Contact us today:

Author Archives: Bernard and Company

MAGMA, Sea Scouts, Castings and Sea Shells…Foundry Market Leader Teaches Next Generation

Steve Sikorski from Magma (far left) led the teaching experience for the Racine, Wisconsin Sea Scouts, as they learned about metalcasting.

In March 2013, representatives from MAGMA Foundry Technologies used the Foundry in a Box, donated by AFS, to teach the Racine, Wisconsin Sea Scouts, Ship 5750, about metalcasting. Sea Scouting is a division of the Boy Scouts of America for young men and women between 14 and 21 years old. The group focuses on developing future leaders through developing maritime skills, both on and off the water. The Scout group devotes their summer activities to sailing and their winter activities to learning manufacturing skills to produce useful items. Previous projects included land sailing vessels, a pig roaster and rebuilding engines for use in boats.

During this past winter, the scouts focused on developing their metalworking skills by making wind vanes using welding, grinding, machining and plasma cutting technologies. This project had all the Scouts excited about metalworking and it created a great opportunity to expose them to metalcasting technology, where Magma is the market leader in casting simulation and process optimization for foundries worldwide.

For more information on this story, please contact:

Christof Heisser

President

MAGMA Foundry Technologies, Inc.

10 N. Martingale Road, Suite 425

Schaumburg, IL 60173

Phone 847-969-1001, ext. 225

Email cheisser@magmasoft.com

Web www.magmasoft.com

SIGMASOFT and RJG announce training session at Plastics News: Plastics in Medical Devices conference in Boston May 13-15

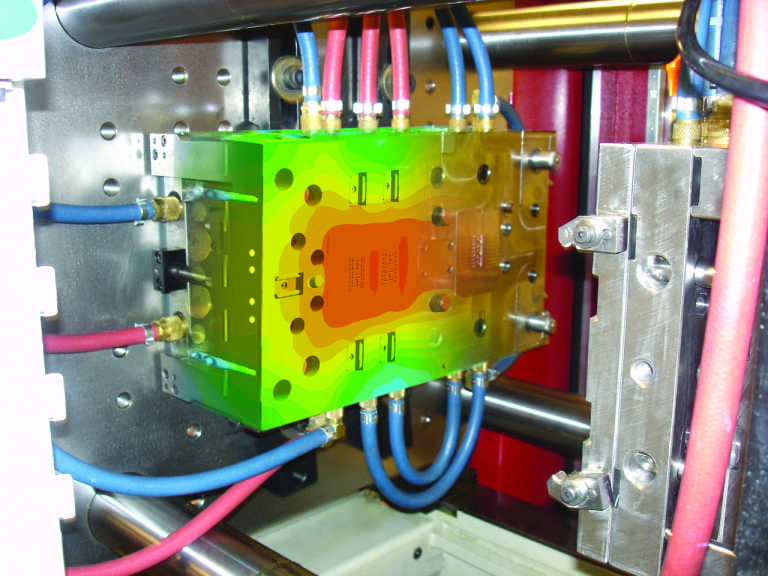

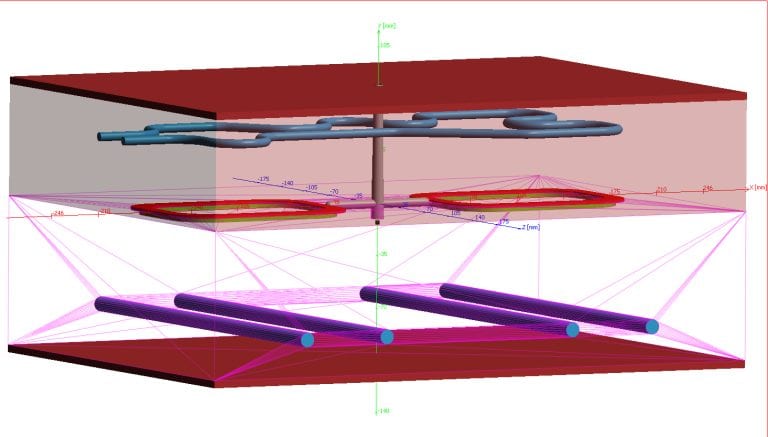

Working together with RJG at the Medical Devices conference, the goal is to provide attendees with a demonstration on how to utilize currently available technology to their best advantage. Reducing time to market with higher quality and repeatable molding processes are key to the future success of injection molding professionals and OEM’s.

RJG and SIGMA will take you through the critical steps from product design to production with best practices for successful, profitable molding. Develop and merge the part design, the polymer, the mold, and the process in a virtual production environment where all of the critical aspects related to profitable part quality can be evaluated and optimized before the actual mold is ever built.

This is an actual workshop with worksheets and exercises that can be used to develop improved communications within your work environment.

Should the mold insert be P20, H13, or a Cu based alloy?

Where are the most critical areas for cooling?

What will the cycle time be?

Is the distortion related to fiber orientation or temperature?

Can it be controlled with packing?

Will it be pressure limited when the viscosity shifts?

How big is the process window?

Can the process be maintained?

Where do we need sensors?

How to contain parts produces outside of the process window

If the mold is already built and the part dimensions from the quoted 30s cycle are out of spec, what are you going to do about it, other than lose money…..? There are more profitable ways of doing things.

For more information, contact:

Matt Proske

Vice President

SIGMA Plastic Services, Inc.

10 N. Martingale Road, Suite 425

Schaumburg, IL 60173

Phone 847-558-5602

Email contact@3dsigma.com

Web www.3dsigma.com

Rubber Forming Pad History: Comparisons of Materials and Introduction of Gümmilast Polyurethane for Forming Pads and Fluid Cells

Gümmilast material from Kastalon offers metalformers greater levels of performance and wear characteristics, compared to conventional polyurethane or Neoprene forming pads and fluid cells.

Short run forming of complex sheet metal shapes using rubber dies and pads is quick and highly effective. This technique was first accomplished using the Guerin Process. After the Second World War, the Wheelon process was developed as an improvement over the Guerin Process. A Wheelon press is capable of manufacturing large, complex, short run parts with economic tooling. This type of hydraulically actuated bladder forming is widely used in the aerospace industry today.

When the Wheelon process was first employed, the forming press fluid cells and forming pads were made of Neoprene rubber. The Neoprene formulations of the day were developed by rubber molders’ chemists. Their formulas were proprietary and highly secretive.

The high grade formulation of Neoprene used was an excellent material for the function of forming pads and fluid cells. It was tough, had very high extensibility, good cut resistance, excellent oil resistance and produced good detail with moderate pressures.

This was the standard material for Wheelon forming pads and fluid cells for many years. However, as the U.S. industrial rubber goods industry matured, its productive capacity diminished. The industry lost the capacity and knowledge required to make Neoprene pads and cells. There are presently no suppliers of rubber Wheelon or Guerin cells or pads in North America.

Product shown in use in the Wheelon process, one used extensively in the aerospace and other industries.

Fortunately, there was capacity to produce these parts from polyurethane. Polyurethane is a synthetic elastomer that is far stronger than Neoprene. Polyurethane has greater cut resistance, more abrasion resistance, greater tensile strength and has suitably high elongation for effective use in the Wheelon process.

Polyurethane is also a more environmentally stable material than the original Neoprene. Most often, when installing forming pads and upon starting forming operations, the Neoprene would be “dried out”. This would lead to shrinkage of the pad and increased stiffness. In order to install the pad and/or start the operation, it would be necessary to heat the Neoprene to restore it to its original softness and resilience. Polyurethane is far more consistent, retaining its size, shape and maintaining its softness and resilience. This eliminates the need for heat “rejuvenation”.

However, in spite of the superiority of the physical properties of polyurethane over the previously used Neoprene, there is a drawback to polyurethane. Due to its increased strength and toughness, far greater pressures must be employed to achieve acceptable part definition and this results in greater strain on the press, its components and some reduction in forming definition.

Some of the difficulties encountered with the use of commercial and even Kastalon KAS43210AE forming pads and cells are:

- Increased wear and maintenance of the press due to the high degree of loading

- Decreased press life

- Reduction in size capacity

- Reduced part definition requiring increased handwork

- Increased set-up time, due to the need for more accurate filler/intensifier pad placement

- The risk of damage to the forming pad if the press filler/intensifier pads are not properly used

- Increased tendency for forming pad extrusion due to higher pressures

- Increased risk of catastrophic failures

- The inability to make field repairs

The challenge to industry has been to create a material that has polyurethane’s toughness and the extensibility of the lost Neoprene material.

Our initial discoveries led us to improve the traditional polyurethane formulations to increase extensibility, reduce working pressure and improve cut and tear strength in the “mid extension” ranges where these pads operate. However, this was only a compromise and a temporary solution to producing a forming pad with superior performance.

After years of continuing research, a hybrid polyurethane compound, trademarked Gümmilast by Kastalon, has been developed. The properties of Gümmilast are very similar to the original Neoprene in performance and exceed the toughness of traditional polyurethane. A comparison of the original Neoprene, Gümmilast, Kastalon KAS43210AE and commercial polyurethane is presented in the following table.

Physical Properties: Traditional Neoprene vs. Polyurethane

| Neoprene | Gümmilast KAS021909A | Kastalon KAS43210AE | Commercial PUR | |

| Hardness,Shore ATensile, psi | 55-602,002 psi | 602850 | 704153 | 704660 |

| Elongation | 773 % | 774 | 694 | 630 |

| 25% modulus | 92 psi | 133 | 201 | 221 |

| 50% | 119 psi | 184 | 260 | 282 |

| 100% | 157 psi | 229 | 340 | 360 |

| 200% | 277 psi | 262 | 434 | 475 |

| 300% | 472 psi | 337 | 522 | 670 |

| 400% | 741 psi | 471 | 738 | 985 |

| Split tear | 228 psi | 191 | 181 | 185 |

| Dynamic modulus | 289 | 372 | 733 | 836 |

The similarity between Gümmilast and the original Neoprene is apparent. In the operating range extension (250-400%), previously available polyurethanes create far higher internal stresses. The rapid increase of these stresses in this operational strain range leads to need for higher pressure and less definition. This makes tool design and the use of intensifier pads highly critical.

When using Gümmilast, the reduction in operating pressure will yield greater press life, while offering greater part definition.

Life testing of Gümmilast pads and cells is ongoing. To date, Kastalon anticipates 3-6 times the life of Improved Kastalon Polyurethane and an even greater life over commercial polyurethane.

In conclusion, Kastalon Gümmilast will provide the Wheelon Process user with a material that offers similar process ease, forming definition and reparability as experienced with the original rubber and providing significantly improved life over commercial polyurethane. Gümmilast is also available for hydroforming bladders, throw pads and Guerin Process pads.

Kastalon Gümmilast products are available from your press parts provider or from Kastalon, Inc.

For more information on this product, please contact:

KASTALON, INC.

4100 W. 124th Place

Alsip, IL 60803

Phone: 708-389-2210

Fax: 708-389-0432

Web: www.kastalon.com/engineering-guide.php

Email: sales@kastalon.com

Attention: Marty Pokorney

Three-level Rotary Hearth Oven for Curing Sealant

This Grieve rotary hearth oven features 6” insulated walls, Type 304, 2B stainless steel interior, integral leg stand, an 8” W x 23” H front access opening built into the oven door and a 30” diameter three-level hearth constructed from perforated steel sheet and driven by a ¼-HP motor through a gear reducer with torque limiting device.

Controls onboard No. 1029 include a digital indicating temperature controller, manual reset excess temperature controller with separate contactors, recirculating blower airflow safety switch, circuit breaker disconnect switch plus a proximity switch and 12-tooth sprocket to index the hearth a 1/12 rotation per index.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

Jennerjahn Realizes Time Savings Up To Two-thirds on New Control Platform Implementation

Three-drum surface slitter rewinder outfitted with Siemens hardware and software achieves Category 4 safety standard with space savings and more flexibility in design

Jennerjahn JLS-120, a popular 120” wide format slitter rewinder, capable of producing 400-foot rolls in less than 30 seconds, was customized using a total package of Siemens controls and software. The robust frame on this machine makes it ideal for construction grade materials, such as house wrap, roofing and flooring underlayment, billboard vinyl and landscaping rolls.

Jennerjahn, located in Matthews, Indiana, is a manufacturer of assorted lines of narrow and wide web slitter rewinders and custom machinery used by converters of point-of-sale cash register rolls, ATM rolls, lottery rolls and a variety of tape rolls, as well as a wide range of paper and other products, including laminating film, plotter paper, house wrap, landscaping products, vinyl billboard sheeting, flexible packages, box tape, roofing underlayment and other construction materials. Founded in 1978, the company also provides customer solutions for roll handling and roll packaging equipment. Today, Jennerjahn equipment can be found in markets worldwide.

On a recent job for a building products company in Australia, the Jennerjahn engineering team, led by Roger Vogel and Will Adams, was confronted with a unique set of requirements on a 120-inch wide, three-drum surface slitter rewinder, a variation of the company’s standard Model JLS-120, to be used to wind a variety of non-woven web materials, used in the construction industry. The machine required five axes of motion control. The JLS line features an unwind with pneumatic braking, a driven surface winder and driven lay-on roll. The machine typically slits a web into multiple sections and the surface winder winds a small diameter roll to a precise length.

The Jennerjahn team estimates that the implementation of the Siemens controls platform on this machine was achieved with a start-up time savings up to two-thirds, the result of various factors in the relationship between this builder, the controls vendor and the local distributor. Will Adams explains, “Siemens provided us design assistance to verify the sizing information and specify the required drive hardware. Our local distributor then provided a complete bill of materials to us, which saved us a great amount of time, owing to our lack of detailed knowledge about the Siemens products.” Adams also notes his company received several days of onsite engineering support provided by the controls supplier to help with drive set-up, network troubleshooting and the integrated safety program modifications required on this machine build.

Since 1978, Jennerjahn has been a leading supplier to the converting industry and today provides an international partner to the industry, offering the most efficient solutions to customer needs on a wide variety of end uses. As a full line machine and ancillary equipment manufacturer, the company maintains a showroom of assorted automated slitter and rewind machinery, so any potential application can be tested, free of charge, according to the company’s website.

For more information on this story, please contact:

JENNERJAHN MACHINE, INC.

901 Massachusetts Avenue

Matthews, IN 46957

Phone: 765-998-2733

Fax: 765-998-2468

Web: www.jennerjahn.com

Email: sales@jennerjahn.com

Attention: Chris Jennerjahn, Roger Vogel or Will Adams

or

SIEMENS INDUSTRY, INC.

Drive Technologies — Motion Control

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/motioncontrol

Email: SiemensMTBUMarCom.industry@siemens.com

Attention: John Meyer, Manager, Marketing Communications

EMAG Tackles Non-Productive Time on Its Machining Centers

EMAG has a long history, starting back in 1867 in Bautzen, Germany, as an iron foundry and engineering works. Re-established 60 years ago in Eislingen, Germany, in 1952 to make lathes and special-purpose machines, today it makes manufacturing systems for precision metal components from its headquarters in Salach, Germany. Its machines range from basic round-part vertical turning centers to machining centers with as many as six axes handling large workpieces. They perform turning, milling, grinding, hobbing, drilling and more as singular purpose setup or combination machines.

EMAG’s equipment differs from typical vertical lathe machining centers, whose head stock is mounted, typically horizontally, and a turret turns to do the machining. “Our turret is mounted in a concrete base, so it’s not moving,” Loetzner explains. “We have a head stock that moves outside of that design. That gives us better precision and better tool life.”

Another example comes from Precima Magnettechnik in Brückeburg, Germany, whose customers expect absolute perfection from, in this case, housings for brakes used mainly for wind turbines. Precima had had issues with machine vibration causing negative effects on tool life and surface finish. However, the rigidity of EMAG’s turning machines and the vibration damping quality of the base allows for the very high feed rates and cutting speeds required in precision hard-machining. Precima now runs four vertical pick-up turning machines from EMAG.

In one recent case study, EMAG needed to provide grinding, turning and turn-grind machines to a major agricultural equipment builder, and the machine builder relied on the 840D CNC. “We needed to devise a control solution that would satisfy all the needs of the various machines we were supplying to this demanding customer, based on a common platform, to enable easier design, integration, startup, commissioning on-site and training for our customer’s operations and maintenance personnel,” Loetzner said at the time.

The CNC also enables remote monitoring over a wireless network so that process engineers can see what the operator sees on each machine. The agricultural equipment customer mentioned has used the remote monitoring capability on a wide variety of EMAG machines for several years, with all data communicated through a single information network that’s accessible by both EMAG and Siemens. Through this arrangement, they have been able to significantly reduce downtime, service calls and troubleshooting identification time.

While happy with the precision capabilities, EMAG’s focus on future development is trying to decrease the downtime between producing components. “On the automation and the part handling, the challenge is you want the machine to run and make parts all the time, right? But once a part is done, you have to take it out and put the other in,” Loetzner says. “Those non-productive times are the biggest enemies.”

“While we have shown the industry we can master any part to highest precision, over the last five years we’ve been more and more focused on tightening non-productive time,” Loetzner says. At IMTS in Chicago in September, 2012, EMAG showed a new machine generation that significantly reduces the non-value add times. “Our chip-to-chip time was between 6 and 7 seconds for typical automotive gear,” Loetzner says. “Now it would be a second or less.”

For more information:

Kristal Kilgore

EMAG LLC

38800 Grand River Avenue

Farmington Hills, MI 48335

Tel: (248) 875-0313

Fax: (248) 477-7784

E-mail: kkilgore@emag.com

Web: www.emag.com

EMAG at IMTS 2012: VL 2 P

Check out Cutting Tool Engineering’s coverage of EMAG’s VL 2 P at IMTS 2012 HERE.

Contact for press and publishers:

EMAG LLC

38800 Grand River Avenue

Farmington Hills, MI 48335

Tel: (248) 875-0313

Fax: (248) 477-7784

E-mail: info@usa.emag.com

Web: www.emag.com

Attention: Peter Loetzner

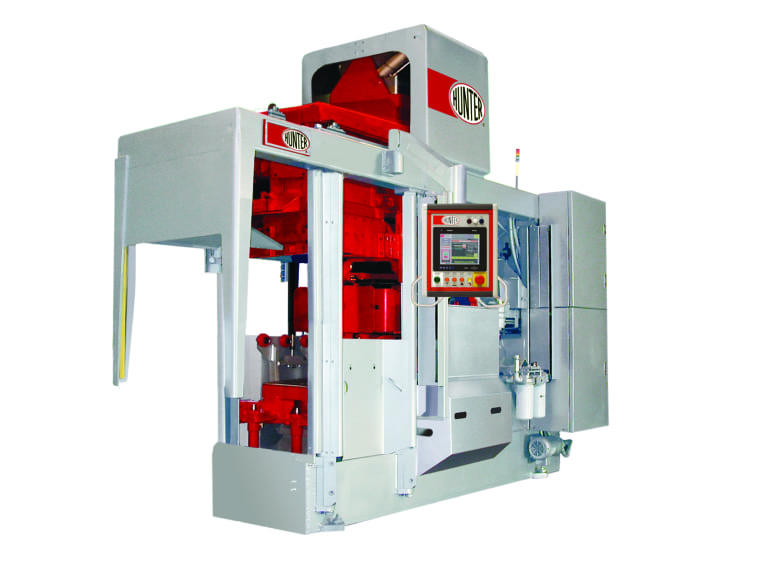

Continue readingHunter Announces Sale Made to Swedish Foundry

Skeppshult Gjuteri AB buys XL 2430 automatic matchplate molding machine from Hunter for cast iron cookware production

The foundry, located on the Nissan River in southern Sweden, is the last remaining cast iron cookware production facility in Scandinavia. Skeppshult cookware and other household items carry a 25-year guarantee, owing to the quality of materials, production and craftsmanship provided by this manufacturer.

The Hunter XL 2430 is used at Skeppshult Gjuteri AB for the production of sand molds, the technology employed at this cast iron foundry.

This sale was made through the European office of Hunter in Milan, Italy and overseen by the director of European Operations for the company, Dr. Paolo Nazari. The local Hunter representative for this success was HYBE Maskin AB of Halmstad, Sweden.

ABOUT THE COMPANY

Hunter Foundry Machinery Corporation was founded in 1964 as Hunter Automated Machinery Corporation with the invention of the first gravity-filled automated matchplate molding machine. This development established the company’s history of innovation and launched the foundry industry into a new industrial revolution. Pioneered by William “Al” Hunter in his garage, the original HMP-10 machine streamlined the laborious metal casting process by offering foundries unimagined new production capabilities, producing as many molds in one hour as most had been able to produce in an entire day. As industry demands grew, Hunter responded with advanced solutions such as automated mold handling equipment and coresetters.

Now in its 50th year, Hunter Foundry Machinery Corporation’s inventions have earned nearly 150 patents around the world. With more than 1,800 molding machines and mold handling systems installed around the world, the Hunter sales and service reach extends from its manufacturing sites in North America, South America and China through its offices in the U.S., Europe, Brazil, India and Shanghai to every corner of the globe. Sales and technical support, as well as the company’s $12 million parts inventory, serve to maintain each machine’s original production capability, as well as Hunter’s preeminence in the world market.

FOR MORE INFORMATION, PLEASE CONTACT:

HUNTER AUTOMATED MACHINERY CORPORATION

2222 Hammond Drive Schaumburg, IL 60196

Phone: (847) 397-5110

Fax: (847) 397-8254

Email: info@hunterfoundry.com

Attention: Bill Hunter, CEO

Web: www.hunterfoundry.com

Connect with Hunter Foundry online:

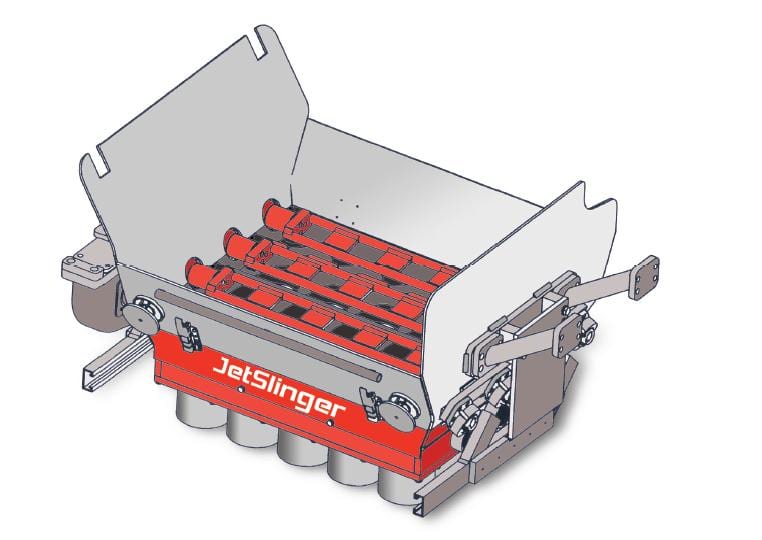

Hunter Demonstrates JetSlinger™ at Cast Expo 2013

Impact-assisted flask filling addition to Hunter’s new HLM and successful XL product lines, JetSlinger helps increase mold production up to 300 percent.

The JetSlinger™ is an air amplification apparatus based on the Venturi principle that accelerates sand into the cope and drag flasks on these Hunter machines. It creates a powerful vacuum and jet exhaust that draws sand mixtures through an array of nozzle assemblies built into a manifold mounted directly below Fillaerator blades, then slings them into a flask. It was invented by company president Bill Hunter. The JetSlinger™ design holds U.S. Patent Number US7819168B2, one of nearly 150 domestic and international patents granted to Hunter since its founding in 1964.

Key features and benefits of JetSlinger™ include:

- Impact-assisted flask filling, adjustable for cope and drag

- Venturi-action air amplification for sand mixture dispersion

- Perpendicular flask filling, superior to side blow fill, no shadow effect

- Improved mold production up to 300% on selected jobs

- Better pattern definition, uniformity of mold hardness and surface integrity

“In contrast to the conventional blow fill machines, no shroud, seals or vented flask assemblies, nor is the usual attendant maintenance required,” according to company president Bill Hunter. “Furthermore, JetSlinger™ allows foundries far greater flexibility, as well as the access needed to produce various castings with the use of chaplets, ram-up cores and exothermic risers,” he adds.

With its perpendicular fill, this impact-assisted device produces molds more quickly and with substantially improved surface quality, owing to the powered pre-compaction of the sand. This action results in greater uniformity of mold density and wall hardness, without sacrificing the accessibility and flexibility of a gravity fill machine. Additionally, the JetSlinger™ achieves a flask filling operation that compensates for the types of mold quality limitations that are often caused by the flowability of the sand and pattern configuration during the high-pressure squeeze cycle. The basic operation of the JetSlingerTM is as follows:

1) Sand mixture is loaded into a hopper

2) Hopper gates open

3) Rotating Fillaerator blades aerate the mixture

4) Mixture is delivered into the Venturi action air acceleration manifold

5) Mixture under pressure dispersed (slung) through 20 nozzles into the flask

6) Flask fills with pre-compaction around pattern plate.

Click HERE to see the JetSlinger™ in action!

ABOUT THE COMPANY

Hunter Foundry Machinery Corporation was founded in 1964 as Hunter Automated Machinery Corporation with the invention of the first gravity-filled automated matchplate molding machine. This established the company’s history of innovation and launched the foundry industry into a new industrial revolution. Pioneered by William “Al” Hunter in his garage, the original HMP-10 machine streamlined the laborious metal casting process by offering foundries unimagined new production capabilities, producing as many molds in one hour as most had been able to produce in an entire day. As industry demands grew Hunter responded with advanced solutions such as automated mold handling equipment and coresetters.

Now in its 50th year, Hunter Foundry Machine Corporation’s inventions have earned nearly 150 patents around the world. With more than 1,800 molding machines and mold handling systems installed around the world, Hunter’s sales and service reach extends from its manufacturing sites in North America, South America and China through its offices in the U.S., Europe, Brazil, India and Shanghai to every corner of the globe. Sales and technical support, as well as the company’s $12 million parts inventory, serve to maintain each machine’s original production capability, as well as Hunter’s preeminence in the world market.

FOR MORE INFORMATION PLEASE CONTACT:

HUNTER FOUNDRY MACHINERY CORPORATION

2222 Hammond Drive – Schaumburg, Illinois 60196-1094 – USA

Phone: +1 847 397 5136

info@hunterfoundry.com

www.hunterfoundry.com

Attention: Bill Hunter, CEO

Hunter Introduces CESAR™ at Cast Expo 2013

New technology provides safer, cleaner work environment, as well as cost savings, for foundries by capturing and recycling unused pattern spray.

SCHAUMBURG, IL — Hunter, the first name in automated matchplate molding machines and mold handling equipment, announced today the introduction of its new CESAR™ vacuum pattern spray recovery system. The CESAR system will be made available to the world market at the company’s Cast Expo 2013 Booth #473, where it will be mounted on Hunter’s new HLM-10 linear motion molding machine. CESAR will run throughout Cast Expo 2013, one of the foundry industry’s leading events, being held April 6-9th at America’s Center in St. Louis, MO.

According to Hunter Foundry Machinery Corporation president and CEO Bill Hunter, who invented the system, “CESAR” stands for Contain, Evacuate, Separate And Recover. “This relates to the proper disposition of pattern spray typically used in sand molding operations, to act as a release agent between the mold and the pattern plate,” Hunter said. “We invented it in response to our customer’s needs, in recognition both of modern foundry and global environmental standards and to help improve their return-on-investment (ROI).

In operation, the closed-loop CESAR System from Hunter executes the following:

- Containment and collection of the unused sprayed materials

- Air-powered, vacuum-Evacuation removal of the spray fumes

- Cyclonic Separation of the usable liquid from the fumes, And

- Recovery, recycling and reuse of the fluid.

Most typical molding machines include a spray head positioned in the sand filling station and a spray evacuation device positioned near the rotary cradle or the spray head. The spray is then dispersed onto the pattern plate as it enters the rotary cradle. But uncontained, excess spray can go onto other parts, as well as into the foundry atmosphere. This is why Hunter created its new CESAR System.

“In our new CESAR System the evacuation device – a slotted tube on the circumference of the rotary cradle – connects to an inline vacuum pump. Then, a cyclonic separator and water separator capture release agent vapor from the air collected in the tube,” Hunter stated, adding that CESAR provides a cleaner, safer working environment in the sand foundry while providing not only substantial savings to a foundry’s operation but also a positive environmental benefit to that foundry’s “green” initiative.

ABOUT THE COMPANY

Hunter Foundry Machinery Corporation was founded in 1964 as Hunter Automated Machinery Corporation with the invention of the first gravity-filled automated matchplate molding machine. This established the company’s history of innovation and launched the foundry industry into a new industrial revolution. Pioneered by William “Al” Hunter in his garage, the original HMP-10 machine streamlined the laborious metal casting process by offering foundries unimagined new production capabilities, producing as many molds in one hour as most had been able to produce in an entire day. As industry demands grew Hunter responded with advanced solutions such as automated mold handling equipment and coresetters.

Now in its 50th year, Hunter Foundry Machine Corporation’s inventions have earned nearly 150 patents around the world. With more than 1,800 molding machines and mold handling systems installed around the world, Hunter’s sales and service reach extends from its manufacturing sites in North America, South America and China through its offices in the U.S., Europe, Brazil, India and Shanghai to every corner of the globe. Sales and technical support, as well as the company’s $12 million parts inventory, serve to maintain each machine’s original production capability, as well as Hunter’s preeminence in the world market.

FOR MORE INFORMATION PLEASE CONTACT:

HUNTER AUTOMATED MACHINERY CORPORATION

2222 Hammond Drive Schaumburg, IL 60196

Phone: (847) 397-5110

Fax: (847) 397-8254

Email: info@hunterfoundry.com

Attention: Bill Hunter, CEO

Web: www.hunterfoundry.com

Connect with Hunter Foundry online: