Contact us today:

Author Archives: Bernard and Company

CASTING SIMULATION ACHIEVES NEW LEVELS WITH MAGMA5

MAGMA presents the economic benefits of casting process simulation at GIFA 2011

During the upcoming GIFA 2011 show in Dusseldorf, Germany, Magma will present its new software generation for casting process simulation, MAGMA5. At the 300 sq. m stand 12A16, the company will demonstrate how casting process simulation with MAGMA5 can be used for optimization at all stages of casting manufacturing to contribute to foundry profitability. MAGMA will show the newest version MAGMA5 5.2 with extended capabilities for all cast materials and processes, introduce its new software MAGMA C+M for the simulation of the core production processes and provide a view into the future of autonomous optimization of casting processes. Additionally, MAGMA is participating in the initiative “ecoMetals” from the Messe Düsseldorf, which supports companies who develop innovative products and processes leading to a more efficient use of energy. MAGMA will demonstrate, using practical examples, how the application of casting process simulation considerably increases a foundry’s energy and resource efficiency.

MAGMA5 – optimized simulation

Autonomous optimization of casting processes and layouts, shown here for gating optimization in die casting, is the future of casting processsimulation.

MAGMA5 5.2 introduces several new simulation capabilities: new process modes for permanent mold, low pressure sand and low pressure die casting, as well both hot-chamber and cold-chamber die casting, allow for detailed process-specific definitions. The software also supports process design by controlling process parameters during a simulation run. For gravity casters, process modules for DISAMATIC and investment casting are now available.

At GIFA, MAGMA will also present its newest developments for the quantitative prediction of as-cast and heat treated local microstructures and properties in aluminum, iron and steel castings. MAGMA5 simulates sand and reoxidation inclusions during mold filling and predicts defects related to molding materials. MAGMAnonferrous calculates the final microstructure and mechanical properties for aluminum alloys considering the metallurgy, inoculation, and hydrogen content of the melt. MAGMAiron predicts local microstructures for iron materials from graphite growth through to the distribution of phases making up the matrix. MAGMAsteel calculates macrosegregation in steel castings and the local microstructure resulting from heat treatment.

The stress module MAGMAstress for the first time offers casters the option to calculate thermally induced casting stresses in permanent molds for all manufacturing steps, including heat treatment and finishing, in order to predict casting crack problems and distortion. The simulated distortion results can be evaluated just as on a coordinate measuring machine and compared directly with real measurements. For the first time, the new module MAGMAdielife facilitates the evaluation of the effects of tooling design and thermal stresses on the durability of permanent molds.

MAGMA Core+Mold – transparency in core production

With MAGMA C+M, the simulation of the core shooting process is possible for complex tools, shown here for three cores including blow tubes in a single core box.

With MAGMA C+M, MAGMA introduces an integrated tool for the simulation of core production processes. MAGMA C+M simulates core shooting, blowing and hardening of organic and inorganic cores. Processes where binder hardening is driven by a catalyst gas as well

as core production with tempered core boxes are supported. MAGMA C+M considers all aspects of core production starting from the core shooter, in order to calculate the flow of the air-sand mixture based on the real shot parameters. An integrated database provides the ability to specify the characteristics of the sand and the binder system as well as core box vents and blow tubes. The program simulates gassing, purging and the curing reaction of gas-hardened cores. The design and control of core box tempering for heat-cured cores (hotbox, croning, inorganic) is effectively supported by modeling of heating cartridges and oil channels. For inorganic cores, MAGMA C+M calculates the drying of the core in the heated core box as well as due to transport of water vapor by hot air during gassing. MAGMA C+M takes advantage of all the functionality of MAGMA5 and is available as an add-on module to MAGMA5 or asa stand-alone product.

Autonomous optimization is the future

With autonomous optimization, foundrymen can make use of simulation in order to pursue their objectives for quality and cost. Autonomous optimization makes proposals for the right casting layout or the optimum process parameters. The virtual test foundry in the computer enables variation of parameters and systematic examination of influencing variables leading up to the optimum configuration. Based on the fundamental physics embedded in MAGMA5, the program finds the best possible dimensions and positions of ingates, as well as the location of feeders and chills including their optimum size. Using industrial examples, MAGMA will present state-of-the-art capabilities and provide a view into the future of optimization.

MAGMA – very involved

At the accompanying WFO Technical Forum, MAGMA will give presentations on the topics of aluminum casting, core production, and optimization. At the NewCast exhibition, which takes place in parallel with GIFA, simulation specialists will discuss the prediction of residual stresses and distortion in cast iron components.

MAGMA also has a further exhibition stand (12A15) as part of the “Get-In-Form” project “Youth-Technology-Future” (“Jugend-Technik-Zukunft“). Here, the attractiveness of work as a professional or specialist in the metal casting industry will be illustrated to students and apprentices in an entertaining and interactive manner.

About software for casting process simulation

Casting process simulation software considers the complete casting process including mold filling, solidification and cooling, and also provides the quantitative prediction of mechanical properties, thermally induced casting stresses and the distortion of cast components. Simulation accurately describes a cast component’s quality upfront before production starts, thus the casting layout can be designed with respect to the required component properties. This results in a reduction in pre-production sampling, but also the precise layout of the complete casting system leads to energy, material and tooling savings for the foundry.

The range of application of MAGMA solutions comprises all cast alloys, from cast iron to aluminum sand casting, permanent mold and die casting up to large steel castings. The software supports the user in component design, the determination of melting practice and casting methodology through to mold making, heat treatment and finishing. This saves costs consequently along the entire casting manufacturing line.

During the last 10 years, the use of casting process simulation has become a valuable business asset for many foundries. MAGMA5 now expands the capabilities of casting process simulation and will further accelerate the acceptance of this technology.

About MAGMA

MAGMA offers comprehensive solutions to the metal casting industry, casting buyers and casting designers worldwide. The MAGMA product and service portfolio includes the powerful modular simulation software MAGMASOFT®,with the newest release MAGMA5, as well as engineering services for casting design and optimization.

Today, MAGMASOFT® is used throughout the metal casting industry, especially for the optimization of cast components in automotive and heavy industry applications.

MAGMA Giessereitechnologie GmbH was founded in 1988 and is headquartered in Aachen, Germany. A global presence and support are guaranteed by offices and subsidiaries in the USA, Singapore, Brazil, Korea, Turkey, India and China. Additionally, more than 30 qualified partners represent MAGMA around the world.

For more information on this release, please contact:

Christof Heisser President MAGMA Foundry Technologies, Inc. 10 N. Martingale Road, Suite 425 Schaumburg, IL 60173 Phone 847-969-1001 ext. 225

Email: cheisser@magmasoft.com Web: www.magmasoft.com

Agency contact: Tim Daro Bernard & Company 847-934-4500 tdaro@bernardandcompany.com

Continue reading650°F Indexing Chain Conveyor Oven

The oven has 5” insulated walls and an aluminized steel interior and exterior. It features three zones: 2’ long open belt loading zone, 7’ long insulated heat zone with recirculated airflow and 4’ long open unloading zone. The mandrels holding product move through the oven on two strands of 60 pitch roller chain on 35” centers, powered by a ¼ HP motor drive with fixed speed of 32 inches per minute.

A 4200 CFM, 3-HP recirculating blower provides vertical downward airflow to the workload, while a 325 CFM powered forced exhauster is also onboard. Motor operated vertical lift doors are provided at each end of the oven.

Controls onboard No. 874 include SCR power controller and fused disconnect switch. A PLC controls temperature and conveyor indexing.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

Hunter Open House To Feature New Maus Grinding Center For Metal Casters

SAM 600G machine being introduced to the foundry market at open house, to be held at Hunter Automated near Chicago on May 19

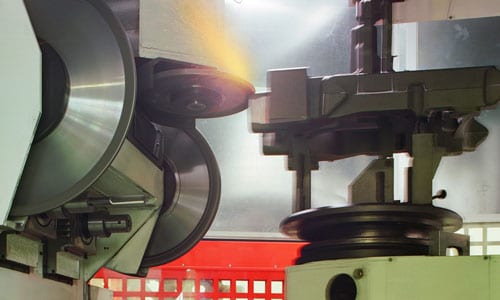

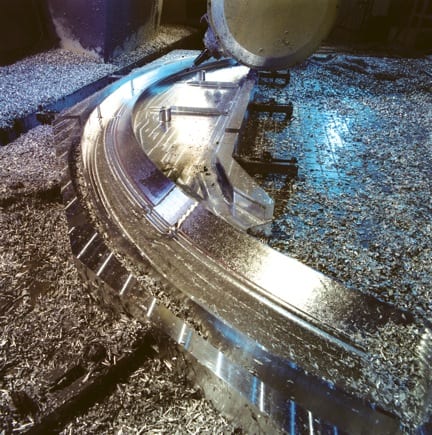

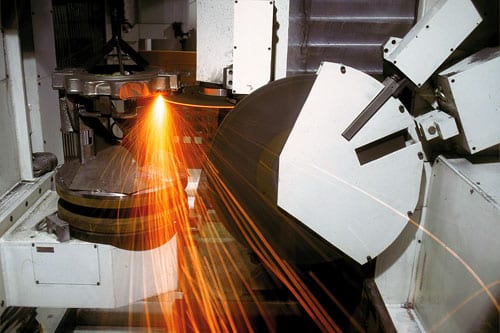

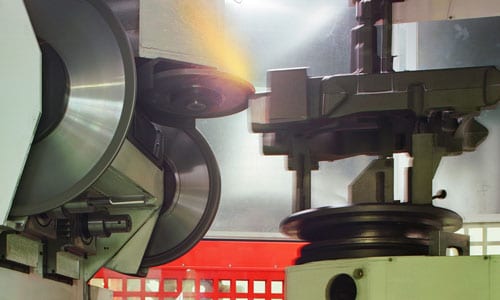

The SAM 600G is a fully automated CNC automatic grinding center, compact yet powerful, with four-tool capacity and a product load/unload time less than four seconds.

Built with a rotary turntable for loading/unloading of the workpieces, this Maus machine can significantly improve the finishing operations. Multi-spindle grinding is programmable for cutting of risers and gating, plus surface and internal grinding.

In the North American market, Hunter also represents Space’, Primafond and Versatile, all builders of related foundry equipment for metalcasting.

For further information on this announcement, interested parties may contact:

HUNTER AUTOMATED MACHINERY CORPORATION

2222 Hammond Drive Schaumburg, IL 60196

Phone: (847) 397-5110

Fax: (847) 397-8254

Email: info@hunterfoundry.com

Web: www.hunterfoundry.com

Connect with Hunter Foundry online:

-0-

The Maus SAM 600G, a CNC grinding center for cast metals finishing, will be introduced to the North American foundry market at an open house, to be held at Hunter Automated in Schaumburg, IL, near Chicago, on May 19.

Continue readingSiemens Presents New Innovations That Enhance Machine Tool Productivity

For machine tool end-users and OEMs, Siemens will exhibit new value-added services ranging from condition monitoring and manufacturing IT to innovative solutions for CNC training and machine tool retrofit, as well as the newest innovations in CNC (computer numerical control), motor and drive technology.

SOLUTIONS FOR MANUFACTURING EXCELLENCE

Condition Monitoring and Manufacturing IT are two value-added services that are continuing their introduction to the U.S. machine tool market.

Condition Monitoring is an internet-based service from Siemens that supports maintenance processes while simultaneously forming a platform for cross-company service and support between OEMs and machine operators. Services can be configured over secure Internet connections from anywhere in the world via a standard PC, an internet connection and a web browser.

Manufacturing IT solutions from Siemens provide software tools for fast, easy integration of machines in a production network, while ensuring that production planning, scheduling and execution

is always problem-free and based on the very latest data.

An entire line of powerful software modules for production machines ensures optimum integration of the machines in the IT-environment and supports a wide range of different functionalities including:

- Production data management (MDA / PMT / PDA)

- Numerical control program management (DNC)

- Tool management (TDI)

- Maintenance management (TPM)

- Service management (RCS)

- Computer interfacing (RPC)

For the aerospace market, the new Sinumerik 840D solution line is the latest in CNC technology that increases performance and user productivity. The Sinumerik 840D sl is a universal and flexible CNC system featuring the innovative Sinamics S120 drives that can be used for up to 31 axes. It is a distributed, scalable, open and inter-connecting system offering a wide range of specialized functions for milling, drilling, turning, grinding and handling technologies.

The Sinumerik 840D offers users innovative features that increase productivity on the manufacturing floor, especially the challenging segments of high-speed and five-axis aerospace machining.

SOLUTIONS FOR THE JOB SHOP

For the job shop, the new Sinumerik 828D numerical control will be presented. Perfect for

mid-range machine tools, the Sinumerik 828D is designed to address the needs of complex milling and turning machines in the job shop segment. It combines CNC, PLC, operator panel and axis control for six CNC measurement circuits in a single, robust operator panel.

The Sinumerik 828D is capable of full graphical, high-level language command and supports ISO programming that is customary in the United States. Programming time can be further reduced for small-batch production with the use of the ShopMill and ShopTurn graphical workstep programming system, while high-level language programming can be used in conjunction with programGuide to significantly reduce programming times for large-scale serial production.

With the introduction of the Sinumerik 828D, modern PC and mobile phone technology is now available to the mid-range machine tool. Extensive online help animations and a new type of input prompting system with moving picture sequences provide the basis for exceptional user convenience. USB, Compact Flash (CF) card and Ethernet ports enable high-speed data transfers onto storage media or integration of the control system into corporate networks. Through the use of its Easy Message functionality, the Sinumerik 828D offers production status monitoring by text messaging (SMS). Depending on the recipient’s profile setting, the machine will transmit information about workpiece machining status, report on the tool condition currently in use and send machine maintenance bulletins to a mobile phone, anytime and anywhere. These combined functions are designed to help keep machine downtime to a minimum.

Newly introduced to the American machine tool industry, and based upon the new Sinumerik Operate user interface, SinuTrain is the ideal solution for control-identical CNC training.

With SinuTrain, actual NC programs are developed and simulated, to speed the program generation protocol. In this way, machine tool operators not only learn the control language commands, but they also visualize part programs on a PC screen that are identical to the machine tool’s screen. As a further benefit, programs generated through SinuTrain can then be used on actual machines.

SinuTrain is available for different needs and budgets including a trial version, a study version, a single-user license and an educational license. It is available in English, Spanish, French, German, Italian and Simplified Chinese, and requires Windows® XP (32-bit). Support for Windows 7 (32- / 64-bit) coming in 2011.

For more information about CNC solutions and services from Siemens, point your web browser to www.usa.siemens.com/cnc.

For specific product information and inquiries:

SIEMENS INDUSTRY, INC.

DRIVE TECHNOLOGIES

MOTION CONTROL

MACHINE TOOL BUSINESS

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/cnc

Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communication

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue readingEXCEL GEAR SUPPLIES GEARBOXES FOR GIANT APE QUADKONG PILE DRIVER

Sixteen precision 112.5º gearboxes fully manufactured, tested, assembled and shipped in ten weeks; run at 1800 RPM on 100 HP

Using its “design for manufacturability” approach, according to N.K. “Chinn” Chinnusamy, Excel Gear president and its chief engineer, the company manufactured the spiral bevel gears, machined the castings, engineered special Teflon seals, created

The sixteen gearboxes, filled with environmentally-friendly biodegradable canola (vegetable) oil and protected with special Teflon bearing seals, are used in pairs at each of eight stations to provide the sequential vibration to the massive assembly that holds the piling above the insertion tube. As the piling vibrates, it literally shakes its way into position. (This is shown in the video.)

“The toughest part of this job…and there were many tough parts,” comments Chinn, “was to get the shaft keyways aligned properly in orientation to the surfaces of the spiral bevel gears. The math involved here was staggering.” In addition, Chinn notes that special fixturing had to be built to facilitate the machining of the very large surface areas involved on this job. He proudly reports that the very first test runouts saw keyway alignments within 0.0005” of parallel.

Another aspect of this immense job was the need to minimize backlash for noise and distortion. The offset bearing calculations needed the highest accuracy possible and, owing to the very nature of spiral bevel gearing, this was an immense math and machining challenge. Excel maintains a battery of the largest gearmaking machines in the industry, as its customer base comprises heavy materials handling equipment, naval vessel gun turret builders, barge off-loading crane and other manufacturers where huge gears and precision motion are both required.

For more information on this success, please contact: EXCEL GEAR, INC. 11865 Main Street Roscoe, IL 61073 Phone: 815-623-3414 Fax: 815-623-3314 Web: www.excelgear.com Email: sales@excelgear.com N.K. Chinnusamy, President

250°F Belt Conveyor Oven

The oven has 4” insulated walls and an aluminized steel interior and exterior. A 4200 CFM, 3-HP recirculating blower provides vertical upward and downward airflow to the unit. The oven has three zones: a 2’ long open belt loading zone, 10’ long insulated heat zone with recirculated airflow and a 2’ long open unloading zone. The product is moved through the oven on a 24” wide, 1” x 1” Type 304 stainless steel flatwire conveyor belt with a 1/4 HP motor drive, with variable speed from 0.3 to 6 feet per minute.

Controls onboard No. 829 include a digital indicating temperature controller, manual reset excess temperature controller with separate contactors, SCR power controller, fused disconnect switch and a recirculating blower airflow safety switch.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank Calabrese.

Continue readingWOMEN IN MANUFACTURING…A YOUNG GIRL’S JOURNEY

13-year-old student visits Forest City Gear to explore career options; meets many women already succeeding in “a man’s world”

Accompanied by her grandfather, Brian Cluff, vice president of Star-SU, a major gearmaking machinery and tooling supplier, Alexi Cluff toured Forest City Gear to see the manufacturing world and discuss the options there for young women. Alexi, though only 13, is currently enrolled in an advanced engineering class at Northern Illinois University, designed to encourage more young women to explore engineering and science as a career.

Roscoe, IL-Forest City Gear frequently opens its doors to visitors, usually from customer and prospect companies, as well as international trade associations, the media, vendors and occasionally competitors. Company owners Fred and Wendy Young have always believed this policy was beneficial to the visitors, who see some of the industry’s finest gearwork, produced and validated for quality on absolute state-of-the-technology, world-class equipment.

On March 30, 2011, however, another visitor came to tour Forest City Gear with a slightly different agenda. 13-year-old Alexi Cluff, accompanied by her grandfather Brian Cluff, vice president of Star-SU, a leading supplier of gearmaking machinery and tools, visited Forest City Gear to learn about manufacturing and especially to explore the options for women in manufacturing, an environment traditionally thought to be “a man’s world.”

Alexi is not your typical 13-year-old. She is currently enrolled in a program sponsored by a grant from the Motorola Foundation and conducted at the College of Engineering and Engineering Technology at Northern Illinois University. The program is a workshop in partnership with NIU-Enhanced Engineering Pathways, the Society of Women Engineers and the Girl Scouts of Northern Illinois. The stated objective of the program is to challenge and sharpen the skills of accelerated learning for 12- and 13-year-old girls selected by their local middle school science and math teachers. Currently, 48 girls work in small groups, assisted and taught by NIU women engineering professors and women engineers from various industries. These instructors mentor the girls on various engineering projects, from the building of simple electrical circuits to create sound, motion and light, to bridge building, chemical engineering and lean manufacturing simulation. The groups meet on Saturday mornings on the NIU Napervillie (IL) campus and also attend a summer camp, held each June.

Forest City Gear President Wendy Young conducts the tour through the plant, showing Alexi Cluff the many types of machines used to produce and validate quality on the company’s high-precision gearwork.

Often, the groups or individual students have tours arranged for them at local area manufacturing locations such as electronics and communications giant Motorola, where they can absorb “real world” experiences and especially meet women of all ages who have succeeded in the various disciplines required in a manufacturing environment. Since Alexi’s grandfather had a long working relationship with Forest City Gear, he reached out to Fred and Wendy Young to arrange a tour. The Young’s obliged, giving the young lady a complete tour of their factory and quality lab, plus arranging a roundtable discussion with a number of the women at the company, who perform all categories of activity for Forest City Gear. A world leader in precision gear manufacturing, Forest City Gear has an international reputation for “excellence without exception,” which happens to be the motto of the company.

Women from all departments of the company, including application engineering, human resources, gear grinding, gear deburring, gear hobbing, order processing, estimating, expediting, procurement, materials inspection, quality validation, machine set-up and company management were at the table. Alexi’s eyes and ears were wide open, as she listened attentively to every word.

Seated at the table for Forest City Gear, in addition to Wendy Young, president, were Kika Young, Geneva Parr, Mary McClellan, Krista King, Sharyl Stewart, Lori Lovett and Ingrid West. These women are involved in literally every aspect of the company. As Mary McClellan mentioned, “We touch the products at every step of the process, especially me (in gear deburring), because of my little fingers!” These women were unanimous in their advice to Alexi Cluff. “Always be willing to learn more, never be afraid to speak up with your ideas, bring all your skills to the job, every day, and don’t hesitate for ask for directions…something men never do!” They all had a good laugh.

Alexi said, “I’ve always been interested in making things and finding out how they work,” a sentiment her grandfather echoed. “I started making gears when I was 14 and it’s fascinated me, ever since.” If there’s anything to that old adage about the genes skipping a generation, perhaps the gear industry will have another Cluff in its future!

Forest City Gear CEO Fred Young explains some of the company’s gear successes to Alexi Cluff at the company’s display showcase.

At the end of the roundtable, Forest City Gear CEO Fred Young had some comments. He detailed the difference in the European education model, where there’s considerably more encouragement given to young women to explore any and every working option. In America, he noted, “Our greatest strength came from manufacturing, the basic ability to make things better and faster than anybody else. The value-added service of making something from raw materials is what builds a nation’s wealth and makes us more self-reliant. Letting go of manufacturing would be a big mistake. By learning and using the technology we develop, as well as what we can gather from other countries, we’ll make America a stronger nation and more successful, in the long run.”

Following the visit, her grandfather remarked to Forest City Gear President Wendy Young, “Alexi was excited and, on the way home, quite animated. The sharing time with your ladies impressed her immensely. She has been journaling her observations. She told us in the car on the way back home that the very first class she had at the NIU workshop for girls was a hands-on exercise in lean simulation and that what she saw at Forest City Gear, from the way the routing sheets, bar codes and processing were set up, that you obviously have implemented lean manufacturing practices! As she downloads, processes and articulates what she saw and observed, she has already started to ask me questions about gear geometry. Such sweet candy to this old grandpa!”

At this roundtable discussion, Alexi Cluff listened as women from every department of Forest City Gear spoke of their roles at the company and the many opportunities for women in the traditional “man’s world” of manufacturing. Many of these women are the lead or key individual in their respective departments at the company.

In reviewing the NIU program and the comments above, perhaps it’s possible Alexi Cluff actually IS your typical 13-year-old girl. They just need to be shown their options.

Forest City Gear was founded in 1955 by Stetler and Evelyn Young, parents of the current CEO, Fred Young, who runs the company with his wife, President Wendy Young. Forest City Gear is considered among the premier gearmakers in the worl

d, with successes ranging from the Mars Rover to the BMW/Oracle, winner of the America’s Cup.

Brian Cluff and his longtime colleague and partner, David Goodfellow, manage and operate Star SU LLC, located in Hoffman Estates, IL. The company sells various leading brands of gearmaking machinery, other machine tools and a proprietary line of cutting tools.

Here is a link to the news release about the program on the NIU-EEP website (www.niu.edu/eep): http://www.niu.edu/PubAffairs/RELEASES/2008/nov/scouts.shtml

For more information on this story, please contact: FOREST CITY GEAR CO., INC. 11715 Main Street Roscoe, IL 61073-0080 Phone: 815-623-2168 Fax: 815-623-6620 Web: www.forestcitygear.com Email: wyoung@forestcitygear.com Attention: Wendy Young, President

PR agency contact for Forest City Gear: Tim Daro Bernard & Company 847-934-4500 tdaro@bernardandcompany.com

Continue reading

Core3D provides dental labs with new materials and new products through advanced manufacturing techniques

International firm uses robotic ultrasonics and conventional machine tools to supply product, usually with 24-hour turnaround; achieving near 24-7 unattended operation with over 15 percent reduction in scrap material on very expensive substrates.

We interviewed Tim McKimson, Core3D’s Worldwide Director of Engineering, at OpenHealth’s Las Vegas-based Core3D facility, located near the prestigious Las Vegas Institute for Advanced Dental Studies (LVI), where restorative and cosmetic dental techniques are taught to practicing dentists and lab technicians, Here, Core3D provides a full range of CAD/CAM/CNC machining and finishing services to LVI and dental labs across the United States. Led by technical operators Mark Ferguson, Danny Palomares and Drew Hrubes, the Core3D team prepares CAD files developed from data typically gathered with an iTero oral scanning wand or from CAD files from scans of conventional dental impressions from the patient’s mouth, which are then digitally captured in a dental scanner from companies such as 3shape. CADENT and other software are typically used to image the impression and begin the process of creating the crown, bridge, abutment, coping, implant or even full denture restoration, as required by the individual lab. 3D CADENT files are G-coded at a remote location of the parent company for transfer to the CNC machine tools at the various Core3D facilities worldwide.

The next step is translation of the digital impression to a RenShape® mold, using conventional machine tools. In most cases, the required structures are designed simultaneously, then the mold with coping is introduced to the DMG Sauer ultrasonic dental machine for preparation of the final structures. This is where the most advanced substrates are processed, ranging from conventional, yet difficult to machine metals such as titanium and cobalt chrome, to the newest advanced materials, including glass ceramics, lithium disilicate and zirconia. These substrates are quite expensive, therefore extreme care is taken in their handling and processing to reduce scrap and conserve operating costs.

As McKimson explained, the decision to cut with ultrasonic technology was relatively easy, given the inherent wear conditions and high cost of conventional tooling. In the ultrasonic process, a combination of electrolysis and fluid lubrication act in concert to create an ionic attraction of particles, removing material in a highly predictable and accurate manner, without the mechanical stress implicit in conventional machining techniques. As a result, the surface of even the hardest materials can be machined with the necessary tactile smoothness required for dental implants.

The extremely hard materials being machined are produced with accuracies in the 2-4 micron range, owing to the combination of ultrasonic technology and the high precision of the Sinumerik CNC, according to McKimson, who notes the reliability of this accuracy has been a significant advantage in reducing scrap at Core3D.

In another area of the facility, conventional mills are used to make polyurethane models and Wieland Zeno 4820 and 4030 mini-milling machines are also utilized for the production of various crowns, wax/resin forms and models, veneers, inlays and implant abutments.

As evidence of the decidedly international nature of this emerging dental giant, all the zirconia and lithium disilicate materials are provided in the IPS e.max System from Ivoclar Vivadent, a company based in Liechtenstein. The company has branches in the United States and Canada, which supply the Core3D Centres in those countries. The templates and cutting tools are closely controlled and validated by the manufacturer to ensure that the preparation of these materials in dental applications is properly executed.

In commenting on the use of the DMG Sauer ultrasonic machines, McKimson notes that it was the machine builder who recommended the Siemens control. “They knew we were dental technicians and engineers, not machinists, by nature. The Siemens control has been extremely easy-to-use and our training time from the builder was minimal. Troubleshooting is mostly done by our operators, with only occasional assistance from Siemens.” Danny Palomares, one of the technical operators, agrees. “My training is in the dental lab world, not on machine tools. It was a great relief to have such a sophisticated control operate with relatively simple language commands and cycle adjustments.”

While there are substantial differences between the European and American dental labs in terms of the materials and assembly techniques used, and despite the fact that literally all projects are highly customized based on the individual needs of the patients and the preferences of the labs and those of the dentists performing the procedures, in the end, the typical project is being turned in 24 hours or less.

For Core 3d Centres, utilizing the best-in-class equipment is critical. In complement the quality machines here, a key part of the overall efficiency protocol in the Core3D network of companies, McKimson points out, is the “know-how” provided through their CAM-DO committee. This global technical committee conducts regular online meetings to discuss what’s working and what’s not in their various worldwide operations and then optimizes and standardizes the processes. He recalls one unanimous vote of approval was voiced on the performance of the DMG Sauer ultrasonic machines with Siemens controls. Core3D currently has nine such machines in their network, all used to process the most advanced materials.

® RenShape is a registered trademark of Huntsman Corporation.

For more information on this story, please contact:

Core3D Centres

Tim McKimson

Engineering Technology Director

5955-2 Wigwam Avenue

Las Vegas, NV 89139

Toll-Free: 1-888-750-9204

Phone: 702-750-9204

http://www.core3dcenters.com/

tmckimson@core3dcenters.com

OR

Siemens Industry, Inc.

John Meyer

Manager, Marketing Communications

390 Kent Avenue

Elk Grove Village, IL 60007

(800) 879-8079 ext. Marketing Communications

www.usa.siemens.com/cnc

SiemensMTBUMarCom.industry@siemens.com

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue readingTravis Pattern Buys Its Fourth Hunter Molding System

Hunter XL2024 matchplate molding system, just purchased by Travis Pattern & Foundry to boost their production. This is the fourth Hunter machine now in operation at Travis.

Spokane foundry, largest privately-owned aluminum caster west of the Mississippi, adds to its already impressive capacity with new matchplate molding system

Schaumburg, Illinois (USA)-Travis Pattern & Foundry Inc., a major producer of aluminum castings for the irrigation, power transmission substation and general-purpose fittings markets, as well as the originators of Li’l Mac sinker molds for the fishing industry, announces its purchase of a fourth Hunter matchplate molding system, the XL2024. According to Gene Johnson, project manager at Travis, “This new line will expand our already substantial casting capabilities for aluminum, as well as brass and cast iron work. We’re seeing an upturn in our business and purchased the machine in anticipation of increasing demand.” The machine is scheduled to be operational by the end of March, 2011.

The XL2024 is a fully automated matchplate molding system, using gravity-fill technology pioneered by Hunter. It produces sand molds up to 20” x 24” with shallow 6-1/2” cope and 5-1/2” drag (165mm/140mm) at 180 cycles per hour, using 400 lbs. (181kg) of sand. Variable squeeze surface pressure to 142 psi (10kg/cm2) can be achieved in production.

Travis Pattern, founded in 1922 and now a fourth-generation company, is the largest privately-owned aluminum caster (over 7,000,000 lbs./3,181,818kg annually) west of the Mississippi and boasts a network of affiliated companies through which their castings are marketed. The company also produces a variety of brass and cast iron products. Travis products are sold throughout North America.

Gene Johnson further described his company’s use of their Hunter molding systems. “We typically run jobs in the hundreds up to 1000 pieces. The fast pattern changeover and the flexibility of the Hunter system really speeds our production.” He estimated approximately 90% of the jobs run on the new Hunter machine will be aluminum, with the balance being brass.

For further information on this announcement, interested parties may contact: TRAVIS PATTERN & FOUNDRY INC. 1413 E. Hawthorne Road Spokane, WA 99218-3100 Phone: 509-466-3545 Fax: 509-467-6465 Web: www.travispattern.com Email: tpfgj@travispattern.com

Attention: Gene Johnson, Project Manager

Or

HUNTER AUTOMATED MACHINERY CORPORATION 2222 Hammond Drive Schaumburg, Illinois 60196-1094 USA Phone: +1 847 397 5136 Email: kpurdy@hunterauto.com Web: www.hunterauto.com Attention: Kevin Purdy, Vice President

Editor Note: Please direct all publication-generated inquiries to Kevin Purdy at Hunter. Thanks!

Agency contact for Hunter: Tim Daro Bernard & Company Palatine, Illinois (Chicago) USA +1 847 934 4500 tdaro@bernardandcompany.com www.bernardandcompany.com

Travis Pattern produces a variety of aluminum, bronze and cast iron products at its 220,000 sq. ft. complex in the Spokane, Washington area. Sand casting, permanent mold and no bake operations are conducted here, as well as machining, heat treating and galvanizing.

Continue readingMagna Electro Casting Purchases Maus Grinding Center

Major Indian caster anticipates dramatic improvement in surface quality and production rates from new Italian grinding/fettling center

Mr. N. Krishna Samaraj, managing director for Magna, stated it was the company’s expectation that this machining system, scheduled for start-up after July, 2011, will result in significant improvements in the surface quality and production rates at the company. Magna is a vertically integrated foundry, as it performs various machining, surface treatment and heat treating operations, in addition to its full foundry capabilities for various products sold to the valve, refrigeration, rail, hydraulics, automotive, wind turbine and other industries worldwide.

Magna runs a fully automated sand prep and mold line, as well, using equipment from its longtime supplier, Hunter Automated Machinery, who represents Maus in various world market areas. Magna currently runs a Hunter HMP20E Automatic Molding Machine (1994) and an HLH 20 Type II mold handling system (2007).

The sale of this Maus grinding/fettling machine was finalized between Mr. N. Krishna Samaraj for Magna and Mr. Ashwin Katke of Carraro, the parent company of Maus, with offices in India.

For further information on this announcement, interested parties may contact:

MAGNA ELECTRO CASTINGS LIMITED 43, Balasundaram Road Coimbatore – 641 -018 Tamilnadu, India Phone: +91 4322 2240109 Email: magnacast@vsnl.com Web: www.magnacast.com Attention: Mr. N. Krishna Samaraj, Managing Director

Or

MAUS SpA Via Caltana, 28 35011 Campodarsego Padova, Italy Phone: +39 0499299311 Sandra Selwan, Marketing Manager Sandra_Selwan@maus.it www.maus.it

Or

HUNTER AUTOMATED MACHINERY CORPORATION 2222 Hammond Drive Schaumburg, Illinois 60196-1094 USA Phone: +1 847 397 5136 Email: kpurdy@hunterauto.com Web: www.hunterauto.com Attention: Kevin Purdy, Vice President

Editor Note: Please direct all publication-generated inquiries to Kevin Purdy at Hunter. Thanks!

Agency contact for Hunter: Tim Daro Bernard & Company Palatine, Illinois (Chicago) USA +1 847 934 4500 tdaro@bernardandcompany.com