Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

North American users can now make full use of the benefits of a modular product, built to NEC (NFPA 70) standards, to configure common DC bus lineups and high horsepower drives, with optional UL/cUL listing

Key to the global growth of the Sinamics S120 CM range is its modularity and flexibility. Pre-designed, fully type-tested modules, including line side components, line infeeds (bus supplies) and motor inverters, all with a broad range of standard options, are selected and configured by the customer. Compared to the traditional approach of custom-engineered systems, this approach offers significant reduction in engineering and manufacturing lead times, which translates into reduced project costs and a compressed delivery schedule, while minimizing technical and commercial risk on even the most complex drive systems.

Individual cabinet modules from Siemens have a standardized power and control interface, which allows them to be freely positioned in a lineup that best suits the particular application and makes them easy to install and connect. The broad range of standard options including the DC bus current rating and enclosure type, for example, is available to tailor selections to best meet jobsite and environmental conditions. Despite standardization, this design offers a high degree of flexibility for both power and control circuits. For line side converters, there is a choice of non-regenerative Basic Line Module (diode rectifier) or fully regenerative Smart and Active Line Modules. Both of these are IGBT inverters, the Smart Line Module being a more basic six-pulse unit, while the Active Line Module offers low harmonics exceeding the demands of IEEE 519. Unity or controllable power factor and DC bus voltage control allows stable operation of motors even on irregular power supply systems. Basic and Smart Line Modules can also be configured in 12-, 18- or 24-pulse systems for low harmonic operation. All these configurations are now compliant with the National Electrical Code (NFPA 70) and Short Circuit Current Ratings per UL508A supplement SB, up to 100 kA.

The SINAMICS S120 firmware, combined with Drive-CLiQ (the flexible backplane bus), allows users to assign control units multiple Line and Motor Modules, plus mount the control units and associated I/O and sensor modules anywhere within the line-up or even remotely in a centralized control cabinet or control room. Drive-CLiQ provides automatic electronic nameplate, real-time control data transfer, diagnostic and parameter value gathering and fault tolerant transfer protocols. For external control systems, high-speed industrial Ethernet communications can be parameterized for EtherNet/IP, PROFINET or Sinamics Link (peer-to-peer), while programming can be done via a dedicated port or Ethernet TCP on the Ethernet network simultaneously with Profinet or EtherNet /IP.

Sinamics S120 Cabinet Modules were designed to address the need for a complete, ready-to-connect-and-run drive system that enables customers to configure an enclosed drive lineup with a central line infeed (rectifier) and common DC bus, supplying power to multiple motor modules (inverters). Typical uses for such systems requiring multi-motor coordinated drive systems include paper machines, steel rolling mills, test stands, cranes, mixers and oil/gas field equipment. Very high horsepower single drive applications also benefit from this Siemens system.

The use of a common DC bus configuration with these new drive packages allows energy exchange between motors that are simply powering and others regenerating power back to the AC system, which can save up to 80% of the energy consumed when using standard installations.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com

Continue readingStandard and custom styles available for all popular machine tools; offered for all tapers, including HSK and BT30; fixed and adjustable models

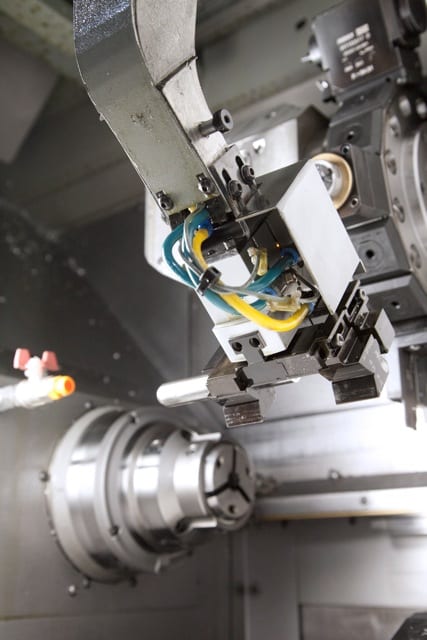

Heimatec, a world leader in live tools and multi-spindle drill heads, today announces immediate availability of its newest development, a line of standard and custom angle heads, available in all popular sizes and styles to accommodate today’s machine tools and CNC machining center builders.

Designed for heavy milling, deep drilling and tapping operations often found in the off-highway, energy, rail and other heavy-duty industries, this new Heimatec line of angle heads features twin or double twin sets of matched angular contact bearings plus a rear radial support bearing, ensuring maximum stability in use.

All the gears on these angle heads have inclined teeth made from high-resistance gear steel and have been specially hardened, ground and lapped in sets to provide the smoothest transmission output possible.

Heimatec angle heads are made from high-tensile strength aluminum. High-precision spindle bearings maintain the highest possible spindle concentricity.

Full 360º body rotation with positive compression locking, 90º incremental repositioning without indicating, maximum torque to 150 Nm, gear ratio 1:1 standard with others available, spindle speeds to 18,000 rpm and interchangeable torque arms are other standard features of this line from Heimatec.

CAT 40, BT 40, BT 30, HSK 63A, CAT 50, BT 50 and HSK 100A taper styles are available, as well as custom modifications such at 18” extension shafts. Heimatec offers a full one-year warranty on all parts and labor.

Click HERE to view a short video on the product.

For further information and literature, or to arrange a demo on this new line, please contact:

Preben Hansen, President

HEIMATEC INC.

16 E. Piper Lane Suite 129

Prospect Heights, IL 60070

Phone: 847-749-0633

Fax: 847-749-2445

Email: info@heimatecinc.com

Website: www.heimatecinc.com

—

Heimatec is an international tooling manufacturer, based in Renchen, Germany. Its experienced staff is dedicated to providing customers the most innovative tooling technology possible. In 2010, the company opened Heimatec Inc. in Prospect Heights, IL, near Chicago, to serve its growing North American customer base with sales and service, plus an extensive inventory of products. Heimatec serves the auto, aero, medical, off-highway, rail, energy, woodworking, composites and other industries, as well as an ever-increasing number of machine tool OEM’s worldwide.

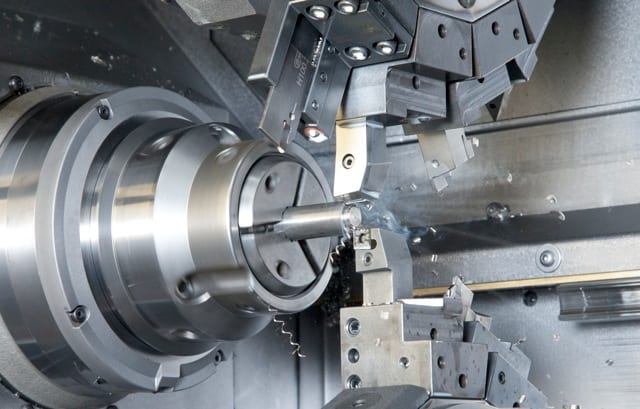

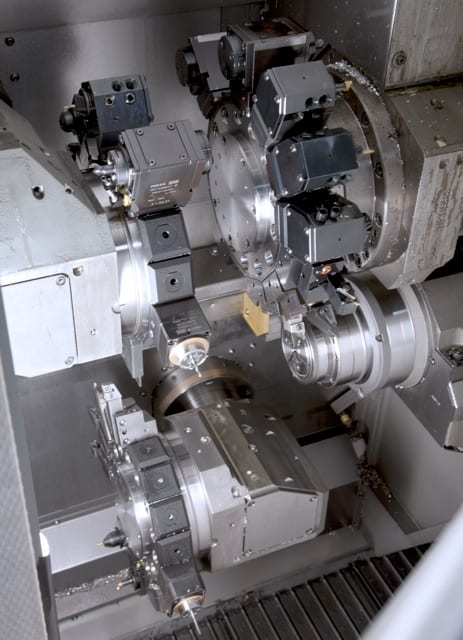

Continue readingWhen Task Force Tips, Inc. (TFT) decided to study the true costs of ultra-priced, high-speed machining, the company expected nominal gains on its machine-control investment; but when TFT began cutting the same precision parts in one-third of the time, it was, in the words of the company owner and president, Stewart McMillan, “a wake-up call.”

See the video on this story HERE.

Task Force Tips (TFT) is a manufacturer of highly engineered fire suppression tips, nozzles and other agent delivery equipment used by fire departments globally. For more than four decades, the company has always invested in premium machine tool brands associated with quality, performance and logically, higher price tags. Even so, it was the latter variable – the perceived barrier of price and cost – that prevented company owner and president, Stewart McMillan from ever considering more ultra-priced, high-speed machining options on the market.

“I hadn’t really looked at the economics when it came to an INDEX machine,” recalls McMillan. “And why? Because it always seemed like the INDEX brand was so prohibitively expensive. I never even thought its machines were within our league.”

That was prior to IMTS 2008, before TFT brought the company’s first INDEX machine into its 168,000 square foot facility in Valparaiso, Indiana, where TFT manufactures over 5,000 products across three shifts, seven days a week, all year around.

The Index C100’s “literal” coordinate system establishes actual reference points for programming the machine’s precise motion, rather than use arbitrary points in space.

“It was an INDEX C100 automatic production lathe, ultimately fitted with a Siemens 840D control package,” McMillan says. “We started making parts on it and our production times became typically 30%. I don’t mean a 30% reduction. I mean our run time for a part dropped to 30% of what it was before.”

As to why the company’s new machine made such an unprecedented productivity impact, McMillan points to both the high speed design of the machine and to the equally capable Siemens control package, which represented yet another paradigm shift for TFT.

Previous to the INDEX C100 purchase, TFT had scant experience with Siemens control packages. Much like the INDEX brand, Siemens five-axis controls were perceived as prohibitively sophisticated and just plain different. This lack of familiarity had been reason enough for TFT not to consider Siemens.

These were the company’s perceptions in 2008, before the INDEX C100 machine came into the plant, powered not by a Siemens control package, but by a more commonly accepted brand of CNC.

Upon learning that its new machine was underperforming for TFT, McMillan says INDEX swapped out the machine with an identical model, with one difference. This time, the INDEX C100 was powered by a Siemens motion control package, and TFT was able to set out in earnest to explore what price/cost lessons could be learned from its machine tool investment.

Zero to 5,000 RPM in one second

The INDEX C100 features automated remnant removal. The design has helped TFT increase revenues by eliminating the production delays caused by manual remnant stock removal cycles– typically not an option on lower priced machines.

McMillan recalls that an immediate revelation was seeing the difference a few thousand RPMs can make. The company began to run jobs at 5,000 to 6,000 RPM, ramping up from zero to 5,000 RPM in less than one second and ramping down just as fast. Several economic lessons soon emerged from this capability, as the sustained speed of the machine maximized motion in new time/cost saving ways.

“We never realized before just how much time we were losing waiting on the spindle to stabilize at a new commanded speed,” McMillan reports. “The turret indexing was also extremely fast, with the multiple tools overlapping to cut at the same time with incredibly fast accelerations.”

The INDEX C100 also leverages speed in new ways, as TFT discovered. The company can run more than 1,000 parts without having to change an offset. In addition, an automated remnant removal feature enables the machine to run continuously, by rapidly reloading bar stock without operator interaction.

“On the rest of our machines, we need to pick the remnant out and load a new bar into it,” McMillan explains. “That step should take just a few minutes. But the way things work, a machine can sit idle for six minutes before somebody realizes it, and then it takes five minutes to reload, and all that lost time adds up.”

Another speed-related discovery was the integration of rapid traverse rates, which have always been less than rapid in the company’s experience “A lot of machines advertise rapid traverse rates at maximum speed, but the fact is, unless you’re traveling 10 or 12 inches, traverse speeds have never reached maximum for us.”

Taking motion accuracy literally

As to how the machine eliminates slower traversing and other cost related functions, McMillan says the design of the INDEX C100 is unlike the design of conventional and yes, lower-priced machine bed coordinate systems.

“The INDEX doesn’t use the same coordinate system as other machines. It uses a set of parallelogram bars, a very unique system for rigidity,” McMillan explains. “The machine has a picture frame mount for its turret. The turret is not leveraged off a set of ways like most turrets. It’s close to where it’s sliding, so there’s not a big length over diameter ratio in terms of the tools of the turret hanging out from its support structure. This gives the machine a lot of rigidity for turning, and you can accelerate the axes so fast that you really do achieve faster traverse rates. The window on this machine is just a blur of motion.”

The coordinate system of the INDEX C100 uses a set of parallelogram bars for uniquely rigid motion that is fully exploited by the Siemens SINUMERIK 840D.

TFT’s lead programmer, Nate Price, sees additional efficiency advantages made possible by the INDEX machine’s unique coordinate system, whereby measurements and motion can be programmed based on actual numerical reference points and not on arbitrary points in space.

“On the INDEX, every machine space coordinate, every offset, every measurement that’s used to define how the machine operates has a legitimate explanation of why it is what it is and to where it relates,” Price explains. “This makes it much easier to automate these measurements; whereas, in the past we would measure manually, because these were arbitrary points. On the INDEX, they are defined, literal points. We know exactly what they relate to, so we can define them automatically before the program ever gets to the machine, before the set-up ever starts.”

(Click here to see: Normal Lathe Coordinates and Index C100 Coordinates)

Advanced cost control

According to Price, the Siemens 840D control interface brought a refined and intuitive approach to machine programming, setups and operation — an approach that was especially empowering to him as a programmer.

“I don’t know if anybody just doing set-ups would understand how much of a difference the Siemens control has made in the programming,” Price explains. “It has enabled me to more quickly and easily write the programs, write the post-processes, thus making the setup of special routines go much faster.”

In addition to easier programming and faster setups, Price says the machinists have found that the Siemens 840D enables them to more efficiently control and capitalize on the production potential of the INDEX machine.

“The control gives you ample shortcuts,” says Price. “There is a method of presenting messages to the operator that was not present in the other control. There is so much happening on the machine, it is really difficult to capture all that information on a single screen, but the control helps you keep track of what everything is doing. It’s really easy to get into more detail, without having to go through a lot of pages.”

As another example of CNC operational efficiency, Price points to the way the control manages error messages.

Another advantage brought about by the Siemens control was faster tool loading, made possible by faster and easier CNC programming.

“Tool loading was a big area of improvement,” Price says. “You essentially give the control a mini-program that tells it what tools you’re going to be putting in for this job that you’re setting up. The control will then present the stations on the turrets for you, tell you what tools to put in and what tools to take out. And it’s entirely guided. This has been a huge departure from what we traditionally had dealt with. It really accelerates set-up time.”

More profit per square foot

“I started to look at the numbers from a different perspective,” McMillan relates. “You have all these initial and ongoing costs to build a shop, to put in a floor, to put a roof over it, heat it, cool it, and all these costs can equate to so much per hour. Now you buy a machine that’s $600,000 versus a machine that’s $300,000 over 10 years. We run almost 24 hours a day, seven days a week, which helps our analysis. For us, it comes out to about an eight dollar per hour difference to buy the $600,000 machine. And for eight bucks more an hour, we’re getting triple the production out of that same square footage.”

Another way the company has measured its return on its investment in advanced machine-control manufacturing has been to witness the change in the people uplifted by the technology. Now, owner, programmer, machinists and others at TFT are enthusiastic about the possibilities of their more advanced, CNC-based manufacturing.

McMillan says that it will be such investments in machines and in people that will keep his company from selling itself short, having proven that with the right machine and the right motion control technology, anything is possible.

“We had a job that ran a couple of weeks ago,” McMillan recalls. “I received several e-mails before I even came to work that day. Different people were sending me e-mails that said in effect: Wait until you see what we’re doing with the INDEX today!”

See the video HERE!

For more information, contact:

Siemens Industry, Inc.

Motion Control Business — Machine Tools

390 Kent Avenue

Elk Grove Village, IL 60007

Tel: (847) 640-1595

Fax: (847) 437-0784

Web: www.usa.siemens.com/cnc

E-mail: SiemensMTBUMarCom.industry@siemens.com

Attention: John Meyer, Manger, Marketing Communications

Twitter: www.twitter.com/siemens_cnc_us

Facebook: www.facebook.com/SiemensCNC

Hennig custom enclosures and fuel tanks provided for three Cummins 2MW generators at Broken Arrow, Oklahoma project for Cummins Southern Plains LLC

The project began in early 2012 with the bid for the standby power system awarded to Cummins Southern Plains LLC, Tulsa, for the parent company based in Arlington, Texas. The project will utilize three 2 MW generators powered by Tier II emission certified Cummins 16 cylinder QSK 60 series diesel engines.

Due to the environmental and acoustic specifications of the water treatment facility, special enclosures and fuel tanks for the generator sets were required. Cummins Southern Plains LLC sales representative Mike Teague asked Hennig Enclosure Systems (Machesney Park, Illinois) to provide a possible solution. As Mike explained, “Al Grabowski from Hennig had been in contact with Cummins Southern Plains. We gave him the opportunity to quote the project and were quite pleased with the results.”

Cummins Southern Plains LLC provided the performance characteristics of the generator sets to Hennig Enclosures Systems, who then provided submittal drawings of the enclosure packages in Solid Works CAD format for the customer to review. Each enclosure measured 40’ long x 10’ wide and nearly 14’ high to allow ample airflow and provide a 25 dba sound reduction. After the customer and contractor approved the drawings, Hennig Enclosure Systems began cutting and bending steel. “Hennig is a one-stop shop. We manufacture the entire enclosure and fuel tank in addition to mounting the genset and landing all the electrical connections for the customer,” Grabowski added.

The Hennig solution involved a topcoat finish of TGIC polyester powder coat paint for weather resistance and UV protection. Grabowski notes, “Hennig utilizes a durable powder coat finish along with stainless steel hardware on every enclosure we build to meet the broad range of environmental conditions across the United States. We want our enclosures to look as good in 20 years as they do the day they were installed.”

A few weeks after the generator sets arrived at Hennig, the enclosure and fuel tank packages were ready to ship. There were some logistics challenges on this project, as the facility site was in the midst of construction. Delivery was made down a temporary dirt road and the three 2 MW Cummins emergency power generators were set in place without a hitch at the new Broken Arrow Water Treatment facility site.

The Broken Arrow municipal water treatment facility is primarily funded by loans totaling $64.8 million, administered by the Oklahoma Department of Environmental Quality and the Oklahoma Water Resources Board. The facility is being constructed by Crossland Heavy Contractors of Columbus, Kansas. The first phase of the project is scheduled to be operational in July, 2013.

-0-

Hennig Enclosure Systems, a division of Hennig Inc., manufactures innovative enclosures and fuel tanks for standby/emergency/prime power/peak shaving generators and switchgear. Hennig enclosures are designed and built to provide environmental protection and meet today’s demanding acoustical requirements of power generation equipment. The company operates facilities in Machesney Park, IL. To learn more, visit www.hennig-enclosure-systems.com.

Hennig, Inc. designs and produces custom machine protection and chip/coolant management products for state-of-the-art machine tools. Hennig products are designed to protect against corrosion, debris and common workplace contaminants. Manufacturing facilities located in the USA, Germany, France, Brazil, India, Japan, Czech Republic, England and South Korea. Repair centers are located in Machesney Park, IL; Chandler, OK; Livonia, MI; Blue Ash, OH; Mexico City, Mexico; and Saltillo, Mexico. To learn more, visit www.hennigworldwide.com.

To learn more about Hennig products & services, visit www.hennigworldwide.com or call 1-888-HENNIG6 (436-6446).

Tim Waterman

Hennig Inc.

9900 N. Alpine Rd.

Machesney Park, IL 61115

(815) 316-5277

info@hennig.ame.com

www.hennigworldwide.com

For more information on Cummins Southern Plains in this story, please contact:

Cummins Southern Plains LLC.

525 E. Skelly Drive

Tulsa, OK 74116

Phone: 918-234-3240

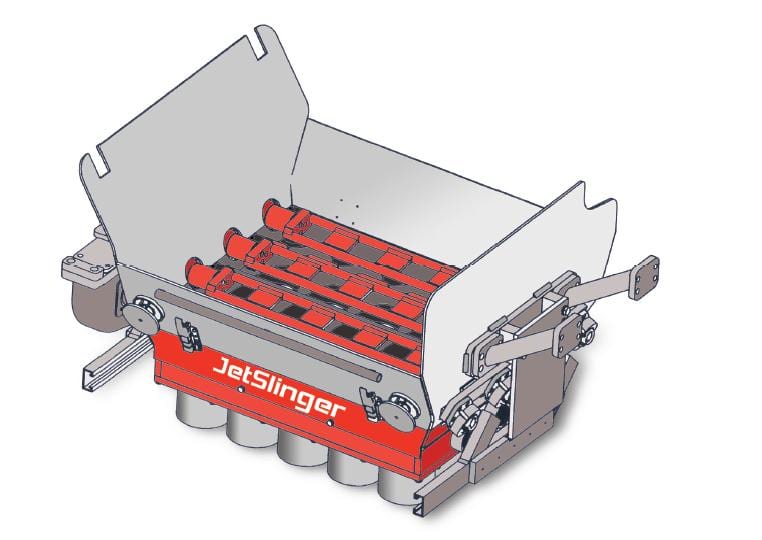

Impact-assisted flask filling addition to Hunter’s new HLM and successful XL product lines, JetSlinger helps increase mold production up to 300 percent.

The JetSlinger™ is an air amplification apparatus based on the Venturi principle that accelerates sand into the cope and drag flasks on these Hunter machines. It creates a powerful vacuum and jet exhaust that draws sand mixtures through an array of nozzle assemblies built into a manifold mounted directly below Fillaerator blades, then slings them into a flask. It was invented by company president Bill Hunter. The JetSlinger™ design holds U.S. Patent Number US7819168B2, one of nearly 150 domestic and international patents granted to Hunter since its founding in 1964.

Key features and benefits of JetSlinger™ include:

“In contrast to the conventional blow fill machines, no shroud, seals or vented flask assemblies, nor is the usual attendant maintenance required,” according to company president Bill Hunter. “Furthermore, JetSlinger™ allows foundries far greater flexibility, as well as the access needed to produce various castings with the use of chaplets, ram-up cores and exothermic risers,” he adds.

With its perpendicular fill, this impact-assisted device produces molds more quickly and with substantially improved surface quality, owing to the powered pre-compaction of the sand. This action results in greater uniformity of mold density and wall hardness, without sacrificing the accessibility and flexibility of a gravity fill machine. Additionally, the JetSlinger™ achieves a flask filling operation that compensates for the types of mold quality limitations that are often caused by the flowability of the sand and pattern configuration during the high-pressure squeeze cycle. The basic operation of the JetSlingerTM is as follows:

1) Sand mixture is loaded into a hopper

2) Hopper gates open

3) Rotating Fillaerator blades aerate the mixture

4) Mixture is delivered into the Venturi action air acceleration manifold

5) Mixture under pressure dispersed (slung) through 20 nozzles into the flask

6) Flask fills with pre-compaction around pattern plate.

Click HERE to see the JetSlinger™ in action!

ABOUT THE COMPANY

Hunter Foundry Machinery Corporation was founded in 1964 as Hunter Automated Machinery Corporation with the invention of the first gravity-filled automated matchplate molding machine. This established the company’s history of innovation and launched the foundry industry into a new industrial revolution. Pioneered by William “Al” Hunter in his garage, the original HMP-10 machine streamlined the laborious metal casting process by offering foundries unimagined new production capabilities, producing as many molds in one hour as most had been able to produce in an entire day. As industry demands grew Hunter responded with advanced solutions such as automated mold handling equipment and coresetters.

Now in its 50th year, Hunter Foundry Machine Corporation’s inventions have earned nearly 150 patents around the world. With more than 1,800 molding machines and mold handling systems installed around the world, Hunter’s sales and service reach extends from its manufacturing sites in North America, South America and China through its offices in the U.S., Europe, Brazil, India and Shanghai to every corner of the globe. Sales and technical support, as well as the company’s $12 million parts inventory, serve to maintain each machine’s original production capability, as well as Hunter’s preeminence in the world market.

FOR MORE INFORMATION PLEASE CONTACT:

HUNTER FOUNDRY MACHINERY CORPORATION

2222 Hammond Drive – Schaumburg, Illinois 60196-1094 – USA

Phone: +1 847 397 5136

info@hunterfoundry.com

www.hunterfoundry.com

Attention: Bill Hunter, CEO

TCT Stainless Steel, Inc., a Lebanon, Tennessee metal service center, is proud to announce the commissioning of a new 64” wide heavy gauge EMAG slitter. This line is capable of slitting .035 to .3125 gauges. Maximum coil weight is 40,000 lbs. with a maximum 72” outside diameter uncoiler/recoiler. The line is complemented with an Alcos (8) position carousel packing line.

This new line is in addition to the existing 20” Stanat light gauge slitter commissioned by TCT in late 2012, which slits .005 gauge.

The addition of this line complements the other (4) slitters, rolling mill, edger and cut-to-length capabilities that TCT currently offers to customers. With these additions, TCT now offers more in-house capabilities and services than any service center in the Southern United States, according to a company spokesperson.

TCT invites all interested parties to visit the company at 711 Maddox Simpson Parkway, Lebanon, TN for a personal tour or visit www.tctstainless.com for a virtual tour. Let TCT show you what these new lines can do to benefit your operation.

For more information, please contact:

TCT STAINLESS STEEL, INC.

711 Maddox Simpson Parkway

Lebanon, TN 37090

1-800-877-8366

Phone: 615-443-4657

Fax: 615-449-6079

Web: www.tctstainless.com

Email: tcttn@tctstainless.com

Attention: Sherry Shaub, General Manager

TCT Stainless Steel, Inc. is one of the steel industry’s leading service centers. Our vast, in-house capabilities include virtually every facet of coil processing. Our capabilities include slitting, tempering, gauge reduction, cut-to-length, edging, buffing and tension leveling. TCT currently serves the aerospace, medical, electronic, telecommunication, automotive, lift equipment, building trade and other markets.

The combined inventory of our Michigan and Tennessee service centers include annealed and tempered stainless, aluminum, carbon and coated steels. Our dedication to providing high-quality products, short lead times and reliable delivery has always been the key to our success. We are constantly improving our facilities to include state-of-the-art technology, SPC and quality control standards.

Customer satisfaction is our specialty. Whether it be heavy or light gauges, narrow or wide widths, small or large quantities – TCT guarantees satisfaction and dependability at competitive prices. Our outstanding reputation for product quality is backed by our dedicated, customer-oriented team. Our sales staff welcomes all orders and inquiries and will respond quickly with reliable service and industry leading lead times.

Heimatec is a world leader in the development and manufacturing of live tools, angle heads and multi-spindle drill heads. With U.S. head quarters located in the Chicagoland area and company head quarters and manufacturing in Renchen Germany, we are dedicated to supplying our customers the most innovative tooling technology possible.

Check out the new look at www.heimatecinc.com!

For more info on Heimatec:

Preben Hansen, President

HEIMATEC INC.

16 E. Piper Lane Suite 129

Prospect Heights, IL 60070

Phone: 847-749-0633

Fax: 847-749-2445

Email: info@heimatecinc.com

Website: www.heimatecinc.com

—

Heimatec is an international tooling manufacturer, based in Renchen, Germany. Its experienced staff is dedicated to providing customers the most innovative tooling technology possible. In 2010, the company opened Heimatec Inc. in Prospect Heights, IL, near Chicago, to serve its growing North American customer base with sales and service, plus an extensive inventory of products. Heimatec serves the auto, aero, medical, off-highway, rail, energy, woodworking, composites and other industries, as well as an ever-increasing number of machine tool OEM’s worldwide.

Continue readingWhether the application involves producing/removing chips or moving parts/scrap pieces, Hennig can provide the chip conveyor for all machine tool requirements. The company’s new 2-1/2” pitch steel belt can be made for most applications in the field when the standard 1-1/2” pitch belt is not effective for the particular conditions present.

Conveyors from Hennig, a leading supplier of chip conveyors to the global machine tool market, can be manufactured in widths from 4” to 80”, depending on the need. The unique Hennig belt hinge is designed as one continuous piece, whereas many competitive brands do not have this feature. The manufacturing of these belts is done on Hennig’s in-house press equipment.

Hennig recognizes the special requirements needed when designing a parts conveyor on which direct loads contact the belt. Impact plates are just one of the many options to be considered when customizing a conveyor for these applications.

Chip volumes can also vary between applications, so speeds and sizes are always evaluated by Hennig’s engineers. Special incline covers (top hat design) can be included when larger amounts of stringy/balled chips are to be evacuated from the machine.

As adjunct to this new 2-1/2” pitch steel belt conveyor, Hennig also offers complete filtration systems, as needed. The company’s Chip Disc Filtration (CDF) systems can also be used with the new 2-1/2” pitch conveyor. These systems can filter down to 25 microns and additional bag filters can be included to achieve the through-spindle requirements on most machine applications.

Whether the need involves moving chips into a hopper, evacuating larger volumes of chips through a plant wall into a truck/dumpster or hauling scrap parts from the machine, Hennig can assist machine builders and end users alike with any specific requirements.

Innovations and new developments in machine tool design present myriad opportunities for the engineers at Hennig (www.hennigworldwide.com), who have been designing and producing custom machine protection and chip/coolant management products for state-of-the-art machine tools for over 50 years. Hennig products are designed to protect against corrosion, debris and common workplace contaminants. Hennig has manufacturing facilities in the U.S., Germany, Czech Republic, France, Brazil, India, Japan, China and South Korea. Its North American repair centers are located in Machesney Park, Ill.; Chandler, Okla.; Livonia, Mich.; Blue Ash, Ohio; Mexico City, Mexico; and Saltillo, Mexico.

For more information, contact:

Tim Waterman

Hennig Inc.

9900 N. Alpine Rd.

Machesney Park, IL 61115

(815) 316-5277

info@hennig.ame.com

www.hennigworldwide.com

European Contact:

Hennig GmbH, Überrheinerstr. 5, 85551 Kirchheim, Tel. 49 089 96096140

Continue reading24,000 RPM max. styles available for all popular machine tools

Heimatec, a world leader in live tools, angle heads and multi-spindle drill heads, announces immediate availability of its newest development, a line of 1:4 live tool speed multipliers in 24,000 RPM max. styles, available for all popular live tool lathes currently on the market.

These speed multipliers are provided as axial or radial drilling and milling heads, with either external or internal coolant design, and mounting configurations to suit virtually any machine tool turret set-up, including all VDI and BMT sizes.

Radial milling and drilling head style speed multiplier from Heimatec, ER 16 variation

Speed multipliers for Haas and Nakamura machines are now in stock with others in production for short lead time deliveries.

According to Heimatec President Preben Hansen, “As our presence in the American machine tool market continues to expand, so does our product line. These speed multipliers are a great addition to our line. They give us more to offer the job shop and large production departments, through our growing network of reps and distributors, serving the market here.”

For further information and literature, or to arrange a demo on this new line, please contact:

Preben Hansen, President

HEIMATEC INC.

16 E. Piper Lane Suite 129

Prospect Heights, IL 60070

Phone: 847-749-0633

Fax: 847-749-2445

Email: info@heimatecinc.com

Website: www.heimatecinc.com

—

Heimatec is an international tooling manufacturer, based in Renchen, Germany. Its experienced staff is dedicated to providing customers the most innovative tooling technology possible. In 2010, the company opened Heimatec Inc. in Prospect Heights, IL, near Chicago, to serve its growing North American customer base with sales and service, plus an extensive inventory of products. Heimatec serves the auto, aero, medical, off-highway, rail, energy, woodworking, composites and other industries, as well as an ever-increasing number of machine tool OEM’s worldwide.

Continue readingTest stand builder collaborates with Siemens Industry, Inc. on variable speed drives and motors to affect green, lean solutions for testing Apache, Blackhawk helicopter powertrains at Department of Defense customer; over 20 test stands reduced to five.

RedViking, located in Plymouth, Michigan, made its mark in automotive power transmission test stands, beginning in 1981 as Superior Controls. Today, the company is providing multi-disciplinary engineering and equipment construction services to major corporations such as Caterpillar, GE, Boeing, General Motors and others. Spun off in 2010, RedViking designs and builds a variety of powertrain test equipment, metrology and production solutions for government and commercial OEMs alike.

For a recent Department of Defense (DoD) customer, RedViking was presented with a challenge that involved an existing bank of over 20 individual test stands, used for dynamic testing of performance factors on helicopter transmissions, primarily in the Apache and Blackhawk classes. The existing test stands ranged from 20–50 years in age and had been built with single-purpose functionality. This scenario resulted in constantly increasing maintenance requirements for the customer, plus excessive power consumption and plant floor space capacity overload. The test stands suffered from a lack of readily available spare parts, required unique training to operate each stand, and did not produce the desired level of data for analysis.

When a unit test was required, the test article would be built up and dressed within the envelope of the test stand, fully connected, then tested, disconnected and removed from the work cell. This procedure resulted in extremely long downtime impact on the customer’s equipment utilization, with various corresponding logistic challenges. Coupled with the age of the equipment and the excess power used by the older equipment, this situation presented the RedViking engineers with a series of hurdles to overcome.

New testing system requirements included better compilation of test data, automatic closed loop operation of the machinery, true speed and torque measurement with a local Test Executive as the main operator interface to the test machine and finally, a standardized control platform to allow easier operator cross-training on the equipment.

The customer targeted a goal of three to four tests per working shift versus the current one test per shift being achieved with their multiple machines. RedViking performed its onsite assessment and subsequent situation analysis, and then devised a solution that utilized common components and an entirely new material handling strategy. A series of five flexible test stand designs was determined to be sufficient for the replacement of all existing machines.

To accomplish greater efficiency in the utilization of these test stands, a series of workpiece carriages was designed, allowing the Units Under Test (UUT) to be mounted and staged outside the envelope of the test stand and then brought into the work cell for faster connection, test, disconnect and exit. RedViking terms these devices Transportable Test Fixtures (TTFs), which automate shaft connections, clamping and positioning, as well as providing 360° access to the UUT. This design provides significantly greater efficiency as well as a safe and ergonomic operator environment. As RedViking explained, hours of test setup time are reduced to minutes.

RedViking Controls and Software Manager Jason Stefanski at the main transmission flexible test module.

RedViking Controls and Software Manager, Jason Stefanski, and his team devised an entirely new, modular software system and common Human Machine Interface (HMI) platform for all five test stands, with a common user interface and plug-in architecture, comprising common function blocks, I/O coding and CAT 4 safety functions. This design approach allows the software to be easily configured to accommodate the various transmission models being tested.

Once the test article in the TTF is automatically positioned and attached, RFID tags on the TTF identify both the article and its test profile configuration and communicate them to the Test Executive.

All test profiles are generated and stored offline, with modifications made by the customer’s engineering staff outside of the test cells. Test profiles are then linked to the UUT type and model data for further system integrity.

The main software feature of the test machines is the ability to execute a fully automated, repeatable, and traceable test. To provide this functionality, RedViking has developed a Test Sequence Set (TSS) Editor, allowing all parameters to be set by the customer, downloaded to a Test Executive from a localized laptop, thus eliminating the need to modify validated machine code.

The TSS editor provides the customer with adaptability to easily modify future or existing test profiles.

After a thorough review of the potential suppliers for the power components and controls on these new test stands, Siemens Industry’s Drive Technologies Division was chosen to provide the motors and AC flux vector drives packages with regenerative braking for increased energy efficiency. RedViking worked closely with Siemens to devise an AC system, utilizing the regenerative technology found in Sinamics drives with 480V and 690V standards. Jason Stefanski recounted a number of field trips to Siemens customers to investigate the performance and application specifics of regen drives used with 3000 hp motors.

The use of Siemens regenerative braking technology allows a system to recover power, minus the parasitic losses. Conventional dynamic load testing requires loading to occur via an eddy current or fluid brake system, which requires additional energy, maintenance and up front capital investment. In more innovative industrial environments, according to Siemens, Sinamics regenerative drive technology can enable energy savings of 40 percent or more.

With a common DC bus architecture, this allows for only one AC to DC conversion in the motoring direction and the regenerative braking power goes straight to another inverter, which is motoring via the common DC bus link. This method eliminates two conversion points where energy would be lost which increases the overall efficiency. In addition, the common bus solution paired with the active front end (AFE) has the ability for power factor correction, which will further increase the overall savings of a common bus system. All AFE drives allow for unity power factor and low total harmonic distortion (THD) that meets IEEE 519 harmonic standards. This means these drive systems can improve the present power factor displacement in a customer’s facility.

RedViking estimates that a test on the Main Transmission Flexible Test System, while running at full capacity, will cost approximately $400 less per hour to operate than current comparable systems. With improvements over the conventional non-regen testing process, the RedViking Main Transmission Test System could generate approximately $500,000 in annual power savings.

For this project, Siemens Industry, Inc. supplied its high-performance asynchronous Simotics 1PL6 and 1RN4 motors, the largest being 3000 hp, to power the various mechanisms on the RedViking test stands. When in operation, these motors simulate the power generated by the helicopter’s jet engines, in addition to simulating the loading of the main rotor and tail output blades. This allows RedViking to test the helicopter transmission components to the full speed and torque requirements as specified by the military with very precise closed loop control.

On the Tail and Intermediate Gearbox Flexible Test Module, it was determined that the use of two more Siemens Simotics motors was less expensive and more efficient than the previous test stand’s gearbox design. This solution involves multiple motor connections to an output variable frequency drive (VFD) with auxiliary connections, thereby eliminating the need for additional VFDs.

Stefanski noted that one of the reasons that Siemens was selected for this project is their global support structure combined with a U.S. base of manufacturing. RedViking prides itself on designing and building systems in the U.S. and seeks out vendors who build their products in the U.S. as well.

Joshua Gibbs, RedViking Manufacturing Coordinator, commented, “We knew we were building these test stands to validate the performance of military helicopters that see wartime action. We take it very personally at RedViking to ensure these systems protect man and machine alike, as well as provide the ultimate in test validation.” RedViking further noted the substantial energy savings and operational efficiencies realized by the RedViking customer gave their entire team considerable pride of accomplishment on this project. RedViking currently performs both DO and DX contracts for the military and its subcontractors.

For more information:

SIEMENS INDUSTRY, INC.

Drive Technologies — Motion Control

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595 Fax: 847-437-0784

Web: www.usa.siemens.com/motioncontrol

Email: SiemensMTBUMarCom.industry@siemens.com

Attention: John Meyer, Manager, Marketing Communications

OR

RedViking

46247 Five Mile Road

Plymouth, MI 48170

Phone: 1-734-927-1460

Web: www.redviking.com