Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Advanced Machine & Engineering Co. is the pioneer in carbide sawing and sawing technology, with over 40 years of manufacturing. They will be presenting:

Hennig, Inc. design and produces custom machine protection and chip/coolant management products for state-of-the-art machine tools. Hennig products are designed to protect against corrosion, debris and common workplace contaminants. Manufacturing facilities located in the U.S., Germany, Brazil, India, Japan, France and South Korea. Repair centers are located in Machesney Park, IL; Chandler, OK; Livonia, MI; Blue Ash, OH; Mexico City, Mexico and Saltillo, Mexico. To learn more, visit www.hennigworldwide.com.

For more information, contact:

Tim Waterman

ADVANCED MACHINE & ENGINEERING CO.

2500 Latham St.

Rockford, IL 61103

Phone: 815-316-5277

Fax: 815-962-6483

E-mail: info@ame.com

Connect with AME online:

No. 855 is a 1250ºF electrically-heated, inert atmosphere cabinet oven from Grieve, currently used for heat treating at the customer’s facility. Workspace dimensions on this oven measure 38” W x 26” D x 38” H. 40KW are installed in Incoloy-sheathed tubular elements to heat the oven chamber, while a 1500 CFM, 1-1/2 HP recirculating blower provides horizontal airflow to the workload.

This Grieve cabinet oven features 10” insulated walls comprising 2” of 1900ºF block and 8” of 10 lb/cf density rockwool insulation, Type 304, 2B finish stainless steel interior with continuously backwelded seams, plus inner and outer door gaskets with the inner gasket sealing directly against the door plug while the outer gasket seals directly against the face of the oven.

Full inert atmosphere construction further includes a pressure regulator, flow meter, pressure gauge, internal high-temperature gasket, all welded expansion connection in doorway throat, air jacket on inner oven for cooling, ½” thick silicone rubber atmosphere seal, blower shaft seal, positive latching door hardware, adjustable offset door hinges, outlet with pressure relief, interior seams welded gas-tight and all wall penetrations fitted with compression fittings. A 325 CFM blower pulls air through the air jacket on the inner oven for cooling.

Controls on No. 855 include a special heating/cooling temperature controller to control heating elements for heating and modulating damper on cooling blower for cooling. The oven also has an SCR power controller and circular chart recorder onboard.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847)546-9210. Web: http://www.grievecorp.com. Email: sales@grievecorp.com Attention: Frank Calabrese.

Continue readingThrough the use of Siemens SINUMERIK CNC technology, plus PLC and HMI, on a combination servo-controlled cold saw cut-to-length and brush deburring system, Rattunde customer achieves triple the output on small engine exhaust components

Rattunde ACS + BDM tube and bar production system at Cosmos.

Rattunde Corporation of Grand Rapids, Michigan is the five-year-old subsidiary of Germany’s Rattunde & Co. GmbH, a machine tool builder of tube, pipe and bar processing equipment. The company is already making its mark in the American manufacturing industry, as demonstrated by a recent success it had at Cosmos Manufacturing of South Chicago Heights, Illinois, a major supplier of small engine exhaust tubes to the leading outdoor power equipment manufacturers in the country.

The Rattunde system, incorporating a servo-controlled cutoff saw and brush deburring mechanism, is consistently producing up to 11,000 parts per hour at Cosmos, according to Mike Jemilo, the end user’s general manager. “This number represents triple the output production for Cosmos.” He continues, “Better still, it’s been in operation more than a year and we have not reported a single reject, with only routine maintenance and zero downtime due to machine problems. This is truly a win-win scenario for the machine tool builder and us alike.”

At the heart of the Rattunde system, according to Richard Stadler, company president, is the computer numerical control (CNC) system used by this builder. It consists of a Sinumerik 840D CNC, Simatic S7 PLC with various analog and Profibus modules, plus numerous Simotics servomotors, motor protection devices, circuit breakers and other components supplied by Siemens.

Machine performs all servo-controlled saw cut-to-length, washdown, brush deburring and packing operations on a single line, controlled by Siemens CNC and HMI.

At Cosmos, this Rattunde system is used to process mill-length tubes to customer-specified dimensions, using a fully NC-controlled cold saw. Cut-to-length parts are then automatically measured for dimensional accuracy and brush deburred. Production of these parts runs up to 11,000 units per hour, according to Cosmos’ Mike Jemilo. Because of the overall improvements in automation, speed and parts handling, plus the precision of the Sinumerik CNC system, Cosmos is further experiencing significant reductions in parts handling, secondary operations and final assembly.

The primary products being produced on this equipment at Cosmos include mountings, connectors and sections for muffler tubes in dozens of lengths, typically in 3/8-inch, 7/16-inch, 12 millimeter and 1/2-inch sizes. Products are routinely run in mild steel, aluminized steel and stainless steel on the same Rattunde system, with offline pre-programming done by the Cosmos engineering team. The final products are sold by Cosmos to leading manufacturers of chain saws, leaf blowers, lawn mowers and other small engine-powered equipment.

All machine functions and 13 axes of movement are affected by the Siemens CNC, which also provides remote monitoring capability for the builder Rattunde.

Jemilo concluded by citing the Rattunde service advantages. “From the initial contacts with their application engineering, through the build process, commissioning and on-site training, we’ve been extremely impressed with their work — very professional and responsive. Our previous system had nowhere near the production of the Rattunde solution and we are already working with this supplier on our next system.”

From the machine tool builder’s perspective, the same relationship is echoed about Siemens. Alec Banish, vice-president at Rattunde, commented, “We were asking Siemens to do some fairly complex operations in motion control, including 13 total axes with an articulating gearbox, plus the conveyor and part articulations, spindles and servomotors.” He further noted the scalloped motion of the ID/OD brushing with disc transfers all presented unique motion challenges for the control hardware and software alike. “The Siemens servo technology automated our entire process in a totally controlled, high-precision manner, allowing customers such as Cosmos to process a wide variety of materials, dimensions, shapes and lengths with easy-to-manage presets.” Banish concluded by saying, “The Siemens support is greatly enhanced by the remote monitoring capability of the Sinumerik CNC. About 70 percent of our issues are resolved remotely, working between us and Siemens or directly with the customer’s plant personnel.”

Prior to the implementation of the Rattunde system, all the piece part work done at Cosmos required two or three saws, with the attendant fixturing, parts handling, logistics and labor costs. These bottlenecks in production were eliminated by the fully automated and single operation processing of the tubes provided by the Rattunde system. Four tubes are processed per cycle, with servo control of the entire bundle, as it moves through the saw, brush and loading zones on this fully integrated machine line.

Rattunde builds various production systems for tube and bar product manufacturers.

From a factory utilization perspective, the prior system at Cosmos ran in three shifts for six days, each week. Today, with the Rattunde system on the floor, occupying a far smaller footprint, one shift per day working just five days produces the same output with far superior quality and virtually no rework, according to company sources.

Rattunde President Richard Stadler further comments on the power of the Siemens CNC and related motion control products. “We’re using all ten channels and pushing the axis capability to some extreme limits, but have seen absolutely no problems in signal degradation or processing speeds.” Stadler also observed the Sinumerik CNC program storage capabilities were quite impressive. “All the operator needs to do is provide a size range indication onscreen and all the relevant programs appear for easy selection. Repeatability is obviously critical for our customer, who often process dozens of shapes and sizes per shift.”

He recalled meeting the Cosmos team at FABTECH in 2009. “They approached us with their scenario and it was right in our wheelhouse. We did some test cuts and time/motion studies for them and the results were quite impressive, both to them and to us,” Stadler muses.

Rattunde operates facilities in Grand Rapids, Michigan as well as a service center in Burlington, Ontario to better serve their North American customer base.

Rattunde markets its tube and bar production systems to makers of precision parts. Currently selling 60 percent automotive, the company’s systems produce airbag canisters, cam shaft cylinders, steering components, rack mounts, driveshafts, frame components, seating parts, headrests, shock absorber parts, door impact devices, luggage racks and a variety of axles. In addition to the cut-off and brush deburring system detailed here, the company also supplies production systems to perform various types of secondary machining operations, including threading, facing, chamfering and ID turning.

For further information on this story, please contact:

RATTUNDE CORPORATION

4980 Kendrick St. SE

Grand Rapids, MI 49512

Phone: 616-940-3340

Web: www.rattunde-corp.com

Email: r.stadler@rattunde-corp.com

Attention: Richard Stadler, president or Alec Banish, vice-president

OR

SIEMENS INDUSTRY, INC.

DRIVE TECHNOLOGIES

MOTION CONTROL

MACHINE TOOL BUSINESS

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/cnc

Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communication

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue readingSiemens Sinumerik 840D is the control of choice on turning, grinding and turn/grind models, resulting in substantial savings for its customer and EMAG

EMAG L.L.C. is the U.S. subsidiary of a major German machine tool builder who specializes in machine tools for the production of automotive, off-highway, agricultural and oil field components. The company’s equipment ranges from basic prismatic part turning centers to large workpiece, five-axis machining centers, gear hobbing machines and alternative cutting equipment such as lasers and electro-chemical machining centers. This wide variety of machine tools requires an assortment of control technologies to power and manage the motion. For one recent customer requirement, where a major agricultural equipment builder in Iowa needed grinding, turning and turn-grind machines, EMAG looked to its longtime partner Siemens for a standardized CNC solution.

CEO Peter Loetzner put it simply, “We needed to devise a control solution that would satisfy all the needs of the various machines we were supplying to this demanding customer, based on a common platform, to enable easier design, integration, start-up, commissioning on-site and training for our customer’s operations and maintenance personnel.” After reviewing the entire line of CNC offerings from various suppliers, the decision was made to use the Siemens Sinumerik 840D CNC for all of the grinding, turning and turn-grind machines to be supplied. Collaboration was a key element in the decision-making process, as Loetzner explains.

“The control we selected offered great flexibility in application, which was very important to us and our customer. They were seeking a scenario that would allow considerable cross-training of their operators, who might run a turning center one day, then a grinding or turn-grind center the next.” Loetzner further noted the control chosen offered his machine designers and the customer’s production management team an enhanced remote monitoring feature, so changes could be made on the fly with very little downtime. As a result, over 20 machines of various sizes and styles can be monitored over a wireless network, enabling process engineers to see what the operator sees on each machine.

Furthermore, owing to the global capabilities of Siemens, Loetzner commented on the control’s ability to function

in U.S., German and even Asian factories with seamless data integration. Regardless of the machine tool’s location, EMAG and its customer are able to monitor the performance of any particular machine and even report comparative production data from one continent to another. Because it sells into every industrialized nation, EMAG “…works with its customers on every aspect of a job, from the order process to tooling usage, materials handling strategies to predictive maintenance. The cultural differences are substantial sometimes and the control must be programmed to adapt to such variations. We have been most satisfied with the help Siemens has provided to us, worldwide, in this area.”

Those differences, he continued, must nonetheless be based on a common technology to streamline the integration of the CNC on the machines under construction.

Loetzner cited specifics from the project referenced in this story. “We were looking at a fairly diverse group of machines being supplied to the customer. Frankly, many of their operators were more comfortable with a CNC that is very popular in the American job shop community. However, we were able to demonstrate the immediate advantages of the Siemens control to them and they accepted our recommendations.” This value proposition, he said, hinged on the greater capability of the Sinumerik 840D to run different machine types, which translated into considerable savings on the training and commissioning side of the equation. Coupled with the remote monitoring and programming aspects of the Siemens control solution, the customer was convinced.

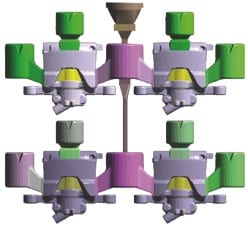

Production VSC from EMAG is a vertical pick-up turning center capable of milling, turning, grinding, drilling, even gear profiling and honing.

More than 75 percent of the EMAG machines at this particular customer are equipped with robotic devices, enabling a lights-out manufacturing scenario, another instance where the Siemens remote monitoring via Ethernet feature benefits both the machine tool builder and its customer alike. Loetzner explains, “Remote monitoring of the machine tools can be done directly through the Sinumerik CNC in a one-to-one exchange between our customer and us. Alternatively, we can communicate with Siemens and our customer in a three-way exchange of machine data and cycle information, all protected through a firewall for security and customer peace-of-mind. That’s important with all our major OEMs, of course.” Loetzner cited one customer in the agricultural machine building market, who’s used the remote monitoring capability of the Sinumerik CNC on a wide variety of EMAG machines for over three years currently, with all data communicated through a single information network, accessible by both EMAG and the control supplier. Significant reductions in downtime, service calls and troubleshooting identification time have been achieved, translating into documented savings for everyone.

Shaft machining is done on a VTC, with full 4-axis machining plus loading and unloading, all controlled by a Siemens CNC.

As a further advantage to the machine tool builder, the space reduction of more than 20 percent in the control, compared to competitive brands, meant a smaller footprint for the machine, further improving the workspace productivity of the EMAG machines for their customer. Especially in brownfield applications, where a limited space is being utilized to maximize production for an OEM, this physical space-savings combines with other advantages of the Siemens control, according to Peter Loetzner. These include reduced wiring and lower power consumption with the attendant lower operating temperatures, due to reduced ambient heat.

At this particular customer, the EMAG machines are used to produce gears, gear blanks, shafts and splines for

powertrain applications. Gear hobbing and synchronous support grinding are among the advanced machining technologies performed here. Heavy, hardened steels are the most often worked substrates.

The specific control used on these machines is the Siemens Sinumerik 840D solution line, a distributed, scalable and open control for up to 31 axes of motion, incorporating the CNC, HMI, PLC, closed loop control and communications functions into a single NC unit. Sinumerik Safety Integrated further provides a comprehensive, yet efficiently packaged suite of personnel and machine protection functions, fully compliant with internationally-accepted standards.

Commenting on the competing brands of CNC often found in job shops worldwide, Loetzner noted that the Siemens communication architecture easily accepts input from such devices, owing to its ability to capture, standardize and transmit all data in a seamless manner through its legacy tracking. “This service is another example of a forward-thinking supplier, such as Siemens, responding to brownfield conditions in the marketplace,” he noted.

EMAG machines are used by the majority of American companies for the production of such products in the Agriculture, Earthmoving, Motorcycle and Automotive and subsequent leading TIER1 suppliers. The machine builder has had a presence in the American market for over 20 years and, according to Peter Loetzner, “…we’ve received great support from Siemens, both in Germany and in the United States, for on-site service, application engineering, parts distribution, remote monitoring implementation and communications between our customers and us.”

For more information on this story, please contact:

EMAG L.L.C.

Peter Loetzner

CEO

38800 Grand River Avenue

Farmington Hills, MI 48335

Phone: 248-477-7440

Fax: 248-477-7784

Web: www.emag.com

Email: info@emag.com

OR

SIEMENS INDUSTRY, INC.

DRIVE TECHNOLOGIES

MOTION CONTROL

MACHINE TOOL BUSINESS

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/cnc

Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communication

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue readingNo. 1019 is a 500ºF electrically-heated walk-in batch oven from Grieve, currently used for curing coatings onto large discs at the customer’s facility. Workspace dimensions on this oven measure 18’ W x 18’ D x 10’ H. 260KW are installed in Incoloy-sheathed tubular elements to heat the oven chamber, while a total of 66,000 CFM generated by two 30-HP recirculating blowers provides combination airflow to the workload.

This Grieve walk-in oven features 6” insulated walls, aluminized steel exterior and interior, 2” thick insulated flooring with built-in oven truck wheel guide tracks and motorized dampers on the intake and exhaust for accelerated cooling of the oven chamber. The oven was sectioned into four pieces for shipping convenience.

All safety equipment required for handling flammable solvents, including explosion-venting door hardware, is provided on No. 1019.

Controls on this jumbo walk-in oven include an SCR power controller.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart

Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-

9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank

Calabrese.

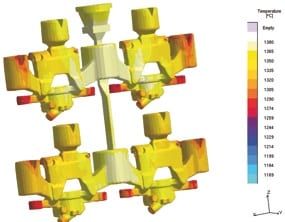

Continue readingUsing a completely 3D-approach and the integration of a highly developed thermal solver, the injection molding simulation software SIGMASOFT® allows the calculation of multiple consecutive production cycles, considering the thermal interactions throughout all the components in the mold. The accuracy of the entire simulation is thus dramatically increased.

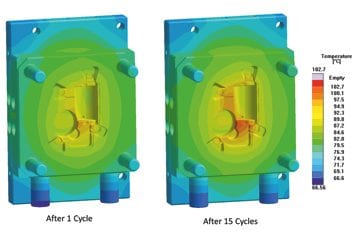

Figure 1 – The multi-cycle analysis of SIGMASOFT® allows simulating the heat transfer in the mold from start-up over multiple production cycles, and thus exactly reproduces the real production conditions in the cavity. Left: Temperature distribution in a half of the mold cavity after one cycle. Right: Temperature distribution after 15 cycles.

Schaumburg, Illinois – SIGMA® Plastic Services presented its SIGMASOFT® software designed for 3D injection molding process simulation at the recent Euromold 2011, hall 8, stand A 101. One of the highlights of the presentation was the SIGMASOFT® unique functionality of its “multi-cycle analysis”, a new benchmark in injection molding simulation.

“In conventional injection molding software, a fixed mold temperature is defined and the whole simulation is carried out under the assumption that this value remains constant over time”, explained Dr. Marco Thornagel, Executive Director of SIGMA® Engineering. “In reality, however, you have a very complex thermal process taking place within the mold: the steel is cooled with a tempering system, the mold is heated when the hot polymer melt enters the cavity and there is a loss of thermal energy towards the surrounding environment. All governed by the heat transfer properties of the materials present throughout the system: polymer melt, runner system, inserts, mold, isolation materials. Only when these complex interactions are considered will the real production conditions be reproduced in the simulation. And our customers really appreciate that we already have 25 years of experience in how to make this kind of simulation, with a user friendly meshing algorithm,” observed Dr. Thornagel.

The 3D-approach of SIGMASOFT® allows all the components in a mold, including all the thermal and physical properties of each one of them, to be exactly reproduced. Therefore, the heat transfer process can be accurately calculated between each one of the components.

To accurately simulate the production conditions, the heat transfer process taking place in reality must be exactly reproduced in the simulation. This includes the heat-up during the start-up of the machine, when the mold is heated from room temperature to its production conditions (typically between 60º and 120°C) by the tempering system. It also includes the warming up produced by the hot polymer melt over several consecutive pre-production cycles, as happens in actual run conditions.

SIGMASOFT® is able to exactly reproduce the heat-up stage, as well as simulate the thermal evolution of the mold over multiple consecutive production cycles. This accurate calculation predicts the real temperature in each location of the mold during production, producing a condition that more closely reflects reality for the polymer as it sets inside the cavity. This allows the software, for example, to predict how long the polymer remains in a fluid condition so that post-pressure can be applied, or where will the thermally induced deformation most likely compromise the part quality.

Another of the advantages of multi-cycle simulation is the possibility to calculate how many production cycles are required for the mold to achieve cyclic equilibrium – and thus consistent quality conditions over a production run. Therefore, the number of parts required before the actual production begins can be more accurately predicted. The system can be optimized to minimize the number of pre-production parts that are required. Another possibility is to compare the efficiency of different tempering systems to understand how to achieve equilibrium more quickly or how to consume less energy.

SIGMA® (www.sigmasoft.de) is 100% owned by MAGMA® (www.magmasoft.de), the world market leader in casting process simulation technology based in Aachen, Germany. Our SIGMASOFT® process simulation solution optimizes the manufacturing process for injection molded plastic components. SIGMASOFT® combines the 3D geometry of the parts and runners with the complete mold assembly and temperature control system and incorporates the actual production process to develop a turnkey injection mold with an optimized process.

At SIGMA® and MAGMA®, our goal is to help our customers achieve required part quality during the first trial. The two product lines – injection molded polymers and metal castings – share the same 3D simulation technologies focused on the simultaneous optimization of design and process. SIGMASOFT® thus includes a variety of process-specific models and 3D simulation methods developed, validated and constantly improved for over 25 years. A process-driven simulation tool, SIGMASOFT®, with its comprehensive simulation approach, provides a tremendous benefit to production facilities. Imagine your business when every mold you build produces required quality the first time, every time. That is our goal. This technology cannot be compared to any other conventional “Design” simulation approach employed in plastics injection molding.

New product success requires a different communication between designs, materials, and processes that design simulation is not meant for. SIGMASOFT® provides this communication. SIGMA® support engineers, with 450 years of combined technical education and practical experience, can support your engineering goals with applications specific solutions. SIGMA® offers direct sales, engineering, training, implementation, and support, by plastics engineers worldwide.

For further information on this announcement, interested parties should contact:

Christof Heisser or Matt Proske

SIGMA Plastic Services, Inc.

10 N. Martingale Road, Suite 425

Schaumburg, Illinois 60173

USA

Phone: +1 847 558 5600

Email: cheisser@3dsigma.com or mproske@3dsigma.com

Web: www.3dsigma.com

Agency contact for SIGMA:

Wendy McCormick

Bernard & Company

Palatine, Illinois (Chicago)

USA

+1 847 934 4500

North American sales to automotive, heavy equipment, steel, rail, OCTG and other metal fab markets to be handled by leading supplier of machine tools

MAE offers a broad line of manual, semi-automatic and automatic straightening equipment with press forces to 25,000 kN, used particularly in the automotive, heavy equipment, steel, rail and OCTG markets on round, profiled and complex shaped workpieces in lengths up to 100 feet. MAE machines possess the high accuracy and repeatability necessary for extremely tight straightening tolerances on such large workpieces.

Finally, MAE also offers special application presses in C-frame, as well as four-column styles with press forces to 10,000 kN. These special application presses are typically used in forming and calibration.

Scott Knoy, vice president of sales for American Wera, states, “We believe the MAE line will complement our existing equipment, making us a greater value adder to current customers, plus it will open new markets where our expertise can be helpful to a variety of end product manufacturers.”

Executing the agreement were American Wera President Walter Friedrich and MAE Managing Director Ruediger Goetzen.

For more information on this announcement, please contact:

GMTA (German Machine Tools of America) Formerly American Wera

4630 Freedom Drive

Ann Arbor, MI 48108

Phone: 734-973-7800

Fax: 734-973-3053

Web: www.gmtamerica.com

Email: scott@gmtamerica.com

Attention: Scott Knoy

Facebook: GMTA

Twitter: @GMTA_US

With aid of the interface SIGMALINK®, the weld lines predicted with the injection molding simulation software SIGMASOFT® can now be mapped into Finite Element Analysis Software and be considered in the structural design of injection molded parts

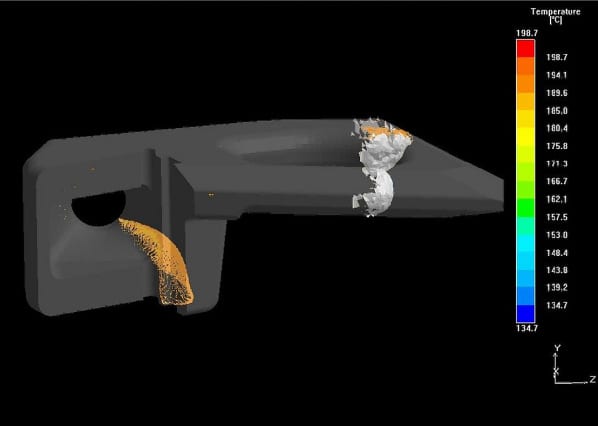

The tracer technology in SIGMASOFT® allows visualizing the fully 3D profile of weld lines over the part thickness. With SIGMALINK this information can now be mapped into structural FEA.

Schaumburg, IL – Sigma Plastic Services, presents a new functionality of its injection molding simulation software SIGMASOFT®. The simulation of the cavity filling in injection molding allows identifying regions where weld lines are formed, not only on the surface but also through the part’s thickness, with a completely 3D approach. With the interface SIGMALINK® it is now possible to transfer this 3D information into FEA (Finite Element Analysis) Software, to consider the drop in mechanical properties in these regions when performing structural design. A particular advantage of SIGMASOFT® is the fully 3D prediction of the weld lines, which reproduces the weld regions not only on the surface, but also through the part’s thickness, as it occurs in reality.

Weld lines occur as a consequence of the collision of two (or more) flow fronts in the cavity of a mold. This disruption in the homogeneity of the injection molded part causes optical defects, which compromise the surface quality, but also produces a weakening from the mechanical point of view and, under certain circumstances, weld lines can even act as stress concentrators. Therefore, there is a loss in the mechanical properties in the regions where weld lines appear.

Using the “tracer” technology, which has been available for years in SIGMASOFT®, the appearance of weld lines can be reproduced during the filling stage. The location of the weld lines can be described precisely and an indication is given regarding how critical they are. The formation of the weld lines during the filling stage and the way they flow as the packing pressure is applied are predicted accurately in a 3D approach.

The interface SIGMALINK enables exporting (mapping) physical and flow-related properties into commercial software for FEA (such as Ansys, Abaqus, Radios, etc.). Factors such as flow and thermal induced stresses and fiber orientation can be considered in the FEA. With a further expansion of SIGMALINK® it is now possible to export the information about the final position and 3D profile of the weld lines in the structural FEA. In this way, the drop in the mechanical properties produced by the apparition of weld lines can also be considered in the mechanical part design.

In Figure 1 the formation of a weld line region in SIGMASOFT® is presented. The flow front is depicted in grey. The “tracer” particles in orange show clearly that the melt fronts do not collide in a flat region, but that this weld line has a complex 3D profile at the end of the filling and packaging phases.

SIGMA (www.sigmasoft.de) is 100% owned by MAGMA (www.magmasoft.de), the market leader in casting process simulation technology based in Aachen, Germany. Our SIGMASOFT® process simulation solution optimizes the manufacturing process for injection molded plastic components. SIGMASOFT® combines the 3D geometry of the parts and runners with the complete mold assembly and temperature control system and incorporates the actual production process to develop a turnkey injection mold and optimized process.

At SIGMA and MAGMA, our goal is to help our customers achieve required part quality during the first trial. The two product lines – injection molded polymers and metal castings – share the same 3D simulation technologies focused on the simultaneous optimization of design and process. SIGMASOFT® thus includes a variety of process-specific models and 3D simulation methods developed, validated and constantly improved for over 25 years. A process-driven simulation tool, SIGMASOFT®, with its comprehensive simulation approach, provides a tremendous benefit to production facilities. Imagine your business when every mold you use produces required quality the first time, every time. That is our goal. This technology cannot be compared to any other conventional “Design” simulation approach employed in plastics injection molding.

New product success requires a different communication between designs, materials, and processes that design simulation is not meant for. SIGMASOFT® provides this communication. SIGMA support engineers, with 450 years of combined technical education and practical experience, can support your engineering goals with applications specific solutions. SIGMA offers direct sales, engineering, training, implementation, and support, by plastics engineers worldwide.

For further information on this announcement, interested parties should contact:

Christof Heisser or Matt Proske

SIGMA Plastic Services, Inc.

10 N. Martingale Road, Suite 425

Schaumburg, Illinois 60173

USA

Phone: +1 847 558 5600

Email: cheisser@3dsigma.com or mproske@3dsigma.com

Web: www.3dsigma.com

Agency contact for SIGMA:

Wendy McCormick

Bernard & Company

Palatine, Illinois (Chicago)

USA

+1 847 934 4500

Continue readingPremier Aluminum and Hodge Foundry techs receive the highest level of simulation software competency designations from foundry market leader

Premier – Jason Lythjohan of Premier Aluminum in Racine, Wisconsin receives his MAGMA certification.

Schaumburg, IL – MAGMA Foundry Technologies Inc. has been a provider of proprietary casting process simulation software, MAGMASOFT®, for over 20 years. More than simply providing software, MAGMA also shares its engineering expertise through its contract service group and comprehensive training programs. This extensive training program comprises several intensive course levels, where the users gain knowledge to better utilize the software from a functional standpoint, plus insights on practical approaches to applying the technology to their metalcasting process.

Currently, the highest achievable training level is the Certified MAGMASOFT® User. There is a set of specific criteria the user must meet to be eligible to participate in the program and a list of objectives that must be met to receive the certification from Magma.

There are many benefits to completing the certification program, which aid not only the software user, but also the user’s organization and its casting customers.

Some of the key benefits include:

Hodge Foundry – Ian McNally from Hodge Foundry in Greenville, Pennsylvania receives his MAGMA certification.

In 2011, two successful users achieved the MAGMA Certification, namely, Jason Lythjohan from Premier Aluminum, LLC and Ian McNally from Hodge Foundry.

Premier Aluminum has opened a technology center for its customers and potential customers to come in and use MAGMASOFT® Simulation Software for the design and engineering of their castings.

Premier Aluminum, located in Racine, Wisconsin and part of Ligon Industries LLC, is an ISO 9001-2008 certified permanent mold aluminum casting and machining shop. Premier has a reputation for partnering with its customers to find flexible and cost-effective solutions to a variety of product problems.

Hodge Foundry, founded in 1876 and located in Greenville, Pennsylvania, is an internationally-recognized specialty engineering foundry that manufactures high quality complex gray and ductile iron castings.

For more information on this release, please contact:

Christof Heisser

President

MAGMA Foundry Technologies, Inc. 10 N. Martingale Road, Suite 425 Schaumburg, IL 60173

Phone +1 847-969-1001 ext. 225 Email: cheisser@magmasoft.com Web: www.magmasoft.com

Agency contact for MAGMA:

Wendy McCormick

Bernard & Company, Palatine, Illinois (Chicago) USA +1 847 934 4500 wendy@bernardandcompany.com

Continue readingCasting process simulation to automotive industry standards

Cast components can be found throughout engine, brake system, body and interior components. For this reason, Continental, with its three automotive divisions, is one of the world’s largest consumers of castings. Continental does not produce the castings itself, but instead buys these parts in large quantities from outside vendors. In view of the great importance of these components in its products and systems, the Automotive Group devotes a great deal of attention to its cooperation with foundries. For Continental, it is vital that all suppliers reliably meet their quality standards and can guarantee secure processes. If production lines come to a standstill at Continental – or worse, at Continental’s customers – losses can quickly run into the millions.

As a direct supplier to carmakers, Continental is in a sandwich position. The company must guarantee product and process quality to its customers and pass on these requirements to its own suppliers. Consequently, continuous audits of partners are used to assure a constant, sustainable productivity and to ensure the use of the most competitive technologies. The same applies to requirements for product and service quality, which must be highly cost effective, as well as comply with project deadlines.

Casting simulation as foundry selection criterion

When it comes to the quality of purchased castings, Mustafa Ata, Senior Expert Casting Quality, is in demand in Continental’s Automotive Group. He audits the foundries which supply Continental worldwide. “The quality requirements for castings, which are for the most part installed in safety-relevant areas of cars, are extremely high. The prevailing international standards are supplemented by internal group standards, e.g. with regard to service life, material strength, metallurgical properties (microstructure), machinability of the components and optical appearance,” Mustafa Ata said when describing what he expects from foundries.

From Continental’s point of view, a reliable compliance with this performance catalog cannot be achieved without the foundries using the latest casting technology and tools. In the case of safety components, the group requires its suppliers to use software for casting process simulation, to check the casting process and analyze the results with Continental before production starts. Continental also requires that their foundries be in a position to optimize the process if necessary.

“Simulation is anchored as an important part of supplier communication. This means that in every casting project, product realization is supported from the very beginning by numerical simulation. We expect our suppliers to possess a simulation tool,” Ata noted, leaving no doubt in this regard.

The casting development process begins at Continental. The design department designs the casting according to the automotive manufacturer’s requirements. The 3D data produced goes to selected foundries to enable the latter to simulate the casting process with suitable software. The simulation checks various factors that are critical for casting quality simultaneously.

First, the simulation can determine whether the casting was designed in a casting-appropriate manner or whether the design department, in cooperation with the suppliers (simultaneous engineering), needs to readjust the design to permit standard-compliant parts to be reliably produced in a cost-effective casting process. Second, the simulation results can reveal whether, under the specific production conditions of the foundry, a stable, economical process can be established or whether changes need to be carried out.

Simulation result: production and delivery security

As its final result, the simulation provides Ata with the certainty that the foundry can reliably produce and deliver a casting that meets the requirements at optimal costs. Without casting process simulation, such security could only be achieved with multiple casting trials and machining, at costs and project times that are no longer competitive in the automotive industry.

Simulation with MAGMASOFT® welcomed

In general terms, Continental allows its suppliers to choose which software they use for casting process simulation. But, most foundries opt for the MAGMASOFT® software from MAGMA Gießereitechnologie GmbH, which Ata welcomes for various reasons.

MAGMA is the pioneer in casting process simulation software. As a software developer, more casting engineers work at MAGMA than in many foundries. Because of this, MAGMA is regarded as the worldwide market and technology leader and sets the standard in this field.

The simulation results provided by MAGMASOFT® are extremely realistic.

Empirical checks through real trial castings regularly demonstrate that the results correspond to a large extent with the observable properties of the cast components.

“Simulation results from MAGMASOFT® are accepted as reliable by all parties involved in the production process. As a result, they form the basis on which designers, foundrymen and users can discuss component quality and process optimization, further developments and modifications,” according to Ata.

MAGMASOFT® offers solutions for all casting processes and process steps. In doing so, the software covers every possible simulation situation which arises at Continental in the cooperation with foundries. Therefore, the partners do not need to deal with different applications.

In the foundry, MAGMASOFT® users benefit from the simple operation of the software and the service of the provider, which meet the high demands of the automotive industry.

Continental considering using MAGMASOFT® itself

Until now, Continental has only required that its vendors utilize casting process simulation software. However, Continental is now considering using MAGMASOFT® itself. In this way, the design of a component could be checked for casting suitability immediately and the feedback loops shortened further. Simultaneously, communication with Continental’s development partners could be improved even more through the common “language” of simulation results.

About software for casting process simulation

Casting process simulation software considers the complete casting process including mold filling, solidification and cooling, and also provides the quantitative prediction of mechanical properties, thermally induced casting stresses and the distortion of cast components. Simulation accurately describes a cast component’s quality upfront before production starts, thus the casting layout can be designed with respect to the required component properties. This results in a reduction in pre-production sampling, but also the precise layout of the complete casting system leads to energy, material and tooling savings for the foundry.

The range of application of MAGMA solutions comprises all cast alloys, from cast iron to aluminum sand casting, permanent mold and die casting up to large steel castings. The software supports the user in component design, the determination of melting practice and casting methodology through to mold making, heat treatment and finishing. This saves costs consequently along the entire casting manufacturing line.

During the last 10 years, the use of casting process simulation has become a valuable business asset for many foundries. MAGMA5 now expands the capabilities of casting process simulation and will further accelerate the acceptance of this technology.

About MAGMA

MAGMA offers comprehensive solutions to the metal casting industry, casting buyers and casting designers worldwide. The MAGMA product and service portfolio includes the powerful modular simulation software MAGMASOFT®,with the newest release MAGMA5, as well as engineering services for casting design and optimization.

Today, MAGMASOFT® is used throughout the metal casting industry, especially for the optimization of cast components in automotive and heavy industry applications.

MAGMA Giessereitechnologie GmbH was founded in 1988 and is headquartered in Aachen, Germany. A global presence and support are guaranteed by offices and subsidiaries in the USA, Singapore, Brazil, Korea, Turkey, India and China. Additionally, more than 30 qualified partners represent MAGMA around the world.

For more information on this release, please contact:

Christof Heisser

President

MAGMA Foundry Technologies, Inc.

10 N. Martingale Road, Suite 425

Schaumburg, IL 60173

Phone 847-969-1001 ext. 225

Email cheisser@magmasoft.com

Agency contact:

Wendy McCormick

Bernard & Company

847-934-4500

Continue reading