Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Sinumerik MDynamics Milling Roadshow is coming to IMTS 2010.

If your company is looking for the way to more efficiently cut parts for aerospace, automotive or medical, one thing is certain — the demand for five-axis CNC machining has risen dramatically. And now there’s MDynamics: using one solid CAD/CAM/CNC process chain will get you to market faster than your five-axis competitors who will be lagging under a less integrated approach.

What is Sinumerik MDynamics?

“For users, it is extremely important to get from the blueprint to the finished part quickly, precisely and cost-effectively,” says John Meyer, marketing communications manager, Siemens Industry, Inc. “Sinumerik MDynamics combines our milling expertise together with our powerful Sinumerik CNC hardware platform, intelligent CNC functions, and our unique CAD/CAM/CNC process chain to form integrated technology packages for three- and five-axis milling.”

Seeing is believing.

According to Robert Scholz, international business development manager, Siemens Industry, Inc., Motion Control Business, “Together with leading machine tool OEMs, Siemens will demonstrate how users can benefit from accurate, high-speed machining and perfect workpiece surfaces. Every roadshow event will demonstrate part programming and simulation with NX CAM, followed by five-axis part manufacturing using MDynamics functions and Sinumerik CNC. With real applications for the automotive, aerospace and medical industry, we will prove to our customers that we are the perfect fit for every industry.”

From A-Z and everything in between, Siemens has you covered.

By providing a uniform and integrated system that ranges from programming directly at the CNC for simple parts, to a CAD/CAM system for complex workpieces, Siemens has the right solution for all CNC machining needs. With NX CAM, Siemens provides manufacturing engineers with an open and flexible 3D system that applies not only to the development of part models and drawings, but also to full NC programming and machining simulation. NX enables 3D and 2D construction in a full-, partial- and non-paramaterized form. The fully-integrated NX CAD/CAM system supports a complete part model to CNC program process and even offers 3D quality inspection programming in the same system. NX CAM provides optimized output for Siemens-controlled machines with additional programming commands and automated post-processor functions. During planning and into production, special focus is placed on the process related to the workpiece.

This process chain includes:

Product and process development using advanced CAD/CAM software

Part program generation for the most advanced machine tools

Optimized part program and post-processor output for maximum machining performance

Integrated and offline simulation for checking and optimization of manufacturing process on the PC

Optimized and highly-efficient manufacturing on the machine

See what Sinumerik MDynamics can do for your business!

Attend the Siemens Sinumerik MDynamics Milling Roadshow.

Roadshow schedule

20-minute demonstrations every day

during IMTS, September 13–18, 2010

12:30 p.m. — Milling for Medical

DMG/ Mori Seiki, booth S-8900

1:30 p.m. — Milling for Automotive

Grob Systems, booth S-9066

2:30 p.m. — Milling for Aerospace

MAG, booth S-8519

www.usa.siemens.com/cncroadshow

Continue readingNo. 898 is an electrically-heated 650°F(~343.3°C) universal oven from Grieve, currently used for heat depyrogenation. 12 KW are installed in Incoloy sheathed tubular heating elements. Workspace dimensions are 36” wide x 36” deep x 36” high. The unit has 6” insulated walls and a type 304, 2B finish stainless steel interior and an aluminized steel exterior.

A 600 CFM, 1/2-HP recirculating blower provides universal airflow to the oven. The oven is also equipped with positive latching door hardware, a solenoid operated door lock and an integral leg stand. Safety equipment is included for handling flammable solvents and the floor of the oven contains an explosion venting panel.

Controls onboard No. 898 include a digital indicating temperature controller, motor control push buttons and an on-off heat switch.

For more information, please contact: THE GRIEVE CORPORATION, 500 HartRoad, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank Calabrese.

Continue reading

Han-Kwang USA announces immediate availability of its new Series PL, specifically Model PL 3015, a long bed, 2D flying optic laser system capable of handling 60” wide x 120” long workpieces. With a long bed gantry arrangement, less motion is required on the machine, providing greater working stability and reduced maintenance requirements.

Model PL 3015 features rapid single axis speed of 4724 ipm, simultaneous X-Y axis speed of 7900 ipm and maximum cutting speed of 1181 ipm, all with positioning accuracies better than +/- 0.004” per 118” of travel and repeatability to 0.001”. A dual shuttle pallet system is onboard to maintain optimum productivity in processing.

This Han-Kwang laser system features a powerful Panasonic CO2 laser resonator in 2, 2.5, 4 and 6 KW versions, as well as the builder’s patented beam radius control, which optimizes the beam

All machine mechanical movements and laser cutting operations are controlled by the powerful Siemens SINUMERIK 840D CNC. With its open architecture, 10GM hard drive and plain language commands, the CNC enables faster start-up and reduced time to first part for the programmers and operators alike. Further, a remote service support feature allows online communication to the CNC manufacturer for troubleshooting assistance.

An optional rotary axis is available for tube cutting up to 12” OD with this Han-Kwang laser system. Fully automated materials handling systems, pallet towers and other equipment for production improvement are also offered by the company.

For more information, the name of a local Han-Kwang dealer or to arrange a demonstration, please contact:

HAN-KWANG USA INC. 1120 Garfield Street Lombard, IL 60148 Phone: 630-916-0200 Fax: 630-916-0300 Web: www.hankwangus.com Email: salesusa@hankwang.co.kr Attention: Robert Won or Erik Kim

Siemens CNC controls all machine movements, allows remote service support

Editor note: Robert Won, director for North American operations, is available for interviews to discuss the company, its laser technology and other aspects of the industry. Han-Kwang is Korea’s largest laser builder and the company has embarked on an aggressive marketing effort in North America.

Agency contact: Tim Daro Bernard & Company tdaro@bernardandcompany.com 847-934-4500

Continue readingOver 400 customers attend Sominn event to see metalworking machines, meet company representatives.

Han-Kwang USA, a leading supplier of CO2 lasers and automated handling equipment for metalcutting operations, attended the Open House held on July 21-22 by its dealer, Southern Minnesota Machinery Sales (Sominn) in Dodge Center, Minnesota, just south of the Twin Cities. Over 400 customers of this major machine dealer attended the event, where Han-Kwang’s Director of North American Operations, Robert Won, was present to discuss his company’s offerings. Highlighting the Han-Kwang presentation was the new PL-3015, a dual-shuttle table, 60” x 120” workpiece, long bed CNC laser, available in various KW power models.

Sominn is the Han-Kwang dealer for Minnesota, North Dakota, South Dakota and Eastern Iowa. The company sells and services Han-Kwang plate and tube lasers, as well as over 20 other leading brands of metalworking and fabricating machinery, including various waterjet, plasma cutting, press brake, shear, saw, bending and other equipment.

The open house was held at Sominn’s 30,000 square-foot showroom, with representatives from all their lines present to discuss the equipment needs of those in attendance. Sominn President J.J. Francis hosted the event, which drew attendees from this dealer’s entire territory, during the two days.

Sominn has been a major dealer in the area for 38 years and is a member of the Machinery Dealers National Association (MDNA).

Robert Won of Han-Kwang commented, “This was a first-class event, as customers could see the substantial inventory Sominn maintains and also learn about their full sales and service capability. We had many excellent inquiries about our lasers. Han-Kwang is proud to call Sominn our partner in this region.”

For more information on this dealer, please visit www.sominn.com.

For more information on lasers, the name of your local Han-Kwang dealer or to arrange a demonstration, please contact:

HAN-KWANG USA INC. 1120 Garfield Street Lombard, IL 60148 Phone: 630-916-0200 Fax: 630-916-0300 Web: www.hankwangus.com Email: salesusa@hankwang.co.kr

Attention: Robert Won or Erik Kim

Editor note: Robert Won, director for North American operations, is available for interviews to discuss the company, its laser technology and other aspects of the industry. Han-Kwang is Korea’s largest laser builder and the company has embarked on an aggressive marketing effort in North America.

Agency contact: Tim Daro Bernard & Company tdaro@bernardandcompany.com 847-934-4500

Continue readingLeading manufacturer of high-precision gears feeds, educates and entertains over 250 employees, suppliers and others

Roscoe, IL-Forest City Gear supplies some of the world’s leading companies with high-precision gear work. These include such diverse yet demanding customers as aircraft, military ordnance, every car in the starting field at the Indy 500, the winning boat in the America’s Cup and, perhaps their crowning achievement (pun intended), the Mars Rover. Already onboard Spirit and Opportunity, Forest City Gear products will deploy the solar panels and drive the wheels on the next generation of the Rover project, scheduled for lift-off in late 2011.

Meanwhile, back on planet Earth, the company celebrated its 55th year in business with a good old-fashioned corn boil on the company premises, July 24, 2010. Owners Fred and Wendy Young, along with their family, welcomed all the employees, their families, many suppliers, customers and friends of the company from the local Roscoe, IL community, to dine, socialize and stay out of the rain with them. Fred also gave tours of the facility, explaining to even the youngest visitors how a gear is made, measured and applied in the “real world” of mechanical motion, in all the industries served by this longtime market leader.

Highlight of the event were the karaoke performances by many of the employees, including the owners, who took all in attendance back to the halcyon hippie days of the 60’s with their heartfelt rendition of “I Got You, Babe” by Sonny & Cher. While the likelihood of the Young’s leaving the gear business for the glitz and glamour of the entertainment world is minute, every second of their performance brought rousing cheers from the enthralled mass, under the big top tent erected in the company’s parking lot.

There was face painting and a bouncy house for the kids, though Fred was looking at the latter with a mischievous grin, all afternoon!

In the end, despite a bit of rain, a good time was had by all, as they say. The hosts had allocated 4.5 ears of corn for all in attendance and many folks ate their quota and then some, while many were seen exiting the event with ears aplenty in hand, courtesy of Wendy!

Besides, where else on a rainy Saturday could one get a detailed explanation of the AGMA gear rating system?

See photos attached for more of the fun. For the real risk-takers, click here to see the Young’s singing for their supper!

For more information on the event or the company, please contact:

FOREST CITY GEAR CO., INC. 11715 Main Street Roscoe, IL 61073-0080 Phone: 815-623-2168 Fax: 815-623-6620 Web: www.forestcitygear.com Email: sales@forestcitygear.com Attention: Fred Young or Wendy Young

PR agency contact for Forest City Gear: Tim Daro Bernard & Company 847-934-4500

Continue reading

The unit has 4” insulated walls and a Type 304, 2B finish stainless steel interior with continuously welded seams. The exterior is finished in white epoxy paint and has a #4 brushed finish stainless steel door cover and control panel face.

A 600 CFM, 3/4-HP recirculating blower provides horizontal airflow to the oven and a 24” x 24” x 6” thick stainless steel high temperature HEPA recirculating filter helps to purify the air to the Class 100 standard. The oven is also equipped with a 12” x 12” x 6” thick HEPA fresh air filter with 2” prefilter. Safety equipment is included for handling flammable solvents, including explosion venting door hardware.

Controls onboard this Grieve cleanroom oven include a digital programming temperature controller and SCR power controller.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank Calabrese.

Continue reading

Han-Kwang USA announces immediate availability of its new Series PS, specifically Model PS 3015, a short gantry, 2D flying optic laser system capable of handling 60” wide x 120” long workpieces. With the short gantry arrangement, operator vision is enhanced on the machine, plus the more compact design facilitates a high degree of regulation in the cutting process.

Model PS 3015 features rapid single axis speed of 4724 ipm, simultaneous X-Y axis speed of 7900 ipm, driven by twin servos on the gantry and maximum cutting speed of 1181 ipm, all with positioning accuracies better than +/- 0.004” per 118” of travel and repeatability to 0.001”. A dual shuttle pallet system is onboard to maintain optimum productivity in processing.

This Han-Kwang laser system features a powerful Panasonic CO2 laser resonator in 2.5, 4 and 6 KW versions, as well as the builder’s patented beam radius control, which optimizes the beam diameter for various material substrates and thickness variations,

A plasma monitoring unit constantly tracks cut errors to further reduce out-of-tolerance conditions in the cutting cycle, while a built-in lens crack sensor monitors the state of lens contamination, with instant alerts through the onboard Siemens CNC to provide operators and maintenance personnel useful and immediate alarm notifications.

All machine mechanical movements and laser cutting operations are controlled by the powerful Siemens SINUMERIK 840D CNC. With its open architecture, 10GB hard drive and plain language commands, the CNC enables faster start-up and reduced time to first part for the programmers and operators alike. Further, a remote service support feature allows online communication to the CNC manufacturer for troubleshooting assistance.

For more information, the name of a local Han-Kwang dealer or to arrange a demonstration, please contact:

HAN-KWANG USA INC. 1120 Garfield Street Lombard, IL 60148 Phone: 630-916-0200 Fax: 630-916-0300 Web: www.hankwangus.com Email: salesusa@hankwang.co.kr Attention: Robert Won or Erik Kim

Editor note: Robert Won, director for North American operations, is available for interviews to discuss the company, its laser technology and other aspects of the industry. Han-Kwang is Korea’s largest laser builder and the company has embarked on an aggressive marketing effort in North America.

Continue reading

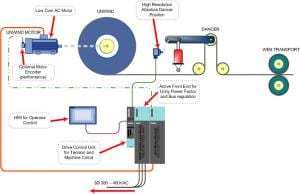

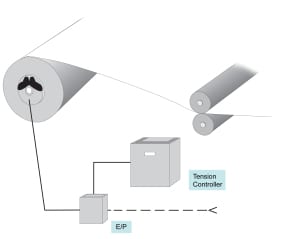

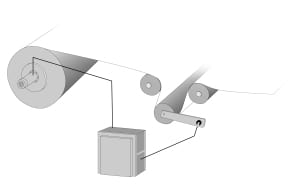

by William Gilbert, Industry Business Development Manager, Converting and Cranes, Motion Control Solutions

During the operation of any converting machine, whether for film, foil, wire, paper or board, plus most large printing presses, rolls of materials are handled by unwinds, often still driven by pneumatically operated braking systems. The traditional tension control system for an unwind stand is a simple mechanical brake. In principal, the unwind brake mechanically operates much like the braking system on your car, with a disk, caliper and pads, but is controlled by a tension sensor linked to a setpoint controller. As the roll unwinds, the tension is maintained by the brake for smooth passage of the material through the dies or rollers, resulting in better package alignment, less wrinkling, better print registration, even more consistent wire dimensioning and other production positives. These mechanical brake unwinds are effective in controlling the tension, but have inherent problems of heat and power loss, plus mechanical wear and constant maintenance needs, substantially impacting machine uptime.

The typical mechanical brake is pneumatically controlled and may utilize several sets of friction pads to control the web tension as the roll dimension decreases. Plus, a reasonable pressure range in many applications might be from 15-90psi or a 6:1 drop, a range significantly less than the core to full roll ratio for most jobs, an obvious inefficiency in operation.

To affect good tension control on the brake, these friction pad sets need to be manually changed in an out of the brake assembly, depending on the desired operating tension and the roll diameter changes involved. Often, the adjustments are several per roll during this manual changeover. Because the mechanical brake creates the unwind tension through friction, it generates substantial heat and often requires a separately powered fan for cooling to operate effectively. This friction also means the pads are subject to rapid wear, requiring frequent and time-consuming changes or maintenance checks.

For almost a decade now, this old technology has been gradually replaced, though usually in the lower power ranges, by newer precision technology, involving AC motors, drives and electronic loadcells. On converting lines today, a further leap forward is being made with the onset of

With such technology, the operating principle is as follows.

Since the unwind application is regenerative (regen) in nature, a driven unwind needs to return the energy that the mechanical the brake produced as heat back to the AC line. In the past, regen DC drives have been successfully applied as driven unwinds, but DC drive systems are no longer common and even during their prime were very costly. Early in the AC drive technology for these applications, the drives did not have the capability to regenerate the power back to the AC line and, when applied as unwind brakes, required regen resistors to dissipate the tension energy. This was wasteful and costly.

Today’s AC drive systems now have the technology to regenerate the energy back to the AC line just as the DC drive did, but with added benefits to the user and machine designer alike. Sending the tension energy back to the line means power that once was wasted can now be retained, instead of the system producing heat and worn parts. When the drive is equipped with active front end technology, it will return the previously wasted energy with near unity power factors, something not possible for any DC drive system.

Even an open loop AC drive motor combination offers a tension control range far beyond the limits of a pneumatic braking system. Synchronous AC motors can offer precision open loop torque control without a tension sensor, thereby saving further cost and inventory. Today’s highly accurate tension control systems can be designed with high resolution (sin/cos) feedback encoders on both the unwind motor and dancer position feedback. Additionally, in more advanced active front end designs, the regen capability of the drive can actually assist in the increase of stopping times and tension control regulation, owing to the four quadrant control, i.e., the motor can sink or supply current to the motor in both directions.

Beyond the obvious cost savings of pad replacements on mechanical braking systems, AC motors are virtually maintenance free by comparison to DC motors, as AC motors have no brushes, do not require controller contactors to reverse direction of motor rotation or have commutators. Fewer moving parts invariably means less motor maintenance, for additional cost and time savings.

In the most advanced systems, common DC bus regulation, energy-monitoring devices for near unity power and, through the use of mechatronic services often provided by the manufacturers, “turn off” parameters in vector drives are possible. Mechatronic services can also be utilized for the proper tuning of these drives onsite or during machine build. For designers, such services further assist in the proper sizing of motors, based on the mechanical and electrical forces generated by machine operation or computerized simulation of it.

This combination of improved operation, reduced maintenance, motor power savings and conservation of nearly all energy within the system make AC regen drives with active front end technology a decided advantage for machine designers and end users of converting, packaging, printing, wireforming and other roll-fed machinery, where driven unwinds can be implemented.

For more information on regenerative drive motors and systems, please contact:

Siemens Industry, Inc. Drive Technologies — Motion Control

390 Kent Avenue Elk Grove Village, IL 60007 Phone: 847-640-1595 Fax: 847-437-0784 Web: www.usa.siemens.com/motioncontrol Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communications

Editor Note: Siemens will make the author as well as various other product and market specialists available to you for interviews on the many aspects of regenerative drive motors detailed in this article, as they apply to the particular nature of your audience. Please contact the agency to arrange. Thanks!

PR agency contact: Tim Daro Bernard & Company 847-934-4500 tdaro@bernardandcompany.com

Continue reading

Joe Drilling has a pride in his company that’s classic American entrepreneur. After years at a leading label machine builder, he founded Drilling Technical Services (DTS) in Milford, Ohio, a virtual engineering company specializing in the mechanical, electrical and process engineering of mid-width and narrow web printing, drying, converting, RFID and digital print equipment. DTS has a particular emphasis on web transportation, die-cutting and laminating solutions. As the installed base grew and responding to current market conditions, Joe founded a second company, Pre-Owned Press & Parts Solution LLC (POPPS), also in Milford, specializing in the evaluation, reconfiguration, remanufacturing, sale, commissioning and servicing of pre-owned presses. Another vital component of the business models at both DTS and POPPS is the engineering of energy recovery systems for containment of utility costs, an ongoing challenge in the printing industry.

The two companies primarily serve the needs of the flexible packaging, folding carton, tag and label, health and beauty, wine and beer, plus other label segments.

During a recent project for one global leader in label and filmic product solutions, DTS was commissioned to develop a mid-width web roll-to-roll die cutter with various unique substrate manipulation functions. The substrate’s physical parameters, especially the desire to reduce material thickness, represented particular challenges to the DTS team.

DTS utilized its “QC Mod Cut Series” modular web transport system and quick change die cassette technology as the design platform.

Every aspect of the work was to be done to the customer’s strict system specifications for equipment criteria, including die cutting accuracy, line speed accuracy, tension control and wound roll precision. These process functions were to be controlled by the machine’s Human Machine

Based on previous experience with Siemens, the DTS engineering team looked to integrate electronic line shafting and process control functions that could be achieved with standard component architecture. Having a local and experienced distributor of Siemens components, Richard Equipment Company (RECO) in Cincinnati, the investigation into a process solution began. As Joe Drilling further noted, “The worldwide support of Siemens was an additional factor in our decision and really gave us that comfort zone in selecting them for this project. Our customer is itself a world player and so we felt confident in Siemens’ ability to provide components and service, wherever needed.”

To achieve the desired accuracies in every machine function, DTS utilized the Siemens Simotion D435 motion controller, a compact, drive-based platform that incorporates motion control, logic control and drive control in a single hardware unit for drive mounting. In this manner, the drive became the control for the entire machine’s functionality. Feeding off this platform are the multi-axis control drives of the Siemens Sinamics family, as well as Simatic I/O components and runtime software, plus the related HMI hardware, as supplied by RECO.

Components were selected by the DTS engineers using the unique Siemens Converting Toolbox, a suite of product specifications and application software that allows an engineer the flexibility to customize portions of a machine build, then recall and reuse them or make modifications for subsequent builds. The reduction in subsequent machine design engineering time, according to Joe Drilling, reached approximately 80 percent on the second machine and he anticipates a repeat of that scenario, every time.

These factors were found most satisfying for DTS and especially their customer, who had previously used a vendor for machine upgrades who typically took months, even years, to research, develop and implement design changes in the customer’s machine lines, according to Drilling. “With our more simplified layout of components and the flexibility we enjoyed with the Converting Toolbox, the learning curve shortened tremendously. Product and Matrix winder modules were able to be configured to allow the diverse web tension ranges and accuracy required. And, most of all, the shaftless drive system we implemented allowed our web transport roll design on the individual machine sections to become much easier, faster and completely repeatable.” The end result is very accurate web control and re registration capability.

Siemens system training and project development took place on-site at DTS.

Other recent projects accomplished by DTS engineers include an air-to-air heat exchanger for dryer efficiency, a dryer system upgrade for water-based inks, a unique accumulator stacker specially designed for thin substrate processing, a near-zero defect RFID system and various anilox system upgrades to integrate more advanced motion control technology. The company also performs considerable process layout and process improvement consulting to its customers throughout the industry.

For more information on this story, please contact:

DRILLING TECHNICAL SERVICES INC.

6062 Kells Lane

Milford, OH 45150

Phone: 513-831-2952

Fax: 513-831-4825

Web: www.drillingtechservices.com

Email: jdrilling@drillingtechservices.com

Attention: Joe Drilling, President

Or

SIEMENS INDUSTRY, INC.

Drive Technologies — Motion Control

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595 Fax: 847-437-0784

Web: www.usa.siemens.com/motioncontrol

Email: SiemensMTBUMarCom.industry@siemens.com

Attention: John Meyer, Manager, Marketing Communications

—

Drilling Technical Services Inc. in Milford, Ohio is machine builder specializing in the mid-width and narrow web press market. Its sister company, Pre-Owned Press & Parts Solutions, offers full reconfiguration engineering and remanufacturing services, plus full installation and commissioning on pre-owned presses.

Through the use of the Siemens Converting Toolbox and Simotion selection of drive/control technologies, all the motion control drive-based components and logic software were selected from a suite of available options. A reduction of over 80 percent in engineering time has been reported by the machine builder.

Continue reading

These self-cooled 1FK7-HI servomotors provide stall torque in the 3 Nm to 20 Nm range and are offered in IP64 or IP65 with IP67 flange degree of protection, with selectable options for plain or keyed shaft, holding brake, 22-bit incremental or absolute encoders, as well as 18 color options.

A mechanical decoupler between the motor and encoder shaft protects the encoder from mechanical vibrations, providing a long service life. In cases where the encoder needs to be exchanged, the device automatically aligns the encoder signal to the rotor pole position, enabling feedbacks to be changed in the field in less than five minutes.

These new Siemens 1FK7-HI servomotors also feature the unique Drive-Cliq® serial bus and electronic nameplate recognition, allowing virtual plug-n-play operation when paired to the Sinamics® S drive platform. All servomotors in this new line are also configured to interface with Siemens Sinumerik® CNC technology for machine tool applications and the motion controller Simotion® for general motion control use.

Selecting the proper motor to suit the application is facilitated by the Siemens Sizer® toolbox and compatible 3D CAD model-generating CAD-Creator package. For more information, visit www.usa.siemens.com/motioncontrol.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Continue reading