Contact us today:

Author Archives: Bernard and Company

Exact Metrology Offers RS6 Laser Scanner

Exact Metrology, a comprehensive metrology service provider, recently released the Hexagon RS6 laser scanner, designed for high-speed and accuracy scanning. It scans up to 1.2 million points/sec with a scan rate of 300 Hz. The RS6 also has a wider laser stripe of 150 mm at mid-range and a visual guide that provides real time feedback for stand-off distance.

Built using SHINE technology (Systematic High-Intelligence Noise Elimination), the RS6 laser scanner always delivers full scanning performance, even on the most challenging surfaces. Whether it’s a glossy black plastic automotive body part or a molded carbon-fiber component, this scanner scans without any reduction in quality or productivity. Furthermore, SHINE allows users to scan 99% of parts without touching the scanner exposure. With repeatable mounting (using the Absolute Arm 7 Axis), the scanner can be removed if necessary and replaced without need for calibration. The Hexagon RS6 laser scanner is certified ISO 10360 8on all 7 axis RA8 Absolute Arms.

When compared to other scanners, the RS6 has 3x faster frame rate, 30% wider laser stripe and excellent scanning performance on difficult surfaces with SHINE. With the arm mounted scanner, it is easier to measure due to less preparation, less set up, less settings and scans with full frame, with full line width, all the time.

Exact Metrology is an ISO 9001:2008 and AS9100 Certified Company

Exact Metrology, with facilities in Cincinnati, OH, Moline, IL and Milwaukee, WI and affiliated offices throughout the country, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

Exact Metrology offers a complete line of portable scanning and measurement technologies as well as contract measurement for 3D laser scanning services, reverse engineering services, non-contact inspection, metrology services, and 3D digitizing. The company’s newest equipment includes a CT Scanner, the first in America being used for metrology rather than medical testing. Exact sells and rents metrology equipment solutions, in addition to providing testing as a service and application software training.

For information, please contact:

EXACT METROLOGY, INC.

Dean Solberg

20515 Industry Avenue

Brookfield, WI 53045

Local: 262-533-0800

www.exactmetrology.com

deans@exactmetrology.com

EXACT METROLOGY, INC.

Steve Young

11575 Goldcoast Drive

Cincinnati, OH 45249

Local: 513.831.6620

Toll Free: 866.722.2600

www.exactmetrology.com

stevey@exactmetrology.com

1250°F Inert Atmosphere Oven From Grieve

This Grieve oven is a 1250°F (667°C) inert atmosphere oven, currently used for heat treating firearms components at the customer’s facility. Workspace dimensions of this oven measure 48” W x 48” D x 36” H. 30 KW are installed in Incoloy sheathed tubular heating elements, while a 1400 CFM, 1-1/2 HP recirculating blower provides horizontal airflow to the workload. Inert atmosphere ovens protect parts from oxidation using any non-flammable gas such as nitrogen, argon or carbon dioxide.

This Grieve inert atmosphere oven features 12” insulated walls, all interior seams welded gas-tight, an air jacket on the inner oven for cooling, 16” high integral oven stand, 16-gauge 304 stainless steel interior and enamel-painted aluminized steel exterior. The oven is reinforced for 2000 lb. loads, allowing the customer’s part rack to sit on the oven work space floor.

The oven meets all requirements for inert atmosphere construction, including those in NFPA 86, FM and OSHA standards.

Controls on this Grieve oven include a programmable temperature controller with data logging, capability, 975 CFM cooling blower with air flow safety switch and automatic purge solenoid. An inert atmosphere inlet (1/2” NPT) with pressure regulator maintains positive pressure within the oven.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, Illinois 60073-2835

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese.

2000°F Gas-Fired, Heavy-Duty Furnace

No. 1042 is a 2000°F (1093°C), gas-fired heavy-duty furnace from Grieve, currently used for heat treating at the customer’s facility. Workspace dimensions of this furnace measure 30″ W x 60″ D x 30″ H. 750,000 BTU/HR are installed in four modulating natural gas burners with a floor mounted combustion air blower. Burners fire below hearth, with 9″ thick insulated walls comprising 5″ thick 2300°F ceramic fiber, 4″ 1900°F block insulation and 8 1/2″ floor insulation made from 4-1/2″ of 2300°F firebrick and 4” of 1900°F block insulation.

This Grieve furnace has two lanes of roller rails supported by firebrick piers and an air-operated platform with roller rails to bridge from loading table to workspace. Features include a 1/4” plate steel exterior reinforced with structural steel, 1/2″ steel faceplate at doorway and an air-operated vertical lift door.

Other features include safety equipment required by IRI, FM and National Fire Protection Association Standard 86 for gas-heated equipment plus a free-standing 390 CFM high-pressure combustion blower.

Controls on the No. 1042 include a digital indicating temperature controller and manual reset excess temperature controller with separate contactors.

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

Exact Metrology Holds Open House in Brookfield, Wisconsin

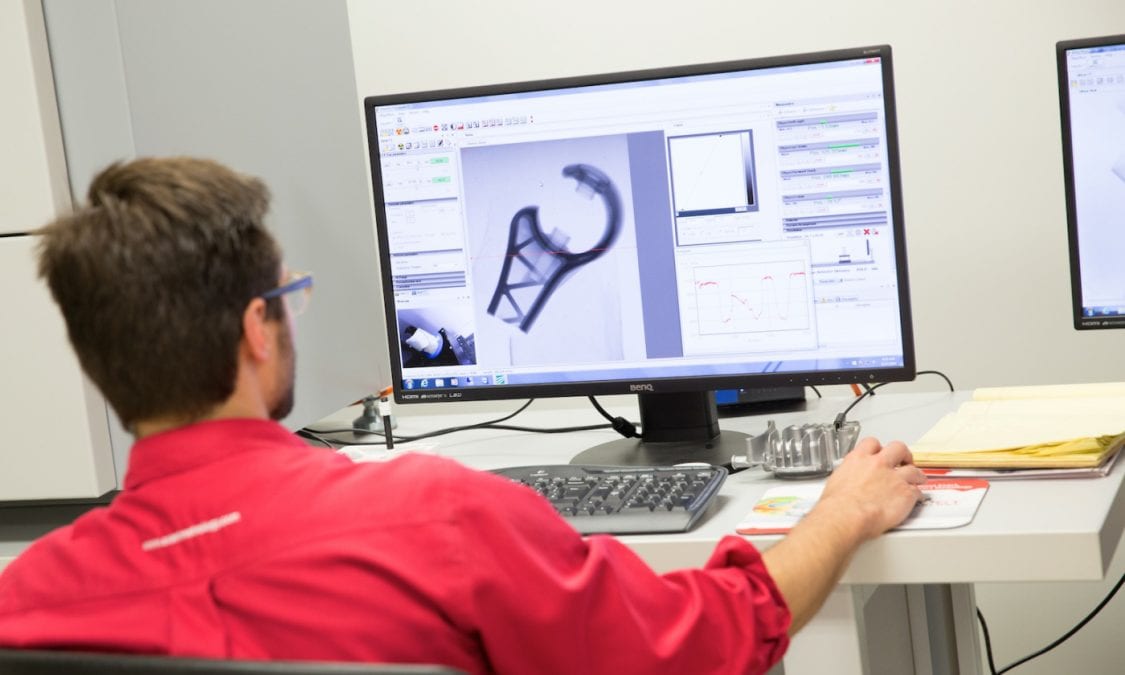

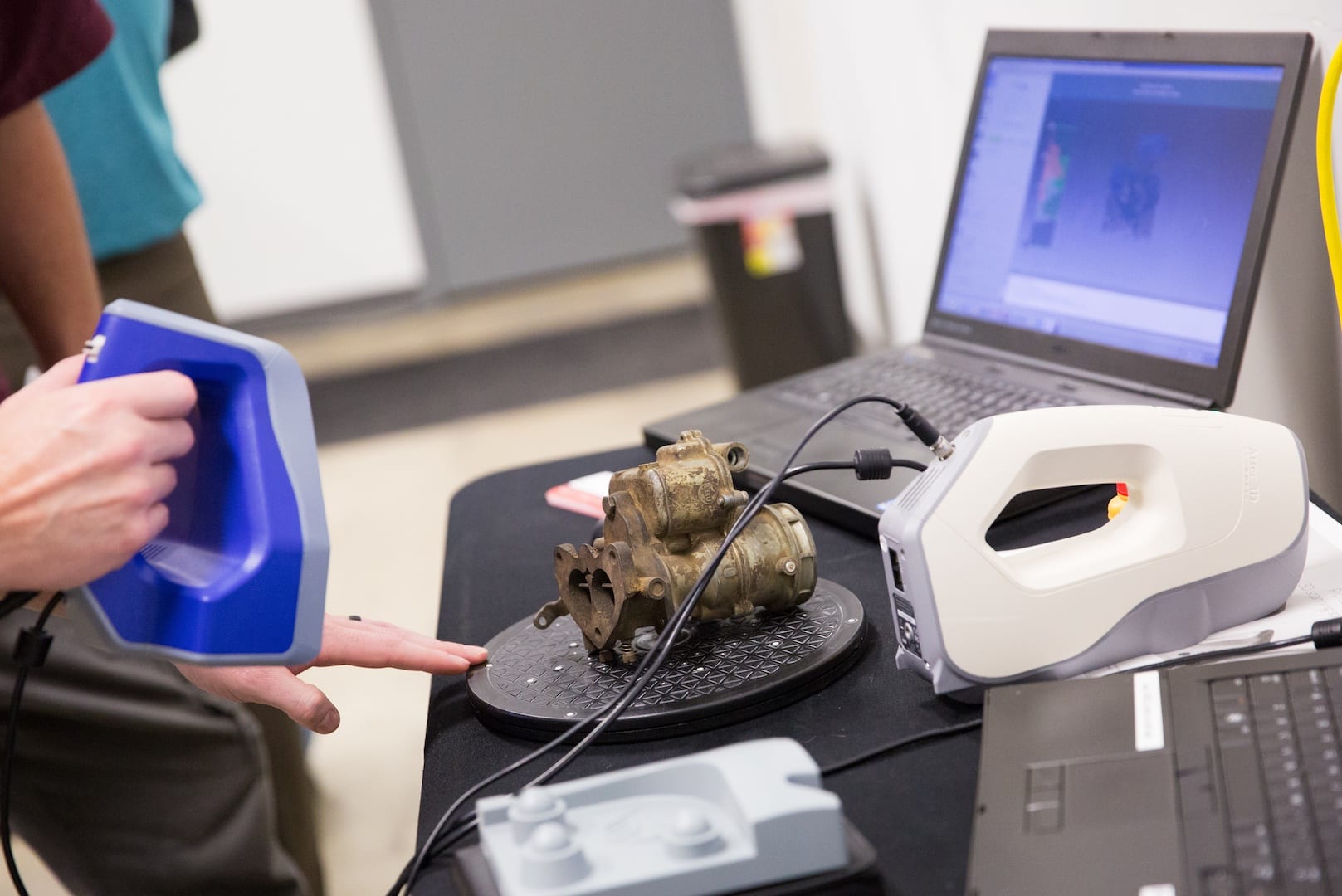

On June 23, 2016, Exact Metrology held an open house at their Brookfield, Wisconsin location, showcasing its newest products in 3D printing and CT scanning equipment. The event was attended by a large number of people from several Midwestern states and a diverse range of business sectors, including manufacturing companies, civil engineering firms, municipalities, local artists and art museums.

Hosted by Dean Solberg, Exact Metrology co-president, the day included product demonstrations featuring the newest technology in 3D & CT scanners from Exact Metrology engineering specialists. Ten stations were set up throughout the facility, each demonstrating equipment from the top names in the industry and most of the equipment was available for hands-on use by the attendees. Products included the Romer measurement and scanning arm, Hexagon Q Flash, Leica tracker, Surphasers, ATOS II Blue Light Scanner, Artec Space Spider and Exact Metrology’s newest acquisition, the ProCon Compact CT scanner. Several attendees brought their own parts and had them scanned onsite, then 3D printed.

Running simultaneously throughout the day were several breakout sessions on: 3D systems (Geomagic Design X/Geomagic for Solidwork) presented by Mike Tsang; 3D Software Innovmetric (Polyworks) by Julien Thibodeau Gagne; and 3D printing by Mastergraphics demonstrated by Kevin Carr.

These high-definition CT imaging devices were, until recently, only available for use in the medical field. They now serve a wide range of product applications, including but not limited to, industrial, manufacturing & construction, power generation/nuclear, medical, aerospace and the arts, the latter already seeing applications in the detection of forgeries and sculpture structural integrity, as examples.

Exact Metrology offers a complete line of portable scanning and measurement technologies as well as contract measurement for 3D laser scanning services, reverse engineering services, non-contact inspection, metrology services and 3D digitizing. The company’s newest equipment includes a GE CT Scanner at its Cincinnati location, the first in America being used for industrial metrology rather than medical testing. Exact sells and rents metrology equipment solutions, in addition to providing testing as a service and application software training.

For more information on this event, please contact:

Dean Solberg

Exact Metrology, Inc.

20515 Industry Avenue

Brookfield, WI 53045

Phone: 262-533-0800

Local: 866-722-2600

www.exactmetrology.com

deans@exactmetrology.com

Exact Metrology is an ISO 9001:2008 Certified Company.

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

Continue reading

Rattunde to Host Open House for Its 10-Year Anniversary Celebration

Rattunde, a leading builder of tube and bar processing machinery, is hosting a Technology Open House to celebrate its 10-Year anniversary at the company’s North American headquarters in Caledonia, MI. The two-day event kicks off on Thursday, September 15th and runs through Friday, September 16th, 2016. The anniversary celebration starts at 5 pm on Thursday, while the Technology Open House takes place on Thursday and Friday from 9 am to 4 pm.

At the Technology Open House, visitors will have the opportunity to see and learn about Rattunde machining production systems on various applications through the fully operational production unit in-house and the live machine demonstrations featuring new technology. On-site technical discussions will be conducted and requests can be made for personal meetings with technical experts. Meals will be provided.

Don’t miss this exciting opportunity to learn about Rattunde’s capabilities and celebrate their milestone anniversary! RSVP by August 15th, 2016, to Janelle McFarlane at 616-940-3340 x 207 or J.McFarlane@rattunde-corp.com.

For more information, please contact:

Janelle McFarlane

Project Coordinator

RATTUNDE CORPORATION

5080 Beltway Dr. SE

Caledonia, MI 49316

Telephone: 616-940-3340 x 207

www.rattunde-corp.com

J.McFarlane@rattunde-corp.com

Rattunde is a leader in the high speed, high precision sawing and machining production systems for tubes and solid bars. Operations performed on Rattunde production systems include sawing, machining, inspection, wash/dry and packaging.

Suhner Introduces Turbo Trim Meat Cutting Unit

Complete Unit for Cutting and Trimming Beef, Pork and Poultry

Photos show unit variations and the flex shafts that supply the rotary power transmission, when in use.

Rome, Georgia – Suhner Industrial Products, LLC introduces the TurboTrim – a complete unit for cutting and trimming beef, pork and poultry. The unit has multiple sized trimmers available for use in the different steps of the meat cutting process, helping to increase productivity, performance and product yield.

Features of the unit include high-quality, long-lasting stainless steel blades which require fewer sharpenings, a coated housing which runs smoothly and quietly with minimal vibration and a patented, adjustment free housing with fewer moving parts to save time. The TurboTrim has a hard plastic handle which is ergonomically designed for operator comfort and a lightweight handpiece to enhance operator performance and reduce fatigue.

TurboTrim knives are based on the principle of a rotating round knife, and manufactured with the highest Swiss quality and precision.

The TurboTrim has a stainless steel motor assembly featuring a slide out bracket which allows motor to be easily removed for cleanup without the use of tools. Downtime is reduced with a quick change assembly for flexible shaft replacement.

For more information, please contact:

SUHNER Industrial Products, LLC

43 Anderson Road SW

P.O. Box 1234

Rome, GA 30161

Phone 706/235-8046

Fax 706/235-8045

info.usa@suhner.com

www.suhner-abrasive-expert.com

Attention: Guido Broder, President

550°F Belt Conveyor Oven from Grieve

The oven travel comprises an 1-1/2’ long open belt loading zone, 20’ long insulated heat zone with recirculated airflow, 1’ long open zone, plus a 12’ long cooling zone and an 1-1/2’ long open unloading zone.

This Grieve belt conveyor oven features 4” insulated walls, aluminized steel exterior and stainless steel interior. Two 12” diameter tubeaxial fans, each driven by a ½ HP motor, push/pull air through cooling zone and a 12” wide, ½” x ½” high carbon steel flat wire conveyor belt with 1/3 HP motor drive, variable from 16 to 44 inches per minute, are also onboard the oven.

Controls on the No. 866 include a 10” diameter circular chart recording temperature controller and a manual reset excess temperature controller.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, Illinois 60073-2835 USA

Phone: (847) 546-8225

Fax: (847) 546-9210.

Web: www.grievecorp.com.

Email: sales@grievecorp.com.

Attention: Frank Calabrese.

Suhner Introduces Rotomax Flexible Shaft Machine

Rome, Georgia – Suhner introduces the Rotomax flexible shaft machine, a unique unit with interchangeable hand pieces that allow a user the freedom to perform a wide variety of machining operations with a single machine. The Suhner Rotomax functions as an angle grinder, straight grinder, drum polisher, belt sander, tube polisher or die grinder, simply by changing the hand piece. This new machine has myriad applications in industrial steel fabrication, polishing operations, sheetmetal assembly, food processing and foodservice equipment builds, appliance manufacturing, various stainless steel fabrications including medical and more.

The Suhner Rotomax offers users a range of power from 2.0-4.7HP and features electronically-controlled speeds ranging from 500-15,000 RPM in increments of 100 RPM at the touch of a button. The combination of an industrial grade motor and solid-state electronic control ensure constant speed and torque during any application. With no gearing, the Rotomax operates very quietly. Other features include soft start, integrated braking and an LED-displayed speed gauge.

The Rotomax is offered as a hanging model, for the user wishing to keep the power flex shaft above the work; on the basic stand, which can be mounted wherever the user desires; or on a specially-designed stable trolley (STM) for portability around the work shop or production line.

For more information, please contact:

SUHNER Industrial Products, LLC

43 Anderson Road SW

P.O. Box 1234

Rome, GA 30161

Phone 706/235-8046

Fax 706/235-8045

info.usa@suhner.com

www.suhner-abrasive-expert.com

Attention: Aaron Beck, National Sales Manager, Abrasives & Power Tools

GMTA Names Dan Thomas New Project Manager

GMTA Vice President Scott Knoy comments, “We welcome Dan to our team. His role will be a vital part of our ongoing efforts to be more customer-centric, as we expand our machine offerings, penetrate new markets and expand existing ones.”

Thomas will be responsible for the end-to-end coordination of the project flow at GMTA, from initial contact through commissioning of machines and systems onsite.

GMTA is a major supplier of machining centers, integrated laser-based work cells, fully-automated parts washing lines and related tooling, focusing primarily on gear, spline and other power transmission components.

See us at IMTS!

For more information, please contact:

GMTA (GERMAN MACHINE TOOLS OF AMERICA)

4630 Freedom Drive

Ann Arbor, MI 48108

Phone: 734-973-7800

Fax: 734-973-3053

Web: www.gmtamerica.com

Email: scott@gmtamerica.com

Attention: Scott Knoy, VP

Continue reading

Rep Names New National Sales Director

Responding to growth in sales and expanded market opportunities, industry leader in rubber injection presses adds to staff

Bartlett, IL – REP Corporation announces the appointment of Derek Williams to the new position of National Sales Director, effective immediately. This move represents a return of Mr. Williams to the REP team, where he previously served as a Regional Sales Manager.

Commenting on the appointment, REP Corporation President Tim Graham observed,

“We welcome Derek back to REP. He brings us over 20 years in the rubber industry and his market knowledge is backed by very strong technical machine and material processing know-how. His new role at REP will bring us additional strength in project management and best practices. Current and future customers will benefit from Derek’s hands-on experience plus his knowledge of our company’s leading edge press technologies.”

For more information on this announcement, please contact:

REP Corporation, 8N740 Tameling Court, Bartlett, IL 60103-8146. Phone: 847-697-7210. Fax: 847-697-6829. Web: www.repinjection.com. Email: tgraham@repcorp.com. Attention: Tim Graham, President.