify our position as a leader in measuring technology. The Stotz customer base consists of the top manufacturers and suppliers in the machine tool, automotive, aerospace and medical industries,” according to company president, Chris Koehn.

Harold Goellner, Vice President at AME, also contributed to this article.

For more information: STOTZ USA, LLC Email: chris@stotz-usa.com Attention: Chris Koehn, President

All photos kindly supplied by Bill Edmundson of Advanced Machine & Engineering

Release: STOTZ USA, LLC

Date: January 20, 2010

Continue readingCrowning: A Cheap Fix for Noise Reduction and Misalignment Problems and Applications On Gears

Some popular solutions to the noisy gear problem include enlarging the pinion to reduce undercut, using Phenolic, Delrin or other noise-absorbing products, where possible, or changing to a helical gear train. Other methods include tightening specifications to insure greater gear quality or redesigning the acoustical absorption characteristics of the gearbox. Occasionally, experimentation with gear ratios can limit harmonic frequency amplification, which otherwise can cause a gearbox to amplify noise like a finely tuned stereo system. The engineer can also study material and hardness requirements, so that modifications may be made to minimize heat treatment distortion or possibly eliminate the need for heat treatment entirely.

Particular attention must also be paid to gear geometry to insure maximum contact.

Another approach to the gear noise problem that yields good results is crowning or barreling of the teeth. This technique involves changing the chordal thickness of the tooth along its axis. This modification eliminates end bearing by offering a contact bearing in the center of the gear.

A second benefit of the crowning approach to gear cutting is the minimization of misalignment problems, caused by inaccurate machining of the casting, housing, shafting, gearboxes or bearing journals. Crowning can also reduce lead problems in the gears themselves, which causes the gears to wear unevenly and bind because of eccentricities and position errors. Obviously, a gear with a center contact is less affected by discrepant manufacturing or design; furthermore, one can reduce the backlash requirements and allow the gears to wear in rather than wear out.

Shaving is a secondary gear finishing operation done after rough hobbing or shaping to create the desired crown. Crown shaving has long been a popular method, especially in manufacturing coarse pitch gears. With the recent evolution of gear equipment capable of crowning while cutting, the need for shaving just to achieve a crown has been eliminated.

Two variations of the crown shaving method will produce a gear to compensate for off-lead or misalignment conditions.

One approach produces a crown by rocking the table during the reciprocation of work and cutter. The degree of crown is readily changed by this method. The other approach is plunge feeding, which requires dressing the shaving cutter to the desired crown. Generally, it is faster to plunge feed, but the technique can subject the cutter to greater wear. Of course, it is more difficult to change the crown, provided one starts with good quality gears. Shaving improves the quality of profile and reduces error in the gear tooth, through the cutting and burnishing action of the cutters.

The crown form can be produced on gear teeth in several other ways. One method is to shape the gear by use of a crown cam in the shaper back-off mechanism. The proper radius of the gear is calculated by using the amount of crown on the flank and the pressure angle of the gear. Unfortunately, the blocks, while not complex, tend to be expensive.

The advent of the latest generation of gear equipment has made two methods of crowning while hobbing popular. Both methods produce crowns by increasing and decreasing the center distance of cutter to workpiece. The first method utilizes physical copying of a template by a hydrocopying or mechanical following device. This allows taper hobbing or even the creation of sinusoidal wave forms, if desired. More recently, the second method, CNC hobbing, has become commonplace.

Depending on software limitations, CNC allows cutting gears in almost any desired form. A disadvantage to this approach is the high cost of the equipment, though the payback has decreased considerably, in recent years.

New CNC shapers can cut a crown gear or spline without the need for buying a special crowning cam. On our Gleason Pfauter P 300 ES, for example, we can crown by cutting a slight right and left hand helix angle along the face width of the part. This leaves the root diameter straight. We also have a Bourn & Koch Fellows MS 450 with a U-axis for controlling the back-off. It can be programmed to move the cutter spindle in and out during the stroking cycle to crown the tooth by cutting deeper at the ends of the face width and more shallow at the high point of the crown.

Who is using this gear cutting technology today?

Users of heavily loaded gears have been using crowning for quite some time. Another area ripe for the use of crowning is in the manufacturer of hydraulic wobble motors. Here, the application is strictly for misalignment problems rather than for noise

Prime candidates for use of the crowning technique are the small fractional horsepower motor manufacturers or anyone dealing with spur or helical pinions that are susceptible to noise or misalignment. Because crowning on foreign gear hobbing equipment has been available for a greater length of time, this method has been developed to a greater extent in Europe.

American manufacturers would be wise to take advantage of the availability of this kind of technology. Exploration of crowning as a solution to noise and misalignment problems can produce a real competitive advantage for gear manufacturers and users alike.

Fred Young, CEO Forest City Gear Roscoe, Illinois

For more information, please contact Fred Young at: Forest City Gear 11715 Main Street Roscoe, IL 61073 fyoung@forestcitygear.com 866-623-2168

AUTHOR-Fred Young is the owner and CEO of Forest City Gear Co. in Roscoe, Illinois. He has worked for the company since the mid-1950s and assumed its management in 1968. He is a graduate of Rockford College, where he studied physics, mathematics and English literature. Mr. Young is a leading authority on gear manufacturing.

Agency contact: Tim Daro Bernard & Company tdaro@bernardandcompany.com 847-934-4500

Editor note: Mr. Young is available for interviews on this or other gear design and manufacturing issues. Please contact agency to arrange. Also, any publication-generated leads from this article should be sent to Wendy Young at wyoung@forestcitygear.com. Thanks!

Continue reading

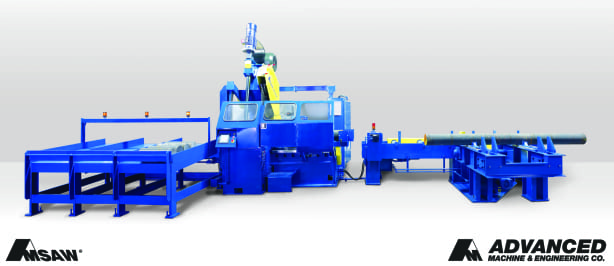

Advanced Machine & Engineering (AME) To Display Billet Sawing Systems at Upcoming Shows

At both the AIST Iron & Steel Show and the Forge Fair, Advanced Machine & Engineering will be displaying their carbide circular sawing systems.

AMSAW® high-speed, production saw machines are specifically designed to use carbide blades to improve the cutting speed of ferrous and non-ferrous material, bars or billets, rails, profiles, pipes and tubes. Standard design features include:

- Highly compact, rigid design

- Hardened spindle gears ground for minimum backlash

- Special saw blade guide and dampening device for accurate cutting to stabilize the blade and prolong tool life

- Low maintenance design

- Dry operation – no coolant needed

- Saw blade changeover in less than 3 minutes

- Double and triple measurement strokes for extra length cuts

- Fast, dependable chip disposal

Also displayed will be various chip conveyors, safety devices and machine enclosures offered by AME and its sister division, Hennig.

Advanced Machine & Engineering Co., is a manufacturer located in Rockford, IL, serving the Machine Tool Industry with precision components and accessories, including spindle interface components, workholding devices, and, through our sister company, Hennig, machine enclosures, chip removal and filtration systems. The Fluid Power – Safety markets are served with cylinder rod locks and safety catcher devises; and the Production Saw market with our Amsaw carbide saw machines and Speedcut blade products. AME has manufacturing partners and customers around the world and across the U.S. To learn more, visit www.ame.com.

Hennig, Inc. design and produces custom machine protection and chip/coolant management products for state-of-the-art machine tools. Hennig products are designed to protect against corrosion, debris and common workplace contaminants. Manufacturing facilities located in the U.S., Germany, Brazil, India, Japan, China and South Korea. Repair centers are located in Machesney Park, IL; Chandler, OK; Livonia, MI; Blue Ash, OH; Mexico City, Mexico and Saltillo, Mexico. To learn more, visit www.hennigworldwide.com.

For more information, contact:

Tim Waterman

ADVANCED MACHINE & ENGINEERING CO.

2500 Latham St.

Rockford, IL 61103

Phone: 815-316-5277

Fax: 815-962-6483

E-mail: info@ame.com

Connect with AME online:

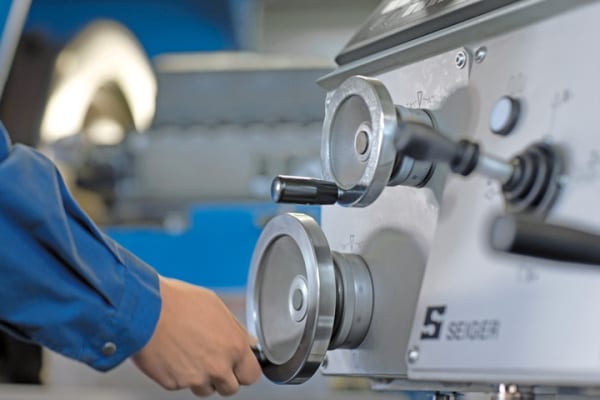

Handwheel Mode For Specialized Processing Operations in Locomotive Wheel Manufacturing for SCHÖMA

The SCHÖMA machine factory opted for a cycle turning machine with Sinumerik 840D solution line CNC for the manufacturing of individual parts and small batches of locomotive wheels; this machine also features Siemens ShopTurn with Manual Machine function. This hardware and software solution combines the flexibility and benefits of conventional machining with the productivity and efficiency of a CNC and this is what tipped the balance in its favor for one customer.

Christoph Schöttler Maschinenfabrik GmbH (SCHÖMA) is based in Diepholz, Germany. The company specializes in the development and production of diesel-engine locomotives. The model range includes tunnel and shunting locomotives; service, field and narrow-gauge locomotives; handcars, passenger carriages and gang cars. Around 90 percent of the locomotives produced each year at SCHÖMA are destined for use in tunnel construction.

Each construction project brings its own specific requirements and each country through which the locomotives travel has different environmental and safety legislation. SCHÖMA uses a modular system to meet a diverse range of customer requirements and the resulting need for a variety of equipment and product versions. One of the tasks facing the company is working out how to equip the locomotives for transportation by rail on differing track widths. Another requirement is locomotives with driving wheels featuring diameters between 600 mm and 900 mm, depending on local track usage.

Faced with even more demanding requirements in terms of production capacity and flexibility, SCHÖMA’s Managing Director, Christoph Schöttler, last year decided to add a cycle-control Seiger Record LC 1400 lathe to his inventory of machines. “We opted for a head turning machine, as we do not need a tailstock to produce driving wheels, axle bearing housings and gear wheels. It is working just as we envisioned, so we obviously made the right decision,” says Schöttler.

SCHÖMA constructs around 120 locomotives each year, which equates to 480 wheels. In addition, there are also repair orders, which increase the workload to between 560 and 600 driving wheels per year. These wheels are produced in two mountings from forged blanks on the cycle turning machine. The first mounting is used to machine the wheel flange on the reverse side and the wheel hub. The shaft locating bore is pre-turned. In the second mounting, the first task is to pre-turn the driving wheel profile, then the rolling circle level and the wheel shaft locating bore are finished.

Careful approach

The cycle turning machine is controlled by a Siemens Sinumerik 840D sl CNC, equipped with the ShopTurn software package with Manual Machine feature. If required, ShopTurn programming can be performed on a separate PC as part of an operator’s work planning, without interrupting the work sequences on the machine. The programs are routed to the machine via the network, where they are called up as required, depending on the workpieces to be produced. The Sinumerik CNC is used for both numerically controlled machining and manual operation with the ShopTurn’s Manual Machine functions. In manual mode with electronic handwheels, the machine behaves just like a conventional lathe with an actual value display.

During face and longitudinal turning, the process operates with the entered feed and spindle speed. The real highlight of the system is that every cycle can be used straightaway, without having to create a custom program. At SCHÖMA, the option for manual intervention is used for setting the zero point or for simple contours. Diameters are determined manually, if driving wheels have been newly profiled or if driving wheel profiles require resurfacing. The wheel profiles abrade as a result of the high loads experienced in heavy-duty operation or on poor-quality tracks or as a result of the driven wheels skidding.

“With a machine that uses only CNC, it is difficult to rework the driving wheels, as it is not possible to determine how much material needs to be removed. With this optional manual mode, however, users can adopt a careful approach. This sums up the ease of control,” explains Walter Horstmann, head of mechanical production and wheel set construction at SCHÖMA.

Siemens ShopTurn with Manual Machine for the job shop

After machine start-up, the basic MANUAL screen is immediately displayed and offers direct access to choosing machining options without having to create a parts program.

Machining procedures such as “taper turning” and “straight line face and longitudinal turning” can be executed immediately. The operator simply selects tool, feed speed, spindle speed and orientation, plus, if required, machining angle, then presses “Start”. The active direction is graphically displayed in the basic screen, using a compass rose symbol. All machining steps such as entry, thread grinding and drilling can also be started in manual mode.

For additional product information and inquirie, contact:

SIEMENS MACHINE TOOL BUSINESS

John Meyer

Manager, Marketing Communications

Siemens Industry, Inc.

(847) 640-1595

www.usa.siemens.com/cnc

SiemensMTBUMarCom.industry@siemens.com

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue readingIntegrated Controls Automation Enables High-Speed Float-Glass Stacking

The float glass industry is facing multiple challenges, not the least of which is a growing array of applications requiring a broader offering of products and sizes, and competition from offshore producers.

The need for more flexibility and speed in the production process has never been so important. Similarly, the necessity to reduce production costs and optimize profit margins has never been so critical. Smart glass producers are finding that replacing manual functions with streamlined automation is not only meeting these objectives, but also has become a requirement for long-term stability and success.

Of all the functions on the float glass line, stacking remains the most labor intensive, and therefore a key target for automation. Glass producers have been looking for a more efficient, reliable and cost-effective method to stack the expanding selection of glass sizes they manufacture. Some producers have automated their stacking, but have experienced difficulties with speed of throughput, because of glass stacking displacement causing breakage.

But many more float glass producers are still handling stacking manually without the aid of any controls automation.

Fully automated cold-end line

Effectively streamlining the uniformity and quality in the making of plate glass – a new generation of glass-handling equipment has emerged, which is destined to change the landscape of cold-end line process efficiencies. Developed by Grenzebach, in tandem with Siemens, a new line of glass-handling equipment is being released featuring integrated controls systems that provide a fully automated solution to the handling of finished float glass. Every function of the cold-end line is being integrated into one controls automation platform – including take-over of the glass from the lehr, cutting the glass ribbon into sheets of optimum size, glass snapping, rejection of faulty glass sheets, sorting according to size and quality, and stacking into glass racks with robotics.

The cold-end line requires that multiple, continuously-operating functions be precisely and sequentially connected. Grenzebach and Siemens have effectively brought each of these functions into one complete and totally integrated automation controls system, with the net effect of reducing production costs and increasing throughput. This package of automation controls is equally applicable to individual machines in the line, so additional line equipment can easily be added to the system at the discretion of the plant.

Grenzebach

Grenzebach is a pioneer in float glass cold-end equipment. In 1974, the company developed the world’s first processing systems for automated float glass production. In addition to machines for transport and handling operations, and cutting and breaking lines, systems for identifying flaws, glass quality control and optimization of material yield have also been created.

Grenzebach Corporation is the U.S. subsidiary of Grenzebach Maschinenbau GmbH of Hamlar, Germany, which is a global manufacturer of production equipment for the flat glass and construction material industries. It is recognized as an international mechanical engineering company, with development and production facilities in Germany, the United States and China. Worldwide, the Grenzebach Group has some 1,400 employees.

High-Speed Stacker

The first piece of Grenzebach equipment to exclusively utilize this advanced automation technology is the company’s new High-Speed Stacker. Designed to increase glass manufacturer’s efficiency and flexibility, it was developed for stacking small glass formats with high cycle times, and is currently the only device which can stack glass sheets in less than a one-second cycle. The new system is the world’s most flexible glass stacker.

It is a robot-assisted float glass stacker, which reaches its speed from quickly forming sub-packs of glass and achieves its flexibility by stacking the sub-packs with a robot. The system improves employee working conditions and stacking accuracy and efficiency, while decreasing product damage and ultimately costs. The High Speed Stacker is an ideal answer to today’s flexibility and speed demands in the glass manufacturing industry.

The High-Speed Stacker stacks glass formats from 12” x 18” up to 73” x 97”, and then transports glass sheets by a suction belt into a packet frame, where each sheet is placed successively until a sub-pack has been created. Next the packet is transported to a robot for take-off, either from above or from the side, to be stored on a glass rack that is used to transport the product to other facility locations or to end customers.

The system’s six-axis robots are capable of correcting the stacking alignment and creating precise glass stacks. For small glass sheets, two packets are built up and stacked parallel. Using this production method, up to 80 glass plates per minute can be taken off and stacked. The robots have a payload capacity of up to 220 lbs. and also feature integrated energy supply systems to reduce floor space.

The stacker can stack multiple sizes of glass with varying orientation – landscape or portrait, tin side in or tin side out with accuracy and speed. The High-Speed Stacker offers manufacturers the flexibility to adapt to product variations and rack and equipment changes. Feeding can be performed in a double stream, so that two packets are built up and stacked in parallel. It can be integrated into existing side-legs, but also demonstrates its stacking qualities in off-line cutting operations.

High-Speed Stackers can automate the entire packing capacity of a typical float glass production line, and can completely eliminate manual packing of glass.

Ideally, the angle of the glass rack is known and accurate. Since glass is heavy and the racks are being exposed to rough handling during regular operations, this angle can change over time compromising the structural integrity of the rack. As a result, a conventional stacker would not stack the glass in an optimal manner and glass breakage could occur. The robot of the Grenzebach High-Speed Stacker scans the rack for dimensional and angular discrepancies and adjusts its stacking program according to the actual geometry of the rack.

“Our customers have been demanding a better solution for stacking the many different glass sizes that they manufacture,” says Gerald Haas with Grenzebach Corporation. “Until now, they have had to rely on manual labor for their stacking operations. With the High-Speed Stacker, not only do they improve their employee’s working conditions, but they increase their operational efficiency and flexibility.”

Grenzebach’s totally automated cold-end line, and specific application to the High-Speed Stacker, is functionally based on Siemens’ concept of Totally Integrated Automation (TIA). TIA is characterized by its unique continuity. It provides maximum transparency at all levels with reduced interfacing requirements. It encompasses the field level and production control level, up to the corporate management level.

It also provides maximum interoperability, covering the controller, HMI and drives, up to the process control system. This reduces the complexity of the automation solution in the plant.

Motion Control, PLCs and Tech functions in one system

Central to Siemens’ TIA system in place with the Grenzebach line and High-Speed Stacker is SIMOTION®, Siemens latest generation of motion controller. SIMOTION, which includes a palate of high-tech control system components which are optimally harmonized.

Most machines require motion control (positioning, synchronous operation), PLC functionality and technology tasks (i.e. pressure control and temperature control).

The fusion of these functions into one system – as with SIMOTION – has a number of advantages, such as lower engineering costs, higher machine performance, the elimination of time-critical interfaces between individual components and simple, uniform and transparent programming and diagnostics for the entire machine with a single tool. The focus here is placed on a simple and flexible solution for numerous motion control tasks.

The motion controller, the drives and the motors encompass the scope of the Grenzebach cold-end line needs. This was a very big step forward technologically for Grenzebach, in terms of the wiring, drive integration and motion control. Taking standard, off-the-shelf Siemens technologies and applying them to a machine solution presented significant advantages to Grenzebach as an OEM.

Integrated with SIMOTION is Siemens SIMATIC® S7-300 automation system. Applicable for centralized and distributed configurations, it has the ability to integrate powerful CPUs with Industrial Ethernet/PROFINET interface. It can be set up in a modular configuration without the need for slot rules with I/O modules.

The Siemens SIMOTION motion control and SIMATIC controller provide a fusion of motion control, PLC and technology functions in one unit. This means that the new sophisticated stacking robots in use with the High-Speed Stacker can now be more easily controlled and operated.

Improved safety

A critical requirement of machine manufacturers and operators is seamless safety between humans and machines.

A truly safety-integrated system is a complete and consistent safety portfolio, which covers all tasks to be accomplished in the field of safety technology – ranging from detecting through evaluating, to reacting. In float glass production, safety is a critical concern. The automation built into the Grenzebach system greatly increases safety with handling sheet glass, resulting in far less accidents and injuries.

The Siemens S7 controllers are SIMATIC Safety Integrated, which provide the highest level of safety for humans, machines and environ¬ment. They are used to prevent accidents and damage resulting from a fault or mal¬function. The safety SIMATIC controllers monitor themselves, detect faults autonomously and immediately change into or remain in a safe mode when a fault occurs. They are optimized for use in production engineering and provide air-tight safety for all operations.

Fail-safe CPUs have been exercised for safety-oriented applications with the Grenzebach High-Speed Stacker and all other equipment on the cold-end line. The PROFIsafe profile for safe communication via PROFIBUS and PROFINET allows the integration of safety-related functions into standard automation environments.

Automation for a changing market

“We are making the SIMOTION and SIMATIC technology available to float glass producers so they can benefit from its system-wide controls capability and streamline their cold-end line production,” says Chad Shaffer with Siemens.

“This totally-integrated solution has been successfully applied to many other industries, but it is quite unique to float glass production until now.”

“Siemens has teamed with Grenzebach to help effect production efficiencies in the glass industry,” continues Shaffer. “More efficient equipment, safer production systems and a better bottom line for glass producers are our objectives.”

As glass producers deal with the influence of an increase in cheaper off-shore glass being imported and a more diverse product mix, production automation is more important than ever before. With new equipment providing better solutions, like the High-Speed Stacker equipped with a truly integrated controls package, glass fabricators stand in a much better position to operate their plants more efficiency and maintain a more competitive stature in the market.

Grenzebach Corporation can be reached by contacting: www.grenzebach.com

Grenzebach is a pioneer in float glass cold-end equipment. In 1974, the company developed the world’s first processing systems for automated float glass production. In addition to machines for transport and handling operations, and cutting and breaking lines, systems for identifying flaws, glass quality control and optimization of material yield have also been created.

The first piece of Grenzebach equipment to exclusively utilize this advanced automation technology is the company’s new High-Speed Stacker. Designed to increase glass manufacturer’s efficiency and flexibility, it was developed for stacking small glass formats with high cycle times, and is currently the only device which can stack glass sheets in less than a one-second cycle.

OR

SIEMENS INDUSTRY, INC.

Drive Technologies — Motion Control

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595 Fax: 847-437-0784

Web: www.usa.siemens.com/motioncontrol

Email: SiemensMTBUMarCom.industry@siemens.com

Attention: John Meyer, Manager, Marketing Communications

HAN-KWANG INTRODUCES THREE NEW LASERS

HAN-KWANG INTRODUCES THREE NEW LASERS

Korean giant enters U.S. market with big splash at recent FABTECH show

At the recent FABTECH show in Chicago, the largest builder of laser machines in Korea introduced three new CO2 lasers for metal fabrication, including two plate/sheetmetal machines and one tube/pipe cutter. Reaction from the attendees was very positive and interest quite high, as all three machines ran continuously throughout the show.

Details on the machines follow here:

Han-Kwang takes the next step in its technology development with the introduction of the Series PL laser system. Incorporating our unique Beam Radius Control (BRC) and Constant Beam Delivery System (CBDS), Series PL also features the newest Han-Kwang laser technology, our S5 High-Speed Cutting Head, which significantly increases the cutting speeds on all sheet metals, up to 1120 IPM for 20ga mild steel and 790 IPM for 16ga stainless. In addition, the practical machine design and highly functional, ergonomic controls make the Series PL the new benchmark in long gantry laser systems.

Features

• BRC-Beam Radius Control

Through optimizing the beam diameter for each different material and thickness, cut quality is greatly increased.

• CBDS-Constant Beam Delivery System

By keeping the entire length of the beam delivery constant over the work area, beam quality at the cutting focal point is enhanced.

• S5 High Speed Cutting Head

Adopting the new generation of the sensing board and the cutting head means cutting speeds for sheet metals such as mild steel, stainless and aluminum are dramatically increased.

• PMU-Plasma Monitoring Unit

Constantly monitors cut error such as plasma and restart with faster piercing and more stable cutting quality.

• LCS-Lens Crack Sensor

Built-in LCS monitors the status of lens contamination to give maintenance personnel instant alerts for replacement.

• Rotary axis for tube cutting

Cuts tubes up to 12” OD to give your operation substantial flexibility in work strategies

• Siemens SINUMERIK 840D with 15” touch screen

Use of the highest powered CNC, with open architecture and simplified set-up with plain language commands, plus full interface to your shop programming/monitoring network, means greater productivity at the machine and overall in your operation

• Onboard high-efficiency air filter & dehumidifier with monitoring window

Utilizing its own power supply, this unique Han-Kwang system guarantees contamination-free cutting and unmatched consistency.

—————————————————————–

Han-Kwang takes the next step in its technology development with the introduction of the Series PS laser system. Incorporating our unique Beam Radius Control (BRC) and Constant Beam Delivery System (CBDS), Series PS also features the newest Han-Kwang laser technology, our S5 High-Speed Cutting Head, which significantly increases the cutting speeds on all sheet metals, up to 1120 IPM for 20ga mild steel and 790 IPM for 16ga stainless. In addition, the practical machine design and highly functional, ergonomic controls make the Series PS the new benchmark in short gantry laser systems.

Features

• BRC-Beam Radius Control

Through optimizing the beam diameter for each different material and thickness, cut quality is greatly increased.

• CBDS-Constant Beam Delivery System

By keeping the entire length of the beam delivery constant over the work area, beam quality at the cutting focal point is enhanced.

• S5 High Speed Cutting Head

Adopting the new generation of the sensing board and the cutting head means cutting speeds for sheet metals such as mild steel, stainless and aluminum are dramatically increased.

• PMU-Plasma Monitoring Unit

Constantly monitors cut error such as plasma and restart with faster piercing and more stable cutting quality.

• LCS-Lens Crack Sensor

Built-in LCS monitors the status of lens contamination to give maintenance personnel instant alerts for replacement.

•Siemens SINUMERIK 840D with 15” touch screen

Use of the highest powered CNC, with open architecture and simplified set-up with plain language commands, plus full interface to your shop programming/monitoring network, means greater productivity at the machine and overall in your operation

• Onboard high-efficiency air filter & dehumidifier with monitoring window

Utilizing its own power supply, this unique Han-Kwang system guarantees contamination-free cutting and unmatched consistency.

—————————————————————–

Highlight of the Series TL is our highly advanced S5 cutting head, which combines superior measurement and sensing mechanisms to change from signal size to pulse monitoring, resulting in optimum cutting conditions. This new cutting head design is further enhanced by Han-Kwang’s quick piercing nitrogen-injection technology. Smaller holes, quicker ambient area cooling and a substantial reduction in hole-to-hole cutting time will all benefit your production and your bottom line.

Features

• BRC-Beam Radius Control

• CBDS-Constant Beam Delivery System

• Magazine-fed bundle tube loading system

• Tube V-support system

• Rotary chucking system

• Completely enclosed safety workstation with automatic doors and light barrier system

• Panasonic 2500W resonator

• Cutting capability to 21’ long x 6” diameter

• Material thicknesses to 0.25” mild steel and 0.2” stainless

• Siemens SINUMERIK 840D, the highest-powered CNC on the market for maintaining complete processing cycle control by a single operator, using touchscreen and simple language commands

• ProDesign 3D CAD/CAM enabling fast adjustments to the production scheduling to yield maximum productivity from the system

• Unique Han-Kwang air filtration and dehumidifying system for cleaner cuts and more operator-friendly environment

For more information on this emerging new player in the laser machine market, please contact:

Robert Won, Director/North American Sales

HANKWANG USA, INC. Web: www.hankwang.com

Agency contact: Tim Daro Bernard & Company www.bernardandcompany.com

Streamlining Machine Controls Automation in the Disposable Products Industry

Seamless integration of Siemens drives, automation and controls products enabled faster startups and improved system productivity with Curt G. Joa, Inc. production machines in the nonwovens industry.

by Bill Gilbert, Application Engineer with Siemens Energy and Automation

In the market of baby diapers and personal hygiene products, competition runs high. Major players in this market know that the slightest changes in product features can yield huge profits for those manufactures that are first to reach the market with a more absorbent, comfortable or easier to use product. Behind this high-stakes competition, however, is another player, Curt G. Joa, Inc., one of the world’s leading manufacturers of machinery for the production of disposable products including baby diapers, sanitary napkins, incontinent pads and related single-use items. Before these products can come to market the production machines that make them need to be designed or retooled. The machine re-design process is frequent as product changes are ongoing. Additionally, there is tight security surrounding these machine design developments. In a first-ever move, however, Joa has allowed a rare glimpse into its manufacturing facility, spotlighting machine automation and a solution developed in concert with Siemens Energy & Automation, Inc.

Since 1932, Curt G. Joa, Inc. (Joa) has earned a worldwide reputation for leadership in the design and manufacture of quality equipment for converting non-woven’s, plastics, paper, films, foil, tape and elastics. The company has machinery operating in over 55 countries throughout the world.

It has created an engineering environment that provides the utmost confidentiality and personalized service. The company maintains a fully-staffed team of mechanical and electrical design engineers representing a complete range of machine-building disciplines. SolidEdge, AutoCAD and EPlan are the drawing standards it uses. The company builds machines to meet a variety of worldwide codes and standards.

Joa goes beyond process design, however, providing rapid prototyping of complete manufacturing processes. Using a broad array of existing converting modules, it builds, tests and verifies the processes for its clients. The company’s multiple test stands are capable of performing a wide variety of web processes at speeds of more than 450 mpm. Its machines can be configured to slit raw materials, apply adhesives, weld web layers, apply discrete patches of one material onto another and perform complex product folding. With this approach, Joa can efficiently provide shortened machine delivery schedules and validated process concepts to its clients.

From engineering and design through installation, Joa provides a complete web manufacturing solution to its clients for new systems and equipment upgrades and improvements. It is one of few global designers in the industry that does not outsource key manufacturing and assembly operations. It does, however, closely collaborate with qualified solution providers, such as Siemens on machine controls automation.

The company’s machines feature modular designs that reduce product changeover times and make future upgrades simple. The modular design drives the configuration of automation, human interface, operations and maintenance. Optional process features permit high-speed production of a wide array of product configurations. Depending on product type and machine design, maximum process speeds can range up to 1200 products produced per minute. Projects can range in technology from a simple rotary cut-off unit to major converting machines over 50 meters long, each using upwards of 150 servo axes.

“A disposable products manufacturer recently contacted us about customizing a piece of equipment to go into its primary production line,” says Kevin Zeinemann, manager of Electrical Engineering with Joa, “The company was adding a new feature into one of its existing products. We began building a 8-meter machine section for them at our location. We were having some difficulty translating their machine’s existing program because we were attempting to cut and paste our new functionality into our client’s existing machine core functionality. Since this was not working we decided to put a stand-alone Siemens PLC into our machine section, bringing in Siemens techs to guide us through the process.”

“It worked out so well that when it was time to marry up the new machine section with our client’s existing machine at their location, they decided to move all of the information out of their main PLC and put it into the Siemens PLC that we had built,” continued Zeinemann. “The Siemens controller slated for use on the new 25-foot machine section, started as a tag-along and then eventually took over full ownership of the entire machine process because it had better functionality.”

The PLC that Joa integrated was Siemens SIMATIC® S7-400. An established platform, the S7-400 controller provides the highest performance in the Siemens SIMATIC S7 family.

A strong feature of the S7-400 is its modularity that is optimized for high-performance machine and factory automation, facilitating integrated and economical system solutions in centralized and distributed architectures. It has a CPU with integral I/O and integrated technology functions and integrated communications interfaces which create efficient processing speed for short machine cycle times.

“Our clients have different control configurations in place, and different comfort levels and preferences with their automation systems,” adds Zeinemann. “So, we work within their control specifications. I will say, however, that Siemens PLCs have excellent speed and performance. Our client has been quite happy with their functionality as well.”

“The Siemens processor also has an embedded safety functionality,” Zeinemann says. “Instead of having hard wired devices we were able to do a lot of safety interlocking via the PLC itself, and then network to our many different devices with a simple ProfiNet connection.”

The S7-400 controllers with safety integration provide the highest level of safety for humans, machines and the environment. They are used to prevent accidents and damage resulting from improper operation. The safety integrated controllers monitor themselves, detecting faults automatically and immediately.

Single Master Drive with Cascading Motion Commands

For the drives, one of the features uniquely designed into the system is the Siemens FM458 drive controller module within the S7-400 PLC. This controls a single master drive that cascades multiple virtual masters to control subsequent groups of drives. Instead of making a synchronized speed change, gear ratio correction or phase advance to each virtual drive, just one change to the master is needed, and every drive in that group will follow.

“Our client also needed 34 additional servo drives to be installed into their new 25-foot machine module,” continues Zeinemann. “They already were using 300 to 400 Siemens Masterdrive® servo motors on the equipment in their plant, so we specified Masterdrives into our new section as well for compatibility.”

The Masterdrives offload much of the performance that the PLC would normally have to handle. It puts it into the drive enabling the processor to pick up speed. The S7-400 PLC communicates to all 34 of servo drives and parameterizes them to send information back and forth. The drives follow at whatever speed they are told to run.

Siemens Masterdrive servo motors are ideal where high dynamic performance and intelligent motion control functions are required. They can handle the most complex motion sequences.

High-Speed Communications Link Improves Performance

As the demand for performance increases, automation networks used to control drive systems have become a limitation to quality and throughput. While open networks have been developed to control, configure and parameterize drives, they are limited by the overhead required to carry out non-control functions. To remedy this, Siemens developed SIMOLINK® designed to be a 100 percent control bus with none of the bandwidth stealing functions that could be carried out over a standard fieldbus.

Integrated into the Siemens control systems used on Joa machines, SIMOLINK provides the high-speed communications link required to synchronize set points from a single external master. It enables peer to peer data transfers between drives, and synchronizes the processor time slices of multiple drives and controllers. While operating at 11 megabits per second with very little overhead, 100 pieces of 32 bit data can be transmitted in 0.63 milliseconds. A high-speed synchronization pulse ensures that the data is acted upon in every drive at the same time. SIMOLINK provides Joa equipment with the high-speed communications required to reduce process variance and increase quality.

Totally Integrated Controls Automation – Faster Start-Ups and Improved Productivity

The Siemens automation solution that Joa employed is based on a concept called Totally Integrated Automation (TIA). TIA is characterized by its unique continuity, providing maximum transparency at all levels with reduced interfacing requirements. Its influence covers everything from the field level and production control level, up to the corporate management level. It also provides maximum interoperability, including everything from the controller, HMI and drives, to the process control system. This reduces the complexity of the automation solution in the plant.

Working closely together, Joa engineers and Siemens were able to develop this project in only a couple weeks. The commissioning was extremely short. Joa sent the machine over to its client and it operated flawlessly when it arrived at the plant. This was one of eight similar machine kits that Siemens jointly produced for this particular Joa client.

“Siemens was closely involved with us on this project from beginning through the final installation,” says Zeinemann. “They spent many hours with us on location, training us and ensuring we were comfortable with the system and their infrastructure and architecture. With Siemens programming assistance, we were able to do the initial bench testing. Additionally, when the project was installed, Siemens was with us at our client’s site working to ensure the installation went smoothly.”

The net result of the project was reduced machine design time and lowered total project costs, realized through faster startup and commissioning, as well as thorough testing, diagnostics and debugging prior to shipment. After observing the results of the first machine, the end user requested that eight other machines in its plant also be upgraded to match this solution design.

Machines in this aspect of the converting industry are very complex, requiring a comprehensive solution. Siemens and Joa were able to deliver a total controls automation solution, providing seamless integration of drives, automation and control products that enabled faster startups and improved system productivity.

To find our more about Curt G. Joa, Inc. visit its website at www.joa.com.

About Siemens

Siemens Industry, Inc., Drives Technologies, Motion Control is a division of the Siemens operating company in the U.S. Headquartered in the Atlanta suburb of Alpharetta, Ga., Siemens Industry, Inc. manufactures and markets one of the world’s broadest ranges of electrical and electronic products, systems and services to industrial and construction market customers. Its technologies range from circuit protection and energy management systems to process control, industrial software and totally integrated automation solutions. The company also has expertise in systems integration, technical services and turnkey industrial systems.

Siemens AG (NYSE:SI) is a global powerhouse in electrical engineering and electronics, focusing on the three key sectors of healthcare, industry and energy. Founded 160 years ago in Germany, Siemens AG reported sales of $96.6 billion in fiscal year 2007 (ended September 30). Siemens today employs more than 470,000 people in some 190 countries. In the United States alone, Siemens had sales of over $25 billion (including export sales), fueled largely by infrastructure projects and innovative solutions in the industry areas of medical, automation and control, power, transportation and lighting. Headquartered in New York City, Siemens in the U.S. employs nearly 72,000 people in all 50 states and Puerto Rico. The U.S. is also home to the global headquarters of nine of Siemens’ worldwide businesses. For more information on Siemens in the United States, go to www.usa.siemens.com.

For more information

SIEMENS INDUSTRY, INC.

GENERAL MOTION CONTROL

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/simotion

Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communications

by Bill Gilbert, Application Engineer with Siemens Energy and Automation.

Continue reading