Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

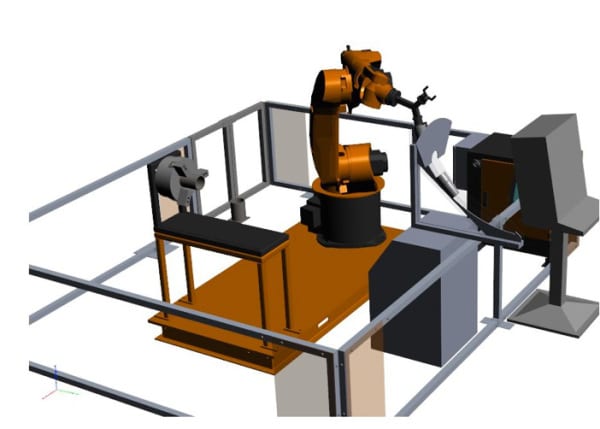

CHICAGO — At this year’s International Manufacturing Technology Show (IMTS) in Chicago, Siemens will demonstrate its recent collaboration with KUKA Robotics. In the Siemens booth E-5010, a KUKA robot will be articulating parts, simulating the operation on a CNC machine tool. Key to this development is the machine builder’s ability to integrate mxAutomation from KUKA directly through the Siemens Sinumerik CNC platform, thereby allowing the operator of the machine to run both the machine tool and robot from the single control panel.

The motion sequence of the robot is entirely engineered within the Sinumerik 840D sl CNC, then transferred by the 840D sl’s PLC function to the mxAutomation interpreter on the KR C4. All program changes to a six-axis robot can easily be input on a second channel of the CNC and fully operated. This scenario provides the ability to not only run a machine tool’s automation sequence more efficiently, but also make more changes on-the-fly to minimize machine downtime, with no special knowledge of robot programming language.

During the operation of the machine tool, all changes made can be visualized directly on the CNC screen, further minimizing operator actions. Siemens is the first CNC supplier to show this capability for single-screen operation of the machine tool and robotic materials handling on the CNC.

In operation, the KRC4 integrator and mxAutomation convert the robot language into the same commands used for multi-axis machine tool functions. A single Profinet cable runs between the robot and the CNC. According to KUKA’s Andreas Schuhbauer, key technology manager for machine tool automation (Augsburg, Germany), “mxAutomation allows the machine tool builder a single I/O language for integrating robotics on the CNC, while the end user operator can run both the machine tool and the robot from a single screen on the control.” mxAutomation for Sinumerik CNC was a joint development between KUKA and Siemens. KUKA created plug-in function modules for the Siemens Step 7 PLC engineering software and provided its robot knowledge to Siemens for creation of the second channel logic on the CNC, Andreas Schuhbauer further noted. All safety functions and test functions for load / unload, brake test, gripper, robot communication and safe operation of the robot are provided through the Siemens Profinet and Profisafe platforms.

Future developments for mxAutomation are planned, including a wider application range for robots in the CNC machine tool environment.

Join the user community by following us on Facebook: www.facebook.com/SiemensCNC and talking to us on Twitter: www.twitter.com/siemens_cnc_us. Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability.

For more information on this story, please contact

SIEMENS INDUSTRY, INC. DRIVE TECHNOLOGIES MOTION CONTROL MACHINE TOOL BUSINESS

390 Kent Avenue Elk Grove Village, IL 60007

Phone: 847-640-1595 Fax: 847-437-0784

Web: www.usa.siemens.com/cnc

Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communication

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability.

Continue reading

Getting started with live tools…

A flexible tool adapter system can be a big time and money saver, if properly utilized and properly designed for maximum power transmission and accuracy in alignment.

When any metalworking manufacturing facility, whether captive or job shop, makes the substantial investment in a new lathe, they are often looking for ways to streamline the manufacturing process. The smarter you are when choosing the live tools for your job, the more efficient the machine becomes. Finding a supplier of live tools who offers high-quality, high-performance products that will allow you more flexibility on the first big job and into the future in your operation is the key.

The first tool feature to consider is the output needed. Standard ER output or quick-change? Do you need coolant through the tool capabilities? Does the tool meet your requirements for precision and performance, including the necessary torque output to complement the machine? Are the tools designed according to the specifications of the lathe manufacturer?

When you look at an ER output, does it give you enough flexibility or do you need a more flexible machining system that will allow you to use the same tool for different applications. If more flexibility is required, then you may want to consider tooling with a system that features adapters for a variety of tools without the cost of new complete toolholder assemblies for each tool needed. However, when you look at such systems, be sure they feature a rigid polygon drive system design to prevent power transmission and alignment issues. Such systems seem appealing, because the live tool stays in place and only the adapter and collet get changed out with each new tool. However, less sophisticated though inexpensive systems will compromise the accuracy of your work. At that point, the few dollars saved will mean very little, compared to the scrap and downtime resulting.

If changeover time is critical, such as when working on a “family of parts,” the option of a true “quick- change system” might be more

A true quick-change system can be set offline and quickly installed, but it must be considered in light of today’s AND tomorrow’s workload.

beneficial. Adapters can be set offline and ready to go for minimal changeover time.

When coolant-thru tools are selected, it is imperative you first check the machine specifications to be sure your tool is capable of handling the coolant pressure of the machine. In general, your internal coolant live tools should be able to handle 1000 psi or more.

If your live tool is constructed with large, high accuracy bearings, the tool will have excellent rigidity and premium cutting performance, with minimal runout. (0.0002” or 0.006mm is a desirable goal.) The bearings, combined with ground, paired and high accuracy gears, make for tools that are consistent and long lasting. Bore tolerance is absolutely key in maintaining proper bearing load and this factor should never be compromised.

In addition, you should consider the many applications that can be accomplished with the proper live tool. You can purchase speed increasers for higher rpm, gear reducers for added torque, adjustable angle tools for compound angles, multiple-spindle tools for additional capacity, or gear hobbing tools for spline or gear cutting. Most of those items are standard catalog devices, but one more piece of advice: never shy away from the custom tool, when appropriate and justified by the job you have in-shop today, as well as the ones you might have tomorrow. A good tooling supplier will work with you to produce custom tools at reasonable prices, but the supplier must be very reliable, so look for one with grinding, finishing and perhaps even heat treating in-house or very closely monitored, to do such work. Additionally, be certain the supplier has local support and tools can be repaired or reworked quickly and correctly.

The workpiece materials are always a driver. Those of you doing medical machining know this well. Buying a less expensive or lower featured tool to work cobalt chromium and titanium is a really bad idea, to be blunt.

Custom tools, though usually dedicated to a particular application, can be the best solution, IF the design and construction of the tool is solid and the application engineering and after-sale support is available locally to service it.

On a practical level, always check the supplier for inventory and source of supply. Today, when your customers are demanding faster response times and more cost off-loading, you can expect the same from your tooling supplier. Likewise, application and engineering assistance should be available from local sources to support your tool choices.

The bottom line is the bottom line for most of us today. However, always consider the future jobs when purchasing tooling systems for your new and existing lathes. What might seem a bargain might not be, after the first big job is completed.

DIN and ABEC standards are the norm in industry and your supplier should be willing to supply all necessary documentation on request. Shortcuts on quality are never, repeat never, worth the short-term savings.

I hope this short primer on tooling will assist you in equipping your next machines.

For addition information or inquiries, please contact:

Preben Hansen, President

HEIMATEC INC.

16 E. Piper Lane Suite 129

Prospect Heights, IL 60070

Phone: 847-749-0633

Fax: 847-749-2445

Email: info@heimatecinc.com

Website: www.heimatecinc.com

—

Heimatec is an international tooling manufacturer, based in Renchen, Germany. Its experienced staff is dedicated to providing customers the most innovative tooling technology possible. In 2010, the company opened Heimatec Inc. in Prospect Heights, IL, near Chicago, to serve its growing North American customer base with sales and service, plus an extensive inventory of products. Heimatec serves the auto, aero, medical, off-highway, rail, energy, woodworking, composites and other industries, as well as an ever-increasing number of machine tool OEM’s worldwide.

Continue readingTo everything, there is a REASON…turn, turn, turn…

Here’s your best reason to stop by our booth:

At this year’s IMTS, Heimatec will display its live tooling in a unique way…a live demo on a rotating machine tool turret. Come and see the show!

Heimatec, a world leader in live tools, angle heads and multi-spindle drill heads, today announced immediate availability of its newest development, recently unveiled for IMTS.

U-tec is the company’s patented flexible tool adapter system that allows a standard ER output live tool to accept various adapters for different applications. This allows users the ability to have quick changeover of tools on almost any lathe, using a single live tool, without having to commit to a quick-change system on the initial purchase. A facemill adapter, for example, can be quickly positioned into the standard holder, without the need for a completely new base being installed. This significantly reduces inventory costs as well as changeover time, for the busy shop.

The U-tec system, according to Heimatec Inc. President Preben Hansen, “…represents a real improvement in lathe and mill/turn tooling design. U-tec allows great user flexibility, while a polygonal drive system ensures extremely high power transmission stability and faster set-up with absolutely no loss in performance or accuracy, because the live tool base remains in position and only the adapter and collet get swapped.”

He went on to explain the unique collet nuts on the U-tec system have internal threading for rigid mounting and that this new tool adapter system enables the actual cutting tool to be brought into closer proximity to the bearing, thus further improving performance in use. This benefit results from the short and compact tool length design. Internal coolant up to 2000 psi(140 bar) is provided standard.

Every adapter in the U-tec system comes complete with any necessary clamping nuts and adapters are immediately available in face mill style, ER extensions, side lock, shrink fit, hydraulic and blank.

The U-tec system is available for all major turning machines on the market today. Heimatec currently manufactures over 10,000 live tool types.

For further information and literature on this new product, please contact:

Preben Hansen, President

HEIMATEC INC.

16 E. Piper Lane Suite 129

Prospect Heights, IL 60070

Phone: 847-749-0633

Fax: 847-749-2445

Email: info@heimatecinc.com

Website: www.heimatecinc.com

—

Heimatec is an international tooling manufacturer, based in Renchen, Germany. Its experienced staff is dedicated to providing customers the most innovative tooling technology possible. In 2010, the company opened Heimatec Inc. in Prospect Heights, IL, near Chicago, to serve its growing North American customer base with sales and service, plus an extensive inventory of products. Heimatec serves the auto, aero, medical, off-highway, rail, energy, woodworking, composites and other industries, as well as an ever-increasing number of machine tool OEM’s worldwide.

Continue readingBill Hunter assumes 100% ownership of pioneering company in automatic matchplate molding machinery for sand casting

Schaumburg, Illinois (USA)-Hunter Automated Machinery today announced the completion of an asset buyout of the company and all its foreign subsidiaries by current President Bill Hunter. In his words, “We have successfully crossed the bridge of generational transition with this arrangement.” Mr. Hunter bought the assets of the company held by his three sisters, Dianne, Linda and Heather. All were the children of Al Hunter, the late founder of the company that began building the automatic matchplate molding machine Al invented, in 1964. Today, Hunter machines and mold handling lines are operating in foundries worldwide. Hunter operates plants in the USA, Brazil and China. The company has European headquarters in Italy and regional offices in India.

Karen Hunter, corporate secretary, Bill Hunter, president and John Purtill, corporate attorney at signing

Bill Hunter noted, “I am very thankful to my sisters, who worked closely with me on this agreement, allowing us to keep the company in the family. Likewise, I will always honor the memory of my father, who taught me much about this business and left a legacy of innovation and achievement in the global foundry market. We fully intend to continue and build on the company’s long-standing traditions of technology, quality and service to the industry.”

The agreement was finalized on June 27, 2012.

For further information on this announcement, interested parties may contact:

HUNTER AUTOMATED MACHINERY CORPORATION

2222 Hammond Drive Schaumburg, IL 60196

Phone: (847) 397-5110

Fax: (847) 397-8254

Email: info@hunterfoundry.com

Attention: Bill Hunter, CEO

Web: www.hunterfoundry.com

Connect with Hunter Foundry online:

Texas foundry buys new equipment, including Hunter XL matchplate molding machine, to respond to customer needs with fast pattern changes, shorter runs and on-the-fly flexibility in job scheduling, deliveries

Schaumburg, Illinois (USA)-In the heart of Limestone County sits Coolidge, Texas, halfway between Dallas and Houston. This classic American small town is home to another classic, Frazier & Frazier Industries, a ductile and gray iron foundry, established in 1972 by C.W. Frazier as a traditional cope-and-drag sandcasting operation with two squeezers and run today as a formidable shop by Plant Manager Will Frazier. An ISO 9002 Certified process operation, F&F combines the best of the old ways with the newest casting technologies and equipment in the market. As Will Frazier points out, “This is one of the biggest reasons we’ve continued to prosper, while so many other foundries have disappeared. We recognize what works and what doesn’t, to best suit our current business and market conditions.”

Once a heavy production shop, F&F today continues to support their large batch customers, but has reshaped the business model in many ways, according to Frazier. “We have traditionally worked in pieces from a few ounces up to 150 pounds or more. The large runs were more typical in days past, while we saw a new business environment emerging, several years ago, when the market began to decline overall.” He continued to explain how many of the company’s traditional customers began to reduce their inventories and thus placed shorter run orders with much tighter lead times. In something of a “perfect storm” scenario, this combination of increased job numbers and more urgent shipping requirements literally changed the pace of business at F&F. Frazier notes, “It’s not unusual for us to come in on a Sunday to finish a job for a customer who really needs it…and we rarely charge a premium, because we know how tough things are, for most of our accounts.”

While the oil & gas market applications are prominent here, as they are with most foundries in the region, F&F currently sells to end product manufacturers for the automotive, agricultural, wind energy, municipal water works and other market segments, a strategy that has helped to maintain a better balance in this shop’s workload. With its own sales force plus several manufacturers’ rep organizations in the field, Frazier & Frazier boasts customers in a wide variety of markets and as far away as Indiana, a relatively rare achievement in the foundry business, especially when larger, heavier workpieces are involved.

With over 8000 patterns in-house, F&F today experiences as many as 15 pattern changes per day per machine on the floor. This further complicated the job scheduling and work flow. Will Frazier and his team of Bob Pranger, general manager and Harlon Easton, vice president of sales, quickly saw the need for more automation in the machinery lineup.

F&F still does hand-rammed oil and air set cores, but over the years they’ve acquired automatic coresetting equipment, as well as automated molding machines, including the most recent purchase, a Hunter XL2024 automatic matchplate molding machine, which is used with the already in-place Hunter mold handling turntable system at F&F, as are other molding machines here. Three melting units feed the certified chemically correct iron to the molding stations. Currently, this shop does approximately 70% of its work in ASTM Class 60-100 ductile and 30% in Class 15-50 gray iron.

The XL2024 is a fully automated matchplate molding system, using gravity-fill technology pioneered by Hunter. It produces sand molds up to 20” x 24” with shallow 6-1/2” cope and 5-1/2” drag (165mm/140mm) at 180 cycles per hour, using 400 lbs. (181kg) of sand. Variable squeeze surface pressures to 142 psi (10kg/cm2) can be achieved in production.

This latest Hunter machine continued the tradition of leading-edge sandcasting technology used at Frazier & Frazier. Although several generations of Hunter and other brands of machines have been used here, when a new machine was planned, Will Frazier notes there were some key criteria to be met. “We’d been having critical problems with another machine builder, getting parts and service. We always knew the Hunter folks were excellent in those areas based on past experience, plus they were willing to provide considerable application engineering assistance and set-up help with the new machine. Coupling that with their stability as a company and great reputation in the world foundry market, we looked at all our options and settled on the XL2024.” Frazier further cites his long relationship with Hunter’s Mike Hughes as a factor. “Mike came down here several times to help us and, since the machine has been up and running, he’s stayed in close touch with us, even though we’ve had no performance issues with the machine.”

Will Frazier also points out that, currently, over 20% of the orders at F&F are rush and the quick changeover time of the Hunter machine makes it a highly productive piece of equipment and a definable competitive advantage in the market for his shop.

Frazier & Frazier provides its customers with metal castings as well as CNC machining, heat treating and galvanizing services, when needed. The shop has a fully equipped quality inspection department, highlighted by CMM and other state-of-the-art lab apparatus.

For further information on this story, interested parties may contact:

FRAZIER & FRAZIER INDUSTRIES, INC.

817 South First Street P.O. Box 279

Coolidge, Texas 76635 USA

Phone: 254-786-2293

Fax: 254-786-2284

Web: www.ffcastings.com

Email: willfrazier@ffcastings.com

Attention: Will Frazier, Plant Manager

Or

HUNTER AUTOMATED MACHINERY CORPORATION

2222 Hammond Drive Schaumburg, IL 60196

Phone: (847) 397-5110

Fax: (847) 397-8254

Email: info@hunterfoundry.com

Attention: Bill Hunter, CEO

Web: www.hunterfoundry.com

Connect with Hunter Foundry online:

Wisconsin foundry adding value to parts produced

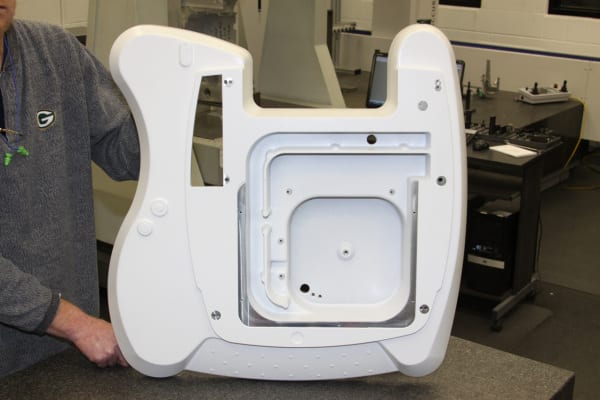

Watry Industries LLC, a large permanent mold aluminum foundry located in Sheboygan, Wisconsin, takes pride in working closely with its customers to co-develop and optimize casting design. In addition to offering casting design assistance and permanent mold casting production in its 172,000 square foot facility, Watry also performs heat treating, precision machining, powder coating and assembly operations in-house.

Watry Industries LLC, a large permanent mold aluminum foundry located in Sheboygan, Wisconsin, takes pride in working closely with its customers to co-develop and optimize casting design. In addition to offering casting design assistance and permanent mold casting production in its 172,000 square foot facility, Watry also performs heat treating, precision machining, powder coating and assembly operations in-house. Watry worked closely with its customer to assist in the design process for this part, as well as two other castings used on the same program, from concept through tooling and into production. Several other production processes were considered for making this part, including injection molded plastic, structural foam, plastic cowling over steel fabrication and several casting processes including sand cast, permanent mold and high pressure die cast. After investigation, mechanical strength concerns eliminated some of the plastic construction methods and a thorough cost analysis eliminated the fabrication options as being too expensive. Aluminum castings had a proven track record in similar applications, and a cost analysis was done to compare the various cast processes. Based on the combination of part cost and tooling cost (total cost of ownership) the result of all these studies was that permanent mold was selected as the best process for the application.

Watry worked closely with its customer to assist in the design process for this part, as well as two other castings used on the same program, from concept through tooling and into production. Several other production processes were considered for making this part, including injection molded plastic, structural foam, plastic cowling over steel fabrication and several casting processes including sand cast, permanent mold and high pressure die cast. After investigation, mechanical strength concerns eliminated some of the plastic construction methods and a thorough cost analysis eliminated the fabrication options as being too expensive. Aluminum castings had a proven track record in similar applications, and a cost analysis was done to compare the various cast processes. Based on the combination of part cost and tooling cost (total cost of ownership) the result of all these studies was that permanent mold was selected as the best process for the application.Dale Christel

Sales Manager

Watry Industries LLC

3312 Lakeshore Drive

Sheboygan, WI 53081

Office: 1-920-457-4886

www.watry.com

dchristel@watry.com

Connect with Watry Industries online:

Tooling supplier expands headquarters, offers specific machine tool brand product lines, detailed in new full-specification catalogs

Heimatec, Inc., the North American operation for a world leader in live tools, angle heads and multi-spindle drill heads, today announces it has relocated to substantially larger headquarters near Chicago.

Heimatec will display a complete line of high-quality live tools for all major turning machine brands, as well as angle heads for milling applications, during the upcoming IMTS 2012 in Chicago. The company will feature its unique HT quick-change system and patented u-tec flexible machining system.

According to company president Preben Hansen, “We made this move to increase our inventory and our staff to better serve the growing ranks of our customers, both end users and distributors alike.” The new location is in Prospect Heights, Illinois, previously home to Heimatec.

It represents a 50% increase in the office and warehouse capacity for this growing supplier to the North American machine tool market. Hansen anticipates hiring new staff for the facility soon.

In related news, Heimatec has introduced complete lines of tooling, each designed for specific brands of machine tools, including the major builders of turning machines used in the North American market, such as Haas, Okuma, Mazak, Spinner, Miyano, Nakamura and others. This full-specification literature by machine brand is immediately available from the company in print and online pdf versions. Interested parties should contact the company. Heimatec also offers its new corporate capability brochure, in which all lines are presented.

For further information on this news release, please contact:

Preben Hansen, President

HEIMATEC INC.

16 E. Piper Lane Suite 129

Prospect Heights, IL 60070

Phone: 847-749-0633

Fax: 847-749-2445

Email: info@heimatecinc.com

Website: www.heimatecinc.com

—

Heimatec is an international tooling manufacturer, based in Renchen, Germany. Its experienced staff is dedicated to providing customers the most innovative tooling technology possible. In 2010, the company opened Heimatec Inc. in Prospect Heights, IL, near Chicago, to serve its growing North American customer base with sales and service, plus an extensive inventory of products. Heimatec serves the auto, aero, medical, off-highway, rail, energy, woodworking, composites and other industries, as well as an ever-increasing number of machine tool OEM’s worldwide.

Continue readingOne job that took two weeks due to reworks now done in two days, the result of Tenaxol polymer quenchant with anti-foaming agent and greater concentration consistency

Brothers TJ (left) and Jacob Dohlun operate Complete Heat Treating, companion company to Wisconsin Steel Industries, both in the Milwaukee area. Complete operates open fire furnaces and quench tanks to process large steel castings and forgings, as well as metal fabrications and some aluminum parts.

TJ and Jacob Dohlun are not easily impressed. Despite their relatively young ages, 40 and 32 respectively, they have both worked in the family’s dual heat treating businesses in the Milwaukee area, as far back as they can remember. Their grandfather, Theodore Dohlun, started Wisconsin Steel Industries in 1939 and the family has had involvement in heat treating for three generations. Their dad Ted continued the tradition until his recent retirement and both of the “boys” have been active a long time. They began Complete Heat Treating in 2007 as a separate entity and run it with their mother, Chris Dohlun.

Both Wisconsin Steel and Complete Heat Treating run commercial heat treating operations, serving regional manufacturers in the mining, construction, wind energy, rail, government contract, medical, off-road and agricultural equipment industries. They also serve companies as far away as Brazil, however. Combined, they employ approximately 50 people at the two facilities, processing materials such as 4140 and 4340 steel in the forms of castings and forgings up to 100,000 pounds, as well as fabrications and some aluminum parts.

Never ones to rest on their laurels, however, TJ and Jake have been making significant improvements in their operations, especially on the technology side. They use a proprietary software system to operate their furnaces, they’ve incorporated a number of green initiatives into the business operation and, about a year ago, switched their polymer quenchant supplier to the originator of that chemistry, Tenaxol (Elkhorn, Wisconsin).

At Wisconsin Steel and Complete Heat Treating, they run a total of 13 open fire car bottom and feed furnaces with capacities up to 1,000,000 pounds and workspaces up to 52’ long x 20’ wide x 16’ high. Quench tanks at the facilities range up to 40,000 gallons.

Typically, hardness and mechanical specs are supplied by the customers and the metallurgists and chemists in the labs at these facilities work to determine the optimum processing conditions. Wisconsin Steel is rated to the GE Nuclear standards, while Complete Heat Treating received its ISO 9001:2008 certification just recently.

Many value-adding secondary services are supplied here, including machining, straightening, roto-blasting and saw cutting, as well as metalcoating.

The quenching operations at Complete were a particular challenge, owing to the large parts processed here, the dwell times in the quench tanks and the recurrent problems of concentration flux and, most notably, foaming and dragout. As TJ explains, “We were having a lot of problems on one part, a spun metal with thin but substantial surface area and a rimmed edge. The dragout and the excessive foaming were causing us to rework parts to hit the spec. There were shipping delays and we were struggling to hold the concentrations in the tanks for any extended period.”

Previous polymer quenchants were causing excessive foaming and were inconsistent in holding concentrations. Both problems were overcome with Tenaxol polymer quenchants, according to the brothers.

Jacob adds, “We had been talking to Tenaxol about their anti-foaming products and, despite some cost differences with our then-current supplier, we agreed to testing. Although we were not a customer, the Tenaxol team really went the extra mile to give us the best results their lab could suggest.” As a result, Tenaxol Quench 2500 Ultra polymer quenchant with a non-nitrite corrosion inhibitor, defoamer and biocide was purchased from this new supplier and the results have been outstanding, according to the Dohlun brothers. “We no longer have consistency issues, the percentages stay in line, plus we can vary the temperatures in the tanks without compromising performance. That opens more opportunities for new business and it’s been working very well.” Complete Heat Treating is currently on a record sales pace, with more customers and much faster throughput, boasting a 25% increase in sales and working capacity today. On that spun metal part, for example, TJ notes, “We went from two weeks with a lot of rework to two days on a typical batch.” Jacob adds, “The savings in staged deliveries alone run to thousands of dollars, each time.”Complete is now able to process a wider range of materials, as a result of using Tenaxol quenchants, according to the brothers, who credit Jim Harrison, CEO at Tenaxol, and his team of chemists and metallurgists with much of the significant improvement in their processing scenario.

Describing the situation when the previous quenchant vendor was used, “On that spun metal part, for example, our stacker crane would come out of the tank, full of foam. It looked like a bubble bath,” Jacob joked. TJ further noted the drain-off of the Tenaxol product allowed the parts to enter the tempering furnace much faster, avoiding excess cooling of the surface area. The Complete customer for this job, Rich Prescott of Glenn Metalcraft (Princeton, Minnesota), echoes the Dohlun’s, “The turnaround time has been super. They made great improvement in their deliveries to us over the last year and that’s helped us satisfy our customers faster.”

“This anti-foaming agent in the Tenaxol product has literally changed our shop,” TJ concludes. Jacob also cited the supplier’s customer service. “We get help from their lab on a regular basis, including water testing and support documentation, which is necessary for the PPAP requirements of several customers.” He adds, “Jim (Harrison) and his team did a lot of testing for us, before making their final recommendations and they continue to help us fine tune our operation.” He further noted Tenaxol’s involvement with MTI was important. “This supplier supports our industry and that meant a lot to us.” The supplier also provided a solution to problems Complete was experiencing in their cooling tower water by conducting lab testing, automated equipment and cost-effective chemical treatments, according to Dohlun.

As a result of this initial relationship with Tenaxol, Complete Heat Treating has expanded its purchases of products to include various greases and lubricants from this vendor, which is part of the Chemtool family of companies, a wide-ranging industry supplier of myriad lubricant, cleaning and metalcutting fluid products.

To see a video of heat quenching at Complete Heat Treat, click HERE.

For more information on this story, interested parties should contact:

COMPLETE HEAT TREATING

125 E. Greenfield Ave. Milwaukee, WI 53204-2937

Phone: 414-643-5161

Web: www.CompleteHT.com

Attn: TJ Dohlun or Jacob Dohlun

TENAXOL TECHNOLOGIES, INC.

1001 E. Centralia St. Elkhorn, WI 53121

Phone: 414-476-1400

Web: www.tenaxol.com

Attn: Jim Harrison

In-depth injection molding simulation software has typically been used by analysts who have the expertise to setup the complex mesh model required for simulation. With advanced simulation technology from SIGMA, injection molding simulation is easier to use and more accurate than ever. This opens the door to product designers, project managers, and engineers in charge of polymer injection molds and processes, as well as analysis groups. Companies no longer need to rely on a “meshing expert” to employ injection molding simulation.

The presentation will highlight the power of injection molding simulation when considering 3D mold components, cooling channels, the complete runner system, and part geometries coupled with multi-cycle analysis. Simulation is a must-have tool for companies wanting to evaluate ‘what if’ scenarios of the entire injection molding process early in the design and tooling stages.

Where: Exponent, Inc. 149 Commonwelath Drive, Menlo Park, CA

When: Thursday, June 30, 2011, 11:30 AM – 1:00 PM (lunch provided to those attending the seminar)

Cost: Lunch: $20 non-members, $15 members, $10 students/unemployed/retired – cash at door or via Paypal

Cost: Webinar: $10 – Paypal only. WebEx invitation will be sent upon receipt of payment

RSVP: Jennifer Hoffman at jhoffman@exponent.com; RSVP by noon, Tuesday, June 28th.

Hunter XL2024 matchplate molding system, just purchased by Travis Pattern & Foundry to boost their production. This is the fourth Hunter machine now in operation at Travis.

Spokane foundry, largest privately-owned aluminum caster west of the Mississippi, adds to its already impressive capacity with new matchplate molding system

Schaumburg, Illinois (USA)-Travis Pattern & Foundry Inc., a major producer of aluminum castings for the irrigation, power transmission substation and general-purpose fittings markets, as well as the originators of Li’l Mac sinker molds for the fishing industry, announces its purchase of a fourth Hunter matchplate molding system, the XL2024. According to Gene Johnson, project manager at Travis, “This new line will expand our already substantial casting capabilities for aluminum, as well as brass and cast iron work. We’re seeing an upturn in our business and purchased the machine in anticipation of increasing demand.” The machine is scheduled to be operational by the end of March, 2011.

The XL2024 is a fully automated matchplate molding system, using gravity-fill technology pioneered by Hunter. It produces sand molds up to 20” x 24” with shallow 6-1/2” cope and 5-1/2” drag (165mm/140mm) at 180 cycles per hour, using 400 lbs. (181kg) of sand. Variable squeeze surface pressure to 142 psi (10kg/cm2) can be achieved in production.

Travis Pattern, founded in 1922 and now a fourth-generation company, is the largest privately-owned aluminum caster (over 7,000,000 lbs./3,181,818kg annually) west of the Mississippi and boasts a network of affiliated companies through which their castings are marketed. The company also produces a variety of brass and cast iron products. Travis products are sold throughout North America.

Gene Johnson further described his company’s use of their Hunter molding systems. “We typically run jobs in the hundreds up to 1000 pieces. The fast pattern changeover and the flexibility of the Hunter system really speeds our production.” He estimated approximately 90% of the jobs run on the new Hunter machine will be aluminum, with the balance being brass.

For further information on this announcement, interested parties may contact: TRAVIS PATTERN & FOUNDRY INC. 1413 E. Hawthorne Road Spokane, WA 99218-3100 Phone: 509-466-3545 Fax: 509-467-6465 Web: www.travispattern.com Email: tpfgj@travispattern.com

Attention: Gene Johnson, Project Manager

Or

HUNTER AUTOMATED MACHINERY CORPORATION 2222 Hammond Drive Schaumburg, Illinois 60196-1094 USA Phone: +1 847 397 5136 Email: kpurdy@hunterauto.com Web: www.hunterauto.com Attention: Kevin Purdy, Vice President

Editor Note: Please direct all publication-generated inquiries to Kevin Purdy at Hunter. Thanks!

Agency contact for Hunter: Tim Daro Bernard & Company Palatine, Illinois (Chicago) USA +1 847 934 4500 tdaro@bernardandcompany.com www.bernardandcompany.com

Travis Pattern produces a variety of aluminum, bronze and cast iron products at its 220,000 sq. ft. complex in the Spokane, Washington area. Sand casting, permanent mold and no bake operations are conducted here, as well as machining, heat treating and galvanizing.

Continue reading