Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

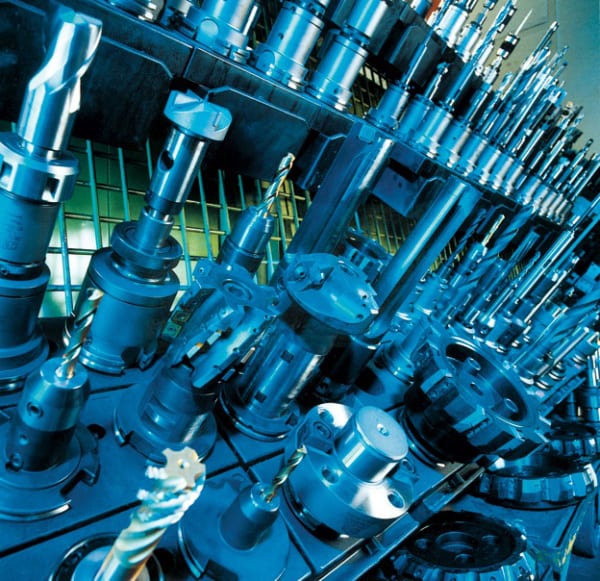

For machine tool end-users and OEMs, Siemens will exhibit new value-added services ranging from condition monitoring and manufacturing IT to innovative solutions for CNC training and machine tool retrofit, as well as the newest innovations in CNC (computer numerical control), motor and drive technology.

SOLUTIONS FOR MANUFACTURING EXCELLENCE

Condition Monitoring and Manufacturing IT are two value-added services that are continuing their introduction to the U.S. machine tool market.

Condition Monitoring is an internet-based service from Siemens that supports maintenance processes while simultaneously forming a platform for cross-company service and support between OEMs and machine operators. Services can be configured over secure Internet connections from anywhere in the world via a standard PC, an internet connection and a web browser.

Manufacturing IT solutions from Siemens provide software tools for fast, easy integration of machines in a production network, while ensuring that production planning, scheduling and execution

is always problem-free and based on the very latest data.

An entire line of powerful software modules for production machines ensures optimum integration of the machines in the IT-environment and supports a wide range of different functionalities including:

For the aerospace market, the new Sinumerik 840D solution line is the latest in CNC technology that increases performance and user productivity. The Sinumerik 840D sl is a universal and flexible CNC system featuring the innovative Sinamics S120 drives that can be used for up to 31 axes. It is a distributed, scalable, open and inter-connecting system offering a wide range of specialized functions for milling, drilling, turning, grinding and handling technologies.

The Sinumerik 840D offers users innovative features that increase productivity on the manufacturing floor, especially the challenging segments of high-speed and five-axis aerospace machining.

SOLUTIONS FOR THE JOB SHOP

For the job shop, the new Sinumerik 828D numerical control will be presented. Perfect for

mid-range machine tools, the Sinumerik 828D is designed to address the needs of complex milling and turning machines in the job shop segment. It combines CNC, PLC, operator panel and axis control for six CNC measurement circuits in a single, robust operator panel.

The Sinumerik 828D is capable of full graphical, high-level language command and supports ISO programming that is customary in the United States. Programming time can be further reduced for small-batch production with the use of the ShopMill and ShopTurn graphical workstep programming system, while high-level language programming can be used in conjunction with programGuide to significantly reduce programming times for large-scale serial production.

With the introduction of the Sinumerik 828D, modern PC and mobile phone technology is now available to the mid-range machine tool. Extensive online help animations and a new type of input prompting system with moving picture sequences provide the basis for exceptional user convenience. USB, Compact Flash (CF) card and Ethernet ports enable high-speed data transfers onto storage media or integration of the control system into corporate networks. Through the use of its Easy Message functionality, the Sinumerik 828D offers production status monitoring by text messaging (SMS). Depending on the recipient’s profile setting, the machine will transmit information about workpiece machining status, report on the tool condition currently in use and send machine maintenance bulletins to a mobile phone, anytime and anywhere. These combined functions are designed to help keep machine downtime to a minimum.

Newly introduced to the American machine tool industry, and based upon the new Sinumerik Operate user interface, SinuTrain is the ideal solution for control-identical CNC training.

With SinuTrain, actual NC programs are developed and simulated, to speed the program generation protocol. In this way, machine tool operators not only learn the control language commands, but they also visualize part programs on a PC screen that are identical to the machine tool’s screen. As a further benefit, programs generated through SinuTrain can then be used on actual machines.

SinuTrain is available for different needs and budgets including a trial version, a study version, a single-user license and an educational license. It is available in English, Spanish, French, German, Italian and Simplified Chinese, and requires Windows® XP (32-bit). Support for Windows 7 (32- / 64-bit) coming in 2011.

For more information about CNC solutions and services from Siemens, point your web browser to www.usa.siemens.com/cnc.

For specific product information and inquiries:

SIEMENS INDUSTRY, INC.

DRIVE TECHNOLOGIES

MOTION CONTROL

MACHINE TOOL BUSINESS

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/cnc

Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communication

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue readingInternational firm uses robotic ultrasonics and conventional machine tools to supply product, usually with 24-hour turnaround; achieving near 24-7 unattended operation with over 15 percent reduction in scrap material on very expensive substrates.

We interviewed Tim McKimson, Core3D’s Worldwide Director of Engineering, at OpenHealth’s Las Vegas-based Core3D facility, located near the prestigious Las Vegas Institute for Advanced Dental Studies (LVI), where restorative and cosmetic dental techniques are taught to practicing dentists and lab technicians, Here, Core3D provides a full range of CAD/CAM/CNC machining and finishing services to LVI and dental labs across the United States. Led by technical operators Mark Ferguson, Danny Palomares and Drew Hrubes, the Core3D team prepares CAD files developed from data typically gathered with an iTero oral scanning wand or from CAD files from scans of conventional dental impressions from the patient’s mouth, which are then digitally captured in a dental scanner from companies such as 3shape. CADENT and other software are typically used to image the impression and begin the process of creating the crown, bridge, abutment, coping, implant or even full denture restoration, as required by the individual lab. 3D CADENT files are G-coded at a remote location of the parent company for transfer to the CNC machine tools at the various Core3D facilities worldwide.

The next step is translation of the digital impression to a RenShape® mold, using conventional machine tools. In most cases, the required structures are designed simultaneously, then the mold with coping is introduced to the DMG Sauer ultrasonic dental machine for preparation of the final structures. This is where the most advanced substrates are processed, ranging from conventional, yet difficult to machine metals such as titanium and cobalt chrome, to the newest advanced materials, including glass ceramics, lithium disilicate and zirconia. These substrates are quite expensive, therefore extreme care is taken in their handling and processing to reduce scrap and conserve operating costs.

As McKimson explained, the decision to cut with ultrasonic technology was relatively easy, given the inherent wear conditions and high cost of conventional tooling. In the ultrasonic process, a combination of electrolysis and fluid lubrication act in concert to create an ionic attraction of particles, removing material in a highly predictable and accurate manner, without the mechanical stress implicit in conventional machining techniques. As a result, the surface of even the hardest materials can be machined with the necessary tactile smoothness required for dental implants.

The extremely hard materials being machined are produced with accuracies in the 2-4 micron range, owing to the combination of ultrasonic technology and the high precision of the Sinumerik CNC, according to McKimson, who notes the reliability of this accuracy has been a significant advantage in reducing scrap at Core3D.

In another area of the facility, conventional mills are used to make polyurethane models and Wieland Zeno 4820 and 4030 mini-milling machines are also utilized for the production of various crowns, wax/resin forms and models, veneers, inlays and implant abutments.

As evidence of the decidedly international nature of this emerging dental giant, all the zirconia and lithium disilicate materials are provided in the IPS e.max System from Ivoclar Vivadent, a company based in Liechtenstein. The company has branches in the United States and Canada, which supply the Core3D Centres in those countries. The templates and cutting tools are closely controlled and validated by the manufacturer to ensure that the preparation of these materials in dental applications is properly executed.

In commenting on the use of the DMG Sauer ultrasonic machines, McKimson notes that it was the machine builder who recommended the Siemens control. “They knew we were dental technicians and engineers, not machinists, by nature. The Siemens control has been extremely easy-to-use and our training time from the builder was minimal. Troubleshooting is mostly done by our operators, with only occasional assistance from Siemens.” Danny Palomares, one of the technical operators, agrees. “My training is in the dental lab world, not on machine tools. It was a great relief to have such a sophisticated control operate with relatively simple language commands and cycle adjustments.”

While there are substantial differences between the European and American dental labs in terms of the materials and assembly techniques used, and despite the fact that literally all projects are highly customized based on the individual needs of the patients and the preferences of the labs and those of the dentists performing the procedures, in the end, the typical project is being turned in 24 hours or less.

For Core 3d Centres, utilizing the best-in-class equipment is critical. In complement the quality machines here, a key part of the overall efficiency protocol in the Core3D network of companies, McKimson points out, is the “know-how” provided through their CAM-DO committee. This global technical committee conducts regular online meetings to discuss what’s working and what’s not in their various worldwide operations and then optimizes and standardizes the processes. He recalls one unanimous vote of approval was voiced on the performance of the DMG Sauer ultrasonic machines with Siemens controls. Core3D currently has nine such machines in their network, all used to process the most advanced materials.

® RenShape is a registered trademark of Huntsman Corporation.

For more information on this story, please contact:

Core3D Centres

Tim McKimson

Engineering Technology Director

5955-2 Wigwam Avenue

Las Vegas, NV 89139

Toll-Free: 1-888-750-9204

Phone: 702-750-9204

http://www.core3dcenters.com/

tmckimson@core3dcenters.com

OR

Siemens Industry, Inc.

John Meyer

Manager, Marketing Communications

390 Kent Avenue

Elk Grove Village, IL 60007

(800) 879-8079 ext. Marketing Communications

www.usa.siemens.com/cnc

SiemensMTBUMarCom.industry@siemens.com

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue reading

The Speed Connect release makes installation and changeover, even in very restricted space applications, fast and easy. No tools are required; just a one-quarter turn locks or unlocks the bayonet-style connectors.

All Siemens Motion-Connect® cables are system-tested to guarantee optimum performance in any motion control system, whether in a Sinumerik® CNC machine tool or Simotion® general motion control application. These cables are also compatible with Sinamics® drive systems and all families of Siemens induction, direct drive and servomotors. Motion-Connect® cables are fully shielded to prevent EMC noise emissions and protect the motion control system from ambient environmental noise. Motion-Connect® cables are certified to CE, VDE, UL and UL/CSA standards.

A wide range of cabling with the new Speed Connect quick release mechanism is immediately available. For more information, visit www.usa.siemens.com/motioncontrol.

Watch an operational video HERE.

For additional product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue readingGM realizes “weeks to hours” reduction in line change and transmission build dynamics at Toledo Powertrain, resulting from Flexible Assembly Configuration System (FACS) and Siemens control/communication

A tried and true euphemism nowadays, “thinking outside of the box” usually refers to a pattern of thought or action that results in rapid innovation, enhanced relationships being developed from established concepts as well as new ones, plus a genuine willingness to forego past practices in favor of a better way. Enter the GF6 six-speed, front wheel transmission line at General Motors Powertrain on Alexis Road in Toledo, Ohio.

Here, a new front wheel drive transmission line for smaller, more fuel efficient vehicles such as the popular Chevy Malibu and new Chevy Cruze is currently ramping up to its initial goal of 2200 units per day. Nothing new about such an event, until a closer look reveals the method used to program this line, implement changeover, stage the workpiece flow, perform all machining, secondary operations and assemble the finished transmissions.

Greg Nazareth, GM controls engineer, demonstrates the reconfiguration procedure on the FACS server, part of the overall Flexible Assembly Configuration System, provided by Elite Engineering of Rochester Hills, Michigan.

During the development of this line, several years ago, GM engineering contacted its longtime controls suppliers to investigate ways of significantly reducing the workflow through the line, as well as enable faster changeover, reduce reprogramming and prevent the curse of all automated manufacturing lines, situations where one out-of-spec machine caused complete shutdown. Another key driver in the development of the GF6 line was the need to minimize maintenance time by installing PLCs, drives and component pallet recognition devices outside the conventional cabinetry found on traditional assembly lines. In addition, controllers were distributed throughout the system, which allowed for removal of typical zone controllers and, in turn, substantially increased system flexibility.

Following considerable investigation into the process for the new line, the major obstacle remained changeover and the need for a more flexible yet highly automated system of transmission builds. In consultation with the controls provider on the existing six-speed, rear wheel drive line, Siemens Automotive Center of Competence (Troy, Michigan), as well as third party software package provider, Elite Engineering (Rochester Hills, Michigan), a deterministic study was undertaken and the result was the line now in production. Siemens provided the PLC, CNC, HMI, RFID and its high-level Ethernet protocol, Profinet, to run on the GM network. Overlaying this hardware and communications topology, Elite Engineering delivered its Flexible Assembly Configuration System (FACS), complemented by Siemens to create its SIFACS solution, wherein all the control elements for every assembly operation and test stations would be fully integrated. SIFACS largely focuses on the integration of the core PLC software blocks and functionalities of the individual stations with the RFID tags on each of the workpiece pallets, according Jim Remski, manager of powertrain activities for Siemens.

Siemens CNC and HMI technology combine with its Profinet high-level Ethernet communications and RFID pallet tags to execute the machining, assembly and testing at this transmission plant, currently targeting an output of 2200 units/day.

AN INTEGRATED APPROACH

Within any flexible automated assembly system, the keyword is flexible. All hardware and related software must be designed with a deterministic functionality that is both valuable to the customer’s build strategy and cost-competitive, as well. Working with technical specialists in safety integrated systems and industrial communications alike was the key to the success of this project at GM Toledo. By creating a decentralized control network that was nonetheless in complete harmony with the overall workflow of the plant, GM and Siemens devised the optimum modular yet flexible architecture for the entire system. This totally integrated automation approach not only addressed multiple families of hardware involved, it also coordinates all code development, safety and communications functions into a seamless and interdependent yet highly flexible and adaptive control scheme.

This integration is nowhere more visible than in the modular and open controller and I/O rack assemblies located throughout the facility. A Siemens Simatic® S7 CPU, the Siemens Safety Integrated drives platform and all I/O, including RF antennas for RFID tag reading are configured and reside here.

Diagnostics in the system are similarly integrated, according to Matthew Thornton and Jeremy Bryant, who consulted from Siemens. “We devised pre-made templates and blocks important to the powertrain build process, as our starting point,” commented Thornton, who further noted the importance of placing the critical performance data on all the HMI panels in the system for easy operator access. “With all motion and safety functions integrated into the drives, there was no need to build a separate troubleshooting architecture for what would be a more traditional safety network of relay cabinetry.”

Bryant continued, “Only a few components talk on the Profibus system, all other I/O and automation components communicate over Profinet.

Reinhold Niesing of the Siemens Automotive Center of Competence further explained the contact process between his group and the provider of the FACS. “They provided the configuration and monitoring system, while we (Siemens) provided the automation run time system. Both systems needed to run in sync to provide GM with configurable options, when changes in production or manufacturing enhancements were needed.”

Each RFID tag carries all the information needed to produce the part at each of the machining and assembly stations in the line.

The result of this collaboration, coordinated under the Siemens Transline solution, whereby all operational, visualization and diagnostic functions are streamlined in a consistent control scheme, was the Transline HMI Lite CE package. This package provides uniform user interface for operational and diagnostic functions on the vast majority of the various machine tools, transfer lines, robotics, assembly machines, sensing devices and vision systems throughout the entire facility. As Michael Grass, project manager for Siemens, explains, “The best part is that the package can be customized to meet specific user needs and preferences. It provides our SIFACS (see sidebar) system of configurable assembly automation very useful information, as the two systems complement each other quite well.” In the safety communications area, he also noted that GM is currently reviewing another Siemens option for open safety communications technology on distributed automation systems.

RFID GETS THINGS STARTED

As a workpiece proceeds through the line, having been delivered by an AGV in most cases, each pallet is equipped with an RFID tag. Reinhold Niesing, engineering manager on the project for Siemens, explains, “The key here is the data throughput in the system, as it directly impacts the cycle time or takt time (maximum allowable time to produce one finished part or product) of the line. The tags must be able to function in static mode, whereby the data on the part must be read before the process begins. Model number, serial number and build status information are all contained in the tag. The faster we read the information, the faster the process begins.” Niesing also detailed the dynamic mode of operation for this RFID system, in which the information at subsequent line stations must be read “on the fly” without any line stoppage, as is often seen in conventional packaging, shipping or other line applications for RFID. In this case, all data are read as the tag passes by the antenna.

Often, in less sophisticated applications, the signal can degrade over time and number of reads. Here, according to the Siemens technical specialists, two interface protocols are supported, namely, ISO 15693 (open standard) and a proprietary Siemens-developed standard, Simatic RF300. The latter uses a state-of-the-art chip paired with highly optimized communications to achieve the faster data read/write rates. Large amounts of data (64kB) are handled in faster cycle times, while the overall RFID solution is applied in a high-speed, non-stop environment. One of the key drivers in the system is the fact that each RFID tag has both EEPROM and FRAM. The 20-byte EEPROM is actually designed to be a one-time programmable memory chip (OTP), a security feature that was deemed most desirable by GM for this application. Meanwhile, the FRAM can be written and rewritten many times for optimum utilization of the hardware, over time.

Despite this level of sophistication in the RFID hardware, the system easily communicates over the existing Profinet, Profibus and other common protocols.

LOGIC BLOCKS ALL AROUND

The overall thrust of the line development, according to George Jewell, the GM engineer responsible for the implementation of the FACS online at the Toledo plant, was to have consistent, even identical logic blocks at every station. This would allow, as is seminal to the FACS architecture, immediate successive modifications to be made in the machine or assembly operations performed, throughout all stages of the line. When rebalancing was needed, when an upturn/downturn in current production was required or when an entirely new model came onto the line, the changeover needed to happen in hours, rather than in weeks, as was the industry norm.

By standardizing on the hardware, software and communication protocols used, engineering costs could be contained and, as a collateral but vital side effect, maintenance on the system could be made much more efficient with much of the system hardware exposed on the line, rather than enclosed in electrical cabinets, again the norm for the industry in the past. Flexible modules would allow more rapid reconfiguration, product changes and a genuine synergy with the ongoing GM commitment to continuous improvement in the line, as the new GF6 transmission ramped up to incremental target levels of production.

Jewell noted that Siemens responded to the challenges, “…with a plug-and-play technology approach, coupled with an understanding of the processes we utilize.”

From the utility perspective, he also noted that the run-time component in the system would function without the full configuration system being online, further complementing a decentralized architecture. Bob Raven, GM controls manager, further commented, “The Siemens commitment to provide this value added functionality geared towards flexibility within our manufacturing principles has substantially supported GM Powertrain’s efforts to standardize processes, controls and continuously improve.”

Currently, GM uses the FACS at various plants in Mexico, China, India, Thailand, Korea and the U.S. — and soon in Canada and Eastern Europe, for the production of transmissions, engines and even the generator on the new Chevy Volt. These products, it should be noted, can be manufactured, assembled and tested, all within the same flexible control architecture, while supporting standardized GM processes.

Rather than textbook product life cycle management, Jewell sees FACS as more of a production line life cycle management tool, as its inherent adaptability means common hardware can be made to do diverse tasks, at varying rates, with on-the-fly changeover, in far less time than previously possible.

TYPICAL STATION DYNAMICS

On one automated assembly station, Hanwha produces the various sub-assemblies of the transmission, as other lines produce the components that go into the sub-assemblies. Adding a station, as Greg Nazareth, GM controls engineer, explained, requires simply adding a PLC with the standard SIFACS logic, desired process devices and downloading an eFACS configuration. In contrast to the traditional zone control, this reconfiguration is not a building block concept; rather, the instructions being given impact the entire line. Nazareth worked with the full GM controls team, headed by Ron Goeckerman, to implement FACS with the host server.

By contrast, all manual workstations on this line have the same download received to a PLC, provided by Siemens in its Simatic lines. While not reliant on the server network in a deterministic mode, the manual stations nonetheless utilize the same software to execute quick tooling changes, machine sequence variations, line balancing and report tracking. Operators received training from both Siemens and Elite Engineering personnel for these tasks.

All part build histories, troubleshooting and machine debugging are recorded for further analysis.

CONTROLS CALL THE BALL AT EVERY STEP

Throughout the metalcutting process here, mostly in the gear and spline forming, hobbing, grinding and finishing, CNC technology is onboard dozens of machine tools. Most of the machines here are controlled by Sinumerik® 840D, the highest-level CNC offered by Siemens. The control not only processes the particular part dimensions in the cutting theater of the machine, it also coordinates all motion control and movements into and out of the machine. Working in tandem with the other hardware and communication network software in the line, for example, ring gears cut on a Wera Profilator machine are indexed from one station to the next, in timed sequences, to coordinate with predetermined production requirements. This operation occurs in a fully automated mode, requiring no operator intervention, except for maintenance and planned inspections.

Likewise, in the machining of valve bodies and transmission cases, each step of the process is controlled by the Siemens CNC to produce the required components in the proper sequence for subsequent assembly and testing operations. During those subsequent operations, other motion control devices and software solutions provided by Siemens execute, monitor and control the assembly process, through the SIFACS solution set. (See sidebar.)

PROFINET TALKS THE TALK

Through a decentralized and cabinet-less design, GM achieves highly integrated RFID control with easy access and true out-of-the-box solutions for the control architecture installed on this line. A Profinet solution provides GM with a high-performance, reliable network with minimum bandwidth impact or additional network load achieved at this plant, all with no special hardware required, a further cost savings for GM.

SAFETY FIRST — AND LAST

Safety features are numerous here, resulting in a complete failsafe system across all Siemens Simatic PLC, I/O devices and safety-integrated drives. All safety devices are networked over Profisafe protocol, a certified safety network, eliminating time-consuming and difficult to maintain traditional hardwired safety connections. All safe I/O, failsafe drives are part of the Siemens Totally Integrated Automation (TIA) protocol. Since it is fully integrated, this protocol provides comprehensive system diagnostics,

Rear wheel drive, six-speed line has been in full production, while the new line is producing front wheel drive, six-speed transmissions for vehicles such as the Chevy Malibu and new Cruze models.

which can help guide maintenance staff to exact fault location and mitigate downtime. Since the drives, starters and machine safety are integrated into the multi-functional machine mount I/O system, Simatic ET 200pro, the overall engineering complexity is reduced because of simplicity in panel design, wiring architecture and seamless integration to the project level hardware configuration, which is reduced due to the totally integrated automation design. For service requirements in the event of a fault, hot swapping of an I/O module is possible during operation, without switching off the entire station. There is nonetheless a very high degree of integral protection, to IP65/67 standards. The fact that an enclosure is not required also helped save on the total cost of the project for GM.

MAJOR INVESTMENT PAYING OFF

Between the two lines here, GM Toledo has invested $872 million on its six-speed, rear- and front-wheel drive transmission production at this 2 million square-foot facility, which currently employs 1400 employees, most members of UAW Local 14.

The highly fuel-efficient rear-wheel drive Hydra-matic 6L80 transmission is now joined by the GF6 front-wheel drive, six-speed

units being produced on this new line under the FACS control solution that supports flexible manufacturing while driving standard processes.

As George Jewell, the GM engineer who spearheaded the implementation of FACS, stated, “From our first installation in Ramos Arizpe (Mexico) to this Toledo plant, we’ve seen great results, with activities that took months reduced to weeks and what took weeks reduced to hours. There’s less ramp-up time, plus the changeover and line balancing upsides are already proving this was a beneficial investment.”

Please direct all inquiries generated by this story to:

John Meyer

Siemens Industry, Inc.

Marketing Communications

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Email: SiemensMTBUMarCom.sea@siemens.com

Wera Profilator gear profiler run by a Sinumerik 840D, the highest level CNC in the Siemens line, used for fully automated production of ring gears.

SIFACS — THE SIEMENS SOLUTION FOR THE FLEXIBLE ASSEMBLY CONFIGURATION SYSTEM (FACS)

Working in tandem with GM process specialists and Elite Engineering, the third party provider of the unique Flexible Assembly Configuration System (FAC

S) used at this GM Toledo transmission plant, Siemens personnel created SIFACS, a solution that integrates the host IT system at the facility with all hardware and software in the line.

SIFACS is quite literally the hub of the information management system for this line, as it coordinates all demand input from the GM server and FACS configuration stations, transmits it via the Profinet communications network in the plant to all the onboard PLC, HMI, motor starters, frequency converters, safety-integrated drives and other controls at the various machine tool, assembly and test stations.

Likewise, the feedback data from all RFID, smart sensors, RS-232 interfaces, hand scanners and other I/O devices are tracked and captured for detailed analysis by production management here.

In this way, not only is the system’s production output closely controlled, but also the line stations themselves can be reconfigured, using a unique Siemens micro memory card that allows easy component replacement, without a laptop. All PLC logic, hardware configuration and process data are embedded on the card, which is interfaced to three Ethernet and one Profibus ports for instant communications.

Critical for a continuous moving line such as those found here, the Siemens Simatic control systems are executing motion commands read from the RFID devices at 8000 bytes/sec, far in excess of the ISO 15693 standards for read and write performance.

SIFACS HMI screen extensions with Cognex Vision View further permit constant monitoring by both a team leader and a conveyor controller, eliminating a PC dedicated to a vision system.

All the smart devices on the line are also interfaced to the SIFACS solution, including fastening, leak test and pressing systems, plus barcode readers, barcode printers, robotic articulation and handling devices, vision systems and protocol gateways.

eFACS functionality is finally integrated into the SIFACS, as this feature of the Elite Engineering system provides connection establishment and monitoring, as well as configuration, process and status data exchanges, plus management of the model configuration data, all stored on the system.

On the most practical of levels, even the data structures feed to the Andon boards for in-plant display is integrated through the resident IT system via SIFACS.

Process Improvement Tools and Process Efficiency Tools, provided with the FACS, enable both process and production engineers to collect data and fine tune the system in real time, keeping build status and cycle time information always current. Line and station balancing can likewise be achieved on-the-fly, with complete process efficiency, operator loading, anticipated cycle time, even individual process operation time calculations being made, charted, displayed and rapidly analyzed by the team leader or station control personnel, in a hierarchy of need-to-know, need-to-act protocol.

The net effects of the Siemens SIFACS® system and the Elite eFACS are sustainable, highly flexible production scenarios, coupled with lower life cycle costs, as the controls and station hardware need not be re-invented for each new model, as well as lean manufacturing strategies, since the line can be constantly tuned without interruption. The flexibility, data analysis and transparent metrics of these systems further allow all employees to understand the current line performance in real time and to make suggestions for improvements that can be implemented almost immediately.

“It’s a win-win-win for all parties involved,” commented George Jewell of GM, whose team pioneered the development and application of these systems for his company’s various plants. Further advancements in FACS and SIFACS are currently being introduced at other GM facilities worldwide, according to Jewell.

For additional product information and inquiries:

SIEMENS INDUSTRY, INC.

DRIVE TECHNOLOGIES

MOTION CONTROL

MACHINE TOOL BUSINESS

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communication

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue readingCHICAGO — During this year’s IMTS, Siemens raffled off a 10th anniversary motorcycle built by Orange County Choppers (OCC), the custom build shop owned by Paul Teutel

The winner was Bob Pool, machining supervisor at Riverview Manufacturing Inc., located in Palmyra, Missouri and a division of Doyle Equipment Manufacturing Company, across the Mississippi River in Quincy, Illinois. Doyle is a major manufacturer of dry bulk handling machinery and Riverview fabricates large-capacity fertilizer spreaders and other equipment for its parent company.

As Bob tells his story, “I’d gone to IMTS with a colleague from Riverview and we noticed the crowd at the Siemens booth. We were waiting in a very long line to get our picture taken with Paul Teutel from Orange County Choppers and the nice young lady who was registering us asked if we wanted to sign up to win the motorcycle. I’d ridden bikes all my life but never owned one. I figured I’d take the chance, but didn’t think about it much, after signing up. The photographer said the photos would be up at the website a couple days later and, when I checked, I couldn’t find them, so I called Siemens. The next morning, I came into the shop and saw a message from Siemens. I called and asked about the photos and got steered to the right spot on the website, but the person said he was really calling for another reason. To my surprise, he said I’d won the bike!”

Riverview is a 25-person shop with full CNC machining, welding and assembly capabilities, all used to produce the 6- and 8-ton spreaders and other Doyle brand equipment built here. Bob says he looks forward to taking very good care of his new bike and using it for many years to come. “I’m really enjoying it and am sure glad I stopped by the Siemens booth at IMTS!”

For more information:

SIEMENS INDUSTRY, INC.

DRIVE TECHNOLOGIES

MOTION CONTROL

MACHINE TOOL BUSINESS

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/cnc

Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communication

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue readingATLANTA — Siemens today announced the release of the new Sinamics® G110D drive platform. The latest solution in the company’s Totally Integrated Automation (TIA) portfolio, the

The Sinamics G110D combines improved functionality, increased energy efficiency, a smaller footprint, lower total cost-of-ownership and enhanced usability in a single drive. Applications for this new drive range from material handling or packaging conveyors and airport baggage carousels — to pumps, fans, compressors and other industrial equipment.

Offered as an economically-priced drive with improved features, the Sinamics G110D includes integrated plug-and-play power and control for easier installation and an optional Intelligent Operator Panel (IOP) for simple text application setup in a reduced footprint. The IOP further assists the machine operator with a greater level of control, as well as alarm status alerts and resolution advice, so troubleshooting time is greatly reduced.

The Sinamics G110D includes an optional power disconnect switch and the IP65 metal housing enclosure has a low profile for easier mounting near the motor, with no drive cabinet required, for further space savings.

The Sinamics G110D is suitable for either direct communication with a Programmable Logic Controller (PLC) or control via I/O inputs. AS-Interface bus configuration and optional maintenance and manual-auto switch are incorporated into the drive, making it easy to integrate with other hardware in an overall control schematic.

Integrated brake control and quick stop functions provide a higher degree of reliability in heavy-load operations.

The new Sinamics G110D complements the recently introduced Sinamics G120D drive, which offers many of the same features plus safety integrated design (Safe Limit Speed, Safe

Stop 1 and Safe Torque Off) and power regeneration capability back to the supply.

For more information on the new Sinamics G110D drive platform, visit: www.usa.siemens.com/motioncontrol.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Continue reading

The embedded PC, which features a DDR3 memory and an Intel Core2 processor, is free of wear from moving parts, such as hard disks and fans. This compact motion control system provides maximum flexibility and accommodates centralized or decentralized machine concepts for PC-based applications or for applications that require a compact size.

It is designed for many different motion control applications with its multiple onboard interfaces. They support communication over Profinet, the open industrial Ethernet standard, as well as Ethernet interfaces that run at 10 / 100 / 1000 megabit speeds. Four USB interfaces make it simple to connect a keyboard, USB stick, printer or other devices. A DVI port rounds out the links so users can attach a display or monitor. The Simotion P320-3 can also be used in a “headless” configuration without a display, monitor or front panel.

LEDs on the front indicate the operating states, making self-diagnosis easy. The integrated power supply bridges temporary power failures. In the buffered SRAM memory, the process data is saved securely even in the event of a sudden voltage drop. Monitoring functions for the batteries, temperature and program execution are also included. The Windows Embedded Standard 2009 operating system, which increases the reliability of the system, is pre-installed. Additionally, the Simotion runtime system comes installed on the Simotion P320-3.

Additional information is available online at: www.usa.siemens.com/motioncontrol.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue reading

Offered to customers as a standard solution, Zoller has written an interface to connect TDI to the company’s presetter, enabling data to be brought directly into the Siemens numerical control. Zoller boasts accuracy on its presetters to two thousandths of a millimeter (0.002mm) or less than eight millionths of an inch (0.00008in).

By utilizing TDI and a Zoller presetter, a machine tool end-user benefits in many ways, including faster access to tool data with no manual entry of values required. All tool data are transferred to the CNC by an automatic link in the presetter, resulting in significant cost-, time- and operator action savings. In addition, the user develops an increased understanding of tool life and tool wear patterns on various operations in the shop. The Zoller presetter writes data directly onto an RFID chip, making transfer to TDI onboard the Siemens CNC is simple and easy. Lastly, an end-user can maintain a central server that indicates the location of any tool in the shop or factory, as well as track the status of the next tool needed to perform an upcoming operation.

Included in the Siemens TDI suite are the following:

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Continue reading

ENERGY MANAGEMENT CONSIDERATIONS WITH TODAY’S DRIVE SYSTEMS

It’s a process, not a product; multiple drive factorscontribute to system energy efficiency

by John Krasnokutsky, Siemens Industry, Inc., Marketing Manager, Motion Control Business

Energy Monitoring Equipment Selection and Optimization (Mechatronics / Parameterization)

Hardware: Common DC Bus / Infeed / Regeneration

While it is valid to state that energy efficiency is defined as the same level of production being achieved at an overall lower energy cost, it is equally important for today’s machine builders and automation engineers alike to remember than an energy-efficient system can actually translate into higher productivity. This is achievable through a comprehensive approach to energy management.

It is a fact that most of the energy loss in a system occurs in three areas, namely, the generation, distribution and conversion of energy into useful work, the last being accomplished through heat exchangers, pumps, motors and drives. This paper will concentrate on the last product group, as it is also a fact that over 25% of all electricity consumed in America is used on industrial electric motor-driven systems. Electric motors represent 65% of the power demand in American industry and, owing to the inefficiency of most motor control systems, the potential for energy savings in an industrial facility can approach 70% for any process where electric motor power is employed.

That said, energy management is a process, rather than a product or series of products installed on a machine, or inline, to achieve a basic energy saving of kW hour consumption. This process must be ongoing and perpetual, meaning that any defined goal should be viewed as a momentary metric of achievement, rather than a final end. While any vendor, including our company, can supply the right products and support services to hit a target mark of energy savings, the mindset of the customer is key in keeping the process recurrent. This ensures a continual increase in the productivity levels achieved, defined as a factor of the energy consumed. In many ways, it can be viewed in the same manner as an ongoing, effective but constantly evolving quality management system at your company.

First, energy monitoring systems must be in place to effectively determine the current consumption. These can include, but are certainly not limited to, energy consumption displays, infeed/supply monitoring devices, power factor meters and more. Next, the proper calculation tools are needed to properly evaluate the life cycle costs of any investment. These tools can be as simple as a motor sizing chart or the software programs used to parameterize drives. However, a more formal mechatronics protocol may be beneficial to your operation. In this scenario, a thorough evaluation of both mechanical and electrical/electronic influences on your system, be it a machine or a process line, is conducted. The results can often open the eyes of machine designers, process engineers and system integrators alike. To realize the benefits this analysis the proper products and system solutions must be implemented.

This is where a competent supplier can be an effective partner for your operation. For example, the solution you need might involve a vector drive that utilizes an energy optimization function to enhance the efficiency of the motor during partial load operations. In a system with multiple motors, energy savings might be realized to a substantial degree by the use of a drive unit with a common DC bus. The designer can also select the most appropriate infeed solution for the machine, pump or process operation, given the particulars of performance and required output. This may include an appropriately sized infeed unit with regenerative capability, the ability to put unused or braking energy back on the incoming power line.

Some applications may allow the use of high efficiency standard induction motors and, in the process, realize a potential savings of 1-3%. The use of frequency converters (VFD) for speed control might raise this to an 8-10% savings. VFDs have myriad applications throughout industry on fans, pumps, blowers and compressors, as well as in wasted energy recovery on cyclical acc/dec and regeneration on lost braking energy applications.

Optimizing your entire system through mechatronic analysis of the machine or process design, can result in a potential savings of 15-20% by the avoidance of over dimensioning of motors, plus partial load optimization by means of energy-related flow control. This analysis may also point to the ability to use controlled energy infeed and recovery.

In order to determine the true efficiency of any drive system, it is necessary to demonstrate the amount of energy required by its power components and a corresponding examination of how the system uses energy. How different drive concepts used on the same system under identical power load must also be considered. This latter exercise might look into partial load efficiencies with various motor and drive combinations, straight comparisons betweens synchronous servo vs. asynchronous induction motors or direct drive vs. motor/gearbox combinations, drives with braking components vs. regenerative drive technology, as well as solutions with single vs. multi-drive, common DC bus solutions.

A corollary to this discussion should also include a review of potential hydraulic/pneumatic component change outs in certain applications where replacement with an integrated package of motion control and PLC technology might better resolve closed loop pressure control of axes, for example. Fewer components and their related power consumption can lead to overall system productivity improvements, as well as ongoing enhanced energy efficiencies. Reduced programming, diagnostic and commissioning times can also flow from such an approach, providing even more opportunities for overall machine or process improvements. Tracking the energy efficiency of such a system may seem problematic at first, but here again today’s sophisticated mechatronic and virtual production protocols can be utilized to validate the real-world performance characteristics of such designs, far in advance of their implementation.

As the emergence of new technologies has impacted many of the products used in energy-efficient systems, it is equally important to take a more holistic look at operational sequences and the overall integration scheme when designing, retrofitting or rebuilding for improved energy utilization. The results can be many, including precise process and power factor control for optimum energy use and significant cost savings, plus the collateral benefits of lower carbon footprints, reduced maintenance due to decreased mechanical stress and lower total cost of product quality derived from less mechanical wear and better production control.

Author: John Krasnokutsky

Email: john.krasnokutsky@siemens.com

Website: http://www.usa.siemens.com/motioncontrol

Siemens Industry, Inc.

5300 Triangle Parkway

Norcross, GA 30092

For an informative PowerPoint presentation or more information on this subject, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Continue reading

ATLANTA — Siemens announced today the release of the new Simatic® CPU 317TF-2DP controller that combines motion control, safety and standard tasks in a single device. This device is the latest solution in its totally integrated automation portfolio that integrates and combines devices for the plant floor environment, further reducing footprints and improving overall efficiencies.

The Simatic CPU 317TF-2DP controller unites a series of important features that all go together in one device to reduce the wiring, coding and the implementation times. It also benefits users by saving space on the shop floor and reducing overall total cost of ownership.

Possible applications for the new device range from controlled single-axis positioning to complex, synchronized sequences of motion, such as geared synchronous motion, curve synchronization or print mark correction. The synchronous axes can be coupled to a virtual master or a real master. For safety-oriented applications, the controller fulfills the rigorous requirements of all the relevant standards, including EN 954-1 up to Cat. 4, IEC 62061 up to SIL 3 and EN ISO 13849-1 up to PL e.

For Siemens PLC users, the Step 7 option package S7-Technology is available to simplify engineering and commissioning. The Step 7 option package, supporting simultaneous processing of up to 64 technology objects, is available to meet engineering requirements for programming and commissioning of all functions. For specific fail-safe applications, the Step 7 option package Distributed Safety offers a set of pre-configured library blocks, including emergency stop, two-hand control, muting and door monitoring. No external safety hardware is required for costly safety precautions at the machine, saving valuable space in the control cabinet.

Centralized and distributed fail-safe I/O and fail-safe drives according to PROFIsafe, the fail-safe communication standard, can be connected to the Simatic CPU 317TF-2DP. The drive safety functions SBC, SLS, SSM, SOS, SS1, SS2 and STO according to PROFIsafe can be used in addition to the familiar safety functions.

PROFIsafe both enhances this controller’s capabilities and value while further simplifying commissioning. In particular, PROFIsafe requires less wiring than other controllers available in the market, making it quicker and easier to set up while reducing the risk of errors through the commissioning process.

For more information, visit www.usa.siemens.com/motioncontrol.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Continue reading