Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

This Grieve cabinet oven has 6” insulated walls, aluminized steel exterior, Inconel 600 interior with continuously backwelded seams and special exterior paint. The oven also features full inert atmosphere construction, including pressure regulator, flow meter, pressure gauge, internal high-temperature gasket, all-welded expansion connection in the doorway throat, air jacket on inner oven for cooling, ½” thick cellular silicone rubber atmosphere seal, blower shaft seal, positive latching door hardware, adjustable offset door hinges, outlet with pressure relief, interior seams welded gas-tight and all wall penetrations fitted with compression fittings.

No. 873 has a 650 CFM blower to pull air through the air jacket on the inner oven for cooling, plus automatic dampers. A hinged door jacket with 4” diameter connector to allow the jacket to be ventilated is also provided.

Sixteen pairs of shelf supports to support thirty-two Inconel 600 pans, with two pans on each level, plus loading truck tracks on the floor of the workspace, are built into this Grieve oven.

Controls on this inert atmosphere cabinet oven include a programming temperature controller, manual reset excess temperature controller, SCR power controller and fused disconnect switch.

To everything, there is a REASON…turn, turn, turn…

Here’s your best reason to stop by our booth:

At this year’s IMTS, Heimatec will display its live tooling in a unique way…a live demo on a rotating machine tool turret. Come and see the show!

Heimatec, a world leader in live tools, angle heads and multi-spindle drill heads, today announced immediate availability of its newest development, recently unveiled for IMTS.

U-tec is the company’s patented flexible tool adapter system that allows a standard ER output live tool to accept various adapters for different applications. This allows users the ability to have quick changeover of tools on almost any lathe, using a single live tool, without having to commit to a quick-change system on the initial purchase. A facemill adapter, for example, can be quickly positioned into the standard holder, without the need for a completely new base being installed. This significantly reduces inventory costs as well as changeover time, for the busy shop.

The U-tec system, according to Heimatec Inc. President Preben Hansen, “…represents a real improvement in lathe and mill/turn tooling design. U-tec allows great user flexibility, while a polygonal drive system ensures extremely high power transmission stability and faster set-up with absolutely no loss in performance or accuracy, because the live tool base remains in position and only the adapter and collet get swapped.”

He went on to explain the unique collet nuts on the U-tec system have internal threading for rigid mounting and that this new tool adapter system enables the actual cutting tool to be brought into closer proximity to the bearing, thus further improving performance in use. This benefit results from the short and compact tool length design. Internal coolant up to 2000 psi(140 bar) is provided standard.

Every adapter in the U-tec system comes complete with any necessary clamping nuts and adapters are immediately available in face mill style, ER extensions, side lock, shrink fit, hydraulic and blank.

The U-tec system is available for all major turning machines on the market today. Heimatec currently manufactures over 10,000 live tool types.

For further information and literature on this new product, please contact:

Preben Hansen, President

HEIMATEC INC.

16 E. Piper Lane Suite 129

Prospect Heights, IL 60070

Phone: 847-749-0633

Fax: 847-749-2445

Email: info@heimatecinc.com

Website: www.heimatecinc.com

—

Heimatec is an international tooling manufacturer, based in Renchen, Germany. Its experienced staff is dedicated to providing customers the most innovative tooling technology possible. In 2010, the company opened Heimatec Inc. in Prospect Heights, IL, near Chicago, to serve its growing North American customer base with sales and service, plus an extensive inventory of products. Heimatec serves the auto, aero, medical, off-highway, rail, energy, woodworking, composites and other industries, as well as an ever-increasing number of machine tool OEM’s worldwide.

Continue readingAdvanced Machine & Engineering Co. (AME) Rockford, IL announces their return to IMTS 2012. As in the past, they will have two booths to showcase their products and services.

Visit Booth W-2405 to learn about precision machine components, featuring:

Visit Booth E-5714, for additional AME products such

Our sister company, Hennig, Inc., will have their complete line of products in Booth E-5714 and W-2405.

Advanced Machine & Engineering Co., is a manufacturer located in Rockford, IL, serving the Machine Tool Industry with precision components and accessories, including spindle interface components, workholding devices, and, through our sister company, Hennig, machine enclosures, chip removal and filtration systems. The Fluid Power – Safety markets are served with cylinder rod locks and safety catcher devises; and the Production Saw market with our Amsaw carbide saw machines and Speedcut blade products. AME has manufacturing partners and customers around the world and across the U.S. To learn more, visit www.ame.com.

For more information, contact:

Tim Waterman

ADVANCED MACHINE & ENGINEERING CO.

2500 Latham St.

Rockford, IL 61103

Phone: 815-316-5277

Fax: 815-962-6483

E-mail: info@ame.com

Connect with AME online:

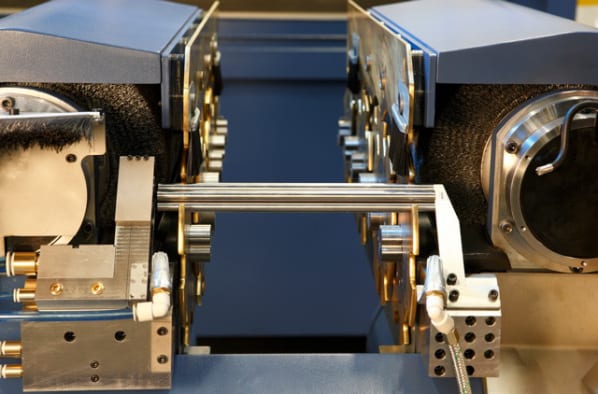

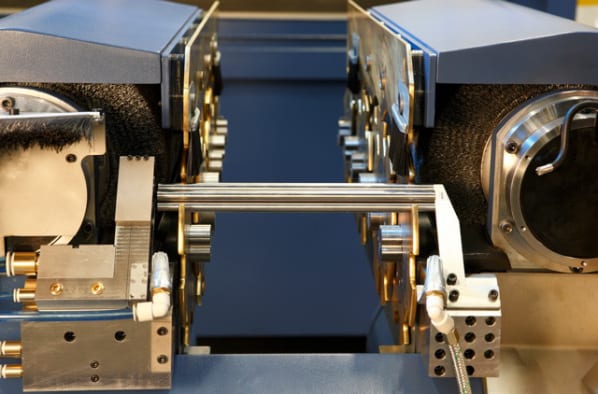

Integrated Sawing and Machining Center Sets New Industry Standard

The ACS Sawing Machine is the new industry standard for cold saws. It utilizes a proprietary sawing algorithm with servo motor controlled feed to continuously adjust critical sawing parameters during each cut. The results are the fastest sawing times, best surface finish and longest blade life available on the market.

The CFMcurve machining center is a patented Rattunde process that

Precision parts are made in one continuous process with no operator intervention. Bundles of mill length stock, up to 16.5 meters (54’) long, are placed in an automatic loader, individually separated and fed to the sawing process. Cut parts are then transferred to the CFMcurve machine for precise finishing. Utilizing advanced CNC controls, linear ball screws and servo motors, all mechanical motion is seamlessly integrated into the machine design for full process control.

The operator interface saves part files for instant recall when changing parts. Servo motors move all cutting and machining tools to their exact positions and implement saved parameters. No tooling change is required in the ACS Saw within a diameter range of 10mm; there is a 5mm diameter range in the CFMcurve. Tooling change for the complete system takes less than 20 minutes, when necessary.

All critical sawing and machining parameters are monitored and controlled. Clamping forces and position, saw blade torque and vibration, plus machining insert torque are continuously displayed and monitored. Operating limits are set and machine functions stop when they are not met. Saw blade and tooling insert wear is predictable and consistent. Key data for each part produced are stored in memory for statistical evaluation. All guesswork is removed for the operator.

Additional processes, engineered and manufactured by Rattunde, are easily integrated with the ACS + CFMcurve, including: part inspection stations, washing and drying, automatic packaging and automatic container changing, all available to further automate customer manufacturing. The system being exhibited at IMTS will include part inspection and automatic packaging.

The ACS + CFMcurve is available in three models with diameter ranges from 10mm to 102mm, 10mm to 136mm and 10mm to 169mm, with finished part lengths from 10mm to 3500 mm. All material types can be processed.

You can watch the machine in action at:

http://www.rattunde-corp.com/tube-sawing-video.htm

For further information, please contact:

Rattunde Corporation

4980 Kendrick St. SE

Grand Rapids, MI 49512

616-940-3340

Alec Banish

IMTS PRE-SHOW NEWS…BOOTH N-6737

No. 1022 is a 550ºF, electrically-heated, two-zone, dual belt conveyor oven from Grieve, currently used for encapsulation curing of large electrical coils in fixtures at the customer’s facility. Workspace dimensions of this oven measure 8’ W x 40’ D x 18” H. 480KW (240KW per zone) are installed in Incoloy-sheathed tubular elements to heat the oven chambers, while two 20-HP recirculating blowers provide a 49,000 CFM vertical downward airflow to the workload.

This Grieve conveyor oven comprises a 2’ long open belt loading zone and 3’ long insulated, unheated entrance vestibule, two 20’ long insulated heat zones with independent recirculated airflow and temperature control, 3’ long insulated unheated exit vestibule and finally a 2’ long open unloading zone for the workpieces.

No. 1022 has 6” insulated walls throughout, aluminized steel interior/exterior and is split into two sections for shipping. Side doors along the length of the oven permit access to the workload and heating chambers. This Grieve conveyor oven is built with all safety equipment required for handling flammable solvents and is constructed to NFPA 79/NEMA 12 electrical standards.

The oven further features two 3’ wide, 1-3/16” diameter cross bar conveyor belts with 1-HP motor drive, variable from 0.5 to 9 ipm. The conveyor belt drive is used in either index or continuous mode. Removable drip pans are provided below the conveyor assembly.

Controls on the oven include separate power and control panels, plus photo eyes at the unload station to signal an alarm, if the workpiece unloading is not cleared before conveyor indexing, SCR power controller for each zone and a tower light to indicate oven status. All control functions are accessed through a touch screen HMI connected to the onboard PLC.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart

Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-

9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank

Calabrese.

Continue reading

Ann Arbor, Michigan –Effective June 11, 2012, American Wera is now officially renamed German Machine Tools Of America (GMTA) and continues to represent various top-quality German metalworking machine builders, including Profilator, Pittler, Praewema, WMZ and MAE. These machines are sold for gear and spline production, vertical turning, flexible machining solutions (blank to finish part solutions), as well as bar, pipe and tube straightening plus wheelset pressing. The company’s target markets include automotive, off-highway, OCTG, rail, wind energy, aerospace and other heavy equipment manufacturing.

This announcement was made jointly by GMTA President Walter Friedrich and Vice President of Sales Scott Knoy.

“The reason for the name change is simply that the parent company wished to use a name that is more representative of all the lines we handle in North America,” said Knoy.

Originally formed as the North American subsidiary for Wera in Germany, GMTA today provides application engineering, sales and service for a broad range of machine tools and metal fabricating equipment. GMTA has representatives throughout the U.S., Canada and Mexico.

Other key company individuals include Claudia Hambleton, Treasurer; Doug VanDeven, Service/Parts Manager and Shawn Wilkin, Senior Service Engineer. Joseph Kemple remains the dedicated Product Manager for the MAE line of straightening and wheelset presses.

For more information on this announcement, please contact:

GMTA (German Machine Tools of America)

4630 Freedom Drive

Ann Arbor, MI 48108

Phone: 734-973-7800

Fax: 734-973-3053

Web: www.gmtamerica.com

Email: sales@gmtamerica.com

Attention: Scott Knoy, VP

Facebook: GMTA

Twitter: @GMTA_US

Fourth annual event to include Banner and Pioneer executives, presenting how to effectively address FDA supplier control concerns through strategic OEM/Supplier partnerships

Carol Stream, Illinois – Banner Medical executives Vince Adams, Vice-President of Sales, Marketing & Strategic Planning, and Bob Khin, Quality Assurance Director, along with Peter Johns, Supplier Quality Manager for Pioneer Surgical, will participate on a faculty panel at the upcoming Supplier Quality Management Congress sponsored by FDAnews, to be held at the Bethesda North Marriott Hotel & Conference Center in Bethesda, Maryland from July 31-August 2, 2012. The Banner Medical / Pioneer Surgical alliance has long been recognized in the industry as a successful strategic OEM / Supplier partnership formed to address the challenging supplier and raw material control issues which has been a focus of the FDA and of the Industry itself for the past decade. The partnership model, which the two companies have developed together, has produced positive results and yielded best practices that have been recognized by many and already adopted by some within the Medical Device industry.

This year’s Supplier Management Congress mark’s the fourth annual event and is designed to bring together suppliers, producers, top regulators / policy makers, legal and advisory consultants to the industry, for the purpose of assuring the integrity of Device raw materials and supply chains. FDA representatives as well a dozen other OEM and Supplier executives will participate as the faculty for this three-day event.

Attendees will include various manufacturers and suppliers to the industry, who will learn about risk management, recalls, liability issues and the new regulations recently instituted by FDA to better control the international drug and device supply chain to the medical markets.

Banner supplies medical and orthopedic device manufacturers with medical-grade materials to meet the highest quality standards. It operates two ISO 13485 and ISO 9001 certified, FDA CFR part 820 compliant facilities in Carol Stream, Illinois and Charlotte, North Carolina. The company provides its GuardiaNTM customer support solution program for supply chain management and medical materials stocking, plus its AssuraNce® protocol that assures all products made for the medical market are produced on equipment validated per the FDA requirements. Banner’s EsseNtial Quality SystemsTM is a patent-pending IT-based quality program that manages the company’s materials selection and production processes to deliver medical-grade bar and plate stock.

Banner Medical is a strategic business unit of Banner Services Corporation, a provider of precision ground bar as well as centerless grinding, turning and straightening, among other machining services.

For more information on this development, please contact:

BANNER MEDICAL 494 East Lies Road,Carol Stream, IL 60188-9425

Phone: 800-323-9732

Fax: 630-653-7555

Web: www.banner-medical.com

Email: getinfo@banner-medical.com

Agency contact:

Tim Daro or Wendy McCormick

Bernard & Company

847-934-4500

tdaro@bernardandcompany.com

wendy@bernardandcompany.com

This Grieve walk-in oven features 5” insulated walls, top-mounted heat chamber, aluminized interior and exterior plus a free-standing oven rack with two 6000 lb. capacity shelves for the workpieces.

Controls on No. 951 include a digital indicating temperature controller, manual reset excess temperature controller with separate contactors and recirculating blower airflow safety switch.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart

Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-

9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank

Calabrese.

Continue readingBill Hunter assumes 100% ownership of pioneering company in automatic matchplate molding machinery for sand casting

Schaumburg, Illinois (USA)-Hunter Automated Machinery today announced the completion of an asset buyout of the company and all its foreign subsidiaries by current President Bill Hunter. In his words, “We have successfully crossed the bridge of generational transition with this arrangement.” Mr. Hunter bought the assets of the company held by his three sisters, Dianne, Linda and Heather. All were the children of Al Hunter, the late founder of the company that began building the automatic matchplate molding machine Al invented, in 1964. Today, Hunter machines and mold handling lines are operating in foundries worldwide. Hunter operates plants in the USA, Brazil and China. The company has European headquarters in Italy and regional offices in India.

Karen Hunter, corporate secretary, Bill Hunter, president and John Purtill, corporate attorney at signing

Bill Hunter noted, “I am very thankful to my sisters, who worked closely with me on this agreement, allowing us to keep the company in the family. Likewise, I will always honor the memory of my father, who taught me much about this business and left a legacy of innovation and achievement in the global foundry market. We fully intend to continue and build on the company’s long-standing traditions of technology, quality and service to the industry.”

The agreement was finalized on June 27, 2012.

For further information on this announcement, interested parties may contact:

HUNTER AUTOMATED MACHINERY CORPORATION

2222 Hammond Drive Schaumburg, IL 60196

Phone: (847) 397-5110

Fax: (847) 397-8254

Email: info@hunterfoundry.com

Attention: Bill Hunter, CEO

Web: www.hunterfoundry.com

Connect with Hunter Foundry online:

Texas foundry buys new equipment, including Hunter XL matchplate molding machine, to respond to customer needs with fast pattern changes, shorter runs and on-the-fly flexibility in job scheduling, deliveries

Schaumburg, Illinois (USA)-In the heart of Limestone County sits Coolidge, Texas, halfway between Dallas and Houston. This classic American small town is home to another classic, Frazier & Frazier Industries, a ductile and gray iron foundry, established in 1972 by C.W. Frazier as a traditional cope-and-drag sandcasting operation with two squeezers and run today as a formidable shop by Plant Manager Will Frazier. An ISO 9002 Certified process operation, F&F combines the best of the old ways with the newest casting technologies and equipment in the market. As Will Frazier points out, “This is one of the biggest reasons we’ve continued to prosper, while so many other foundries have disappeared. We recognize what works and what doesn’t, to best suit our current business and market conditions.”

Once a heavy production shop, F&F today continues to support their large batch customers, but has reshaped the business model in many ways, according to Frazier. “We have traditionally worked in pieces from a few ounces up to 150 pounds or more. The large runs were more typical in days past, while we saw a new business environment emerging, several years ago, when the market began to decline overall.” He continued to explain how many of the company’s traditional customers began to reduce their inventories and thus placed shorter run orders with much tighter lead times. In something of a “perfect storm” scenario, this combination of increased job numbers and more urgent shipping requirements literally changed the pace of business at F&F. Frazier notes, “It’s not unusual for us to come in on a Sunday to finish a job for a customer who really needs it…and we rarely charge a premium, because we know how tough things are, for most of our accounts.”

While the oil & gas market applications are prominent here, as they are with most foundries in the region, F&F currently sells to end product manufacturers for the automotive, agricultural, wind energy, municipal water works and other market segments, a strategy that has helped to maintain a better balance in this shop’s workload. With its own sales force plus several manufacturers’ rep organizations in the field, Frazier & Frazier boasts customers in a wide variety of markets and as far away as Indiana, a relatively rare achievement in the foundry business, especially when larger, heavier workpieces are involved.

With over 8000 patterns in-house, F&F today experiences as many as 15 pattern changes per day per machine on the floor. This further complicated the job scheduling and work flow. Will Frazier and his team of Bob Pranger, general manager and Harlon Easton, vice president of sales, quickly saw the need for more automation in the machinery lineup.

F&F still does hand-rammed oil and air set cores, but over the years they’ve acquired automatic coresetting equipment, as well as automated molding machines, including the most recent purchase, a Hunter XL2024 automatic matchplate molding machine, which is used with the already in-place Hunter mold handling turntable system at F&F, as are other molding machines here. Three melting units feed the certified chemically correct iron to the molding stations. Currently, this shop does approximately 70% of its work in ASTM Class 60-100 ductile and 30% in Class 15-50 gray iron.

The XL2024 is a fully automated matchplate molding system, using gravity-fill technology pioneered by Hunter. It produces sand molds up to 20” x 24” with shallow 6-1/2” cope and 5-1/2” drag (165mm/140mm) at 180 cycles per hour, using 400 lbs. (181kg) of sand. Variable squeeze surface pressures to 142 psi (10kg/cm2) can be achieved in production.

This latest Hunter machine continued the tradition of leading-edge sandcasting technology used at Frazier & Frazier. Although several generations of Hunter and other brands of machines have been used here, when a new machine was planned, Will Frazier notes there were some key criteria to be met. “We’d been having critical problems with another machine builder, getting parts and service. We always knew the Hunter folks were excellent in those areas based on past experience, plus they were willing to provide considerable application engineering assistance and set-up help with the new machine. Coupling that with their stability as a company and great reputation in the world foundry market, we looked at all our options and settled on the XL2024.” Frazier further cites his long relationship with Hunter’s Mike Hughes as a factor. “Mike came down here several times to help us and, since the machine has been up and running, he’s stayed in close touch with us, even though we’ve had no performance issues with the machine.”

Will Frazier also points out that, currently, over 20% of the orders at F&F are rush and the quick changeover time of the Hunter machine makes it a highly productive piece of equipment and a definable competitive advantage in the market for his shop.

Frazier & Frazier provides its customers with metal castings as well as CNC machining, heat treating and galvanizing services, when needed. The shop has a fully equipped quality inspection department, highlighted by CMM and other state-of-the-art lab apparatus.

For further information on this story, interested parties may contact:

FRAZIER & FRAZIER INDUSTRIES, INC.

817 South First Street P.O. Box 279

Coolidge, Texas 76635 USA

Phone: 254-786-2293

Fax: 254-786-2284

Web: www.ffcastings.com

Email: willfrazier@ffcastings.com

Attention: Will Frazier, Plant Manager

Or

HUNTER AUTOMATED MACHINERY CORPORATION

2222 Hammond Drive Schaumburg, IL 60196

Phone: (847) 397-5110

Fax: (847) 397-8254

Email: info@hunterfoundry.com

Attention: Bill Hunter, CEO

Web: www.hunterfoundry.com

Connect with Hunter Foundry online: