Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Standard and custom styles available for Hyundai, Miyano and Nakamura machine tools; offered for all tapers, including HSK and BT30; fixed and adjustable models; many in stock for immediate delivery

Heimatec live tooling is now available in stock for all the popular models in the Nakamura, Hyundai and Miyano lines.

Heimatec, a world leader in live tools and multi-spindle drill heads, today announces immediate availability of live tooling for all popular models in the Hyundai, Miyano and Nakamura turning center lines. According to Preben Hansen, Heimatec president, “We’re carrying a substantial inventory of live tools for our customers’ machines now and it represents a substantial financial and warehouse space commitment we’ve made to support them in the North American market.”

Hansen added that the company will be announcing its in-stock arrangement for many other lines of machine tools, moving forward, as the company commits a major investment to the market. Heimatec Inc. serves its North American customers with a full team of manufacturers’ rep firms, plus its Chicagoland facility offers stocking, repair, application engineering and service for the company’s line of live tools, multi-spindle tool, adapters, UTEC® right angle heads and other items offered.

Literature detailing all the Heimatec products now available in stock for Hyundai, Miyano and Nakamura machining centers is offered at the company’s website, www.heimatecinc.com. Interested parties may also contact the company directly with inquiries.

CAT 40, BT 40, BT 30, HSK 63A, CAT 50, BT 50, HSK 100A and many other taper styles are available, as well as custom modifications such at 18” extension shafts. Offset, Slim, Dual and Adjustable styles. Heimatec offers a full one-year warranty on all parts and labor.

For further information and brand-specific literature, or to arrange a demo on any Heimatec tools, please contact:

Preben Hansen, President

HEIMATEC INC.

16 E. Piper Lane

Suite 129

Prospect Heights, IL 60070

Phone: 847-749-0633

Fax: 847-749-2445

Email: phansen@heimatecinc.com

Heimatec is an international tooling manufacturer, based in Renchen, Germany. Its experienced staff is dedicated to providing customers the most innovative tooling technology possible. In 2010, the company opened Heimatec Inc. in Prospect Heights, IL, near Chicago, to serve its growing North American customer base with sales and service, plus an extensive inventory of products. Heimatec serves the auto, aero, medical, off-highway, rail, energy, woodworking, composites and other industries, as well as an ever-increasing number of machine tool OEM’s worldwide.

Continue reading

SUHNER Flexible Shafts

Handle speeds up to 50,000 rpm with high accuracy; from printing presses and remote control valve control to speedometers and power seat actuation

Suhner Standard Flexible Shafts offer a plug and play solution. Equipped with standard female couplings with set screws, available for left hand, right hand or bi-directional application in a wide range of lengths and torque ratings, flexible shafts are easy, efficient and virtually maintenance free flexible drive shafts allowing for maximum design freedom in a wide variety of OEM applications in myriad industries.

Our K and Ka type plastic casing flex shafts are used throughout the automotive OEM, for engine control and power transmission, as well as interior controls on power seats and steering wheel adjustments.

Interested parties can review the online catalog for power transmission products from Suhner and use the handy math tools and other selection guides provided.

For more information, please contact SUHNER Mfg., Inc. at info.usa@suhner.com or visit our website at www.suhner.com.

Contact info:

Suhner Manufacturing, Inc.

43 Anderson Road SW

Rome, GA 30161

Phone: 706-235-8046

www.suhner.com

Attention: Michael Boehm, Director of Marketing & Sales

Michael.boehm@suhner.com

Continue reading

A brief introduction to the basics of this machine tool method, its concepts and recent developments in the technology

By Preben Hansen, President, Heimatec Inc., Prospect Heights, IL

Live tooling, as the name implies, is specifically driven by the CNC control and the turret of various spindle and powered sub-spindle configurations on CNC lathes to perform various operations while the workpiece remains in orientation to the main spindle. These devices, whether BMT or VDI, are also called driven tools, as opposed to the static tools used during turning operations and are usually customized for the particular machine tool builder’s turret assembly.

Most often, live tooling is offered in standard straight and 90º configurations with a wide variety of tool output clamping systems, including collet chuck, arbor, Weldon, capto, whistle notch, hydraulic, HSK, CAT, ABS and a variety of custom or proprietary systems developed by the many suppliers to the industry.

As your jobs change or volume increases or you encounter specific challenges in machining very large parts with deep pockets or very small intricate parts, for example, and the need arises for new machinery, a common error is made by accepting the standard tooling packages provided by the builder. This is most definitely not a criticism of the standard packages from builders, but this article is meant to give you a set of parameters to consider when evaluating the tooling and toolholding devices to use in your shop or production department. Simply stated, you need to do as much evaluation of your process, when determining the proper tooling to be used, as you did when you evaluated the various machines available for purchase.

This examination can range from the simple (external vs. internal coolant, for example) to the sublime (adjustable or extended tooling configurations) to the truly exotic, an example of which will end this article.

Tool life is the product of cutting intensity, materials processed, machine stability and, of course, piece parts produced. Two seemingly identical job shops can have vastly different tooling needs because one is automotive and one is medical, or one specializes in the one-offs and low-volume work, while the other has a greater occurrence of longer run jobs. The totality of your operation determines the best tooling for the machines being purchased.

Example of a very large, deep pocket tool that initially seemed too expensive, until the tests proved otherwise

Bearing construction and the resulting spindle concentricity drive the life of any tool and you might find that just a 10-15% greater investment in a better design can yield both longer lasting cutters and consistently superior finish on your products. Of course, the stability and rigidity of the machine tool base are also critical factors, especially on large or deep pocket workpieces, where the distance from the tool base to the cutter tip is greater. Bevel and spur gears that are hardened, ground and lapped in sets are best for smooth transition and minimal runout. Roller bearings are consistently superior to spindle bearings in live tooling applications, so look for a combination system to get the highest precision possible. Also look for an internal vs. external collet nut, so the tool seats more deeply in the tool, as superior rigidity will result.

Likewise, coolant high pressure might be desirable. Look for 2000 psi in 90º and 1000 psi minimum in straight tools.

You need to ask another question, namely, is the turret RPM sufficient to handle the work to be done? It’s possible a speed increaser on the tool would be helpful. Would it be beneficial to move secondary operations to your lathe? Gear hobbing can be accomplished or producing squares or flats through the use of polygon machining.

Standard live tooling most often is best suited to production work, where the finish, tolerances and cutter life are critical, while quick-change systems may be better suited to the shop producing families of products and other instances where the tool presetting offline is a key factor in keeping the shop at maximum productivity.

This opens the discussion of long-term flexibility and it’s the most often overlooked consideration in buying live tooling. What work do you have in the shop, what work will be coming in the future and the overall economies of a changeable adapter system on your tooling may be considerations not often made when the focus is centered on the machine being purchased. Dedicated tools for large families of product may be desirable, but consider a changeable adapter system and talk to your supplier before making that determination. Likewise, if the future work you’re bidding involves more families of product, think ahead when buying the initial tooling on the machine.

If standard ER tooling is suitable for the work, there are many good suppliers but do consider the construction aspects noted above. For a quick-change or changeable adapter system, there are fewer suppliers in the market, so seek them out and be sure they can supply the product styles you need for all your lathe brands. Adjustable angle head systems can be costly but very worthwhile, owing to the stability and rigidity of their construction, when producing families of parts with only slight differences in the dimensions.

Now, one of the exotic examples promised earlier…it evidences the value of having test runs done on alternative tool styles…

One company was doing a cross-milling application on an AL6063 sheave, using an ER40 output tool on a Eurotech lathe, running 10 ipm at 4000 rpm. They were making three passes, with a cycle time of 262 seconds and getting a chatter finish on 20,000 pieces per year. The annual cost of the machining was over $130,000. By using an improved adapter tool design with ER32AX output and the same parameters, they were able to produce the part in a single pass with a smooth finish and cycle time of just 172 seconds. Over the course of the year, this turned into a savings of $45,000, approximately 20x the cost of the tool. The bottom line is the bottom line, as the accountants tell us.

In the end, you may not need a +135º/-30 universal adjustable tool or a multi-spindle live holder or even a quick-change adapter system, but do consider all the options. Talk to your machine builder and several tool suppliers, plus the most important people in this equation, your shop personnel, as their input is invaluable.

For further information and literature, or to arrange a demo on this new line, please contact:

HEIMATEC INC.

16 E. Piper Lane Suite 129

Prospect Heights, IL 60070

Phone: 847-749-0633

Fax: 847-749-2445

Email: info@heimatecinc.com

Website: www.heimatecinc.com

Straight and angle head styles available for all popular machine tools; now offered on all tools in company’s current line

Heimatec, a world leader in live tools, angle and multi-spindle drill heads, today announces immediate availability of its newest development, a coolant-thru feature on all the company’s current line items.

Coolant-thru technology is often the answer for faster, cleaner cutting on larger and deeper parts, where the chips and excess heat build-up are significant challenges. Heimatec now offers high-pressure coolant-thru designs up to 1000 psi on straight and 2000 psi on angle head tools.

Company president Preben Hansen comments, “Production drilling should almost always be done with internal coolant tools and this development means we’ll be able to satisfy more customer needs in that area.”

A full range of styles and pressures is available immediately, according to the company.

Heimatec literature is offered, fully detailing all products available, both with and without this coolant-thru feature.

For further information and literature, or to arrange a demo on this new line, please contact:

Preben Hansen, President

HEIMATEC INC.

16 E. Piper Lane Suite 129

Prospect Heights, IL 60070

Phone: 847-749-0633

Fax: 847-749-2445

Email: info@heimatecinc.com

Website: www.heimatecinc.com

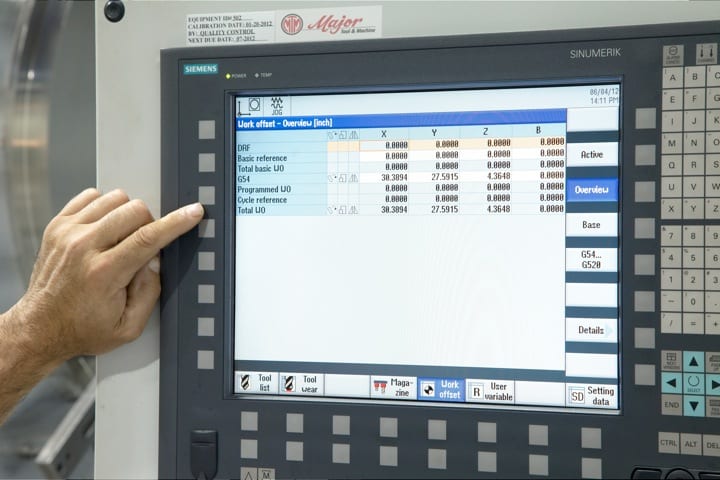

Major Tool & Machine, Inc. retrofitted two of their machining centers in 2010 changing to a CNC technology platform that was completely new to the company. Ten more such large-scale retrofits have followed, bringing increased enthusiasm, momentum and productivity.

Major Tool & Machine has been on track to retrofit over a dozen of its giant milling and turning machines within just two years, all supported by a new Siemens CNC platform. MTM’s management says the process has been an empowering experience for the company.

CNC upgrade enhances performance and precision

Major Tool & Machine (MTM) is a large job shop, producing precision milled and turned hardware throughout the company’s 500,000 square foot Indiana facility. Performance is essential, because MTM contracts with aerospace, energy, nuclear and defense companies on many mission-critical, one-off projects. Owner and CEO Steve Weyreter will tell you openly, MTM is more competitive by way of a significant CNC technology change, starting with an aggressive retrofit strategy.

Günther Zimmermann, CNC Controls Engineer at MTM, says the company’s retrofit program and the decision to change to the Siemens SINUMERIK CNC platform have brought a new enthusiasm and momentum to the company. Over the last two years the change has also brought significant time and cost reductions, especially in the areas of programming, maintenance engineering, and machine operations.

“The initial goal in early 2010 was to retrofit two Cincinnati U5 Gantry machines,” Zimmermann recounts. “We evaluated two CNC technology platforms and after considerable analysis our CEO Steve Weyreter announced that Siemens would best support the company’s future.”

The decision to reduce costs by moving to a single CNC platform was the least difficult decision for the company to make, Zimmermann explains. The larger challenge for MTM was the integration of a new CNC technology platform that was new to the company.

Bill Henderson, MTM’s manager of large machining and maintenance, agrees that the decision to change to a Siemens CNC platform integrated with advanced part and tool probing was critical, because the shop manages constant changeovers from one complex job to the next, making setup times a critical time/cost constraint for the company. Another big advantage is the increased flexibility by only having to train machinists and maintenance personnel on one type of control.

Henderson went on to say “the decision to change to a new control has signaled higher expectations for the company, along with new challenges for those who program, operate and maintain the company’s big machines.

Naturally, there’s a resistance to change,” Henderson says. “People are comfortable with what they normally run, but after our discussions with the people on the plant floor, they understood the overall objective. Our retrofit program is not finished, yet it’s already showing tremendous benefits.”

An advantage MTM gained by its retrofit strategy has been the ability to interchange heads and rotary tables from machine to machine. Easy-to- use head storage and tool management programming provided by the Siemens CNC platform support the new interchange capability.

Retrofitter Doug Huber says having Siemens as a new CNC technology partner has made a difference for Major Tool & Machine, but it’s also been an evolutionary uplift for his own retrofitting company, Indiana Automation.

“Indiana Automation has increasingly retrofit using Siemens controls in recent years, Huber explains. “On a retrofit, we always try to exceed what the original machine could do, and that’s just kind of inherent when you put on a Siemens 840D. Major Tool’s first retrofits were the Cincinnati U5 machines, a bridge model and two gantry models. These are five-axis machines and five-axis is the 840D’s forte. The processing power of the control is so much better, that it just whips through the blocks faster. So right off, cycle time is a major performance enhancement.”

Huber says something else happened this time. As his firm finished retrofitting the first three giant machines with Siemens five-axis controls, drives and motors, the reaction within the company was not just that the machines were now predictably more efficient, but that they performed as very different machines. A new advantage is the ability to interchange machining heads from machine-to-machine, and all driven by the Siemens CNC platform.

Central to MTM’s retrofit program has been the Siemens SINUMERIK 840D sl control, which features the SINUMERIK Operate interface. The highly intuitive interface enables both programmers and operators to easily capitalize on the broad capabilities of the control.

“On many of the U5 machines, the axes come off with the heads,” Huber explains, “and we rebuilt these machines to accept any one of three different heads. That’s one of Major Tool’s key strategies. They insist on having flexible machine capabilities, so that they can run all kinds of different parts. They have straight heads for serious metal cutting, contour heads for five-axis work and finesse work. They have 90-degree heads for more flexibility than a straight head, but it’s also not as fragile as the contour head. And they wanted to interchange all of these heads to automatically go pick up a head out of the shuttle and, on the fly, reconfigure the axes and the zero positions. To do this, the compensation tables all had to be updated. Everything needed to be done with the macro program so that each head came on ready to run.”

The interchangeable head strategy was a challenge, Huber says, because the machines were not originally capable of sharing heads. But with support from Siemens, the strategy has worked, including the ability to interchange rotary tables as well as heads. “Each head or rotary table has a configuration file that has all the settings and compensations and travels with it from machine to machine. So now when you mount that head the control just runs the configuration file that goes with it and its all set up for you. We also incorporated Siemens Tool Management for each machine’s 60-pocket tool chain. We used the feature on these machines to manage all the different tooling MTM uses, both in the automatic tool changer as well as the ones manually loaded.”

Huber says, “MTM’s ability to smoothly transition to more advanced CNC is largely due to the HMI’s ease of use. The Operate interface is a huge help to us and to Major Tool. The HMI helps make better parts. And it didn’t take very long for the operators to fall in love with it.”

Programming as easy as 1-2-3: Using the SINUMERIK Operate interface, a machinist can turn on coolant flow by 1) pressing Cycle Stop to stop the machine, 2) Coolant On, and 3) Restart.

“I had never used a Siemens control before,” admits MTM machinist Mike Burthay. “I have extensive knowledge of G-code and CNC controls and I would say the Siemens 840D sl with the Operate interface is the easiest one I’ve ever run. It’s user friendly, that’s exactly the words for it.”

Burthay reports several ways in which the Siemens SINUMERIK Operate interface has made his life easier. “There’s not as much G-code,” he says. “The control does it all for you as long as you put in the parameters as to size, length, width. Then once you’re in Job Mode, there’s a screen where you can tool change or jog the machine around to certain positions, or turn the spindle on, turn the coolant on, anything that traditionally required G-code. So now you can push a cycle stop button to pause the machine, enter a change such as turning coolant on, then restart the program.

“Another function I love is Block Search, which allows me to start or restart right in the middle of a program. Say you’re finishing a pocket and you have to run the tool two or three times to get a tight tolerance, I can enter in a line number and hit Block Search, the control picks up every line before that, restarts the spindle and everything for you.”

Burthay says the Siemens control also enables him to program parts right on the machine whenever necessary, using a simple yet robust program called ShopMill. “I can go into ShopMill, type in some parameters and it will kick out that G-code program for me automatically. Say I want to drill a hole two inches deep. I open ShopMill, pick my tool, tell it the depth and these steps are all interactive on the screen. It even shows me 3D motion images of the tool path, confirms the drill going down as expected into the part. So I hit go and it puts a drill cycle into the program for me.”

Programmed for collaborative growth

Lead Programmer, Tim Hayden, has from the beginning conducted all processor setups for the newly retrofitted machines. Hayden says integrating the Siemens CNC platform has been an empowering experience he had not expected, given the fact that he had never before set up a post processor to run a Siemens control, nor had he ever before operated a Siemens control.

“Now, when I look at the Siemens control, I think man, it would have been so much better to have had it all along,” Hayden says, “because the other control I’ve been using is just a lot more cryptic. The Siemens control with the SINUMERIK Operate interface is more powerful for writing macros and the language seems modern, whereas the other control seems like it is still based on an old FORTRAN type language.”

Work offsets for compound angles can be scaled and rotated using the Frames function of the Siemens SINUMERIK Operate interface. Many advanced machining operations can be managed simply, without the use of time-intensive manual G-code programming.

Hayden points to the Frames coordinate and offset programming function of the Siemens interface as an example of improved programming convenience.

“We do a lot of work on compound angles,” Hayden explains, “and with the Siemens Frames function, you can scale and rotate your coordinate system on the control, just plug it in with your work offsets. Whereas, on the other control you will see a G54 request, you’ve got to enter G-code. You can’t just plug it into your work offsets like you can with the Siemens control.”

Hayden says the SINUMERIK Operate interface brings greater programming flexibility. The HMI enables him to enter G-code using a comparatively more advanced manual data entry (MDI) function; however the HMI has all but eliminated the need for G-code entry by way of its intuitive design and evolved capabilities.

Another example of such HMI evolution is in the area of data management.

“When we post a program, we no longer have to use a G-code based MDI,” Hayden explains. “We no longer need to type in T= and enter a nine digit number and then enter M6 to make a tool change. With the Operate HMI, you pick your tool off a screen and hit cycle start. It’s just as easy to program going to a position. Instead of doing things the old way by typing G0X0Y0Z0 into the MDI, you open the Operate interface, click position, then click how you want to wrap it and then you just type the numbers into those fields. So it’s a lot more user friendly.”

Hayden says the Siemens CNC platform has supported greater collaboration at MTM between him and the machinists, and this is helping the company find ways to increase performance and efficiency. He agrees with his coworkers’ assessments that shorter setup times and greater operator freedom are making a significant difference.

“One of our production bottlenecks has been programming,” Hayden says. “The machinists that run our machines are professionals, they’re not button pushers, and with the SINUMERIK Operate interface, we can now rely on them to control and program certain parts right on their machines, while we programmers work on the more complex projects.”

“Siemens was the best fit for all of us,” Hayden concludes. “Siemens CNC is set up as an open control, and with that kind of flexibility, it seems anything is possible.”

For more information on Siemens SINUMERIK CNC, visit www.usa.siemens.com/cnc.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Remember when IMTS 2014 announced their photo contest and we submitted this scrumptious morsel of photography?? For #TBT, I’d like to pay tribute to this delicious day in Bernard & Company history: “Chicago’s Favorites” featuring Bernard & Company, IMTS, Portillo’s Chicago-Style Hot Dogs/Fries and Italian Beef Sandwiches, Lou Malnati’s Deep Dish Pizza and Garrett’s Chicago Mix Popcorn.

(Original Tweet here)

(Original Tweet here)

Keep warm and keep having fun, manufacturing world!

– n

Continue readingWhen IMTS 2014 announced their photo contest, we couldn’t wait to get to work!

#IMTS: Everywhere You Look – #Photo Contest! Send us your images spelling out I-M-T-S, we will choose our… http://t.co/pRbDeyo6NS

— IMTS (@IMTSchicago) February 24, 2014

@BernardandCo We are very excited to see how creative our #exhibitors will be. Can't wait to see your #IMTS photos! http://t.co/DRODctM0o0

— IMTS (@IMTSchicago) February 19, 2014

Presenting our entry:

“Chicago’s Favorites” featuring Bernard & Company, IMTS, Portillo’s Chicago-Style Hot Dogs/Fries and Italian Beef Sandwiches, Lou Malnati’s Deep Dish Pizza and Garrett’s Chicago Mix Popcorn. What could be better?? Nothing, I tell ya.

Do NOT miss IMTS this upcoming September!! Our clients, including Siemens Machine Tools, Siemens Production Machining, Rattunde, Advanced Machine & Engineering, Heimatec, TCT Stainless, GMTA, Suhner and Chemtool will all be exhibiting!

And if the photo above did not leave you reaching for a napkin to wipe the drool, IMTS will be home to over 100,000 decision makers showing new manufacturing technology and ideas. So come on over to Chicago and get a taste of everything IMTS will have to offer!

Continue reading

We did it for Mother’s Day, and now it’s dad’s turn. They’ll make you laugh, they’ll make you cry, they’ll make you appreciate dad more than ever before!

Here’s a collection of the best commercials/videos celebrating dads:

American Greetings – The Dad Life Rap

And here’s a little extra:

25 Absolute Greatest Dad Jokes of All Time

** Happy Father’s Day!! **

Do you have must-see commercial to add?? Share the link in the comments below!

Continue readingIs there a better way to celebrate and honour Mother’s Day than to make you weep uncontrollably at your office desk?

Olympics P&G – Pick Them Back Up

Publix – Mother’s Day Commercial

Video – Parents Announce New Baby; Daughter Has Best Reaction. Ever.

And then there’s this one. Disclaimer: this commercial is incredibly creepy. But also hilarious.

** Happy Mother’s Day!! **

Do you have must-see commercial to add?? Share the link in the comments below!

Continue readingAnn Arbor, Michigan – GMTA (German Machine Tools of America) represents various top-quality German metalworking machine builders, including Wera Profilator, Pittler, Praewema and WMZ. These machines are sold to the North American market by GMTA primarily for gear and spline production, as well as other power transmission applications. The company’s target markets include automotive, off-highway, energy and other heavy equipment manufacturing. Machines are provided for gear honing, gear grinding, the patented Scudding® process for gearmaking, polygon milling, turning, gear tooth pointing and multi-task machining operations. This newsletter is provided to our friends in the media to keep you and your readers updated on News of Note at GMTA.

In the news…

– GMTA proudly announces the addition of Stefan Kloos as Product Manager. Stefan will handle the Pittler vertical turning lathes and WMZ centerdrive lathes. He will be based in Ann Arbor, Michigan, North American Headquarters for GMTA.

– German Language and International Careers (LIC) students from Eastern Michigan University visited GMTA on March 12, 2014. Students were given a tour of GMTA facilities and a presentation in German by GMTA President, Walter Friedrich. As EMU Department of World Languages Professor Margrit Zinggeler Ph.D. pointed out, “Eastern Michigan was one of the first universities to combine foreign language with a practical business component. The EMU major in language and international careers (LIC) is designed to integrate the study of modern foreign languages and cultures with preparation for an international business career. The major objective of the program is to provide students with the skills, knowledge and understanding needed to function in a foreign environment and in professional dealings with people and clients who speak a foreign language. It is a very useful course of study in today’s global economy, especially with so many foreign companies setting up shop in the U.S.” After the presentation and questions, students were invited to a typical German “Brotzeit” (evening meal of German bread and coldcuts) and, of course, ample quantities of German beer Reissdorf Koelsch! GMTA is proud to support young people in the community and help provide them with (German) language opportunities in a business environment.

Students from Eastern Michigan University’s Language and International Careers (LIC) program visited GMTA for a detailed explanation in German from the company president, Walter Friedrich, right. Leading the group was Professor Margrit Zinggeler, Ph.D., third from the right

– A definitive explanation on the trademarked Profilator Scudding® process for advanced gearmaking is now available from GMTA. Please contact Scott Knoy below for details.

– GMTA supports the Judson Center, a charity that serves the needs of individuals with life challenges such as autism. Every year, the Center tries to provide the youngsters served with a life-changing event. This year, the Center is providing 150 bicycles. GMTA is part of a group of companies supplying the bikes, along with GM Warren Transmission and local radio station, 95.5 WYCD Detroit Country. Claudia Hambleton coordinated the effort for GMTA.

For more information on this announcement, please contact:

GMTA (GERMAN MACHINE TOOLS OF AMERICA)

4630 Freedom Drive

Ann Arbor, MI 48108

Phone: 734-973-7800

Fax: 734-973-3053

Web: www.gmtamerica.com

Email: scott@gmtamerica.com

Attention: Scott Knoy

Connect with GMTA online: