Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Centrisys/CNP has signed an exclusive U.S. distributor agreement with LIPP America Tank Systems, LLC for water, sludge and digester tanks. LIPP has a patented stainless steel digester system that allows digesters to be built on-site in less than two months. The short construction period and patented digester building system allow Centrisys/CNP to offer its clients cost-effective, high-quality digesters with a long life cycle. The LIPP product line compliments Centrisys/CNPs product portfolio by offering its customers solutions for resource intensification and resource recovery.

“Like Centrisys/CNP, LIPP is a highly innovative, privately-owned company. This partnership allows us to customize digesters and storage tanks with short delivery times and attractive costs,” said Gerhard Forstner, CNP President. “The distributor agreement enables Centrisys/CNP to retrofit even small wastewater treatment plants and convert them to resource recovery centers by recovering water, energy and nutrients.”

“We at LIPP America Tank Systems are honored and extremely excited to be a new partner with the Centrisys/CNP team,” said Al Lettinga, President/C.E.O. “We are confident that working together, we can make tremendous penetration within the municipal bioenergy and waste treatment market with our special LIPP double-fold tank technology. At LIPP America, as in the world markets, we stand out as a high quality and very unique tank technology. The LIPP double-fold and dual stainless plating system are a one-of-its-kind in the entire world market. Therefore, we are set apart against any liquid storage system in the market today.’

LIPP recently built a municipal anaerobic digester in Ohio and three more are currently being built in Michigan.

Centrisys/CNP supports global sustainability through its resource intensification portfolio with water and wastewater equipment and processes. Our systems are designed for simple operation using less energy, less space and fewer chemicals. Centrisys Corporation is a U.S.A. manufacturer of dewatering centrifuges, sludge thickeners and complete dewatering systems for municipal and industrial water and wastewater. Centrisys’ service department is a leader in global service, repair and parts for all centrifuge brands. CNP – Technology Water and Biosolids Corporation designs and supplies nutrient recovery and biosolids treatment optimization systems. CNPs key technologies are AirPrex® and CalPrex™, phosphorus recovery technologies that produce struvite and brushite fertilizers, and PONDUS, a Thermo-Chemical Hydrolysis Process (TCHP) which increases biogas production and digester capacity and reduces sludge volume and polymer consumption. CNP is a U.S. distributor for digester and storage tanks and hydrograv® adapt Variable Inlet System.

For more information, please contact:

Centrisys/CNP

9586 58th Place

Kenosha, WI 53144

262-654-6006

marketing@centrisys.com

www.centrisys-cnp.com

Jason Kleinhenz is one of many Exact Metrology employees at the company’s Cincinnati office, located at 11575 Goldcoast Drive. While he does not have an official job title at the company, Kleinhenz describes himself both as an engineer and as a trainer. His job duties include managing and performing training, as well as marketing and creating content for Exact Metrology.

His first work experience came at age 12, when he and his brother started their own lawn care business. To support himself during his time at the University of Cincinnati, he recalled working “almost every food/beverage position possible.” This included employment at the famous French restaurant Jean-Robert at Pigall’s. Kleinhenz also worked in the university’s Nanomedicine Development Center. As a paid intern, he built RNA nano-motors that would attach to cancer cells and inject healthy DNA. He further broadened his experience with a job at General Electric in Japan, working in the environmental health and safety department. After graduating with a degree in biomedical engineering, Kleinhenz remained at the University of Cincinnati performing research on the female pelvic floor for the Biomedical Engineering Department.

Kleinhenz started working in metrology in 2011, but had a 2-year hiatus. During that time, he worked as a Solutions Engineer at MHI Inc, a specialized heating manufacturer. He started working at Exact Metrology in 2015 as an applications engineer. Next, he took over the position of sales coordinator before handling his current tasks. According to Kleinhenz, “The best part of working in metrology is that one day you might be working on a rocket and the next day on a beautiful piece of art (and everything in between).” Regarding his most memorable experience at Exact Metrology, he mentioned his trip to Peru this past summer. During two weeks, he helped scan Peruvian artifacts for preservation and deliver school supplies to a rural community. “My mission in life is to relay joy, love and enrichment. Peru was a great experience because I was able to check the box of each of those, and the relationships and communities formed are invaluable.”

Besides his work at Exact, Jason started 2 companies. One delivers fresh cooked meals weekly while the other operates as a non-profit to raise money and “do good” for local area parks and communities through a hockey league. He also built and operates 2 donation-based services; a podcast studio and a gym.

Exact Metrology is an ISO Certified, AS9100, FFL and ITAR Certified Company.

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

For more information, please contact:

Jason Kleinhenz

Exact Metrology, Inc.

11575 Goldcoast Drive

Cincinnati, OH 45249

Phone: 513-813-4221

Mobile: 513-262-7097

www.exactmetrology.com

jasonk@exactmetrology.com

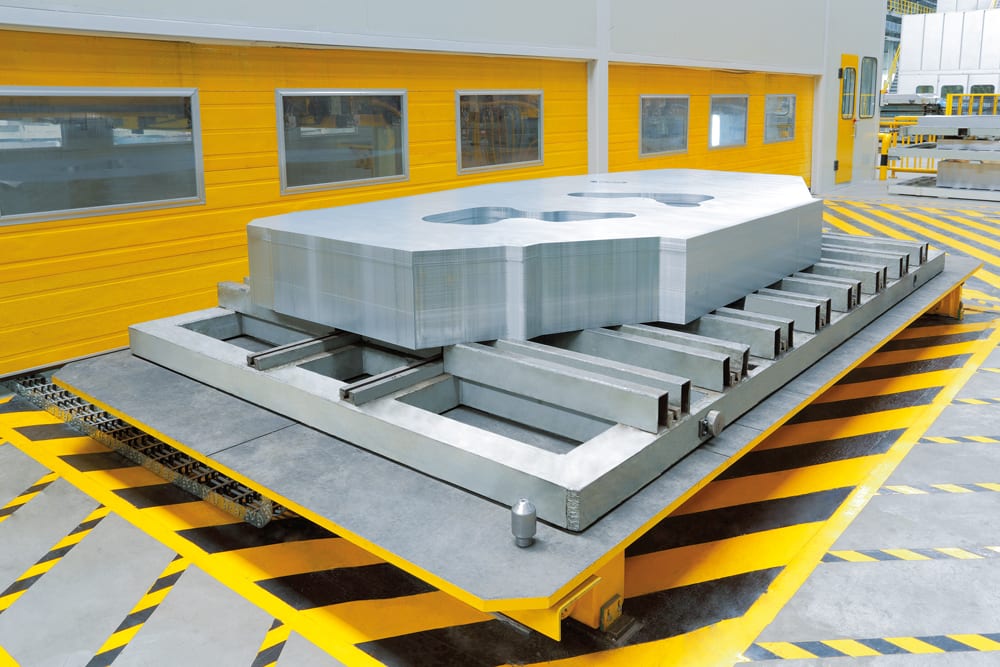

Canton, Michigan, December 2, 2019 – Customers from Germany, the US and China have already invested in laser blanking lines from Schuler. Recently, Schuler received another order from the People’s Republic—this one by one of the largest Chinese steel producers for a plant in Tianjin, as well as an order from a customer in South Africa. Around 50 visitors took advantage of Schuler’s invitation to learn about the benefits offered by the technology during two days in Heßdorf, Germany. They also had a chance to look at the actual system that will be delivered to China.

South African automotive supplier VM Automotive is expected to begin producing blanks for the plant of a high-end German automaker in South Africa (among other jobs) on a Laser Blanking Line 2.18 in the fall of 2020. The newly established blanking operations will handle the full scope of material logistics for the car manufacturer, thereby increasing the value in South Africa. By investing in this highly flexible laser blanking line, VM Automotive was able to gain the upper hand over competitors that use conventional blanking systems. Additional logistics centers are planned for other auto manufacturers in South Africa.

In 2014, a high-end German automaker ordered one of two laser blanking lines for mass production, and the equipment began producing two years later. “Our customer no longer has any dies for these blanks,” noted Martin Liebel, who manages the Schuler site in Heßdorf, a town located in the vicinity of Nuremberg. A highly flexible laser beam now performs the work formerly handled by the dies. This laser beam makes it possible to alter the blanking shape at the push of a button, whereas altering a blanking die can take several months, not to mention the accompanying costs for storage and maintenance. And when the set up time is taken into consideration, the overall equipment effectiveness (OEE) climbs to 80% for the laser blanking line, compared to just 65% for conventional press blanking lines.

With the system’s DynamicFlow Technology, a laser blanking line is up to 70% as productive as a modern servo blanking line with a press. “Output actually significantly exceeded our expectations,” said Liebel, adding that it had been possible to regularly increase output by a few percentage points with the help of a number of smaller measures. A proven cleaning process ensures that the system produces high-quality blanks which are also spotless—an important requirement for critical body shell parts. The same German carmaker went on to order two additional high-tech lines in 2017.

At roughly the same time, Schuler began developing a new concept featuring two laser heads instead of three. “We needed a basic machine that would also deliver solid, acceptable performance for the rest of the world,” said Liebel. The decision proved to be the right one, as evidenced by the orders for one Laser Blanking Line 2.18 each from China and South Africa this year. “The systems are becoming more and more dynamic, and the concept will win out in the end,” said a confident Liebel.

One of the things that makes these systems so dynamic is the distance control for the lasers. This control maintains a distance of 0.7 to 0.9 mm from the continuously moving coil and, where necessary, corrects the distance within fractions of a second to ensure that any residual surface irregularities in the sheet metal do not damage the heads. Liebel explained, “This axis is critical to the line’s output. Each coil contains residual waves. If I’m looking to blank at a rate of 100 meters per minute, I need to be able to respond extremely dynamically.”

Larger surface irregularities are eliminated by the straightener. “The straightening result is a key ingredient to a stable process, especially for the laser blanking line,” added Regional Sales Manager Justine Fonteyne. “To make this happen, we use the ‘Check2Flat’ system, which adjusts the crowning on the straightener rollers.” Either the visualization system makes a recommendation based on the adjustment system, which the operator must then review, or the straightener itself can provide a fully automated control. “It’s important to remove as much of the tension from the material as possible so that the metal doesn’t pop up during blanking. These types of systems help to ensure process stability.”

According to Liebel, another increasingly important aspect for carmakers is the intelligent capacity utilization of production facilities across the globe. “But it’s difficult to make a product somewhere else on short notice if you’re using a press blanking line. To do so, our customers first have to move the die, prepare it for shipment and then send it off.” If a supplier is producing the blanks, the scrap chutes or something else may not fit. “With laser blanking lines in the production network, all I have to do is send a data set for the desired part and make sure that the coil material is available on-site. If the system has available capacity, production can start one or two hours later. It’s really a huge advantage.”

Fonteyne’s coworker Berthold Jüttner offered another example: “One of our customer’s plant managers had a problem with a blanking press and had asked another plant manager if he would be able to cut a few blanks for him on the latter’s laser blanking line. He then immediately sent the drawings and had the coils brought to the site. Blanking began the next day.”

In addition to the newly achieved blank programming freedom, Jüttner saw another advantage in the line’s excellent dimensional accuracy, reproducibility and surface quality. “There are no burrs and the amount of cuttings is significantly less than in conventional blanking.” The so-called “angel’s hair” phenomenon is especially prevalent where blanks are cut from aluminum coils, and is also the reason why blanking presses regularly need to stop so that the dies can be cleaned. “This is no longer an issue with the laser blanking line.”

Laser blanking also makes it possible to support the material across its entire surface area. “We can nest the parts edge-to-edge on the coil and no longer need the 8 to 10 mm dividers required when using the blanking dies. For small cutouts, we can briefly open the belts and the scrap can drop into the scrap chute. On the new lines, the scrap and the usable parts are no longer separated using robots, but rather by an intelligent sorting system. This provides an additional boost in output.”

The growing amount of high strength steels used in automobiles is increasingly pushing blanking presses closer and closer to their maximum mechanical loads, adds Liebel, who noted: “When it comes to yield strengths, there are no limits in laser blanking. We have performed many tests and high-strength steels are no problem.” As Jüttner added, “The laser doesn’t care at all what’s under it.”

According to Liebel,” The bundled beam of light darts across the metal coil at speeds of up to 100 meters per minute and a thickness between 0.7 and 2.5 mm.” Before the year 2000, it was only possible to achieve blanking speeds of 4 or 5 meters per minute using CO2 lasers. Then the fiber laser made its triumphant entrance and opened up the possibility of laser blanking for the first time. This development wouldn’t have been possible with conventional gas lasers.”

In addition, noise emissions are much lower than with blanking presses. “If sound protection is installed on the laser blanking line, you’ll have to look very carefully to see whether the line is running or not,” Jüttner commented. He added that a person can have a completely normal conversation, as long as a press isn’t running next to them. The investment cost is also significantly lower, since the laser line is not as tall and also does not require an elaborate press foundation. “That’s a huge cost factor,” concluded Jüttner. The loop for the material buffer is also routed above ground. However, the laser line’s energy requirements are comparable to those of a press blanking line.

Schuler has developed a software package, the LBL Studio, designed to greatly reduce the operator workload required to program the laser cutting movement. “All you have to do is upload the drawing data and the program will calculate the best-possible contours, the possible nesting options and the optimum level of laser utilization,” Fonteyne said as she listed the software’s benefits. “This means that users can already define the laser movement contours and configure the transitions offline. The binding output quantities can also be predicted. After that, the data can be transferred to the control system, and production can be run exactly as configured.”

www.schulergroup.com/Laserblanking

About the Schuler Group – www.schulergroup.com

Schuler offers customer-specific cutting-edge technology in all areas of forming technology – from networked presses to press shop planning. In addition to presses, the product portfolio also includes automation and software solutions, dies, process know-how and service for the entire metalworking industry. Our customers include automobile manufacturers and automotive suppliers, as well as companies from the forging, household appliance and electronics industries. Presses from the Schuler Group mint coins for more than 180 countries. As a provider of innovative system solutions, we support our customers worldwide in the digital transformation of forming technology. In the 2018 fiscal year, Schuler generated sales of € 1 212 billion. Schuler AG, founded in 1839 at its headquarters in Göppingen (Germany), has approx. 6 600 employees at production sites in Europe, China and America as well as service companies in over 40 countries. The company is majority-owned by the Austrian ANDRITZ Group.

Schuler in Heßdorf was founded in 1962 as Hermann Schleicher GmbH, with the original headquarters in Erlangen, before joining the Schuler Group in 1990. The facility’s product portfolio includes automation solutions ranging from coil loading to end-of-line destacking. The most important areas it serves are the auto manufacturing, automotive supplier, and household appliance industries. The location employs approximately 350 people.

For further information on Schuler Inc., North America, please contact:

Guido Broder, Vice President of Sales & Marketing

Schuler Incorporated

7145 Commerce Blvd.

Canton, MI 48187 USA

734-207-7200

Guido.Broder@schulergroup.com

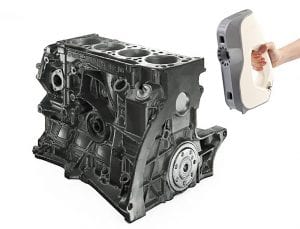

GMTA, the North American distributor of Profilator, has added new machines using the process modules it already supplies. Profilator is suitable when customers require complex machining processes to be carried out effectively, efficiently and with high precision.

Today, an operator working on a modern machine expects a flexible manufacturing process, short cycle times, reduced investment and running costs. With these requirements in mind, Profilator offers polygon & face slot machining, gear tooth pointing, chamfering and deburring, gear and spline cutting, shifter stop machining and Scudding®.

The polygon turning unit is used for castle teeth machining on automotive gearbox parts. The rotating cutterhead is synchronized with the workplace spindle and a front face coupling is produced with the carbide insert arrangement and the transmission ratio. With additional inserts on the same cutter head, the part can be deburred. In gear tooth pointing, the pointing tower can be used in both rotative and indexing modes. Settings and corrections are made through the new Ergo Control SIMPS® (Profilator Simplified Integrated Machine Programming System). For the chamfering and deburring of splines, gear wheels and shafts, Profilator uses the ZEM series gear deburring machines. This vertical, single spindle gear deburring machine offers clear advantages over conventional deburring machines. Gear cutting is used both for the Profilator rotative gear cutting with inserts and for hobbing. Through the application of Schlagzahn tools and carbide inserts, customers achieve the most economical manufacture of splines, gears, involute gears and front face gears. The shifter stop is synchronized so that the tool machines each tool flank. Lastly, Scudding® can be used for a wide range of symmetrical gear applications as well as non-symmetrical gear or profile applications such as belt pulleys and synchronize gears. The same machine can be used for internal and external Scudding® applications.

Profilator developed the S-type machine. This is a compactly and modularly designed, vertical single spindle pick-up gear cutting machine. Machines in the S Series are better than broaching and most applications feature a dry machining process. All machine components are designed for especially high static stiffness and optimal dynamic behavior. Furthermore, the machine’s twin spindle arrangement speeds up the process considerably. A control panel and a media container are installed on the rear of the machine bed. The workplace flow direction is variable. S-type machines are available in three sizes, namely Profilator S-150, Profilator S-250 and Profilator S-500. Profilator S-150 has a part diameter up to 150 mm, while Profilator S-250 and S-500 have a part diameter up to 250 mm and 500 mm, respectively.

For more information, please contact:

Walter Friedrich

President

GMTA

4630 Freedom Drive

Ann Arbor, MI 48108

+1-734-973-7800

walter@gmtamerica.com

www.gmtamerica.com

GMTA is the exclusive distributor for a number of top-quality German and other metalworking machine builders companies including Arnold, BvL, K+G, Praewema, Profilator, Rasoma, Samag and WEMA Glauchau. The company’s headquarters is located in Ann Arbor, Michigan with a subsidiary in Queretaro, Mexico.

Continue reading

Presentations were given by company personnel on September 13, 2019 in Ravensburg, Germany.

The company was founded in 1919 as a mechanical workshop by Anton Arnold. At the time, the company was considered a special welding plant for cast iron and aluminum. From 1950, under the leadership of Karl Arnold, the company developed contract turning for automatic turning parts. From 1969, the focus shifted to equipment construction and special machines for various industries. In 1985, the first laser system was built for ZF Friedrichshafen.

While competitors need to adjust beam guidance after every mirror change, the change was a matter of a few minutes for Arnold and production could be continued immediately. This production-oriented thinking has continued with the company’s machine designs. All important components were geometrically overdetermined and could only be installed with proper production.

In the first years, Arnold focused purely on welding machines. The aim was always to build a single block machine, possibly supplemented by conveyor belts for component supply and removal.

Even though there were isolated laser projects parallel to the classic special machine construction of the first few years, the main focus of the company since the 1990s has been the construction of laser systems. The first few laser applications were used in gear wheels, heat exchangers, shaft welding with induction and starter contacts for incandescent lamps.

New technology developed by Arnold features systems for rotary parts such as a double station and the M800/1500 units. In addition, the company offers new concepts of 3D systems used for welding, cutting, powder application welding, hardening and polishing. The newest flex cell and gantry systems feature up to 7 axes working simultaneously. Lastly, the company developed two extreme expansion stages of gear wheel welding systems. These are fully automated systems.

Functional extensions on the current machines include robots, conveyors, press stations, additional axes, induction preheating, UMH preheating, brushing stations, runout test stations and ultrasonic testing.

Current projects include Melato (manufacture of pressing tools from layered, laser-cut sheets), POLAR (laser polishing), KLASSE (laser cutting and solidification with an optic in a gantry system) and GeKoWig (titanium powder application welding in a protective gas atmosphere).

Together with IWS, Arnold has developed Remoweld Optic, a high-frequency optic scanner. With this scanner, copper, aluminum and mixed compounds can be welded virtually splash-free. With IWS, the company exhibited the optic scanner at various trade shows. The response has been very positive and several interested parties have approached IWS with potential applications.

In conclusion, Arnold has undergone many transformative changes in the past 100 years and it continues to expand its capabilities to better serve its customers.

For more information, please contact:

Walter Friedrich

President

GMTA

4630 Freedom Drive

Ann Arbor, MI 48108

1-734-973-7800

walter@gmtamerica.com

GMTA is the exclusive distributor for a number of top-quality German and other metalworking machine builders companies including Arnold, BvL, K+G, Praewema, Profilator, Rasoma, Samag and WEMA Glauchau. The company’s headquarters is located in Ann Arbor, Michigan with a subsidiary in Queretaro, Mexico.

Continue reading

Daniel Fernandez-Davila has made this trip for 21 years, accompanied by his students and residents from Wayland, Massachusetts. Besides Kleinhenz, the team included Antonia Hieronymous, Rachel Lorenc and Nick Ciorogan. Daniel and Antonia started a non-profit called Loose Change. Based in Wayland, Massachusetts, Loose Change organizes an annual week-long event to gather donations from the community. As the name implies, residents donate their spare change to the organization. All of the funds are used to buy books and educational materials for Peruvian schoolchildren. In addition to providing school supplies, the non-profit also builds/renovates schools. In addition, Fernandez-Davila made it his mission to scan a South American monolith and several artifacts, so that the information could be used in archeological research and also in presentations for museums. Lorenc participated on behalf of her mentor, Dr. Lisa DeLeonardris at Johns Hopkins. Dr. DeLeonardris said that “The purpose of this trip was first and foremost to document the artifacts (shaman vessels and monolith) with hopes of better presenting and/or publishing iconographic analysis.” Ciorogan, a professional photographer and videographer, completed filming for the movie “My Teacher.” With a release date of 2020, the movie focuses on Fernandez-Davila’s work in the Peruvian jungle.

Artec 3D, a world-renowned developer and manufacturer of professional 3D scanners and software, provided a Space Spider and Exact Metrology brought an Eva scanner. The Space Spider is a high-resolution 3D scanner based on blue light technology. It is ideal for capturing small objects or intricate details of large industrial objects in high resolution and with great accuracy. Also supplied by Artec 3D, Eva is used for making a quick, textured and accurate 3D model of medium sized objects. It scans quickly, capturing precise measurements in high resolution. Not only does it capture almost any type of object (including black and shiny surfaces), but it is used in numerous industries including quality control, heritage preservation, forensics, automotive, medical, aerospace and prosthetics.

The data was processed in Artec Studio 14 and 10 by Exact Metrology personnel, namely Chris Lafferty, Greg Hoeting and Jason Kleinhenz. Then, the information was given to Chris Catlett at 3D Systems. The company supplies the best range of 3D printers, materials and application expertise. 3D Systems was used to turn 3D data into PDFs, CAD files and short movies. To complete this task, Exact Metrology employed Geomagic, their leading 3D software for digital reconstruction of the ruins.

Through this project, Exact Metrology showed that they can scan anything, anywhere for educational and research purposes, as well as build partnerships with the local community. The right side of the scanned monolith was dated between 400 BC and 200 AD, while the left side was estimated to date between 700 and 14700 AD. The artifacts are estimated to be between 500 BC and 100 AD. Exact Metrology plans to turn the data into solids by possibly 3D printing a few, turn the solids/meshes into user-friendly interactive tools or turn them into short videos. Furthermore, the company is preparing to present two scientific papers with Johns Hopkins at the 60th Annual Andean Studies Meeting in Berkeley, California in 2020. The videos will be supplied to museums in Peru.

To sum up the experience, Kleinhenz said, “The true value from this project came from the struggle, relationships built and the communities engaged. We’re excited to partner with great people and organizations to further the archeological research and philanthropic work. The community growing from this endeavor is really passionate and driven to deliver results – from my perspective, I’m grateful that I get to be a part of that movement, show Exact Metrology’s capabilities and partner with great people.”

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

Artec 3D is an international company, headquartered in Luxembourg, with subsidiaries in the United States (Santa Clara, California) and Russia (Moscow). Artec develops and produces innovative 3D solutions and products. Artec has a team of professional experts in the collection and processing of 3D surfaces as well as biometric facial recognition. Artec’s products and services can be used in many industries, such as in engineering, medicine, media and design, entertainment, fashion, historic preservation, security technology and more.

For more information, please contact:

Steve Young

Exact Metrology, Inc.

11575 Goldcoast Drive

Cincinnati, OH 45249

Phone: 614-264-8587

Local: 513-831-6620

www.exactmetrology.com

stevey@exactmetrology.com

Exact Metrology, a leading metrology services provider, offers customers and interested parties information on 3D scanning services, CT scanning, metrology equipment and software solutions on their website at www.exactmetrology.com

The company’s 3D scanning includes inspection scanning, CT scanning, reverse engineering, long range scanning and scan to CAD.

CT scanning (computed tomography) is used in aerospace, archeology, automotive, castings, die cast, electronics, food, molds, personal products and plastics. Confident in its ability to obtain 3D views from inside a part, Exact Metrology issued a GOM CT challenge. It invited users to send scanned data they’ve obtained from other technologies. If the results obtained from GOM CT weren’t superior, the company would send the user $100 with no strings attached. In addition, Exact Metrology is a representative and seller in North America of Procon X-ray GmbH, a German developer of x-ray inspection equipment for industrial applications and university/scientific research.

Besides GOM and Procon, Exact Metrology features various leading manufacturers such as: Artec 3D, Geomagic Capture, Hexagon, InspecVision Planar, Leica Geosystems, Leica HDS, Polyrix, Raytech and Surphaser.

Along with its equipment, Exact Metrology offers several software options to complement their offering. This includes Artec Studio, Leica Geosystems Cyclone, Hexagon, Geomagic, GOM Inspect, Polyworks, Volume Graphics and 3D Reshaper.

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

For more information, please contact:

Steve Young

Exact Metrology, Inc.

11575 Goldcoast Drive

Cincinnati, OH 45249

Phone: 614-264-8587

Local: 513-831-6620

www.exactmetrology.com

stevey@exactmetrology.com

Dean Solberg

Exact Metrology, Inc.

20515 Industry Avenue

Brookfield, WI 53045

Phone: 262-533-0800

Local: 866-722-2600

www.exactmetrology.com

deans@exactmetrology.com

New brochure details wide assortment of components for machine tool builders, integrators and end users in all metalworking sectors

Suhner, a leading manufacturer of automated tooling components, slides and multi-spindle components, has expanded its product offering, detailed in a new brochure the Machining Division. Known best for its drilling and tapping units, milling units, machining slides and other specially designed devices for high production work, the company continues to experience increased demand for its machining products and services. As detailed in this new brochure, the Suhner Machining Division offers several new and enhanced products including flex shaft multiple drive system, QUILLmaster Drilling Units, TAPmaster tapping units, stationary and self-feed, flexible-shaft driven drilling units, POLYdrill multiple spindle heads, SPINDLEmaster machining spindles and SLIDEmaster. All are designed for high-production work, especially in the automotive and other mass component market sectors.

The flex shaft multiple drive system works with MULTImaster drilling units. It offers up to 8 driving units, a motor rating of 5 HP (3.7 kW) standard and an output speed between 46-9,320 rpm. Optional features include a larger motor and a right angle drive.

QUILLmaster drilling units are self-fed drilling units, motor driven and pneumatic-fed. The total stroke is up to 4.9 in. (125mm), same as the controlled stroke. Furthermore, the QUILLmaster has a drilling capacity with diameter up to 0.8 in. (20 mm) for mild steel and a motor rating between 0.3-5 HP (0.22 kW -3.7kW). Tool holding options include ER, ST, ISO/CAT, HSK & custom.

Suhner stationary and self-feeding, flexible shaft driven drilling units feature total stroke up to 3.1 in. (80 mm) and controlled stroke up to 2.9 in. (75 mm). The flexible shaft drilling unit has a drilling capacity with diameter up to 0.47 in. (12 mm) into mild steel. Available tooling holding options are ER, ST and custom.

TAPmaster includes CNC or leadscrews tapping units. Leadscrew tappers offer a total stroke up to 3.9 in. (100 mm), a tapping capacity up to .787 in. (20 mm) and a thread pitch between 64-13 TPI (0.4-1.75 mm). Available options are custom leadscrew pitches and crash protection on some units. Servo tappers feature a total stroke up to 5.5 in. (140 mm) and a tapping capacity up to .787 in. (20 mm).

POLYdrill multiple spindle heads include adjustable and fixed spindle heads. Drilling capacity ranges from 0.06 to 1 in. (1.5-25 mm). Minimum hole spacing is 0.27 in. (7 mm), while maximum hole spacing is limitless. Tooling options include ER, ST, JT33, Weldon and custom. Additional features are axial and radial compensation and custom layout/spacing.

The company’s SPINDLEmaster features precision turning spindles and slide units. The drilling capacity has a diameter up to 1.6 in. (40 mm) into mild steel and a motor rating between 0.75-10 HP (0.56 kW-7.5 kW). Tool holding options include ER, ISO/CAT, HSK, Weldon and ABS. Available options are coolant through automatic tool charger, taper roller or angular contact bearings and higher capacity spindles.

Lastly, the SLIDEmaster offers pneumatic, hydraulic and servo (ball screw) slide types. Stroke options include 6.3, 12.6 and 18.9 in. (160, 320 and 480 mm). Additional options include custom stroke lengths and higher capacity slides.

For more information, please contact:

Suhner Industrial Products, LLC

43 Anderson Road SW

Rome, GA 30161

Phone 706/235-8046

Fax 706/235-8045

info.usa@suhner.com

www.suhner.com/en/

Attention: Lee Coleman

Exact Metrology attended this career expo to grow their relationship with schools and businesses in the area, recruit potential employees and educate students on Exact Metrology’s technology offerings. The latter was achieved using Artec 3D, a world-renowned developer and manufacturer of professional 3D scanners and software. The Artec Eva™ is a handheld scanner ideal for quick, textured and accurate scans. Artec Eva doesn’t require markers or calibration and the scanner captures 16 frames per second. These frames are automatically aligned in real time, making scanning easy and fast.

Exact Metrology is an ISO 9001:2008, AS9100, FFL and ITAR Certified Company.

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D scanning, reverse engineering, quality inspection, product development CT scanning and services and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

Artec 3D is an international company, headquartered in Luxembourg, with subsidiaries in the United States (Santa Clara, California) and Russia (Moscow). Artec develops and produces innovative 3D solutions and products. Artec has a team of professional experts in the collection and processing of 3D surfaces as well as biometric facial recognition. Artec’s products and services can be used in many industries, such as in engineering, medicine, media and design, entertainment, fashion, historic preservation, security technology and more.

For more information, please contact:

Steve Young

Exact Metrology, Inc.

11575 Goldcoast Drive

Cincinnati, OH 45249

Phone: 614-264-8587

Local: 513-831-6620

www.exactmetrology.com

stevey@exactmetrology.com

Market leader in sludge and industrial wastewater treatment equipment brings new ideas to market at major Chicago event

During the event, Centrisys personnel will conduct three in-booth presentations. On Monday, September 23 at 3 p.m., Centrisys/CNP shares an update on the first U.S. installation of a Passavant® hydrograv® adapt system that eliminates the need for clarifier systems. An in-booth demonstration unit will be on display. On Tuesday, September 24 at Noon, the company announces the CalPrex Pre-Digestion WRF project results and at 3 p.m., they talk about the recent THK installation updates.

The second session is on Wednesday, September 25 at 2 p.m. in Room S505A, where Menachem Tabanpour, CNP Vice President of Business Development, presents his paper, “High Efficiency Calcium Phosphate Recovery Technology at the Madison Metropolitan Sewerage District: Stability Metrics, Design Optimization and Performance.”

Stop by Booth 7708 and 7711 to learn more about the Centrisys/CNP technology.

For more information, please contact:

Centrisys/CNP

9586 58th Place

Kenosha, WI 53144

262-654-6006

marketing@centrisys.com

www.centrisys-cnp.com

Michele Whitfield or Jessie Jones