Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

This Grieve cabinet oven features an aluminized steel exterior, Type 304 stainless steel interior, brushed stainless steel control panel face, heavy-duty door and door frame with explosion-venting latches and 4” insulated walls.

No. 929 also includes a digital indicating temperature controller, manual reset excess temperature controller with separate contactors and a recirculating blower airflow safety switch.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

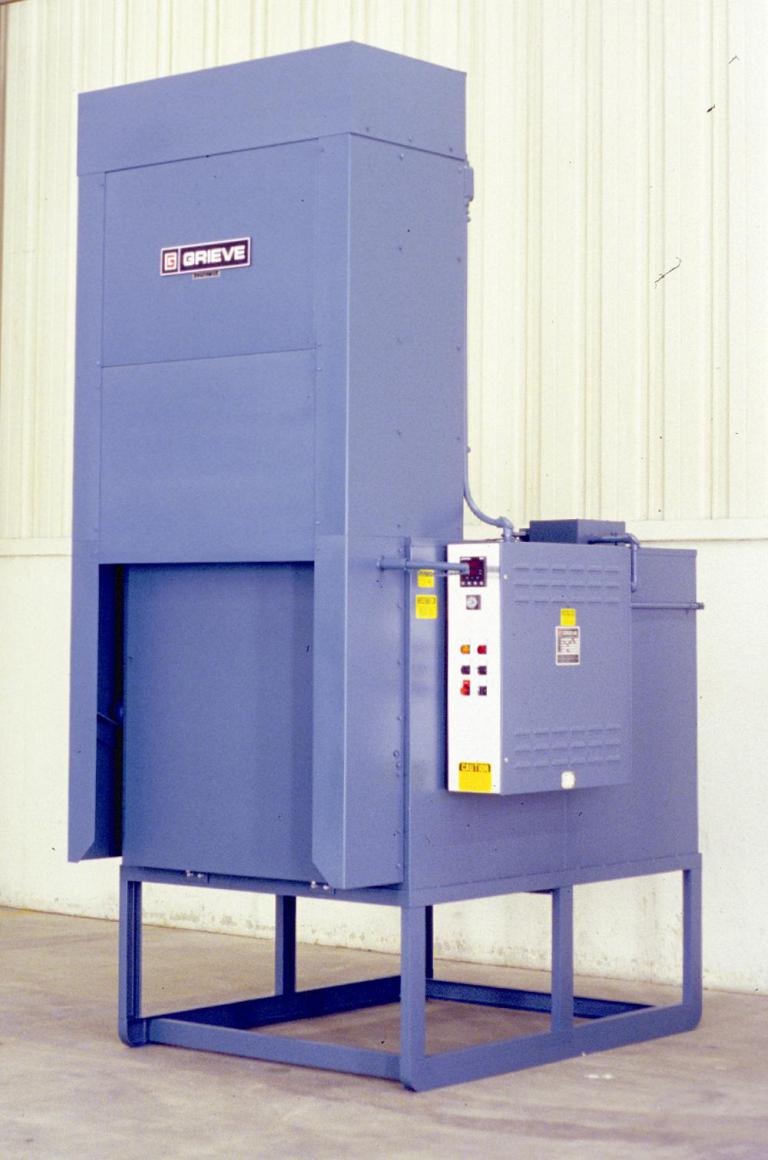

This Grieve ovens features 4” insulated walls throughout, plus an aluminized steel interior and exterior. A motor-operated vertical lift door is onboard, along with an integral leg stand for convenient work height off the factory floor.

No. 928 includes a digital indicating temperature controller, manual reset excess temperature controller with separate contactors and a recirculating blower airflow safety switch.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

This Grieve cabinet oven includes two 24” x 24” x 6” thick stainless steel

high-temperature HEPA recirculating air filters, plus a 24” x 24” x 6” thick HEPA fresh air filter with a 2” prefitter.

No. 927 is constructed with an aluminized steel exterior, Type 304, 2B stainless steel interior with continuously backwelded seams, 6” insulated walls and all safety equipment required for handling flammable solvents, including explosion-venting door hardware.

A digital programming temperature controller, 10” diameter circular chart recorder and 30-hour shutdown timer are also onboard this Grieve cabinet oven.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

This Grieve shelf oven features 4”insulated walls, aluminized steel interior and exterior, plus a 20” W x 56” H double-pane Lexan window in each of the unit’s two doors.

No. 926 also includes a disposable fresh air filter, digital indicating temperature controller, manual reset excess temperature controller with separate contactors, recirculating blow airflow safety switch and a remote control panel, shown separate in the photo provided here.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

Parts pass through a 1’ open belt loading zone, a 5’ insulated heat zone with recirculated airflow, a 20’ insulated heat zone with recirculated airflow, and a 1’ open belt unloading zone. A 2300 CFM, 2-HP recirculating blower in Zone One and 6000 CFM, 5-HP recirculating blower in Zone Two provide vertical downward airflow to the load.

This Grieve belt conveyor oven features 4” thick insulated walls, an aluminized steel interior and exterior, plus an 18”wide, 1” x 1” heavy-duty flat wire conveyor belt with 1/2-HP motor drive, variable from 1.4 to 27.8 inches per minute. The unit was constructed to split into two sections for shipment to the customer’s location..

Control and safety devices on No. 924 include digital indicating temperature controllers, manual reset excess temperature controllers with separate contactors, recirculating blower airflow safety switches and a two-pen, 10” diameter circular chart recorder. Side access doors are provided throughout this Grieve belt conveyor oven (shown in photo) for load inspection and maintenance.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

The unit features 7” thick insulated walls, comprising 5” of 2300°F ceramic fiber and 2” of 1700°F ceramic fiber while the 6-1/2” floor insulation consists of 4-1/2” of 2300°F firebrick and 2” of 1900°F block insulation. This Grieve heavy-duty furnace has a 3/16” steel plate reinforced shell and 1/2” steel front plate construction.

No. 921 also includes a motor-operated vertical lift door, as well as a digital programming temperature controller and manual reset excess temperature controller with separate contactors, for improved efficiency and safety.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

Workspace dimensions of this oven measure 18” wide x 96” deep x 15” high. A 2’ long open belt loading zone, two 4’ long insulated heat zones with independent recirculated airflow and temperature control, 1’ long open zone, 12’ long cooling zone and 2’ long open belt unloading zone constitute the full heat processing system of this Grieve oven. 60KW installed in Nichrome wire heating elements provide the heat, while two 1000 CFM, 2-HP recirculating blowers furnish downward vertical airflow to the workloads.

This Grieve oven features 5” insulated walls, an aluminized steel exterior, Type 304 stainless steel interior, two 16” diameter tubeaxial fans, each driven by a ¾-HP motor to push/pull air through the cooling zone, as well as a 12” wide, 1” x 1” high carbon steel flat wire conveyor belt with ¼-HP motor drive, variable speed from 1.3 to 25.3 ipm.

Safety and control equipment on-board No. 851 include a digital indicating temperature controller, manual reset excess temperature controller with separate contactors, recirculating blower airflow safety switch and fused disconnect switch.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

A 30 KW total heat input is installed in Incoloy sheathed tubular heating elements. A 1,500 CFM, 2 HP recirculating blower provides vertical downward airflow to the workload.

This Grieve cleanroom oven features a stainless steel exterior with #4 brushed finish, as well as a Type 304, 2B finish stainless steel interior with 1/2″ inside radius corners, seams welded, ground and polished.

A 12″ x 12″ x 6″ thick HEPA fresh air filter with 2″ prefilter and a 30″ x 24″ x 12″ thick stainless steel, high-temperature HEPA recirculating filter are provided, with a minihelic pressure gauge and DOP validation port across each filter.

Safety equipment includes a digital indicating temperature controller, manual reset excess temperature controller and SCR power controller.

No. 795 construction features 4″ insulated walls, independent double doors and twenty pairs of shelf supports with ten removable shelves included.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

The unit has 12” thick insulated walls comprised of 2” of 1900°F block and 10” of 10lb. density rockwool. The oven has a type 304, 2B finish stainless steel interior and is equipped with a solenoid operated door lock.

A 3000 CFM, 3-HP alloy recirculating blower provides horizontal airflow to the oven and a 325 CFM cooling blower pulls room air through the air jacket on the inner oven for additional cooling.

An inert atmosphere oven requires a pressure regulator, flow meter, pressure gauge and internal high temperature gasket. Also needed was a bellow type seal in the doorway throat area, 1/2” thick silicone rubber atmosphere seal and blower shaft seal. Positive latching door hardware, adjustable offset door hinges and an outlet with pressure relief were added as well. To keep gas from escaping, the interior seams were welded gas-tight and all wall penetrations fitted with compression fittings.

Workspace dimensions inside this unit measure 54” wide x 72” deep x 72” high. 30 kW power is installed in Incoloy sheathed tubular heating elements, while a 6000 CFM, 5 HP recirculating blower provides horizontal airflow across the workload.

Construction features on No. 825 include 4” thick insulated walls, 2” insulated floor with truck wheel guide-tracks, aluminized steel exterior, Type 304, 2B stainless steel interior with continuously front-welded seams, cellular silicone rubber door gasket, stainless steel water cooling coil located in heat chamber, removable top-mounted heat chamber, to minimize floor space requirements, and the oven body split into three sections for customer loading onto their elevator.

Special safety equipment onboard this Grieve oven includes a digital programming temperature controller, manual reset excess temperature controller with separate heating element control contactors, recirculating blower airflow safety switch, SCR power controller and a 6” strip chart recorder.

This special walk-in oven was entirely designed, engineered, built and full tested by Grieve.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP