Contact us today:

Author Archives: Bernard and Company

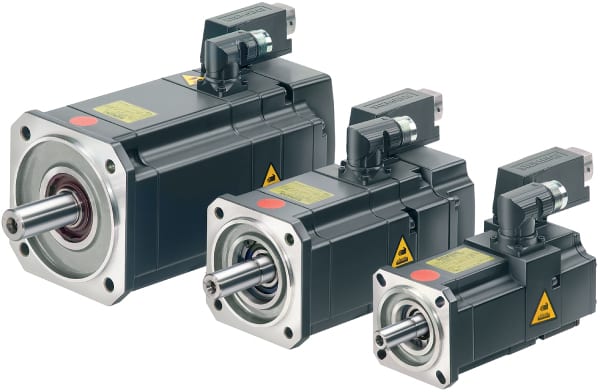

Three-Week Lead Time On All Siemens 1FK7 Servomotors

With a total of 6150 option pairings and 18 color choices, servomotors in the 1FK7 family can be configured to 110,700 possible designs. Options include stall torque and RPM rating, encoder style and bit resolution, holding brake functionality, shaft style, IP rating, AC line supply voltage and electronic nameplate recognition via Drive-Cliq®. 1FK7 geared motor options are not included in this program.

Siemens is making this service available to customers in the U.S. market. With the motion controller Simotion® and the drive system Sinamics® S stocked in the United States, Siemens is now able to supply complete motion control systems in three weeks’ lead time.

According to Arun Jain, general manager, Siemens Motion Control Business, “We have made the commitment to significantly shorten servomotor delivery times. The 1FK7 family has a wide user base for motion control applications, so we have selected this very important line for this major customer service initiative. We have devised and implemented an entirely new protocol for motor manufacturing and production at our factories.”

For more information, visit www.usa.siemens.com/motioncontrol.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Continue reading

Siemens: Volvo Aero Connecticut Gets Two for the Price of One

By using a Zimmermann FZ42 portal milling center, Volvo gets the power and torque needed to cut engine fan cases plus the accuracy to turn the machine tool into a coordinate measuring machine for inspection of finished parts

Located near Hartford, Conn., Volvo Aero Connecticut specializes in the machining of large components: fan cases for aircraft engines and gas turbines, fan and compressor structures, compressor rotors, low-pressure turbine cases (LPT) and military parts, usually from aluminum and titanium, as well as Inconel and Waspaloy. It currently manufactures the largest fan casing in the world, at 3.5 meters (11.5 feet) in diameter, for the massive GE90, the only aircraft engine in existence providing 127,900 pounds of thrust, to power the Boeing 777 line. Volvo Aerospace also produces numerous titanium fan cases for Rolls Royce engines.

With the large workpieces, high material removal rates and challenging geometries inherent in aerospace metals manufacturing, coupled with substrates that are often difficult to machine, such as titanium, there is always a need for powerful machining with superior accuracy. Such conditions present substantial hurdles at aerospace supply companies, as they seek to maintain that delicate balance between these seemingly opposing concepts.

As part of its program for the GEnx engine, to be used on the Boeing 787 Dreamliner, Volvo Aero Connecticut recently added a Zimmermann FZ42 machine tool, a five-axis, five-side portal milling center, to its already impressive manufacturing cells at the Hartford facility. The new machine joins other five-axis mills, vertical turning machines, four-axis machining centers and a deburring robot.

Key features on the FZ42 that led Volvo Aero Connecticut to make this acquisition included:

- The machine’s rigid design

- Very large working areas of 4500 mm x 5000 mm x 1500 mm (177 in. x 197 in. x 59 in.)

- High dynamic stability for machining very heavy and large workpieces

- Fast linear feed rate of 60,000 mm/min. (~2362 in./min.),

- Large swivel ranges within the rotational axes

- Slim profile milling head with patented Zimmermann Multiple Spindle Technology (MuST®) changing system.

In addition, this FZ42 carries a high accuracy package that provides optimum temperature control of the structural machine parts through the use of a special fiber-reinforced compound in the massive side columns. Also facilitating this process are built-in cooling ducts in the portal and Z-axis slide, independent cooling circuits for the A-axis, C-axis and spindle, ground surfaces on the guideways for the Z-axis and side columns, plus a double-pitch measuring system on the A-axis and C-axis.

During the course of manufacturing, thermal expansion of both machine components and workpieces can substantially impact the positioning accuracy of the machine, the stability of the workpiece and the resulting effect on the finished part dimensions. This unique combination of temperature control and mechanical accuracy in the machine construction were an important deciding factor for Volvo Aerospace in acquiring the FZ42.

According to Martin Thorden, engineering manager at Volvo Aero Connecticut, “These features, combined with the onsite machine set-up provided by Zimmermann, were very important to us, especially on this new GEnx project.” Thorden further noted the importance of the control on the machine, a Sinumerik 840D CNC from Siemens. “We see a very big benefit in how well we are able to control the tool with the CNC. We have been able to use the control to take on additional tasks that were previously handled by our CAD/CAM system.” Specifically, he cited the unconventional approach Volvo Aerospace took in machining the big fan cases. They installed the machine without a rotary table, thus realizing over $500,000 in direct cost savings plus material handling time. As a result of that decision, they believed they needed a top-of-the-line control to probe and accurately machine all the features on the part.

Volvo Aero Connecticut, located near Hartford, comprises three buildings, the largest being 40,000 square feet, where various aerospace and military aircraft components are typically produced from aluminum, titanium, Inconel and Waspaloy.

After machining, Volvo Aero Connecticut can actually transition the machine tool into a coordinate measuring machine for inspection, according to Thorden, owing to the superior accuracy provided by the CNC, as well as the special 90 degree angle heads supplied with the machine, part of the MuST® spindle technology from Zimmermann.

Onboard the machine tool, a massive 120-position tool carriage holds various HSK63 and HSK100 tools that are used to machine the substrates worked here. Inside a series of four side stations, within the machine workspace, four additional specialty tools are stored and used for various operations in the machining and measuring process.

All motors and the drive package onboard the Zimmermann FZ42 at this Volvo Aero Connecticut facility are also made by Siemens.

In a typical machining sequence, the milling head on this machine, equipped with the Zimmermann MuST® spindle system, provides Volvo Aerospace numerous other advantages, according to Martin Thorden. All roughing and subsequent finish passes on any material can be achieved in one set-up, which reduces the preparation time and overall production costs by as much as 10%. There is also no need for additional machines and the corresponding materials handling time. The head design further enables Volvo Aero Connecticut to perform tasks other than milling, using the specialty heads stored on the side stations. Changing the spindle, instead of the milling head, enhances repeatability and further reduces the company’s spindle interface costs, according to Thorden.

The combination of increased accuracies, reduced equipment needs and faster throughput has highlighted this Zimmermann machine installation at Volvo Aero Connecticut.

For additional product information and inquiries:

Zimmermann Inc.

Phone: 248-305-9707

Web: www.zimmermann-inc.com

Email: Matthias@zimmermann-inc.com

Attention: Matthias Tockook

Volvo Aero Connecticut

Phone: 860-667-8502

Web: www.volvoaero.com

Email: Martin.Thorden@volvo.com

Attention: Martin Thorden

Siemens Machine Tool Business

John Meyer

Manager, Marketing Communications

Siemens Industry, Inc.

(847) 640-1595

www.usa.siemens.com/cnc

SiemensMTBUMarCom.industry@siemens.com

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue readingB&L Remans Harris M-1000 from Shafted to Shaftless Press, Cuts Make-Ready Time in Half

Located in Effingham, Ill., B&L Machine & Design specializes in the remanufacturing of various printing presses and ancillary equipment. Its particular expertise is on the Harris M-1000 and M-110 series presses, as well as splicers, infeeds, chillers and folders. By redesigning all the electrical and mechanical components and subsystems, B&L exceeds customer expectations for the increased set-up, changeover and print speeds demanded by today’s publishing industry, while saving substantial capital for commercial printing companies.

Ovid Bell Press in Fulton, Mo. specializes in print runs from 5,000 to 125,000 copies and works for a variety of multi-color magazine and journal publishers. Recently, B&L needed to help this customer perform shorter-run production work as well as meet the critical make-ready time reductions. Make-ready, in this case, is defined as the period from deceleration

According to Jim Strange, manufacturing manager and electrical engineering supervisor at B&L, “I would say that the shaftless printing implementation on this particular Harris M-1000 press was the biggest part of our challenge. We had determined a shaftless design was the best solution to provide the flexibility of options needed for our core base of printing equipment, in order to compete in this new short run arena.” Strange explained that the press infeed system was converted to a belt drive, eliminating the need for gear trains and oil baths. All the web tension controls were moved to the servo motion processor, thereby further reducing component count.

Finally, the folder section of the press was rotated, creating a smaller footprint and improving the folder use, which enabled this customer to install another similar press that can feed either the existing folder or new one. This solution created a more flexible pressroom for better response to market conditions and job flow.

To help with this conversion, B&L contacted three of the largest suppliers of servo control systems for its industry. Each candidate was supplied a press layout, specifics on each piece of required equipment and print quality goals needed to achieve a successful project. A 30-day window was allotted for proposals. When all the proposals had been received and reviewed, the project was awarded to Siemens. Larry Hines, president and owner of B&L, attributed this decision to the vendor’s design assistance, technical competence, service

The Siemens solution included a Simotion D445 motion controller, Sinamics S120 drives and 1PH7 servo motors. B&L utilized the Simotion Shaftless Standard, a pre-configured application that implements the basic operations for a coordinated motion system and includes rudimentary HMI screens. This software is provided at no charge and saves a great number system engineering hours.

An all-servo design enabled B&L to eliminate drive lines and gave this remanufacturer considerable flexibility in the reconfiguration of existing equipment. Rod Davidson, senior mechanical engineer for B&L, said, “The servo drives enabled us to redesign the entire infeed, and we integrated an absolute encoder to control web tension for smoother operation. Furthermore, the servo drives in the print units let us remove a large number of existing components. Being able to access all the motor position information and scale it to our needs made it easy to build intelligent HMI screens for setting up the phasing, plate positioning and register control.” Finally, he noted the servo drive in the chill unit facilitated further reduction of component count and simplified belt drive configurations. All the mechanical and electrical reconfiguration was accomplished without the need for costly clutch components, according to Davidson.

Overall install time on the press was cut by over 25 percent, due to less drive line construction required, while manufacturing time was reduced by 20 percent, thereby benefiting B&L and its customer alike.

Mechatronics Identifies Problem During Commissioning, Helping Customer Complete Project

During the commissioning process on this Ovid Bell printing press rebuild at B&L, a mechatronics analysis and optimization protocol was conducted by Razvan Panaitescu, engineering manager for mechatronics standards and regulations at Siemens, working in tandem with his Siemens counterparts in application engineering and installation. Mechatronics is the integration of electronics and mechanical engineering, relating to the performance or the design of equipment and machinery. Razvan Panaitescu is a leading authority in this discipline for Siemens.

A problem had surfaced during the test runs on the rebuilt shaftless Harris M-1000 offset press, involving an out of tolerance registration issue. The registration points were visibly oscillating, and the cause was initially thought to lie with the controllers or drives installed as part of the new Siemens product suite onboard.

However, Panaitescu and his team determined the problem resulted from gaps between both the plate and blanket cylinders on the press. When the controllers were finely tuned in a damping optimal setting of higher integrator times

As Panaitescu mused, “Just as a doctor uses the stethoscope on patients, we listen to the drives and press cylinders. From our analysis, we determined the mesh frequency was indicating a sprocket/gear problem.”

In the end, it was determined by B&L and its supplier that an off-normal angle bore on a gear and sprocket assembly was indeed the root cause of the registration problems. Replacements were installed and the press is running well, the result of the mechatronics applied here.

For more information on this story, please contact:

SIEMENS INDUSTRY, INC.

Drive Technologies — Motion Control

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595 Fax: 847-437-0784

Web: www.usa.siemens.com/motioncontrol

Email: SiemensMTBUMarCom.industry@siemens.com

Attention: John Meyer, Manager, Marketing Communications

OR

B&L Machine & Design

Phone: 217-342-3918

Fax: 217-342-2081

Web: http://www.blmachinedesign.com

Email: lhines@blmachinedesign.com

Attention: Larry Hines, President/Owner

HAN-KWANG INTRODUCES FULLY AUTOMATIC TUBE CUTTING LASER SYSTEM

Automated loading and parts handling system complement state-of-the-industry laser and machine control technology

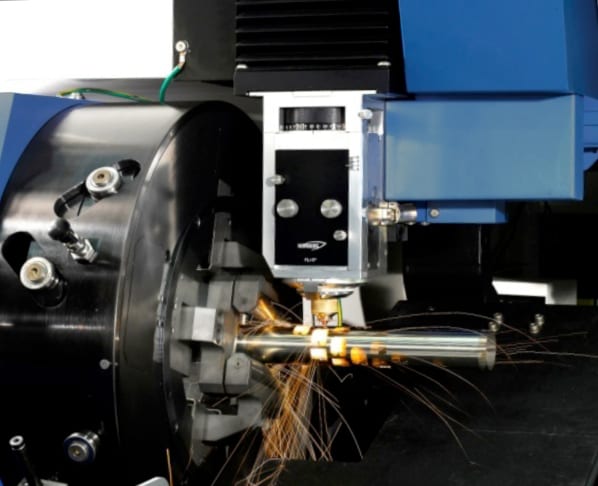

Han-Kwang USA announces immediate availability of its new Model TL 6015, a tube cutting laser system capable of handling 24’ long, 6.5” diameter workpieces up to 1/4” wall thickness in mild steel and 0.200” in stainless steel. Equipped with a powerful 2.5KW Panasonic laser and a versatile Siemens 840D CNC to control all functions of the machine, the TL 6015 can significantly increase the tube production in any department or shop, especially when used with Han-Kwang’s proprietary “Flex 3D” tube cutting software . The unit comprises an automatic bundle loading system with tube V-support, auto-centering rotary chucking system, laser cutting station and automatic parts removal station.

Maximum positioning speed on this new laser system is 4700 ipm for the X-

Han-Kwang S5 Cutting Head, featuring Auto Focus Control; adjusts focal length of cutting lens to automatically compensate for material variations and rapid changeover

axis and 120 rpm for the rotary A-axis. Max acceleration rate is 1G, while the laser beam is precisely controlled by the unique Han-Kwang Auto Focus Control (AFC). This AFC technology allows the machine to automatically adjust the focal length of the cutting lens to accommodate variations in the materials being processed or changes in material feed, which eliminates the downtime normally associated with manual adjustments.

A new generation of sensing board in the S5 laser cutting head on the TL 6015 translates into faster cutting speeds on round, square or rectangular shapes.

In a recent design modification, the entire loading section of the machine has been enclosed, as depicted in the attached illustration.

For more information or to arrange a demonstration, please contact:

HAN-KWANG USA INC. Phone: 630-916-0200 Web: www.hankwang.com

Agency contact: Tim Daro Bernard & Company tdaro@bernardandcompany.com www.bernardandcompany.com

Continue readingCongratulations BMW Oracle Racing on The America’s Cup Victory!

From: Tim Daro (Bernard & Company)

Sent: Mon 15/02/2010 14:47

To: Jon W (BMW Oracle Racing)

Cc: Fred Young (Forest City Gear); Wendy Young (Forest City Gear); Nicole Zermatten (Bernard & Company); Wendy McCormick (Bernard & Company)

Subject: Congratulations!

We all welcomed the news of your success in winning the Cup.

And the story on Forest City Gear is popping up all over the trade press, here in the States.

Good news, all around!

Thanks for your help, Jon. Enjoy the victory.

Tim

—–Original Message—–

From: Jon W (BMW Oracle Racing)

Sent: Mon 15/02/2010 14:47

To: Tim Daro (Bernard & Company)

Cc: Fred Young (Forest City Gear); Wendy Young (Forest City Gear); Nicole Zermatten (Bernard & Company); Wendy McCormick (Bernard & Company)

Subject: Congratulations!

Hi guys,

I don’t think we could’ve written a better script! The victory will carry the article a bit further for you I’m sure. It was incredible to pick up the America’s Cup last night. I’ve been chasing it for more than 10 years!

Bye for now.

Jon

Check out our press release on FCG and BMW Oracle teaming up.

Go to our Facebook page to see more pictures of the BMW Oracle.

Continue readingChristian Schedler Appointed Product Manager of the Speedcut Saw Technology Division of Advanced Machine & Engineering

We are very pleased to announce the promotion of Christian Schedler to the Product Manager position at this division.

In his new role, Christian will oversee P&L responsibility for the division, including its sales, application engineering, product management and project management functions.

Christian’s distinguished career has encompassed R&D, Engineering and Product Manufacturing. He has a broad assembly and service experience on machine tools and knows the market’s needs for productivity improvements. Prior to this promotion, he worked in service as a Global Service Rep for a German machine tool company and as a Designer of carbide saws at Advanced Machine & Engineering. Christian has the experience, energy and judgment necessary to lead the division to continued success, insuring its future growth objectives are achieved.

Advanced Machine & Engineering Co., is a manufacturer located in Rockford, IL, serving the Machine Tool Industry with precision components and accessories, including spindle interface components, workholding devices, and, through our sister company, Hennig, machine enclosures, chip removal and filtration systems. The Fluid Power – Safety markets are served with cylinder rod locks and safety catcher devises; and the Production Saw market with our Amsaw carbide saw machines and Speedcut blade products. AME has manufacturing partners and customers around the world and across the U.S. To learn more, visit www.ame.com.

Hennig, Inc. design and produces custom machine protection and chip/coolant management products for state-of-the-art machine tools. Hennig products are designed to protect against corrosion, debris and common workplace contaminants. Manufacturing facilities located in the U.S., Germany, Brazil, India, Japan, China and South Korea. Repair centers are located in Machesney Park, IL; Chandler, OK; Livonia, MI; Blue Ash, OH; Mexico City, Mexico and Saltillo, Mexico. To learn more, visit www.hennigworldwide.com.

For more information, contact:

Tim Waterman

ADVANCED MACHINE & ENGINEERING CO.

2500 Latham St.

Rockford, IL 61103

Phone: 815-316-5277

Fax: 815-962-6483

E-mail: info@ame.com

Connect with AME online:

CORROSION, DISCOLORATION AND CONTAMINATION IN GEAR PRODUCTION

Steps to take for avoidance of imperfections in the aesthetics and surface integrity of gearworks

Roscoe, IL-Forest City Gear recently disseminated the following tips to its employees and would like to share these ideas with the gearmaking community, as well as users and assemblers of gearworks. This information is provided for reference only and any further questions or comments should be directed to author Fred Young, CEO of Forest City Gear. He welcomes all feedback.

BY: Fred Young, CEO

TO: All Forest City Gear Employees

Recently and historically, we have had issues with gears that suffered from the above conditions, after heat treat. These issues can also appear during hot and humid times, as well. We previously had a sand/vapor blast unit that was used to clean off debris and contamination from gears, prior to further processing.

My suggestions for future handling, based on experience and a reading of the current technology, include the following:

- We should change the routings to include a hand blasting (not tumble blasting) by our heat treaters.

- We should stipulate the further provision to our vendors that this is initiated only for cosmetic cleaning purposes and that they are enjoined from too extensive a blasting, which could cause dimensional changes or damage to our parts.

- We are looking for a uniform and clean surface on all areas that are not ground and this would include gear root diameters, where appropriate. If we do not have high confidence in the individual heat treaters to perform this critical task, we should try to use the Comco blast unit we have in-house or investigate the purchase of a unit similar to the old one we had. I know that the main objections to that equipment were the excessive dust and grit surrounding it and the extra processing time required. However, the returns we have experienced from time to time over these issues demand that we take some aggressive preventative steps. Please note that this is not limited to parts that are only heat treated.

- When we use our ultrasonic cleaner or parts washers with soap and hot water, water spots and/or soap contamination may be objectionable to some very particular and discerning customers. Changing of the final cleaning solution may be necessary, in such cases.

- If it is feasible, we should use any of the currently available vacuum heat treating processes to assist us in maintaining cleanliness and an optimally professional visual appearance, which can help minimize objections by outside inspectors.

I welcome all your suggestions to further our desire for achieving “Excellence without Exception.” (This is the company motto at Forest City Gear.) I think that if all hands are on the lookout to address the corrosion, discoloration, contamination and pitting issues and address corrective procedures prior to further processing-gear grinding, cylindrical grinding or other machine operations- this will help minimize our overall cost. It is very difficult to address these issues after grinding has occurred, as you all know.

The September/October (2009) issue of Gear Technology had an article starting on page 60 entitled, “Gear Corrosion During the Manufacturing Process,” which focused on issues of pitting caused by corrosion, which can be very serious and ultimately lead to gear failure in operation.

While the article discussed the REM Chemical process of isotropic superfinishing in particular, much of the information is germane to the points above and will contribute to your understanding and resolution of these problems. I encourage you to read it. The watchword at Forest City Gear is that all of us are responsible to be on the lookout and take steps to prevent this situation from future occurrence, to the greatest degree possible. It will be prudent to gather some examples and point out exactly what we are trying to prevent from going out the door, by reviewing it with all hobbing/secondary, shaping and grinding department personnel, at the earliest opportunity.

For more information on this announcement, please contact: FOREST CITY GEAR CO., INC. Web: www.forestcitygear.com

Editor Note: Please send any publication-generated inquiries from this article to Wendy Young at Forest City Gear, wyoung@forestcitygear.com. Thanks much.

PR agency contact: Tim Daro Bernard & Company 847-934-4500 tdaro@bernardandcompany.com

Release: FOREST CITY GEAR CO., INC.

Date: January 26, 2010

Continue readingFOREST CITY GEAR PRODUCTS ON LATEST GENERATION OF BMW ORACLE RACING YACHTS

The winches on a racing yacht are critical items of equipment. Speed, reliability and weight are important factors when determining which winch packages will be installed on a racing yacht.

Forest City Gear supplied crown gears and splines of special high-strength, lightweight and corrosion-resistant titanium for use in the engine & winch system of the new BMW ORACLE Racing trimaran. BMW ORACLE Racing is currently competing in the prestigious America’s Cup event in Valencia.

Made from Ti-6-4, a popular alloy often found in aerospace applications, this material is extremely durable and was determined ideal for this project by the Alpha Engineering Consulting designers, customer of Forest City Gear. The process used to manufacture these gears and their corresponding spline components was hobbing and shaping, respectively. The crown radius was the point of main concern, owing to the extreme stress and motion present when such gears are in use.

As Jon Williams, a member of BMW ORACLE Racing’s shore team explained, “During the build-up to the previous America’s Cup in Valencia, Spain, we undertook development of our own transmission components for the winch systems on our yachts. After careful study, we had determined this was a critical area for improveing our performance on the water.” BMW ORACLE Racing was looking to reduce mass and increase in mechanical efficiency of the gear and spline assembly. A prototype project proved successful and the team undertook a complete redesign of the gearboxes for their USA87 and USA98 yachts. These new gearboxes were manufactured in New Zealand and used by BMW ORACLE Racing in the America’s Cup.

The current edition of the America’s Cup sees different rules than previous Cup programs. Under these rules, all equipment for the yachts must be constructed in the country the team represents. In the case of BMW ORACLE Racing, who races under the flag of the Golden Gate Yacht Club of San Francisco, California, this means all equipment must be made in the USA.

For Forest City Gear, Jared Lyford and Tom Christenson ran the project. The gearbox casings and other associated parts were manufactured by RB Enterprises of Everett, Washington. For Arrow Gear, Joe Arvin ran the project to deliver the bevel gears. Final assembly of the gearboxes and their installation occurred at BMW ORACLE Racing’s structural R&D facility in Anacortes, Washington.

At the conclusion of five weeks intensive testing on the waters off Seattle, WA & San Diego, CA, the gearboxes were removed for inspection. The results were impressive: the gears were only showing the first signs of polishing on flanks. They looked new!! It was concluded that the gears were a significant improvement on the New Zealand sourced gears used by BMW ORALCE Racing in their previous America’s Cup program.

Williams concludes, “Arrow Gear & Forest City Gear have provided the team with a quality product. We would use them again.”

For more information on this announcement, please contact: FOREST CITY GEAR CO., INC. Web: www.forestcitygear.com

Check out the BMW Oracle photo gallery on our facebook page

Release: FOREST CITY GEAR CO., INC.

Date: February 5, 2010

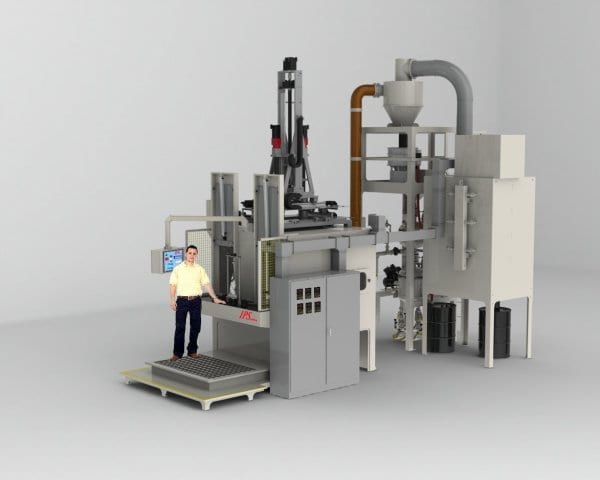

Continue readingSiemens: Better Motion Control Makes Shot Peening Fast and Economical

Robust design combined with smart, powerful motion control components yields high-performance shot peening machines at a user-friendly price

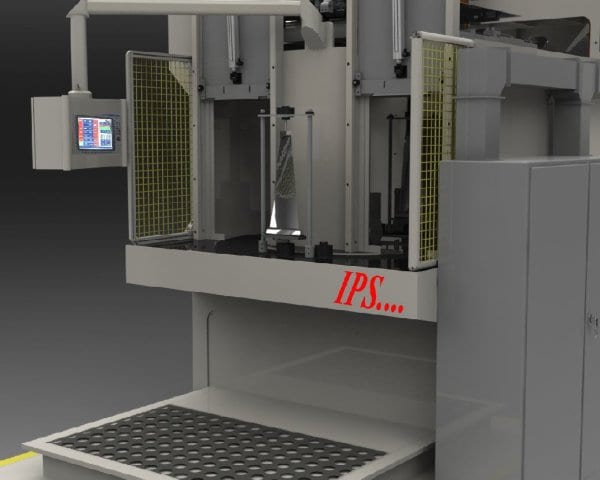

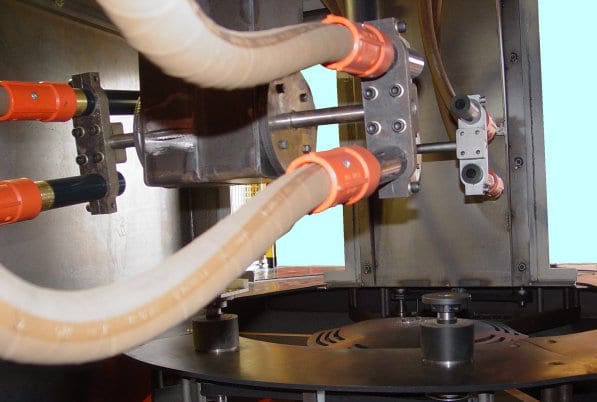

In a shot peening machine, steel shot from a reservoir (right) passes into a compressed air stream and through a nozzle to impact the surface of a part held in an enclosure (left). Photo credit: Innovative Peening Systems Inc.

When it comes to parts like airplane wings or engine blades, failure is unacceptable. To reduce the possibility of metal fatigue, manufacturers use a technique called shot peening, in which a hail of 0.014-in steel balls creates microscopic dents in surfaces of metal parts, strengthening the material and extending its lifetime. The process was once performed manually. Today, at companies like Innovative Peening Systems (IPS; Norcross, Ga.), shot peening is fully automated. IPS combines its proprietary Intelligent Motion Control (IMC) software with motion control technology from Siemens Industry, Inc. (Alpharetta, Ga.) to create reliable, high-performance machines at an economical price.

At first, surface deformation might seem more likely to reduce material strength than enhance it. In reality, the rounded dents generated by shot peening convert tensile stresses, which tend to compromise material integrity, into compressive stresses that act to hold the material together. The shot peening effect extends into the material roughly three times the depth of the dents.

Most automated peening machines leverage computer numerical controlled (CNC) technology. CNC technology is designed for high-precision applications like milling and diamond turning, however, and offers performance somewhat beyond what’s necessary in this, essentially, high-tech sandblasting operation. The design team at IPS, working with Siemens, who happens to be the market leader in CNC, realized that, by using alternative intelligent motion, it could produce a shot peening machine that would perform just as effectively¾and far more economically.

In this three-axis machine, the nozzle (upper left) sprays shot at a part installed on the turntable.

Designing for robustness

In a shot peening machine, a reservoir introduces steel shot into a compressed-air stream that passes through a nozzle to strike the part. The process takes place inside an enclosure that protects both operator and machine¾but only to a point. A typical machine contains about 2,000 pounds of shot, which amounts to hundreds of millions of particles flying around at high velocity. The potential for damage to components exposed to the shot makes the punishment inflicted by caustic washdown seem mild. “The 0.014-inch shot is the perfect size to make its way inside the seal of any kind of moving part and lock it up,” says Nick Hart, electrical engineer at IPS. “Metal shot will get inside anything it can and short it out electrically.”

The IPS team realized early in the process that the solution was to pull the motion control elements outside of th

e enclosure. The resultant six-axis nozzle manipulator consists of a three-axis (x,y,z) gantry that rides above the machine and drives a rigid arm tipped with a nozzle. The arm extends into the enclosure through a single hole with a carefully designed seal; everything else is protected.

The x,y,z motion of the gantry essentially provides coarse positioning for the arm. To ensure that the stream of shot strikes even conformal surfaces at normal incidence, the nozzle itself provides two additional degrees of freedom: rotation about the x-axis(the A-axis) and the y-axis (the B-axis). The actuators for the A-axis and B-axis are sealed inside the solid housing of the arm; the motors and drives remain outside of the enclosure. The final, sixth degree of freedom lies in an axis that rotates the part itself (C-axis).

Rather than redesigning each machine from scratch, IPS started with a standard motion platform, adjusting the enclosure for a particular project. In the case of large parts like 100-ft-long airplane wings, for example, it might gang together multiple nozzle manipulators. “We used standardized components that have been proven in the industry, but we customize every enclosure to fit the customer’s product,” says company president Dan Dickey. “They get a machine that fits their part, at a good price, but it’s not a new invention for us, every time we build a machine.”

Designing for performance

The specifications called for the nozzle manipulator to move at a maximum speed of 500 in/min. On the face of it, such a requirement is more demanding than challenging. The problem is inertia; fully charged with shot, the assembly weighs around 2000 lbs. It requires a lot of muscle to accurately position that much mass at 500 in/min. For a solution, the team again turned to Siemens.

The selected system combines Sinamics S120 drives in Booksize format and servomotors from the 1FK7 family. Although the S120 drives feature onboard memory and processing power, the IPS team chose to use them in a centralized control architecture, in part because the components were already grouped together on the nozzle manipulator carriage and in part to provide additional protection from contamination.

In this shot peening cabinet, a part on the turntable (bottom) projects up between the sets of nozzles for treatment. This type of design is best suited for parts with high production rates.

If Sinamics supplies the muscle, Simotion provides the brains in the form of the D435 drive-based controller. “It allows us the flexibility to create custom software [IMC] for the shot peening application, whereas some of the alternatives in the industry do not give you a lot of freedom,” says Hart. The milling and turning applications typically performed by a CNC machine are inherently rotational, while shot peening is raster-based with a different coordinate system. As a result, engineers using CNC technology for shot peening must write additional code to adapt the system. Motion control with the Simotion D435 enabled the IPS team to develop its shot peening software directly, simplifying engineering and enhancing performance. “In some of the other applications, you are trying to take a product that was designed for a milling machine and teach it how to run a shot peening machine,” Hart says. “This time, we just designed a shot peening machine from the ground up.”

The Simotion system stores parameters on a removable memory card that can be swapped out to instantly update software. The controller also offers trapezoidal motion profiles, compensating for the inertia of the nozzle manipulator at high speed by providing controlled acceleration and deceleration. This approach improves performance while reducing motor wear and, consequently, points of failure.

In this shot peening machine, metal parts in the chamber (right) are exposed to a high-pressure stream of shot, which modifies internal stresses to strengthen the material. A filtering system allows undeformed shot to be reused and deformed shot via spiral discharge to be ejected from the system.

Of course, the most common source of failure is cabling. Connecting the components with Siemens Drive-CLiQ helped create a reliable solution. An Ethernet backplane based on a 100 Mb/s serial interface, Drive-CLiQ automatically captures nameplate data and validates components, speeding device integration. In the harsh shot peening environment, Drive-CLiQ offers other benefits. Manually terminating cables requires closing up open connectors on the factory floor, always a risk for contamination. Drive-CLiQ connectors are pre-sealed at the factory, which speeds commissioning and gives engineers one less problem to worry about.

Ultimately, the machine design leveraged Siemens solutions throughout. Working with a single vendor brought benefits like simplified ordering and integration, as well as reduced cost of ownership. “The members of the IPS team were unfamiliar with Siemens technology at the start of the project, but once they got comfortable with it, they became fans. Initially, we only decided to go to Siemens for that one particular machine, but after we saw what it could do, it pretty quickly turned into something that we are going to use in several applications,” says Hart. IPS is actively pursuing international business and its value proposition gets a boost from the global support offered by Siemens.

Not to mention the performance. In addition to meeting the speed spec, the system positions to 0.001 in, repeatable to within 0.005 in. The company has multiple machines deployed. “The first machine has 18 months in the field,” says Hart. “I just talked to the customer and they say the machine is repeatable, accurate and reliable. They have no complaints.” That is impressive, considering the machine is operating 16 hours a day, five days per week. The others are running around the clock, five days per week, and Hart has heard of no problems, thus far.

In addition to providing robust, intelligent, accurate motion control technology, Siemens supplied the engineering assistance that helped springboard IPS to success with their machines. “The technical support was really outstanding. Anytime I had a question or problem, I could pick up the phone and find someone to help me work through it, or I could go to their facility and simulate the problem on some of their equipment,” Hart says. “They were really helpful in getting this project up and off the ground.”

For more information:

SIEMENS INDUSTRY, INC.

Drive Technologies — Motion Control

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595 Fax: 847-437-0784

Web: www.usa.siemens.com/motioncontrol

Email: SiemensMTBUMarCom.industry@siemens.com

Attention: John Meyer, Manager, Marketing Communications

Thinking Outside the Box…Literally

By combining careful engineering and high-functionality motion control components from Siemens, R.A. Jones produced a high-speed, high-flexibility cartoner that had the customer coming back for seconds.

By: John Ryan, Packaging Industry Consultant, Siemens Industry, Inc.

The HMI (left center) operates the cartoning line (silver and black enclosure at left), which is capable of packaging 330 bottles per minute, the result of Siemens motion control technology and R.A. Jones engineering. The enclosure at center right holds empty cardboard cases after the carton blanks are removed. Photo credit: R.A. Jones

There is a saying in retail that the package sells the product. While this might not be true across the board, for OEM machine builder R.A. Jones, located in Covington, Ky., the package does indeed sell the product—the company builds packaging machines and cartoners for a wide range of applications. When a U.K.-based spirits distiller changed to a new carton for its high-end Scotch, it turned to R.A. Jones for a cartoning solution. With the help of Siemens motion control components, software and engineering support, the resulting machine was so successful that the company ordered a second version even while the first was being commissioned.

One of the challenges of this project was the speed required¾the process needed to run at 300 bottles per minute with a 10 percent surge capability. The machine had to separate the incoming bottles, transfer each into an article bucket, bring the bucket into the machine, erect the carton, transfer the bottles from bucket to carton, close the carton, stand it up, then discharge it from the machine. This complex sequence had to be performed at a rate of five times per second.

Additionally, the project had very stringent quality requirements. Because the product was a high-end Scotch, there was virtually zero tolerance for any marks on the bottle, the label or the box. The customer wanted the ability to reject individual cartons, individual bottles or cartons with no bottles in them, all without derating the line. The line needed to be able to switch rapidly and easily among packaging 700 ml, 750 ml, and 1 L bottles for two premium brands. To further complicate the process, the bottling plant is located in Scotland, while R.A. Jones is based in the United States.

R.A. Jones has a standard line of product platforms, but where it really shines is in customization for challenging applications. “In general, we are known for high speed and flexibility,” says William Kaup, Technical Sales Manager at R.A. Jones. “While we have standard product lines, many customers come to us for custom or complicated projects.” Often, the OEM machine builder develops a solution by making a few modifications to an existing platform. That was not the case for this project, however. The engineering team nominally started with R.A. Jones’ Meridian cartoner design, but instead of augmenting 80 percent standard platform with 20 percent customization, the project followed the opposite ratio. “We knew it would be an engineering-heavy, custom application,” says Kaup. “The high number of axes required for this project, in and of itself, placed this system at the high end of the complexity scale that we see.”

Getting smart with SIMOTION

The cartoner incorporates 27 axes powered by Siemens servo motors and Sinamics S120 drives. Although much of the machine leverages what Kaup characterizes as fairly standard coordinated motion, some aspects required more. To address all these needs, the engineering team chose the Simotion D445, which integrates the capabilities of a PLC and a motion controller to offer significant intelligence and processing power in a compact form factor.

“The D445 works with compiled code versus assembled code, so it is faster,” says Jason Barter, Application and Development Engineer at R.A. Jones. The Simotion D445 provided all the processing muscle for the cartoner, allowing the team to use the Sinamics S120s as passive drives. “This solution worked well,” Barter adds. “For a 27-axis machine with one processor, the overall throughput of the machine was very efficient.”

To connect the drives to the D445, the team used Siemens’ Drive CLiQ. An Ethernet backplane based on a 100 Mb/s serial interface, Drive CLiQ automatically captures nameplate data and validates components, simplifying device integration and replacement by maintenance staff. After all, plug-and-play operation only works if the right device is being plugged in. “Basically, [Drive CLiQ] recognizes that the correct motor and drive for that particular axis have been connected, so someone would not be able to put in the wrong size motor or wrong size drive,” says Barter. “It helps the client get the right components in the right place.”

Maintaining continuous operation at 300 bottles per minute required an automated carton-loading system to ensure a steady supply of packaging materials. In the carton-loading system, a robotic arm from an outside vendor picks up cases of carton blanks from a pallet, inverts them, and sets them, case and all, in the magazine of the cartoner. The Jones flexbot, a two-axis pick-and-place unit powered by Siemens servo motors, lifts the case off of the stack of blanks and sets the empty case on a trash conveyor. The two-axis pick-and-place unit was controlled from the cartoner’s D445 controller as part of the 27 axes. The Siemens support staff developed custom function blocks to allow the R.A. Jones team to more easily program the equipment.

With a system consisting of a 27-axis cartoner, the robotic-arm carton loader and a pallet handling system, the number of connections added up. “We had two racks of Siemens ET200S I/O on the cartoner,” says Barter. “It was quite an extensive machine.” The pallet handler and de-palletizing robot formed a system by themselves. The pallet handling system was controlled by a Simotion D425, which interfaced with the robot controller over Profibus. The design team integrated the pallet handling system with the cartoner by way of a Profibus connection between the D445 and D425. “We interfaced the robot controller with the Siemens D425 controller just to get some [communications] back and forth and also interfaced that controller to the cartoner,” Barter continues. “We connected the D425 to the main cartoner machine controller (the D445) over Profibus, and then ultimately those two machine controllers communicated with one HMI over Ethernet.”

Although the interface between the D425 and the robot was straightforward, having two machine controllers communicating with a single HMI provided more of a challenge. The Siemens engineering team stepped in to help. “Between Siemens and our distributor, we had quite a bit of support to ensure that we could progress through the development and factory acceptance test of the equipment as rapidly as possible,” Kaup notes.

Troubleshooting at a distance

This upstream view of the cartoner shows the pallet stacker of the robotic system (yellow-paneled enclosure) and the main electrical panel (right). Photo credit: R.A. Jones

In addition to the performance specifications, the customer wanted to incorporate remote access to allow R.A. Jones support engineers in the United States to be able to access the machine online. Here, too, Siemens supplied a solution: the Scalance S612 security module, an industrial-Ethernet switch that provides secure remote access through Internet gateways. Using the Scalance security module and standard Siemens engineering software, R.A. Jones engineers can troubleshoot the machine as though they were standing right in front of it.

The approach not only saves the cost of flying in support staff, it reduces the downtime spent waiting for them to arrive. On a packaging line that processes high-end spirits at 300 bottles per minute, this is an important benefit¾an hour of downtime alone can add up to hundreds of thousands of dollars. The Scalance S612 has already been used to resolve minor issues, Kaup says. As an important side benefit, R.A. Jones engineers have also been able to combine that connectivity with the machine network to access the robot arm on the pallet handling system, even though it is not a Siemens product.

The finished cartoner was shipped from the R.A. Jones facility to the spirits distiller’s plant in Scotland on nine full-sized pallets packed into three freight airplanes. With its combination of hardware, software, and engineering, the machine has achieved a maximum speed of 330 cartons per minute, which meets specification with the required 10 percent surge. “The machine is running well, with only a few application specific issues to be resolved,” says Barter. Based on the success of the first machine, a second one was ordered.

“Although we had used the Siemens Simotion D on several of our other standard product lines, there was a learning curve [with the first machine] because this project was on a much larger scale than we had previously done,” says Kaup. “The second machine went much more smoothly.”

The success of the project came from a combination of quality components, careful design and a tight engineering collaboration. “I think the engineering support provided by Siemens and our local distributor, C&E Sales, was vital to the success of the project,” says Kaup. “I do not think the development could have been done in the timeframe required without that assistance.”

The package may sell the product, but in this case the product sold the packager and the result was repeat business, a satisfied customer and a new set of tools to use for success.

About the author

John Ryan is a Packaging Industry Consultant at Siemens Industry, Inc., Drives Technologies, Motion Control, Production Machines, John.Ryan3@siemens.com.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Continue reading