Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Workspace dimensions of this oven measure 30” wide x 96” deep x 24” high. A 2’ long open belt loading zone, 8’ long insulated heat zone with recirculated airflow and 2 ½’ long open belt unloading zone constitute the full heat processing system. 48KW installed in Nichrome wire heating elements provide the heat, while a 4200 CFM, 3-HP recirculating blower furnishes vertical downward airflow to the load.

This Grieve oven features 4” insulated walls, a Type 304, 2B finish stainless steel interior, stainless steel exterior with #4 brush finish, as well as a 24” wide, 1” x1” Type 304 stainless steel flat wire conveyor belt with ¼-HP motor drive, variable speed from 0.9 to 17.6 ipm. A side door allows access to the unit’s workspace.

Safety and control equipment on-board No. 853 include PVC electrical conduit, a remote control panel, 325 CFM stainless steel powered forced exhauster, six-point thermocouple jack panel through the oven wall, digital indicating temperature controller, manual reset excess temperature controller with separate contactors, and recirculating blower airflow safety switch.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

This specially modified Grieve lab oven features 1” insulated walls throughout, aluminized steel interior, stainless steel exterior with #4 brushed finish, heavy duty door latch, reinforced door hinge, shelf supports bolted through the oven walls to support the load at a double shelf height and an adjustable fresh air inlet damper at the oven bottom to control the amount of fresh air entering the chamber.

An added feature for accuracy, the temperature control shaft onboard No. 969 is recessed and slotted to avoid a set point change.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

TCT Stainless Steel, Inc., a Lebanon, Tennessee metal service center, is proud to announce the commissioning of a new 64” wide heavy gauge EMAG slitter. This line is capable of slitting .035 to .3125 gauges. Maximum coil weight is 40,000 lbs. with a maximum 72” outside diameter uncoiler/recoiler. The line is complemented with an Alcos (8) position carousel packing line.

This new line is in addition to the existing 20” Stanat light gauge slitter commissioned by TCT in late 2012, which slits .005 gauge.

The addition of this line complements the other (4) slitters, rolling mill, edger and cut-to-length capabilities that TCT currently offers to customers. With these additions, TCT now offers more in-house capabilities and services than any service center in the Southern United States, according to a company spokesperson.

TCT invites all interested parties to visit the company at 711 Maddox Simpson Parkway, Lebanon, TN for a personal tour or visit www.tctstainless.com for a virtual tour. Let TCT show you what these new lines can do to benefit your operation.

For more information, please contact:

TCT STAINLESS STEEL, INC.

711 Maddox Simpson Parkway

Lebanon, TN 37090

1-800-877-8366

Phone: 615-443-4657

Fax: 615-449-6079

Web: www.tctstainless.com

Email: tcttn@tctstainless.com

Attention: Sherry Shaub, General Manager

TCT Stainless Steel, Inc. is one of the steel industry’s leading service centers. Our vast, in-house capabilities include virtually every facet of coil processing. Our capabilities include slitting, tempering, gauge reduction, cut-to-length, edging, buffing and tension leveling. TCT currently serves the aerospace, medical, electronic, telecommunication, automotive, lift equipment, building trade and other markets.

The combined inventory of our Michigan and Tennessee service centers include annealed and tempered stainless, aluminum, carbon and coated steels. Our dedication to providing high-quality products, short lead times and reliable delivery has always been the key to our success. We are constantly improving our facilities to include state-of-the-art technology, SPC and quality control standards.

Customer satisfaction is our specialty. Whether it be heavy or light gauges, narrow or wide widths, small or large quantities – TCT guarantees satisfaction and dependability at competitive prices. Our outstanding reputation for product quality is backed by our dedicated, customer-oriented team. Our sales staff welcomes all orders and inquiries and will respond quickly with reliable service and industry leading lead times.

Using the process-oriented approach of SIGMASOFT® makes it possible to consider all of the molding times present in an actual injection molding cycle. In the injection molding simulation of elastomeric applications, SIGMASOFT® not only considers the filling and curing times, but also the non-productive times between each production cycle while the mold is opened and closed. If the simulated process considers the influence of multiple consecutive molding cycles, the accuracy of the simulation is dramatically improved.

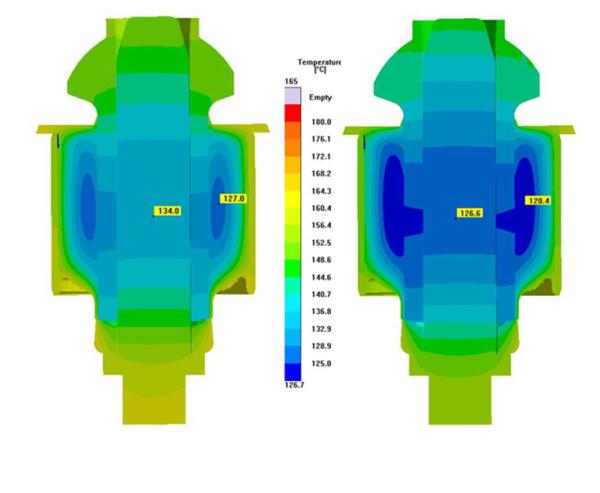

Figure 1 – Temperature distribution in a metallic component over-molded with rubber. Left: without consideration of the mold opening time; right: considering a mold opening time of 60 seconds, where significantly lower temperatures and long curing times are observed.

Even though it is not necessary to include them to complete an injection molding simulation, the “non-productive” times have a major influence on the mold temperature and thus on the process and on the part quality. With the Process Simulation Software SIGMASOFT®, from SIGMA Plastic Services, Inc. (Schaumburg, Illinois), all the non-productive times can also be included into the simulation of multiple consecutive production cycles and a substantial improvement in the accuracy of the results predicted can be achieved.

Considering the times in which the mold opens and closes, the times in which the mold is heated or cleaned, as well as handling times in which the inserts are placed or the parts removed, makes it possible to exactly describe the real multi-cycle production process. The interaction between all components present in the mold is considered with the local temperature dependent material properties, along with the heat that escapes the mold into the environment while it is both opened and closed and the exact timing of each event are coupled together inside of SIGMASOFT® to provide a comprehensive understanding of a very complex system. In this way, even factors that influence the part quality, such as the mold temperature and curing degree, can be predicted before the mold is ever built.

An example is presented in Figure 1. In this case, the mold temperature drops significantly while it is in the open position because heat radiates from both heated mold surfaces. If this time and open condition are not considered in the simulation, the mold temperature calculation will be higher than actual; resulting in a faster curing reaction and a shorter cycle time than what is actually possible. Other events will also be incorrectly calculated such as curing degree during filling and required injection pressure.

In SIGMASOFT®, non-productive times can be defined and individually modified in the simulation. For this reason, it is also possible to optimize the entire production process or mold design simultaneously. Through this simulation, it is possible to decide if changes in the process definition will solve production problems, or if the mold has to be modified to achieve the desired quality and productivity goals.

For more information:

Matt Proske

SIGMA Plastic Services, Inc.

10 N. Martingale Road, Suite 425

Schaumburg, IL 60173

Phone: 847-558-5600

Email: contact@3dsigma.com

Web: www.3dsigma.com

—

SIGMA® (www.3dsigma.com) is 100% owned by MAGMA® (www.magmasoft.com), the world market leader in casting process simulation technology based in Aachen, Germany. Our SIGMASOFT® process simulation solution optimizes the manufacturing process for injection molded plastic, thermoset, rubber, and MIM/CIM components. SIGMASOFT® combines the 3D geometry of the parts and runners with the complete mold assembly and temperature control system and incorporates the actual production process to develop a turnkey injection mold with an optimized process.

At SIGMA® and MAGMA®, our goal is to help our customers achieve required part quality during the first trial. The two product lines – injection molded polymers and metal castings – share the same 3D simulation technologies focused on the simultaneous optimization of design and process. SIGMASOFT® thus includes a variety of process-specific models and 3D simulation methods developed, validated and constantly improved for over 25 years. A process-driven simulation tool, SIGMASOFT®, with its comprehensive simulation approach, provides a tremendous benefit to production facilities. Imagine your business when every mold you build produces required quality the first time, every time. That is our goal. This technology cannot be compared to any other conventional “design” simulation approach employed in plastics injection molding.

New product success requires a different communication between designs, materials, and processes that design simulation is not meant for. SIGMASOFT® provides this communication. SIGMA® support engineers, with 450 years of combined technical education and practical experience, can support your engineering goals with applications specific solutions. SIGMA® offers direct sales, engineering, training, implementation, and support, by plastics engineers worldwide.

Continue readingWith the process-oriented approach of SIGMASOFT®, the injection molding simulation for elastomers is no longer limited to predicting the cavity filling while designing the part, or to answering questions regarding balanced filling. Based on an accurate simulation of the curing reaction (vulcanization), it can be used for designing the mold, identifying process windows and troubleshooting during production.

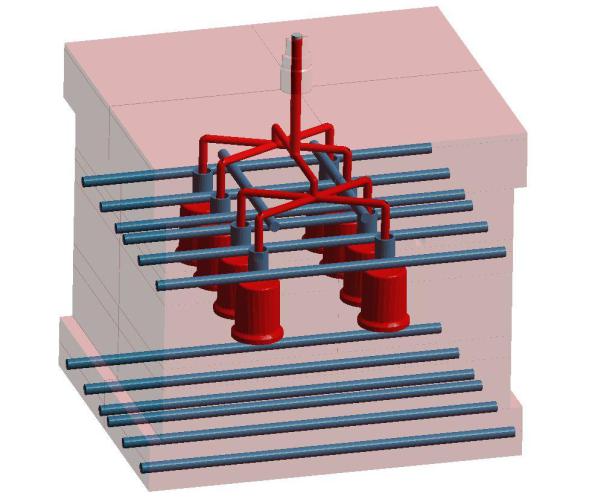

Figure 1 – The process-oriented approach of the Injection Molding Simulation Software SIGMASOFT® allows all relevant information (Part, Insert, Venting, Material, Mold, Heaters, Thermocouples, Process, etc.) to be used in the calculations.

SIGMA Plastic Services, Inc., Schaumburg, IL presents the latest functionality of its 3D Injection Molding Simulation Software SIGMASOFT®. The focus is on reduction of development and production costs using these new developments in process simulation.

Many factors in elastomer injection molding have an influence on product quality and costs. Here it is of little help to solely focus on a single aspect; part design, material, mold design, or molding process. To ensure a competitive advantage, the entire system must be considered simultaneously. Only when everything is optimized during the design phase, before the mold is shipped, can the largest cost savings be achieved.

By means of process simulation, molding feasibility and initial process parameters can be evaluated. Parting line and venting channels can be developed, as well as the optimal type and position of the injection point. Where are weld-lines acceptable, where must they be avoided? How much injection pressure will be required? Ultimately, the complete mold and process must be optimized. What wattage and heater design is most beneficial? Where is the best thermocouple location for each heater? Do inserts need pre-heating and how will they influence the curing? How long is the curing cycle, what areas of the part cure late and why? These questions are all related to the mold design and the production process and they are all important factors regarding part quality.

The simulation results provide answers to all of these questions in a clear and meaningful way, allowing injection molders a way to virtually test the mold before it is built. Costs can be reduced significantly during development, and existing processes can continuously be improved, while substantially reducing material waste and improving quality.

The latest developments in the thermal solver allow for the integration of all mold components and their individual temperature dependent material properties. In this way, an accurate reproduction of the real temperature profile in the mold is possible, even over several consecutive injection molding cycles. The simulation set-up is optimized for the requirements of process engineers. This allows production-minded engineers to use this technology without a simulation background. For example, a process engineer can determine how heating cartridges influence mold temperature and part quality, simulating them with their respective electric power and thermocouple control.

For more information:

Christof Heisser or Matt Proske

SIGMA Plastic Services, Inc.

10 N. Martingale Road, Suite 425

Schaumburg, IL 60173

Phone: 847-558-5600

Email: contact@3dsigma.com

Web: www.3dsigma.com

—

SIGMA® (www.3dsigma.com) is 100% owned by MAGMA® (www.magmasoft.com), the world market leader in casting process simulation technology based in Aachen, Germany. Our SIGMASOFT® process simulation solution optimizes the manufacturing process for injection molded plastic, thermoset, rubber, and MIM/CIM components. SIGMASOFT® combines the 3D geometry of the parts and runners with the complete mold assembly and temperature control system and incorporates the actual production process to develop a turnkey injection mold with an optimized process.

At SIGMA® and MAGMA®, our goal is to help our customers achieve required part quality during the first trial. The two product lines – injection molded polymers and metal castings – share the same 3D simulation technologies focused on the simultaneous optimization of design and process. SIGMASOFT® thus includes a variety of process-specific models and 3D simulation methods developed, validated and constantly improved for over 25 years. A process-driven simulation tool, SIGMASOFT®, with its comprehensive simulation approach, provides a tremendous benefit to production facilities. Imagine your business when every mold you build produces required quality the first time, every time. That is our goal. This technology cannot be compared to any other conventional “design” simulation approach employed in plastics injection molding.

New product success requires a different communication between designs, materials, and processes that design simulation is not meant for. SIGMASOFT® provides this communication. SIGMA® support engineers, with 450 years of combined technical education and practical experience, can support your engineering goals with applications specific solutions. SIGMA® offers direct sales, engineering, training, implementation, and support, by plastics engineers worldwide.

Continue reading

This Grieve cabinet oven features 8” insulated walls, removable top-mounted heat chamber, aluminized steel interior and exterior, plus two tiers of four 300 lb. capacity shelves supported by rollers to extend 14” in front of the oven for easy access.

Controls onboard No. 1028 include a digital indicating temperature controller, manual reset excess temperature controller with separate contactors, recirculating blower air flow safety switch, SCR power controller and circuit breaker disconnect switch.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, Illinois 60073-2835

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese

An announcement from Bill Hunter, CEO of Hunter Automated Machinery Corporation, the world leader in automated matchplate molding machines, mold and sand handling equipment for the foundry market, Jim Fitzgerald will assume the newly created position of Chief Operating Officer, effective Friday – February 1, 2013.

Jim began his career as a machine assembler for Hunter in 1977, shortly after his graduation from Central College in Pella, Iowa. For the past 35 years, he has been dedicated to shop operations and manufacturing management at Hunter. He was promoted to his current position as Vice President at the company, following Art Hisel’s retirement in 1992.

Jim’s responsibilities as COO will include all Schaumburg, IL-based activities, with the exception of Sales and Marketing. His goals will include maintaining and building upon the company’s reputation for producing the world’s highest-quality foundry machinery and for providing superior after-sale support.

“Jim brings the education, proven ability and determination to help Hunter achieve these goals. His leadership and commitment to our company is unquestionable and exemplary,” said Bill Hunter in making this announcement.

For more information on this news, please contact:

HUNTER AUTOMATED MACHINERY CORPORATION

2222 Hammond Drive

Schaumburg, Illinois 60196-1094

USA

Phone: 847-397-5136

Email: sales@hunterauto.com

The NOARK value proposition centers on products that improve the profitability and maintain the highest levels of performance for customer end products, through the combination of local support with local inventory, exceptional value and superior product quality, backed by the industry’s first 5-YEAR WARRANTY.

ALL ABOVE NOARK PRODUCTS ARE UL489 LISTED.

NOARK Electric, Inc., the North American headquarters of the company, was previously located in Rockford, IL and, due to its rapid growth and inventory commitments, has recently moved to a larger facility in Oak Creek, WI, just south of Milwaukee.

The company is currently in the process of establishing a representative and distribution network to serve its primary markets, which include the building trades and electric panel board builders in various industries.

A global supplier, NOARK currently operates four R&D centers, three distribution centers, 15 office locations and employs over 1000 associates. Sales for the company exceed $2 billion worldwide.

For more information, please contact:

NOARK Electric, Inc.

9817 South 13th Street

Oak Creek, WI 53154

Phone: 414-304-8189

Website: www.noark-electric.com

Email: tony.diaz@noark-electric.com

Attention: Tony Diaz

Heimatec is a world leader in the development and manufacturing of live tools, angle heads and multi-spindle drill heads. With U.S. head quarters located in the Chicagoland area and company head quarters and manufacturing in Renchen Germany, we are dedicated to supplying our customers the most innovative tooling technology possible.

Check out the new look at www.heimatecinc.com!

For more info on Heimatec:

Preben Hansen, President

HEIMATEC INC.

16 E. Piper Lane Suite 129

Prospect Heights, IL 60070

Phone: 847-749-0633

Fax: 847-749-2445

Email: info@heimatecinc.com

Website: www.heimatecinc.com

—

Heimatec is an international tooling manufacturer, based in Renchen, Germany. Its experienced staff is dedicated to providing customers the most innovative tooling technology possible. In 2010, the company opened Heimatec Inc. in Prospect Heights, IL, near Chicago, to serve its growing North American customer base with sales and service, plus an extensive inventory of products. Heimatec serves the auto, aero, medical, off-highway, rail, energy, woodworking, composites and other industries, as well as an ever-increasing number of machine tool OEM’s worldwide.

Continue readingSaws built for low vibration work best

by Willy Goellner, CEO, Advanced Machine & Engineering, Rockford, IL

Carbide saws equipped with carbide or coated cermet-tipped blades are designed to cut extremely hard materials. How effective the blade is depends in large part on how the saw is built.

The relatively brittle carbide or cermet tips require very rigid and backlash free machines, operating with low vibration to avoid cracking of the cutting tips and ensure an equal chip load on each tooth of the saw blade. This is especially important with the spindle drive. The spindle drive gears must have low backlash and must be supported by preloaded, heavy-duty bearings to minimize vibration. The same is true with the blade feed mechanism and the head slide or pivot mechanism.

Generally, there are two types of saws, differentiating in the way the blade is fed into the work piece: slide-type or pivot-type saws. The more common saws are slide-type machines, where the head slide could be arranged in a vertical, horizontal or angular position. The preloaded slide could glide on box ways or preloaded linear ways. Experts still argue whether box ways using low friction lining and hydraulically preloaded way clamps have a better dampening effect than linear ways with hardened balls, rollers and blocks.

Pivot-type saws are simpler, have fewer components and, if properly designed with oversized taper roller bearings, can be made very rigid by preloading the pivot bearings to the limits. Built for extreme stiffness, a pivot mechanism for the spindle gear box would be nested in a rigid base close to the floor, fed by a heavy duty ball screw attached to an upper sub-assembly, such as the fixture frame, and having the spindle located between the pivot point and the feed mechanism. Due to the feed force and the center of gravity of the head, the ball screw is always under tension, which eliminates the need for a preloaded ball screw and provides a very positive feed for interrupted cutting, enhanced longevity and efficiency.

This arrangement provides a closed loop force distribution since closed frames are stiffer than open profiles. It also subsequently reduces the remaining deflection of the feed mechanism due to the ratio of ball screw and spindle in relation to the pivot point and contains the cutting forces within the machine structure.

Compared to a standard slide machine (Fig. 1), a pivot machine would be stiffer and less expensive. Pivot saws are built to saw material up to 24” (600 mm) stock size and have proven themselves in various standard and special saw systems.

Circular carbide tipped blades are limited to a maximum of 80 inch blade diameter and can therefore only cut up to about 30 inch diameter material. However, the cutting volume per minute is much higher with circular carbide saws, compared to carbide tipped band saws. In this range up to 30 inch material, carbide saws using circular blades really shine.

For more information, visit www.ame.com or contact:

Tim Waterman

ADVANCED MACHINE & ENGINEERING CO.

2500 Latham St.

Rockford, IL 61103

Phone: 815-316-5277

Fax: 815-962-6483

E-mail: info@ame.com

Connect with AME online: