Contact us today:

Author Archives: Bernard and Company

Hunter Celebrates 50th Year Serving the Foundry Industry with New Name: ‘Hunter Foundry Machinery Corporation’

Expanding its pioneering position as the industry’s preeminent innovator, this new corporate name reflects the company’s single focus and dedication.

Founded in 1964 as Hunter Automated Machinery Corporation, the company’s reputation as a global foundry equipment leader has built steadily, beginning with its creation of the first truly automated matchplate molding machine developed by the company founder, the late William Allan “Al” Hunter. Since that time it has expanded into linear and rotary mold handling lines, sand handling, preparation and testing equipment, and more.

“Ever since my father founded our company nearly 50 years ago, our reputation has been built on the successful development of new products and technologies for the global foundry industry. It has been our privilege to serve this industry with the latest innovations, as was my father’s vision, ever since,” said Hunter.

“As an inventor, his primary focus was pioneering the automation of matchplate molding and mold handling processes to facilitate our industry’s most backbreaking tasks,” Hunter observed, adding, “As an entrepreneur, he named our company Hunter Automated Machinery Corporation to reflect a potential for creating forward-thinking solutions for other industries, as well.”

“Today we’re looking both at our history and ahead, to our legacy of innovation within the foundry industry,” Hunter stated. “Accordingly, we are announcing at Cast Expo 2013 the renaming of our company to Hunter Foundry Machinery Corporation, as a reflection of our single-focus past, present, and future exclusively within this industry,” he noted.

According to Hunter, the company has always been 100% dedicated to the foundry market. “It’s not only our business focus, it’s our inspiration,” he said. “The great people in this industry motivate our company to constantly and tirelessly pursue better ideas, technologies and production solutions for foundries worldwide. Our new name is a clear reflection of our business now, more than ever.”

The company’s introduction of the first gravity-filled automated matchplate molding machine established its history of innovation, and launched the foundry industry into a new industrial revolution. Its original HMP-10 machine streamlined the laborious metal casting process by offering foundries unimagined new production capabilities, producing as many molds in one hour as most had been able to produce in an entire day. As industry demands grew Hunter responded with advanced solutions such as automated mold handling equipment and coresetters.

Hunter’s inventions have earned the company nearly 150 patents around the world. With more than 1,800 molding machines and mold handling systems installed around the world, Hunter’s sales and service reach extends from its manufacturing sites in North America, South America and China through its offices in the U.S., Europe, Brazil, India and Shanghai to every corner of the globe. Sales and technical support, as well as the company’s $12 million parts inventory, serve to maintain each machine’s original production capability, as well as Hunter’s preeminence in the world market.

FOR MORE INFORMATION PLEASE CONTACT:

HUNTER AUTOMATED MACHINERY CORPORATION

2222 Hammond Drive Schaumburg, IL 60196

Phone: (847) 397-5110

Fax: (847) 397-8254

Email: info@hunterfoundry.com

Attention: Bill Hunter, CEO

Web: www.hunterfoundry.com

Connect with Hunter Foundry online:

CastExpo 2013: Hunter Foundry Machinery Corporation

New HLM-10 Linear Motion Machine, First of Hunter’s New Product Line, Unveiled at Cast Expo 2013

Minimizing maintenance while promoting stability, HLM Series combines and integrates magnetically coupled rodless cylinders and linear bearings for movements of squeeze platen, cope flask, sand measuring hopper, and other components on machine. Separation of hydraulic power system facilitates maintenance, while linear motion-operated, programmable access doors maximize operator protection. Linear motion machine also features CESAR™ vacuum pattern spray recovery system.

See the HLM in action HERE!

Hunter Demos JetSlinger™ Air-Amplification Product At Cast Expo 2013

JetSlinger™, the newest add-on to industry innovator Hunter Foundry Machinery Corporation’s latest products, helps ensure improved pattern definition, as well as uniformity of mold hardness and surface integrity.

JetSlinger™ is an available option for the new Hunter HLM linear-motion machine, as well as a retrofit option for the company’s XL automated matchplate molding machines. It is an air amplification apparatus based on the Venturi principle that accelerates sand into the cope and drag flasks on these Hunter machines.

See the JetSlinger™ in action HERE!

FOR MORE INFORMATION PLEASE CONTACT:

HUNTER AUTOMATED MACHINERY CORPORATION

2222 Hammond Drive Schaumburg, IL 60196

Phone: (847) 397-5110

Fax: (847) 397-8254

Email: info@hunterfoundry.com

Attention: Bill Hunter, CEO

Web: www.hunterfoundry.com

Connect with Hunter Foundry online:

GMTA News Of Note (Issue 2013-1)

Ann Arbor, Michigan – GMTA (German Machine Tools of America) represents various top-quality German metalworking machine builders, including Profilator, Pittler, Praewema and WMZ. These machines are sold to the North American market by GMTA primarily for gear and spline production, as well as other power transmission applications. The company’s target markets include automotive, off-highway, OCTG and other heavy equipment manufacturing. Machines are provided for gear honing, gear grinding, Scudding®, polygon milling, turning, gear tooth pointing and multiple machining operations.

In the news…

-DVS, the parent company of Pittler, Praewema and WMZ in Germany, has plans to expand its North American operations, owing to the success achieved with GMTA in this market

-Scudding® technology, pioneered by Profilator, continues to impact the North American gear and spline markets, due to its superior performance compared to other methods of production; several competitors trying to offer it, proving that indeed, “Imitation is the sincerest form of flattery.”

-The renovation of the GMTA facility in Ann Arbor, Michigan is now complete with plans in the works for future expansion of the campus. Additional floorspace, showroom capacity and training facilities, plus more personnel, are planned, according to company VP Scott Knoy.

-Now in final runoff with anticipated start-up in June, GMTA has provided eight machines (16 spindles total) for the advanced cylinder lining program to the Caterpillar operation in Mapleton, Illinois; project for GMTA valued at $15,000,000

-Order received from Chrysler for Phase III transmission line at IPT1 in Indiana

-GMTA and DVS will have joint booth space, considerably expanded, at IMTS 2014

For more information on this announcement, please contact:

GMTA (German Machine Tools of America)

4630 Freedom Drive

Ann Arbor, MI 48108

Phone: 734-973-7800

Fax: 734-973-3053

Web: www.gmtamerica.com

Email: scott@gmtamerica.com

Attention: Scott Knoy, VP

Connect with GMTA online:

650°F Electric Inert Atmosphere Walk-in Oven for Annealing Plastic Rods

Grieve Corporation introduces No. 821, a 650°F electric inert atmosphere walk-in oven, currently in use for annealing plastic rods at a customer’s facility.

Workspace dimensions inside this unit measure 36” wide x 156” deep x 48” high. 80 kW power is installed in Incoloy sheathed tubular heating elements, while a 7800 CFM, 5 HP recirculating blower provides horizontal airflow across the workloads.An aluminized steel exterior and interior are featured on this unit, which also includes 5” thick insulated walls throughout.

Special construction for inert atmosphere processing includes all the following components: pressure regulator, flowmeter, pressure gauge, internal high-temperature gasketing, bellow-type doorway seal, 1/2” thick cellular silicone rubber atmosphere seal, blower shaft seal, positive latching door hardware, adjustable offset door hinges, outlet with pressure relief, interior seams welded gas-tight and all wall penetrations equipped with compression fittings.

An additional 1500 CFM blower is furnished to pull air through an air jacket on the inner oven for cooling. An oxygen analyzer, 0-5% range, is also provided on this oven.

A flatbed loading truck with 3500 lb. capacity and integral channel support sides, plus a transfer dolly with oven-to-dolly and dolly-to-truck latches, was also provided to the customer.

This entire package was completely designed, engineered, built and fully tested by Grieve.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

500ºF Gas-fired Belt Conveyor Oven for Heating and Curing Battery Cans

No. 838 is a 500oF gas-fired belt conveyor oven from Grieve, currently used for heating and curing battery cans at a customer’s facility.

Workspace dimensions of this oven measure 30” wide x 25’ deep by 18” high, with 4’ long open belt loading and unloading zones at each end. A 10,000 CFM, 7 ½-HP recirculating blower provides vertical downward airflow to the load, while a 350,000 BTU/HR modulating natural gas burner provides heat to the workspace.

No. 838 features a 24” wide, B-42-24-16 balanced weave conveyor belt with roller chain edge drive, powered by a 1/3-HP motor drive with variable speeds from 5-100 ipm.

This Grieve conveyor oven has an aluminized steel interior and exterior, with 4” insulated walls throughout. Side doors allow access to the entire workspace.

All safety and control equipment required by IRI, FM and NFPA Standard 86 for gas-heated equipment is on-board this unit, including a 325 CFM, 1/3-HP powered forced exhauster.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

150ºF Electric Drawer Oven for Curing Printing Plates

No. 845 is a 150oF electrically-heated drawer oven from Grieve, currently used for curing printing plates at a customer’s facility.

This Grieve drawer oven features 4” insulated walls, aluminized steel interior and exterior, plus an access door to the heat chamber for maintenance. Eight drawers, 84” wide x 54” long x 1” high, are each rated for 50 lb. loading. Explosion venting panels are built into the oven roof.

Safety equipment is on-board this Grieve oven to handle 1.34 gallons of flammable solvents, including a manual reset excess temperature controller, back-up heating element relay, separately powered forced exhauster, exhauster airflow safety switch, recirculating blower airflow safety switch and purge timer.

The drawers on the No. 845 open to extend 40” in front of the oven to accommodate the large workpieces involved in this particular application.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

500ºF Electric Belt Conveyor Oven from Grieve

Workspace dimensions of this oven measure 30” wide x 96” deep x 24” high. A 2’ long open belt loading zone, 8’ long insulated heat zone with recirculated airflow and 2 ½’ long open belt unloading zone constitute the full heat processing system. 48KW installed in Nichrome wire heating elements provide the heat, while a 4200 CFM, 3-HP recirculating blower furnishes vertical downward airflow to the load.

This Grieve oven features 4” insulated walls, a Type 304, 2B finish stainless steel interior, stainless steel exterior with #4 brush finish, as well as a 24” wide, 1” x1” Type 304 stainless steel flat wire conveyor belt with ¼-HP motor drive, variable speed from 0.9 to 17.6 ipm. A side door allows access to the unit’s workspace.

Safety and control equipment on-board No. 853 include PVC electrical conduit, a remote control panel, 325 CFM stainless steel powered forced exhauster, six-point thermocouple jack panel through the oven wall, digital indicating temperature controller, manual reset excess temperature controller with separate contactors, and recirculating blower airflow safety switch.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

Modified 200ºC Electric Lab Oven for Preheating Molds

This specially modified Grieve lab oven features 1” insulated walls throughout, aluminized steel interior, stainless steel exterior with #4 brushed finish, heavy duty door latch, reinforced door hinge, shelf supports bolted through the oven walls to support the load at a double shelf height and an adjustable fresh air inlet damper at the oven bottom to control the amount of fresh air entering the chamber.

An added feature for accuracy, the temperature control shaft onboard No. 969 is recessed and slotted to avoid a set point change.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

TCT Commissions New 64” Wide Slitter

TCT Stainless Steel, Inc., a Lebanon, Tennessee metal service center, is proud to announce the commissioning of a new 64” wide heavy gauge EMAG slitter. This line is capable of slitting .035 to .3125 gauges. Maximum coil weight is 40,000 lbs. with a maximum 72” outside diameter uncoiler/recoiler. The line is complemented with an Alcos (8) position carousel packing line.

This new line is in addition to the existing 20” Stanat light gauge slitter commissioned by TCT in late 2012, which slits .005 gauge.

The addition of this line complements the other (4) slitters, rolling mill, edger and cut-to-length capabilities that TCT currently offers to customers. With these additions, TCT now offers more in-house capabilities and services than any service center in the Southern United States, according to a company spokesperson.

TCT invites all interested parties to visit the company at 711 Maddox Simpson Parkway, Lebanon, TN for a personal tour or visit www.tctstainless.com for a virtual tour. Let TCT show you what these new lines can do to benefit your operation.

For more information, please contact:

TCT STAINLESS STEEL, INC.

711 Maddox Simpson Parkway

Lebanon, TN 37090

1-800-877-8366

Phone: 615-443-4657

Fax: 615-449-6079

Web: www.tctstainless.com

Email: tcttn@tctstainless.com

Attention: Sherry Shaub, General Manager

TCT Stainless Steel, Inc. is one of the steel industry’s leading service centers. Our vast, in-house capabilities include virtually every facet of coil processing. Our capabilities include slitting, tempering, gauge reduction, cut-to-length, edging, buffing and tension leveling. TCT currently serves the aerospace, medical, electronic, telecommunication, automotive, lift equipment, building trade and other markets.

The combined inventory of our Michigan and Tennessee service centers include annealed and tempered stainless, aluminum, carbon and coated steels. Our dedication to providing high-quality products, short lead times and reliable delivery has always been the key to our success. We are constantly improving our facilities to include state-of-the-art technology, SPC and quality control standards.

Customer satisfaction is our specialty. Whether it be heavy or light gauges, narrow or wide widths, small or large quantities – TCT guarantees satisfaction and dependability at competitive prices. Our outstanding reputation for product quality is backed by our dedicated, customer-oriented team. Our sales staff welcomes all orders and inquiries and will respond quickly with reliable service and industry leading lead times.

Process Simulation in Elastomer Applications: Identifying “non-productive” times pays off

Using the process-oriented approach of SIGMASOFT® makes it possible to consider all of the molding times present in an actual injection molding cycle. In the injection molding simulation of elastomeric applications, SIGMASOFT® not only considers the filling and curing times, but also the non-productive times between each production cycle while the mold is opened and closed. If the simulated process considers the influence of multiple consecutive molding cycles, the accuracy of the simulation is dramatically improved.

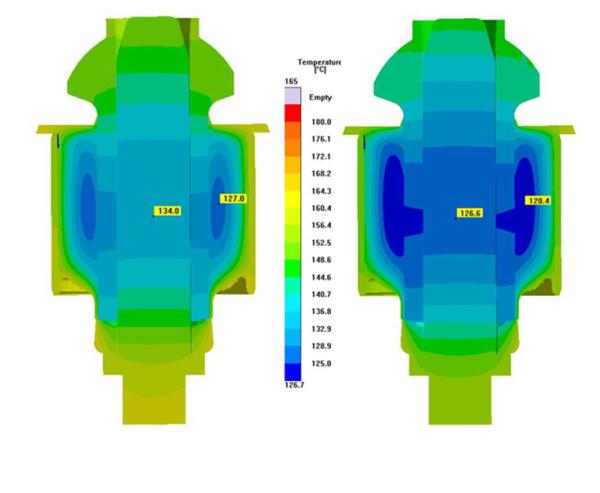

Figure 1 – Temperature distribution in a metallic component over-molded with rubber. Left: without consideration of the mold opening time; right: considering a mold opening time of 60 seconds, where significantly lower temperatures and long curing times are observed.

Even though it is not necessary to include them to complete an injection molding simulation, the “non-productive” times have a major influence on the mold temperature and thus on the process and on the part quality. With the Process Simulation Software SIGMASOFT®, from SIGMA Plastic Services, Inc. (Schaumburg, Illinois), all the non-productive times can also be included into the simulation of multiple consecutive production cycles and a substantial improvement in the accuracy of the results predicted can be achieved.

Considering the times in which the mold opens and closes, the times in which the mold is heated or cleaned, as well as handling times in which the inserts are placed or the parts removed, makes it possible to exactly describe the real multi-cycle production process. The interaction between all components present in the mold is considered with the local temperature dependent material properties, along with the heat that escapes the mold into the environment while it is both opened and closed and the exact timing of each event are coupled together inside of SIGMASOFT® to provide a comprehensive understanding of a very complex system. In this way, even factors that influence the part quality, such as the mold temperature and curing degree, can be predicted before the mold is ever built.

An example is presented in Figure 1. In this case, the mold temperature drops significantly while it is in the open position because heat radiates from both heated mold surfaces. If this time and open condition are not considered in the simulation, the mold temperature calculation will be higher than actual; resulting in a faster curing reaction and a shorter cycle time than what is actually possible. Other events will also be incorrectly calculated such as curing degree during filling and required injection pressure.

In SIGMASOFT®, non-productive times can be defined and individually modified in the simulation. For this reason, it is also possible to optimize the entire production process or mold design simultaneously. Through this simulation, it is possible to decide if changes in the process definition will solve production problems, or if the mold has to be modified to achieve the desired quality and productivity goals.

For more information:

Matt Proske

SIGMA Plastic Services, Inc.

10 N. Martingale Road, Suite 425

Schaumburg, IL 60173

Phone: 847-558-5600

Email: contact@3dsigma.com

Web: www.3dsigma.com

—

SIGMA® (www.3dsigma.com) is 100% owned by MAGMA® (www.magmasoft.com), the world market leader in casting process simulation technology based in Aachen, Germany. Our SIGMASOFT® process simulation solution optimizes the manufacturing process for injection molded plastic, thermoset, rubber, and MIM/CIM components. SIGMASOFT® combines the 3D geometry of the parts and runners with the complete mold assembly and temperature control system and incorporates the actual production process to develop a turnkey injection mold with an optimized process.

At SIGMA® and MAGMA®, our goal is to help our customers achieve required part quality during the first trial. The two product lines – injection molded polymers and metal castings – share the same 3D simulation technologies focused on the simultaneous optimization of design and process. SIGMASOFT® thus includes a variety of process-specific models and 3D simulation methods developed, validated and constantly improved for over 25 years. A process-driven simulation tool, SIGMASOFT®, with its comprehensive simulation approach, provides a tremendous benefit to production facilities. Imagine your business when every mold you build produces required quality the first time, every time. That is our goal. This technology cannot be compared to any other conventional “design” simulation approach employed in plastics injection molding.

New product success requires a different communication between designs, materials, and processes that design simulation is not meant for. SIGMASOFT® provides this communication. SIGMA® support engineers, with 450 years of combined technical education and practical experience, can support your engineering goals with applications specific solutions. SIGMA® offers direct sales, engineering, training, implementation, and support, by plastics engineers worldwide.

Continue reading