Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

E-Z Lok, a leading manufacturer and master distributor of threaded inserts for metal, plastic and wood now offers E-Z Coil™ and thread repair kits.

Wire or helical coil threaded inserts quickly repair or reinforce tapped holes in soft metals. Made from 18-8 stainless steel wire, these helical coil inserts are corrosion resistant and can withstand temperatures up to 800°F. Furthermore, they offer corrosion resistance and protection from wearing and stripping.

E-Z Coil™ helical insert coils are manufactured by forming the stainless steel wire into a diamond shape and then winding it into a spring. Prior to installation, the insert diameters are larger than the tapped hole. During installation, the insert diameter of the helical coil insert is reduced, allowing the insert to thread into the hole. Once properly installed, the radial pressure of the released insert holds the insert firmly in place.

Thread Repair kits are available in both standard and economy, and in a variety of sizes. Each Economy E-Z Coil™ Thread Repair kit includes a set of inserts, an STI tap, and an installation tool. The standard kit also includes a tang break tool and drill bit.

CAD files on this product can be downloaded in over 100 file formats from the E-Z Lok website at https://www.ezlok.com/cad-downloads

For more information, please contact:

Kyle Lindsly-Roach, Director of Sales & Marketing

E-Z Lok

240 E. Rosecrans Ave

Gardena, CA 90248

USA

Phone: 310-323-5613 x221

klindsly@ezlok.com

www.ezlok.com

E-Z Lok is a leading manufacturer and master distributor of threaded inserts for metal, plastic and wood. Inserts for metal include solid wall and helical wire-thread inserts, while inserts for plastic feature press-in and ultrasonic/heat stake designs. Those for wood are die cast zinc alloy hex drives for soft wood and brass knife threads for hard wood. A variety of kits for the above inserts are available and feature installation tools, drill bits, etc.

E-Z Lok is a third-generation family owned and operated company. Founded in 1956, it primarily sells through local, regional, and national industrial distributors.

Continue readingThe GDS µGrind ANCA collet adaptor is designed with the highest level of consistent accuracy and improved productivity in mind

The performance of any process relies on the performance of its individual components. This is particularly relevant in the grinding of precision tools. The increasing need for extreme accuracy and tolerances, as well as competitive and labor pressures, result in the demand for accessories that are more precise, easy to use and maintenance-free.

A selection of good quality, easy to use workholding that provides minimal and consistent runout is one of the prerequisites for successful grinding, resulting in quality tools and happy customers – once again reinforcing that the quality of the whole process relies on the quality of all its components.

ANCA has partnered with GDS, a renowned German manufacturer of high-quality precision accessories for grinding and machining processes. One of their flagship products is the µGrind workholding, which is now available from ANCA’s distribution network. The µGrind has been customized to suit the requirements of ANCA grinding machines and can be set up in a matter of minutes.

Benefits of the µGrind workholding:

µGrind performance has been tested in real-life applications and the results are very consistent. A test was performed over a large batch of 6mm tools where runout was measured before and after grinding at 2.5 x Ø and 10 x Ø. Even with thousands of clamping and diameter changes, the runout remained virtually unchanged.

The GDS µGrind ANCA workholding is a smart investment that will serve you for years to come. By saving time and improving tool quality, this translates into satisfied customers and better business outcomes.

For further information, please contact:

Amanda Bakun

Marketing & Communications Manager – Americas

248-497-1168

amanda.bakun@anca.com

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

Continue reading

Projected global demand for products such as taps, dies, and thread forming tools is anticipated to rise from 2.75 billion to 3.42 billion over the next five years, with a compound annual growth rate (CAGR) of 5%. The high-tech industries, particularly automotive and aerospace sectors, are expected to sustain a significant portion of this growth, accounting for 16% of the overall market demand. Additionally, there is an expected increase in demand from medical applications, which is projected to contribute another 7% to the total market share within the next five years.

Given the impetus from these high-tech markets, tap producers will need to enhance their designs to meet the escalating market share of specialized materials. Notably, composites (expected CAGR of 8.5%) and super alloys (expected CAGR of 7.5%) are anticipated to experience the most substantial growth, necessitating the development of tailored designs in response.

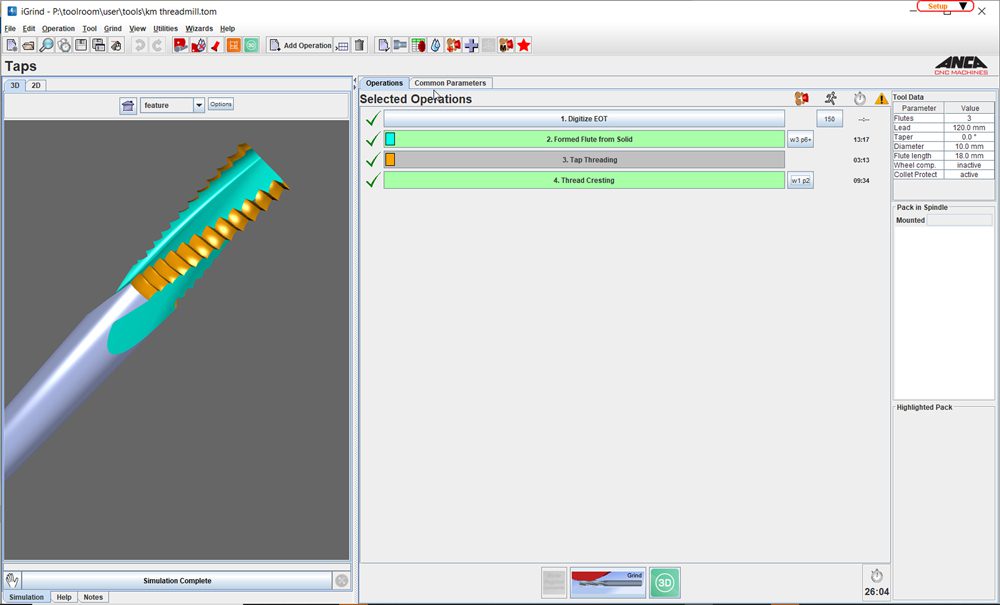

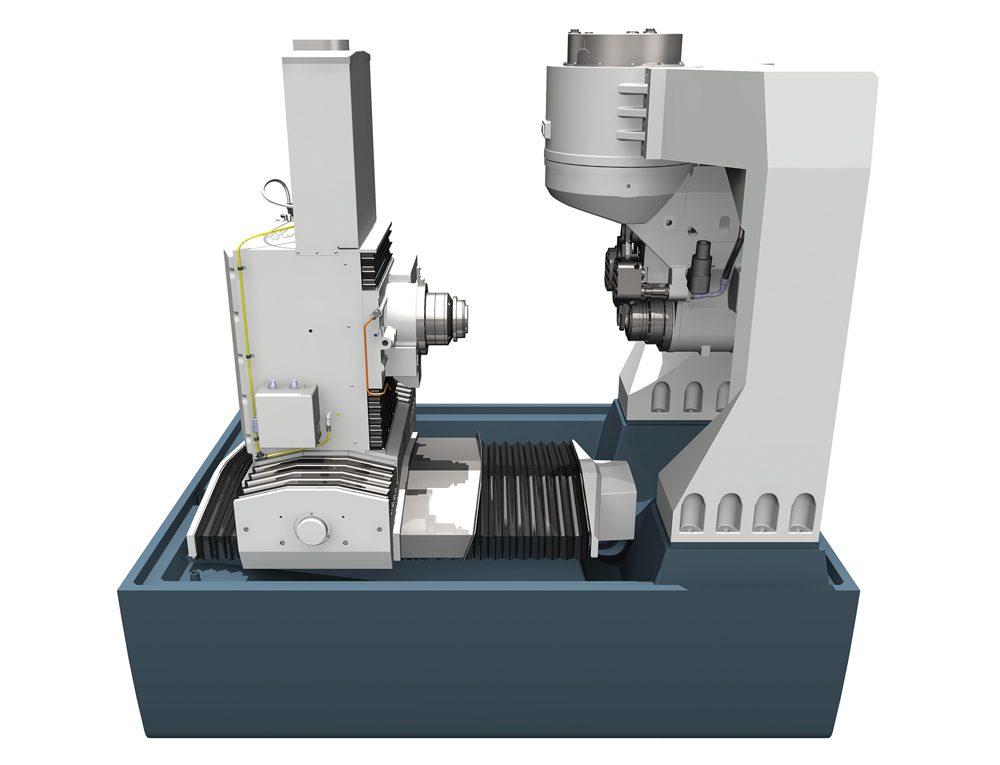

With the boom of automotive and aerospace applications, ANCA sees great potential for the future of the high-end tap market. ANCA’s years of experience working with tap manufacturers has given the company valuable insights into the industry challenges, making it well-equipped to offer the right solution. The TapX is a machine specifically designed and integrated with automation to ensure high productivity in mass production. As a one-machine solution with single clamping, it guarantees substantial benefits for manufacturing standard and special taps by eliminating the traditional requirement of needing several grinding machines.

Flexible, precise and efficient one-stop tap grinding is simply unimaginable on ordinary grinding machines, as high-speed steel taps, carbide taps, micro taps and non-standard taps require different and detailed solutions. The difference lies in the performance of a single grinding process, a parallel grinding process or a combined grinding process. In addition, several grinding machines are usually required, each performing a specific tap grinding task. TapX integrates the various processes into one machine.

Flexibility is a key feature of the tap grinding process on the TapX. The specially designed machine and powerful ToolRoom software ensure a vast range of tap types and sizes can be designed and manufactured in one set-up. Combine this with the benefits of quick changeover time and it’s not hard to see how TapX can increase productivity and reduce lead times.

The production of taps in different materials is an example of how this highly flexible solution can contribute to productivity. Taps are mainly made of HSS and carbide materials, which require high precision, surface finish and reliability for grinding. TapX is suitable for the complete production of HSS or carbide taps. With a single set-up, it can grind various types of standard taps, micro taps and non-standard taps. Its excellent rigidity guarantees repeatable, high-quality results, while its CNC control plus programmable force of the center ensures reliability of high frequency movements.

The TapX uses ANCA’s own LinX motor technology for all linear axes and direct drive technology for all rotary axes. By eliminating all belts, pulleys, and gears, the TapX is not only a more precise machine, but a more reliable one as well.

Although HSS will remain the dominant material of choice, carbide tools are growing in popularity with the increase in thread milling applications and introduction of more exotic materials. Compared with HSS, carbide offers high rigidity, good machining quality and long service life. Consequently, the production of carbide taps presents challenges for machine productivity, accuracy and dressing of special thread grinding wheels.

TapX offers the perfect solution with its single clamping to optimize the grinding process. Combined with greater flexibility in wheel selection and process deployment, this revolutionary solution means more flexibility, reduced costs and increased tap production output. The total set-up time for multiple general machines is reduced from three to four hours to one hour for one TapX machine, which significantly reduces lead time for small to medium batch production, urgent order response and customer changes. In recent years, ANCA continues to innovate and has developed a unique solution for dome carbide taps with a wider application. Its superior performance is unmatched in the industry.

Recognizing the efficiency, accuracy and reusability of TapX, customers have begun to expand their product range to include spiral, straight flute and forming taps, and even micro parts. Micro taps are mostly used in smartphones, glasses, consumer electronics, aviation and military industries. Any miniaturized part may be machined with a small or micro tap.

In recent years, the growing demand for mobile devices and new materials has led to a sharp increase in the consumption of thread tapping tools, which in turn resulted in an unprecedented boom for machines grinding small or micro taps. This means that manufacturers such as ANCA, who have the capability to manufacture these tools, have great potential to meet the ever-growing market demand. To grind small batches of taps, conventional machines simply take too long to set up. With ANCA TapX, customers can integrate the entire process into just one machine, significantly increasing productivity through rapid tap design, set-up and changeover.

The TapX grinding solution is an excellent option to meet the high demand for high-quality tap products or to fulfill the needs of emerging manufacturers in the market. The TapX one-machine grinding concept provides faster tap design, set-up, and changeover to reduce lead times and boost competitiveness. Gone are the high costs, inflexible production and low productivity due to lengthy machine set-ups. ANCA remains committed to offering comprehensive grinding solutions for its customers.

For further information, please contact:

Amanda Bakun

Marketing & Communications Manager – Americas

248-497-1168

amanda.bakun@anca.com

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

Continue reading

E-Z Lok, a leading manufacturer and master distributor of threaded inserts for metal, plastic and wood, now offers E-Z Lok ™ (Solid Wall) Threaded Inserts for metal; including both Assortment and Installation kits.

E-Z Lok ™ inserts are ideal for repairing or reinforcing threaded holes in soft metals such as: aluminum, magnesium and cast iron. External threads are standard size and pitch, so they can be installed with standard drills and taps. Solid wall threaded inserts are installed with a screwdriver, bolt/jam nut (except IC series) or optional power drive tool.

These inserts will not back out or vibrate loose. The pre-applied, microencapsulated adhesive begins to set immediately upon installation and the newly installed insert is fastener-ready in 3-5 minutes. Despite their firm hold while in use, E-Z Lok™ (Solid Wall) threaded inserts for metal can be removed with a bolt extractor, which overcomes the resistance to torque-out produced by the adhesive. They can also be removed by heating the insert to a temperature above 300°F (149°C), at which point the adhesive will release.

E-Z Lok ™ inserts are available in Thin Wall, Standard Wall, Extra Heavy Wall, Screw Locking and Automotive designs. They are available in Carbon Steel and Stainless Steel. Stainless steel threaded inserts are perfect for applications requiring additional corrosion resistance, as well as food, beverage and other clean-critical applications.

Assortment kits are equipped with inserts in a variety of sizes. They provide an easy-to-store solution for thread repair, giving maintenance teams added convenience. Installation kits are specifically designed to make threaded insert applications and repairs as simple as possible. These feature a drill, tap and installation tool.

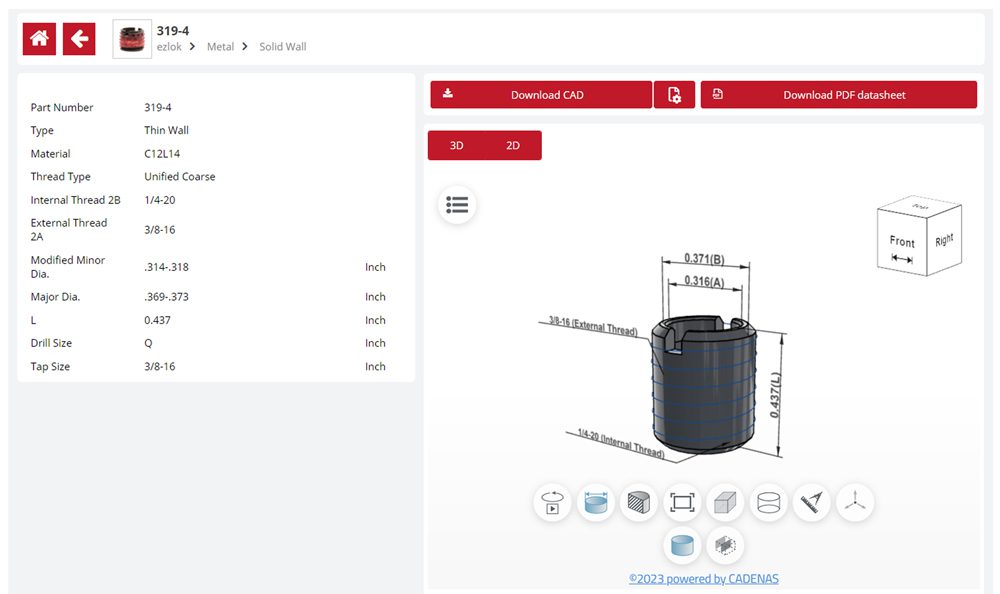

CAD files on this product can be downloaded in over 100 file formats from the E-Z Lok website at https://www.ezlok.com/cad-downloads

For more information, please contact:

Kyle Lindsly-Roach, Director of Sales & Marketing

E-Z Lok

240 E. Rosecrans Ave

Gardena, CA 90248

USA

Phone: 310-323-5613 x221

klindsly@ezlok.com

www.ezlok.com

E-Z Lok is a leading manufacturer and master distributor of threaded inserts for metal, plastic and wood. Inserts for metal include solid wall and helical wire-thread inserts, while inserts for plastic feature press-in and ultrasonic/heat stake designs. Those for wood are die cast zinc alloy hex drives for soft wood and brass knife threads for hard wood. A variety of kits for the above inserts are available and feature installation tools, drill bits, etc.

E-Z Lok is a third-generation family owned and operated company. Founded in 1956, it primarily sells through local, regional, and national industrial distributors.

Continue reading

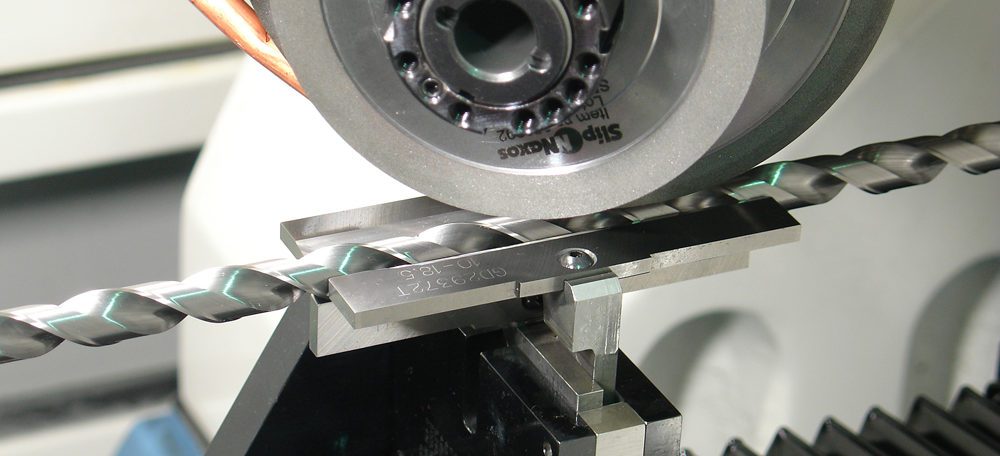

Long drills present several difficulties and challenges in the production process. Their elongated physical size is not the only concern; ensuring accuracy throughout the entire length of the tool can be equally challenging. The extended nature of these drills introduces a host of potential issues that need to be carefully addressed.

One challenge is the need to control grinding forces consistently throughout the entire length of the tool. This is crucial because long drills are designed to create holes that are not only accurate but also maintain their straightness over extended distances. The reduction of deflection caused by grinding forces is important. When fluting the drill in the shortest possible time, high feed rates and forces are necessary. It becomes crucial to find ways to minimize deflection while maintaining the required machining efficiency.

Another concern is runout, which refers to the error that occurs when the tool deviates from the center axis at an angle. While a standard setup may allow for an acceptable 5 µm runout for a 100mm tool, the same setup could result in up to 40µm runout for a 400mm tool. Achieving acceptable runout becomes a priority when dealing with such lengthy tools, as it directly impacts the performance of the tool.

Additionally, long drills often feature coolant holes integrated within their bodies. To ensure proper functioning, these coolant holes must be correctly identified by the machine during the machining process, avoiding any damage that could impede their functionality. Managing grinding forces and preserving the integrity of coolant holes are critical considerations when working with long drills.

By addressing the challenges of tool deflection, runout, fluting, and coolant holes, ANCA’s integrated solutions and software capabilities provide a comprehensive approach to effectively produce long drills with accuracy and efficiency.

ANCA’s TX7 is the machine for long drill production

ANCA is the only CNC grinding machine manufacturer with complete vertical integration in its manufacturing process. This integration not only fosters innovation across all aspects of design and production but also enables ANCA to respond swiftly and effectively to demanding requirements with unique solutions.

The TX7 machine’s powerful 37kW (49hp) direct drive spindle, facilitates the efficient grinding of long drills without putting excessive strain on the machine. It boasts a spacious working envelope and a 6th axis with a traveling steady support that can be positioned strategically to provide support in the grinding zone, allowing for the accommodation of tool lengths of up to 480mm. This setup eliminates deflection and minimizes vibrations caused by grinding forces on the tool. It also addresses the issue of runout, as the steady supports enable compensation control to mitigate runout errors effectively.

One of the remarkable advantages of the TX platform is its ability to grind drills from start to finish in a single setup. This capability grants greater flexibility in production, enabling the manufacture of both high-volume tools and highly customized tools on the same machine with minimal hassle. Customers opting for the TX7 model with a robot cell can achieve fully automated manufacturing, unlocking new possibilities and efficiencies for their operations.

ANCA’s specialized software for long drills

ANCA offers several software solutions for long drill production. The first is ToolRoom, which provides a drill wizard as a standard feature. This wizard is a great starting point and includes convenient features like wheel pack auto-select. Users can easily add and define coolant holes in the blank editor for simulation. The software also integrates many tool features, including advanced ones like S Gash, K land, C land, and variable helix. The ToolRoom software also includes runout compensation capabilities, providing further adjustments to compensate for runout errors.

For formed flutes, ANCA offers iFlute software. Long drills often require specific flute forms, and iFlute simplifies the process. Users can simply import their DXF file, and iFlute will determine the wheel profile and grinding paths accordingly.

To simulate the tool grind and account for machine features, ANCA provides CIM3D. Users can add all the necessary machine features to the simulation, including a 6th axis, to determine the setup and control before proceeding to the actual grinding process. Not only can users set up the required operations, but they can also optimize the grind from their desk with accurate simulations of all features. CIM3D includes intuitive coolant hole collision detection within the simulation, ensuring that potential issues are identified and addressed beforehand.

ANCA’s comprehensive integration, combined with the advanced features and software of the TX platform, establishes the company as a flexible and agile provider of grinding solutions. With this powerful combination, ANCA effectively meets a wide range of challenging demands in long drill production.

Overview

For further information, please contact:

Amanda Bakun

Marketing & Communications Manager – Americas

248-497-1168

amanda.bakun@anca.com

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

Continue reading

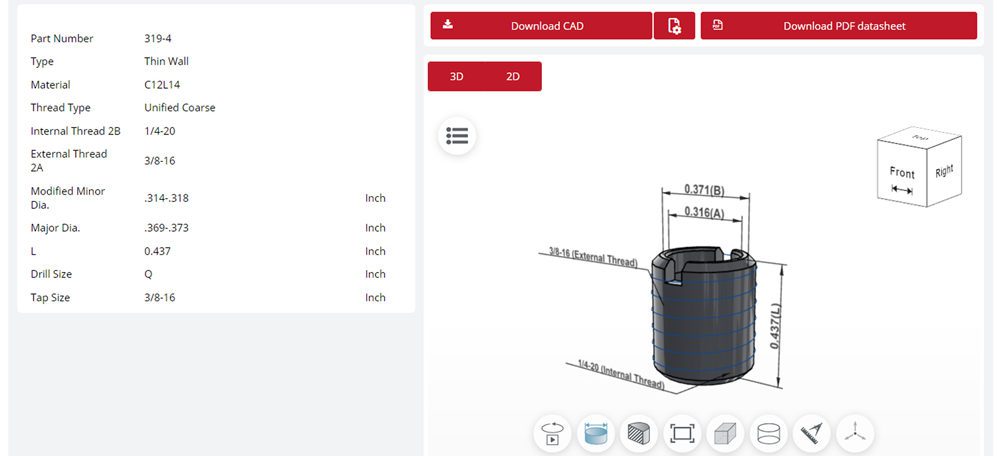

E-Z Lok, a leading manufacturer and master distributor of threaded inserts for metal, plastic and wood, has recently launched an online CAD library to showcase a wide selection of its products at https://www.ezlok.com/cad-downloads.

Built by CADENAS PARTsolutions, this catalog will streamline the design and specification process for engineers, MRO and OEMs by giving them on-demand access to threaded insert CAD models.

Prior to adding the 3D CAD models to their site, the company relied on its customers to create and share CAD files. “We had 2D PDFs that we could make available, but no CAD files, said Kyle Lindsly-Roach, E-Z Lok Director of Sales & Marketing. He added that CAD files are very valuable to engineers and that now they can pull the information directly from the website and obtain product specifications early in the design phase.

The online catalog allows viewers to access robust product information anytime, anywhere through the E-Z Lok website. Customers can view 3D models and visualize the products as well as download PDF datasheets for quick information. Once a product is chosen, OEMs and other engineering buyers can download the CAD file in a variety of native and neutral formats.

For more information, please contact:

Kyle Lindsly-Roach, Director of Sales & Marketing

E-Z Lok

240 E. Rosecrans Ave

Gardena, CA 90248

USA

Phone: 310-323-5613 x221

klindsly@ezlok.com

www.ezlok.com

Guill Tool, global leader in extrusion tooling, recently announced that its state-of-the-art rheology lab is offering its services for a fee to all those interested. Measuring the flow characteristics of plastics and rubber helps predict how a customer’s material will flow through the company’s extrusion dies before production. In addition, tooling geometry is virtually optimized, and the project can be viewed in 3D CAD. Machines used include a rotational rheometer, scanning calorimeter, thermal conductivity meter and a new CT scanner.

The rotational rheometer quickly generates visco-elastic data for polymer melts, precisely capturing polymer melt properties. The test temperature ranges between ambient and 300°C. The lab’s scanning calorimeter characterizes the thermal properties of a polymer sample, such as: crystallization temperature, glass transition temperature and head capacity of the sample. Knowing these thermal properties permits the simulation of shear heating and hot and cold spots in the flow area.

Guill’s thermal conductivity meter is used to determine the thermal conductivity of the polymer sample across a range of temperatures. Capable of high-definition measuring, the newly purchased IM-8000 Series Image Dimension Measurement System has triple the detection performance. With a 20-megapixel CMOS sensor and a new algorithm for stable edge detection high-accuracy measurement is available on up to 300 features. Greater simulation accuracy reduces the number of physical reworks needed.

The in-house lab provides faster turnaround on test results, reducing delays during the design process and offering better control over the testing parameters. The result is a high-quality part delivered on time.

For more information, please contact:

Tom Baldock, Sales Manager, Extrusion

Guill Tool & Engineering

10 Pike Street

West Warwick, RI 02893

USA

Phone: 401-465-5526

tbaldock@guill.com

Partnering with ANCA gave a boost of confidence to the Bengaluru-based company, which extensively uses ANCA machines to make precision cutting tools, prepare blanks, and regrind tools

Journey of growth with ANCA

Kumar started SST Cutting Tools in the middle of the global recession in 2008 with a single tool and cutter grinding machine. The company now has four ANCA machines and many delighted customers.

“I had absolutely no idea about CNC grinding machines, as I had never operated one before. All I knew was that I wanted the best one. I evaluated several global brands and found ANCA to be best suited for my application. More than anything, I needed a user-friendly machine, as none of the team members, including me, had any experience with CNC grinding machines,” adds Kumar.

Enhanced output, efficiency, accuracy

SST Cutting Tools added an ANCA FX3 with linear scale technology, which can produce tools with an accuracy of three microns. “We were amazed by the machine’s output and speed. Our efficiency and accuracy went up. This provided a boost to our much-needed confidence and now we’re out in the market looking for precision cutting tools requirements,” says Kumar.

The company started taking precision cutting tool orders, with many happy customers. “We received several repeat orders and a lot of new inquiries. We needed to enhance our efficiency further by reducing the setup time. I discussed this challenge with the ANCA team, and they suggested the ANCA FX5 fully automatic linear machine. I saw the demo, observed all the features, and opted for it in March 2018. It was the perfect match for my requirements. The machine is equipped with a 2-wheel changer that helps us reduce the number of setups,” informs Kumar. SST added one more advanced version of the ANCA FX5 in 2019. It is fully automatic and provides high accuracy and an in-process measuring camera.

It’s all about meeting requirements

The CPX Linear is capable of achieving a surface finish better than 0.2Ra with a run out of less than two microns. “With the addition of a CPX Linear, we can make tools in a few hours, thereby meeting urgent requirements,” he adds.

Focus on quality, accuracy for applications

Talking about his vision, Kumar says, “I want to be a world-class manufacturer of cutting tools and provide services to the customer’s speculated time with zero defects and a high degree of accuracy.”

The company specializes in customized cutting tools such as drills with sizes ranging from Ø1 to Ø25 with the L/D ratio of Ø X 12; endmills with sizes ranging from 0.8mm to 25mm and 2flutes to 12flutes; and reamers and holemills, with sizes ranging from 1mm to 25mm, within the tolerance of 0.002 mm. Additionally, the company works with threading tools, boring tools, ID and OD grooving tools, pico bars, and angle grooving tools.

“I wanted to learn the fundamentals of mechanical engineering, the functionality of the latest machines, and various advantages of grinding applications. I used to work for 10-12 hours during the day and attend classes in the evening,” he recalls.

SST Cutting Tools’ drive and versatility is also highlighted in their multiple #ANCATooloftheYear entries, showcasing their skill and creativity with ANCA software as well as an enthusiastic commitment to the community of cutting tool manufacturers.

More growth ahead at home and abroad

After close to 15 years of operations and many happy customers in India, the company is now eyeing exports, and expanding their infrastructure to accommodate more machines. “We are looking forward to adding more ANCA machines in the coming days,” says Kumar.

He adds, “We have big plans for the future. However, it is worth looking back at the journey and remembering all that has worked in our favor. Choosing ANCA was one of the best decisions in my career. ANCA has not only enhanced the efficiency and productivity of SST Cutting Tools, it has also given our confidence the much-needed boost.”

“The ANCA team is well-versed with the technical know-how and their service is nothing short of excellent. Whenever we faced any technical hurdles, the team would quickly respond. We never had to face any major delays in our projects thanks to their prompt support. In fact, there have been instances of executives from ANCA flying down to Bengaluru from Australia only to help us better understand the machine’s features. I am looking forward to working with ANCA; they are our growth partner and not just a vendor,” concludes Kumar.

For further information, please contact:

Amanda Bakun

Marketing & Communications Manager – Americas

248-497-1168

amanda.bakun@anca.com

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

A master craftsperson and precision tool mechanic, Lena was the first female at her school to undertake this prestigious degree

As part of their esteemed Tool of the Year event, ANCA introduced an exclusive new category for Female Machinists. A panel of experienced professionals evaluated submissions using the following criteria:

Johanna Boland, Strategy and Communications Manager at ANCA, expressed her pride on introducing the first ever Female Machinist of the Year award for ANCA. “Since joining this industry I have met and worked with some truly intelligent, driven female leaders. However, let’s face it, female machinists are not that common and encouraging diversity can only make our sector stronger and more successful.”

“Women considering a career in our industry need to see there are real and exciting pathways open to them. All the entrants are fantastic examples that ANCA has been proud to showcase and celebrate, taking a step further to increase the visibility of female machinists!”

The winner, Lena Risse from Risse Tool Technology in Germany demonstrates the passion and dedication of women in the industry. Having completed an apprenticeship as a precision tool mechanic, she was the first female in a decade in her region to pursue a specialist master’s degree in the field.

Lena advocates for process optimization in production and hopes to inspire more women to enter this profession by setting a positive example of how women can excel in precision tool manufacturing.

Lena said, “I think it’s very important to give women a stage in our industry. Of course, it’s great to win this competition, but I am also grateful that this platform now exists. I enjoy showing with my work that not only men can grind top tools, but in some situations it’s women who find the better solutions.”

“I am the first woman to take up the Master’s degree as a precision tool mechanic at my university, Jakob Preh School in Bad Neustadt an der Saale. Even in training, female classmates are a rarity and I am fighting to break down typical gender stereotypes. Through my work, I hope to encourage many women to dare to do an apprenticeship in the skilled trades so that the industry will continue to develop in the coming years thanks to the clever ideas of courageous women.”

Female Machinist Award

Winner: Lena Risse, Precision Toolmaker at Risse Tool Technology GmbH

Lena has completed an apprenticeship as a precision tool mechanic immediately after her high school graduation and is pursuing her master’s degree. She is particularly interested in the optimization of production processes and hopes to inspire more women to enter precision tool manufacturing.

Second place: Christina Diamantidis, Tool Grinder CNC, Fraisa GmbH

Christina has been working at Fraisa GmbH for 13 years with a total of 18 years of experience in the industry. Christina is highly qualified and displays a profound passion for the profession of tool grinding. Most notably Christina is currently involved in a groundbreaking project in collaboration with a university, aiming to optimize the re-tooling process through digitization and the use of artificial intelligence. This innovative approach underscores the growing recognition of AI in this industry and its significant role in the future.

Third place: Kajal Bharat Padwal, Senior Production Engineer at Hrithik Tools PVT LTD

Kajal has been working at Hrithik Tools PVT LTDfor six years, specializing in operating ANCA machines. One project Kajal delivered was to create superior wear resistance and extend tool life where she worked closely with abrasive manufacturers to develop specialized grinding wheels for high-speed steel tool grinding. Kajal stands out with exceptional qualifications, is a dedicated team player and approaches her work with great enthusiasm.

Fourth place: Ellen Robson, Renovo Solutions

Ellen is a talented grinder from the northeast of England with great enthusiasm and passion. She dedicates herself to crafting cutting tools and has accumulated four years of experience in this field. Ellen demonstrated outstanding skills and solution-oriented business mindset and is someone who tackles challenges and always looks beyond the horizon to find innovative solutions. She sees herself as a role model for other female grinders, and we thank Ellen for her outstanding application.

For further information, please contact:

Amanda Bakun

Marketing & Communications Manager – Americas

248-497-1168

amanda.bakun@anca.com

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

Continue reading

Major Italian supplier of intralogistic metal handling systems emerges here

Matter SRL Managing Director Giuseppe Rotondi today announces the recent formation of Matter USA Corporation, the company’s new subsidiary for application engineering, sales and service for this major Italian builder of custom and modular Automated Storage & Retrieval Systems (ASRS) for the metals industry. Matter systems are found in mills, metal service centers and metals processing plants worldwide. The company recently exhibited its offerings at FABTECH in Chicago.

Matter systems comprise custom-designed Matter Pro automated intralogistic warehouses for automated storage and handling of large quantities of bar, profile, tube, billet, sheet and slab metal materials, as well as dies and other processing components. These automated warehouse systems are designed to optimize space by increasing the quantity of stored material per square meter, thereby maximizing the efficiency of handling and utilization of plant space. All Matter Pro systems are designed to customer specifications yet offer flexibility and myriad handling options.

Meanwhile, Matt Box systems offer modular and multi-purpose automated warehouse concepts, designed for smaller quantities of material. They are the preferred option for job shops, smaller production departments and specialty metals distributors.

As VP of sales Alec Banish explains, “The degree of automation in the market today is moving very quickly and our systems offer the North American market flexibility, turnkey materials handling and the safety of a totally automated system, plus the security of an under-roof operation, which significantly reduces material damage, and provides instant access to your inventory without human intervention.”

Matter is a global force in automated materials handling and storage systems (ASRS) for the metals industry, as the company assists its customers with full analysis of their production process, then executes the design, engineering, build, test, installation, commissioning and after-sales service of its systems. Matter uses leading-edge software and automation components in its designs. In use, a Matter system offers its users complete data tracking on all materials and product bundles to further the efficiency and effectiveness of a company’s ERP.

As Giuseppe Rotondi notes, “We are very enthusiastic for Matter USA. Our company has developed many innovative solutions for the metals handling market and the establishment of Matter USA will further enhance our presence in the North American market, bringing those solutions to many current and, I’m certain, future customers.”

Matter USA will be based in Texas and serve the North American market, operating in tandem with their longtime rep group, Robert Warnock Co., Inc.

Matter has several systems currently operating in North America at major pipe and tube producers as well as major metal service centers.

To view a variety of Matter systems in action, please visit: https://www.youtube.com/user/mattersrl

For more information on this development, please contact:

MATTER USA CORPORATION

1800 West Loop South

Suite 1740

Houston, Texas 77027 (USA)

Phone: 205-830-3337

info@matterusacorp.com