Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Increasing demands made on precision and the push for the decrease of price of modern components is pushing traditional manufacturing processes. EMAG offers three production technologies that complement or replace traditional processes such as turning, milling and grinding.

PECM for nickel- and titanium-based alloys

The ECM process is used to deburr components only at the points where material needs to be removed, and without it having any mechanical or thermal impact on the workpiece.

With its PECM technology (Precision Electro-Chemical Machining) EMAG presents a production process that opens up completely new fields of application. PECM is a process for the machining of high-alloyed materials, such as nickel- and titanium-based alloys. The disadvantages of traditional metal cutting – tool wear, mechanical stresses, micro-fissuring caused by heat, oxidization layering and the need for subsequent deburring operations – are eliminated, because this process is a non-contact one without heat input. All electro-chemical machining processes are characterized by stress-free material removal, smooth transition points and surfaces without ridge formations.

The ECM process is used to deburr components only at the points where material needs to be removed, and without it having any mechanical or thermal impact on the workpiece.

The advantages that the PECM process provides for different branches of industry are best shown with the example of a turbocharger for the automotive industry. The electro-chemical process is one that can be used to effectively in the machining of many high-alloy components, especially those in the high-temperature sector of the turbocharger – it also offers a much shorter and very efficient process chain. The typical clean-up operations necessary when traditional machining processes are used – such as deburring after milling – are no longer necessary. PECM machining operations are burr-free. And there is hardly any tool wear. The result: downtimes are minimal, when compared to milling (which requires regular tool changes). The process as a whole is sturdier and less prone to errors. And another important factor that our example of the turbocharger shows: the superb surface finish of the PECM process, where Rz-values of 0.3 micron can be achieved.

Will camshafts ever again be made of a single piece?

Another highlight is EMAG’s heat-shrink assembly technology, a process that scores particularly well in camshaft production. The high degree of precision achieved with the joining process drastically reduces the number of cam profile grinding operations or – with the use of precision cams – avoids them altogether. Another benefit of the process is the ability to combine different materials in the construction of the shaft, such as forged cams (e.g. in 100Cr6) and sintered cams, which do not require regrinding. Accessory components, such as plugs and end pieces, can – like the shaft itself – also be made of better materials. This allows for the camshaft to be adapted to the requirements of the engine and to be optimized in load bearing capacity and manufacturing costs.

Operating costs reduced by 50 %

Production laser welding is already a highly productive process in the manufacturing of gearwheels. The use of diode-pumped solid-state lasers – such as disc or fiber lasers –reduces operating costs by up to 50%. EMAG has been involved with the use of solid-state lasers in the welding of powertrain components from an early stage and is considered a pioneer in the technology. EMAG again has fulfilled a promise to their users offering them the lowest possible cost-per-piece, by coming up with an innovative technology that brings true cost benefits.

For many applications, solid-state lasers allow welding without shielding gas. This not only reduces operating costs, it also avoids having to follow the annoying logistics imposed by the use of shielding and laser operating gasses. In many cases, the welding process can also be sped up considerably. This increases productivity and – through a reduction in energy input per unit length – reduces welding distortion, resulting in better component quality.

For more information:

Kristal Kilgore

EMAG LLC

38800 Grand River Avenue

Farmington Hills, MI 48335

Tel: (248) 875-0313

Fax: (248) 477-7784

E-mail: kkilgore@emag.com

Web: www.emag.com

Test stand builder collaborates with Siemens Industry, Inc. on variable speed drives and motors to affect green, lean solutions for testing Apache, Blackhawk helicopter powertrains at Department of Defense customer; over 20 test stands reduced to five.

RedViking, located in Plymouth, Michigan, made its mark in automotive power transmission test stands, beginning in 1981 as Superior Controls. Today, the company is providing multi-disciplinary engineering and equipment construction services to major corporations such as Caterpillar, GE, Boeing, General Motors and others. Spun off in 2010, RedViking designs and builds a variety of powertrain test equipment, metrology and production solutions for government and commercial OEMs alike.

For a recent Department of Defense (DoD) customer, RedViking was presented with a challenge that involved an existing bank of over 20 individual test stands, used for dynamic testing of performance factors on helicopter transmissions, primarily in the Apache and Blackhawk classes. The existing test stands ranged from 20–50 years in age and had been built with single-purpose functionality. This scenario resulted in constantly increasing maintenance requirements for the customer, plus excessive power consumption and plant floor space capacity overload. The test stands suffered from a lack of readily available spare parts, required unique training to operate each stand, and did not produce the desired level of data for analysis.

When a unit test was required, the test article would be built up and dressed within the envelope of the test stand, fully connected, then tested, disconnected and removed from the work cell. This procedure resulted in extremely long downtime impact on the customer’s equipment utilization, with various corresponding logistic challenges. Coupled with the age of the equipment and the excess power used by the older equipment, this situation presented the RedViking engineers with a series of hurdles to overcome.

New testing system requirements included better compilation of test data, automatic closed loop operation of the machinery, true speed and torque measurement with a local Test Executive as the main operator interface to the test machine and finally, a standardized control platform to allow easier operator cross-training on the equipment.

The customer targeted a goal of three to four tests per working shift versus the current one test per shift being achieved with their multiple machines. RedViking performed its onsite assessment and subsequent situation analysis, and then devised a solution that utilized common components and an entirely new material handling strategy. A series of five flexible test stand designs was determined to be sufficient for the replacement of all existing machines.

To accomplish greater efficiency in the utilization of these test stands, a series of workpiece carriages was designed, allowing the Units Under Test (UUT) to be mounted and staged outside the envelope of the test stand and then brought into the work cell for faster connection, test, disconnect and exit. RedViking terms these devices Transportable Test Fixtures (TTFs), which automate shaft connections, clamping and positioning, as well as providing 360° access to the UUT. This design provides significantly greater efficiency as well as a safe and ergonomic operator environment. As RedViking explained, hours of test setup time are reduced to minutes.

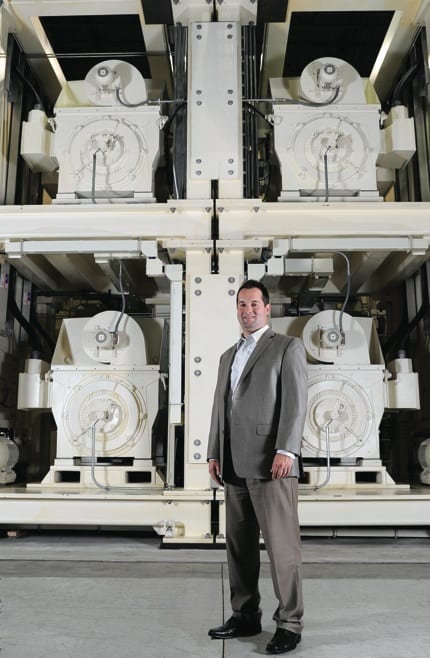

RedViking Controls and Software Manager Jason Stefanski at the main transmission flexible test module.

RedViking Controls and Software Manager, Jason Stefanski, and his team devised an entirely new, modular software system and common Human Machine Interface (HMI) platform for all five test stands, with a common user interface and plug-in architecture, comprising common function blocks, I/O coding and CAT 4 safety functions. This design approach allows the software to be easily configured to accommodate the various transmission models being tested.

Once the test article in the TTF is automatically positioned and attached, RFID tags on the TTF identify both the article and its test profile configuration and communicate them to the Test Executive.

All test profiles are generated and stored offline, with modifications made by the customer’s engineering staff outside of the test cells. Test profiles are then linked to the UUT type and model data for further system integrity.

The main software feature of the test machines is the ability to execute a fully automated, repeatable, and traceable test. To provide this functionality, RedViking has developed a Test Sequence Set (TSS) Editor, allowing all parameters to be set by the customer, downloaded to a Test Executive from a localized laptop, thus eliminating the need to modify validated machine code.

The TSS editor provides the customer with adaptability to easily modify future or existing test profiles.

After a thorough review of the potential suppliers for the power components and controls on these new test stands, Siemens Industry’s Drive Technologies Division was chosen to provide the motors and AC flux vector drives packages with regenerative braking for increased energy efficiency. RedViking worked closely with Siemens to devise an AC system, utilizing the regenerative technology found in Sinamics drives with 480V and 690V standards. Jason Stefanski recounted a number of field trips to Siemens customers to investigate the performance and application specifics of regen drives used with 3000 hp motors.

The use of Siemens regenerative braking technology allows a system to recover power, minus the parasitic losses. Conventional dynamic load testing requires loading to occur via an eddy current or fluid brake system, which requires additional energy, maintenance and up front capital investment. In more innovative industrial environments, according to Siemens, Sinamics regenerative drive technology can enable energy savings of 40 percent or more.

With a common DC bus architecture, this allows for only one AC to DC conversion in the motoring direction and the regenerative braking power goes straight to another inverter, which is motoring via the common DC bus link. This method eliminates two conversion points where energy would be lost which increases the overall efficiency. In addition, the common bus solution paired with the active front end (AFE) has the ability for power factor correction, which will further increase the overall savings of a common bus system. All AFE drives allow for unity power factor and low total harmonic distortion (THD) that meets IEEE 519 harmonic standards. This means these drive systems can improve the present power factor displacement in a customer’s facility.

RedViking estimates that a test on the Main Transmission Flexible Test System, while running at full capacity, will cost approximately $400 less per hour to operate than current comparable systems. With improvements over the conventional non-regen testing process, the RedViking Main Transmission Test System could generate approximately $500,000 in annual power savings.

For this project, Siemens Industry, Inc. supplied its high-performance asynchronous Simotics 1PL6 and 1RN4 motors, the largest being 3000 hp, to power the various mechanisms on the RedViking test stands. When in operation, these motors simulate the power generated by the helicopter’s jet engines, in addition to simulating the loading of the main rotor and tail output blades. This allows RedViking to test the helicopter transmission components to the full speed and torque requirements as specified by the military with very precise closed loop control.

On the Tail and Intermediate Gearbox Flexible Test Module, it was determined that the use of two more Siemens Simotics motors was less expensive and more efficient than the previous test stand’s gearbox design. This solution involves multiple motor connections to an output variable frequency drive (VFD) with auxiliary connections, thereby eliminating the need for additional VFDs.

Stefanski noted that one of the reasons that Siemens was selected for this project is their global support structure combined with a U.S. base of manufacturing. RedViking prides itself on designing and building systems in the U.S. and seeks out vendors who build their products in the U.S. as well.

Joshua Gibbs, RedViking Manufacturing Coordinator, commented, “We knew we were building these test stands to validate the performance of military helicopters that see wartime action. We take it very personally at RedViking to ensure these systems protect man and machine alike, as well as provide the ultimate in test validation.” RedViking further noted the substantial energy savings and operational efficiencies realized by the RedViking customer gave their entire team considerable pride of accomplishment on this project. RedViking currently performs both DO and DX contracts for the military and its subcontractors.

For more information:

SIEMENS INDUSTRY, INC.

Drive Technologies — Motion Control

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595 Fax: 847-437-0784

Web: www.usa.siemens.com/motioncontrol

Email: SiemensMTBUMarCom.industry@siemens.com

Attention: John Meyer, Manager, Marketing Communications

OR

RedViking

46247 Five Mile Road

Plymouth, MI 48170

Phone: 1-734-927-1460

Web: www.redviking.com

CNC upgrade enhances performance and precision

Major Tool & Machine (MTM) is a large job shop, producing precision milled and turned hardware throughout the company’s 500,000 square foot Indiana facility. Performance is essential, because MTM contracts with aerospace, energy, nuclear and defense companies on many mission-critical, one-off projects. Owner and CEO Steve Weyreter will tell you openly, MTM is more competitive by way of a significant CNC technology change, starting with an aggressive retrofit strategy.

Günther Zimmermann, CNC Controls Engineer at MTM, says the company’s retrofit program and the decision to change to the Siemens SINUMERIK CNC platform have brought a new enthusiasm and momentum to the company. Over the last two years the change has also brought significant time and cost reductions, especially in the areas of programming, maintenance engineering, and machine operations.

“The initial goal in early 2010 was to retrofit two Cincinnati U5 Gantry machines,” Zimmermann recounts. “We evaluated two CNC technology platforms and after considerable analysis our CEO Steve Weyreter announced that Siemens would best support the company’s future.”

The decision to reduce costs by moving to a single CNC platform was the least difficult decision for the company to make, Zimmermann explains. The larger challenge for MTM was the integration of a new CNC technology platform that was new to the company.

Bill Henderson, MTM’s manager of large machining and maintenance, agrees that the decision to change to a Siemens CNC platform integrated with advanced part and tool probing was critical, because the shop manages constant changeovers from one complex job to the next, making setup times a critical time/cost constraint for the company. Another big advantage is the increased flexibility by only having to train machinists and maintenance personnel on one type of control.

Naturally, there’s a resistance to change,” Henderson says. “People are comfortable with what they normally run, but after our discussions with the people on the plant floor, they understood the overall objective. Our retrofit program is not finished, yet it’s already showing tremendous benefits.”

Heads-up interchangeability

An advantage MTM gained by its retrofit strategy has been the ability to interchange heads and rotary tables from machine to machine. Easy-to-use head storage and tool management programming provided by the Siemens CNC platform support the new interchange capability.

Retrofitter Doug Huber says having Siemens as a new CNC technology partner has made a difference for Major Tool & Machine, but it’s also been an evolutionary uplift for his own retrofitting company, Indiana Automation.

“Indiana Automation has increasingly retrofit using Siemens controls in recent years, Huber explains. “On a retrofit, we always try to exceed what the original machine could do, and that’s just kind of inherent when you put on a Siemens 840D. Major Tool’s first retrofits were the Cincinnati U5 machines, a bridge model and two gantry models. These are five-axis machines and five-axis is the 840D’s forte. The processing power of the control is so much better, that it just whips through the blocks faster. So right off, cycle time is a major performance enhancement.”

Huber says something else happened this time. As his firm finished retrofitting the first three giant machines with Siemens five-axis controls, drives and motors, the reaction within the company was not just that the machines were now predictably more efficient, but that they performed as very different machines. A new advantage is the ability to interchange machining heads from machine-to-machine, and all driven by the Siemens CNC platform.

“On many of the U5 machines, the axes come off with the heads,” Huber explains, “and we rebuilt these machines to accept any one of three different heads. That’s one of Major Tool’s key strategies. They insist on having flexible machine capabilities, so that they can run all kinds of different parts. They have straight heads for serious metal cutting, contour heads for five-axis work and finesse work. They have 90-degree heads for more flexibility than a straight head, but it’s also not as fragile as the contour head. And they wanted to interchange all of these heads to automatically go pick up a head out of the shuttle and, on the fly, reconfigure the axes and the zero positions. To do this, the compensation tables all had to be updated. Everything needed to be done with the macro program so that each head came on ready to run.”

The interchangeable head strategy was a challenge, Huber says, because the machines were not originally capable of sharing heads. But with support from Siemens, the strategy has worked, including the ability to interchange rotary tables as well as heads. “Each head or rotary table has a configuration file that has all the settings and compensations and travels with it from machine to machine. So now when you mount that head the control just runs the configuration file that goes with it and its all set up for you. We also incorporated Siemens Tool Management for each machine’s 60-pocket tool chain. We used the feature on these machines to manage all the different tooling MTM uses, both in the automatic tool changer as well as the ones manually loaded.”

Huber says, “MTM’s ability to smoothly transition to more advanced CNC is largely due to the HMI’s ease of use. The Operate interface is a huge help to us and to Major Tool. The HMI helps make better parts. And it didn’t take very long for the operators to fall in love with it.”

Leveraging the machinist’s skills

Central to MTM’s retrofit program has been the Siemens SINUMERIK 840D sl control, which features the SINUMERIK Operate interface. The highly intuitive interface enables both programmers and operators to easily capitalize on the broad capabilities of the control.

“I had never used a Siemens control before,” admits MTM machinist Mike Burthay. “I have extensive knowledge of G-code and CNC controls and I would say the Siemens 840D sl with the Operate interface is the easiest one I’ve ever run. It’s user friendly, that’s exactly the words for it.”

Burthay reports several ways in which the Siemens SINUMERIK Operate interface has made his life easier. “There’s not as much G-code,” he says. “The control does it all for you as long as you put in the parameters as to size, length, width. Then once you’re in Job Mode, there’s a screen where you can tool change or jog the machine around to certain positions, or turn the spindle on, turn the coolant on, anything that traditionally required G-code. So now you can push a cycle stop button to pause the machine, enter a change such as turning coolant on, then restart the program.

Programming as easy as 1-2-3: Using the SINUMERIK Operate interface, a machinist can turn on coolant flow by 1) pressing Cycle Stop to stop the machine, 2) Coolant On, and 3) Restart.

“Another function I love is Block Search, which allows me to start or restart right in the middle of a program. Say you’re finishing a pocket and you have to run the tool two or three times to get a tight tolerance, I can enter in a line number and hit Block Search, the control picks up every line before that, restarts the spindle and everything for you.”

Burthay says the Siemens control also enables him to program parts right on the machine whenever necessary, using a simple yet robust program called ShopMill. “I can go into ShopMill, type in some parameters and it will kick out that G-code program for me automatically. Say I want to drill a hole two inches deep. I open ShopMill, pick my tool, tell it the depth and these steps are all interactive on the screen. It even shows me 3D motion images of the tool path, confirms the drill going down as expected into the part. So I hit go and it puts a drill cycle into the program for me.”

Programmed for collaborative growth

Lead Programmer, Tim Hayden, has from the beginning conducted all processor setups for the newly retrofitted machines. Hayden says integrating the Siemens CNC platform has been an empowering experience he had not expected, given the fact that he had never before set up a post processor to run a Siemens control, nor had he ever before operated a Siemens control.

“Now, when I look at the Siemens control, I think man, it would have been so much better to have had it all along,” Hayden says, “because the other control I’ve been using is just a lot more cryptic. The Siemens control with the SINUMERIK Operate interface is more powerful for writing macros and the language seems modern, whereas the other control seems like it is still based on an old FORTRAN type language.”

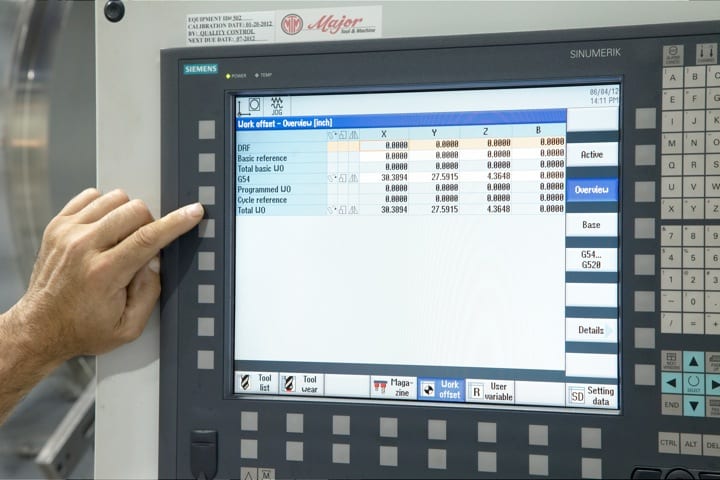

Work offsets for compound angles can be scaled and rotated using the Frames function of the Siemens SINUMERIK Operate interface. Many advanced machining operations can be managed simply, without the use of time-intensive manual G-code programming.

Hayden points to the Frames coordinate and offset programming function of the Siemens interface as an example of improved programming convenience.

“We do a lot of work on compound angles,” Hayden explains, “and with the Siemens Frames function, you can scale and rotate your coordinate system on the control, just plug it in with your work offsets. Whereas, on the other control you will see a G54 request, you’ve got to enter G-code. You can’t just plug it into your work offsets like you can with the Siemens control.”

Hayden says the SINUMERIK Operate interface brings greater programming flexibility. The HMI enables him to enter G-code using a comparatively more advanced manual data entry (MDI) function; however the HMI has all but eliminated the need for G-code entry by way of its intuitive design and evolved capabilities.

Another example of such HMI evolution is in the area of data management.

“When we post a program, we no longer have to use a G-code based MDI,” Hayden explains. “We no longer need to type in T= and enter a nine digit number and then enter M6 to make a tool change. With the Operate HMI, you pick your tool off a screen and hit cycle start. It’s just as easy to program going to a position. Instead of doing things the old way by typing G0X0Y0Z0 into the MDI, you open the Operate interface, click position, then click how you want to wrap it and then you just type the numbers into those fields. So it’s a lot more user friendly.”

Hayden says the Siemens CNC platform has supported greater collaboration at MTM between him and the machinists, and this is helping the company find ways to increase performance and efficiency. He agrees with his coworkers’ assessments that shorter setup times and greater operator freedom are making a significant difference.

“One of our production bottlenecks has been programming,” Hayden says. “The machinists that run our machines are professionals, they’re not button pushers, and with the SINUMERIK Operate interface, we can now rely on them to control and program certain parts right on their machines, while we programmers work on the more complex projects.”

“Siemens was the best fit for all of us,” Hayden concludes. “Siemens CNC is set up as an open control, and with that kind of flexibility, it seems anything is possible.”

See Siemens CNC at Major Tool & Machine in action HERE!

For more information, contact:

SIEMENS INDUSTRY, INC.

MOTION CONTROL

MACHINE TOOL BUSINESS

John Meyer

Manager, Marketing Communications

Siemens Industry, Inc.

(800) 879-8079 ext. Marketing Communications

www.usa.siemens.com/cnc

SiemensMTBUMarCom.industry@siemens.com

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue readingA walking tour of Rattunde’s unique tubemaking machinery, provided by company president for North America, Rick Stadler.

Click here to view the video.

Check out all the machining functions it can perform! Rattunde delivers ready to install products to the assembly line for its customers.

For more information, please contact:

Alec Banish

Vice-President / Business Development

Rattunde Corporation

4980 Kendrick St. SE

Grand Rapids, MI 49512

(616) 940-3340 x202

www.rattunde-corp.com

OR

Richard Stadler

President

Rattunde Corporation

(616) 940-3340

No. 893 is an 850ºF, electrically-heated walk-in oven from Grieve, currently used for heat treating parts on rollout shelves at the customer’s facility. Workspace dimensions of this oven measure 54” W x 72” D x 78” H. 80KW are installed in Incoloy-sheathed tubular elements to heat the oven chamber, while a 6000 CFM, 5-HP recirculating blower provides combination airflow to the workload.

This Grieve oven has 8” insulated walls comprising 2” of 1900ºF block and 6” of 10 lb/cf density rockwool insulation, plus an aluminized steel interior and exterior, top-mounted heat chamber and three rollout shelves, each 48” wide by 60” long and rated at 200 lbs.

Controls on No. 893 include a digital programming and recording temperature controller, manual reset excess temperature controller with separate contactors, recirculating blower airflow safety switch, SCR power controller and fused disconnect switch.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart

Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-

9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank

Calabrese.

Continue readingEngineering TV is now featuring Siemens from PackExpo 2012!

Click here to check it out.

Lee Teschler of Machine Design talks to Bill Henderson, Business Development Manager at Siemens about industrial ethernet connectivity solutions and networks used in several manufacturing environments.

Hosted by: Lee Teschler Videography by: Terry Knight Edited by: Terry Knight

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue readingATLANTA, Oct. 18, 2012 — Siemens Industry, Inc. today announced its plans to open an assembly and manufacturing plant as part of the company’s Drives Technologies Division, Mechanical Drives Business Unit. The 45,600 square-foot facility will be located in the city of Mauldin in Greenville County. Siemens anticipates opening the facility later this year.

“The new South Carolina geared motor facility will place the company and its products manufactured in South Carolina closer to machine builders and manufacturers in the Southeastern United States,” according to Doug Keith, President of Siemens Drive Technologies Division in the U.S.. “The announcement of this plant adds to Siemens ability to be a single-source provider of integrated drive train solutions for industry. Our portfolio of gears, motors, drives and automation is helping to lead a global transformation of the industrial and manufacturing sector, by increasing productivity and energy efficiency to the highest possible levels.”

The facility will assemble Siemens new Simogear family of geared motors, featuring helical, parallel shaft, and helical bevel gear units primarily used in modern conveyor systems often found in warehousing, logistics and distribution, airport baggage handling, automotive manufacturing and food and beverage processing.

Keith added that the site combined all of the necessary elements Siemens was seeking in a location, including proximity to transportation infrastructure, including interstates and ports, a highly skilled workforce with reputable educational institutions nearby, a green-minded community and a dedicated group of business partners.

“It’s a great day in South Carolina when a world-class company like Siemens chooses to locate new operations in our state. We celebrate the company’s decision to invest in South Carolina and create new jobs. Announcements like this show we are doing the right things to attract businesses from around the globe to our state,” said Gov. Nikki Haley.

Throughout the site selection process, Siemens officials worked closely with several entities that were instrumental in the decision to locate in Mauldin, including the State of South Carolina, Greenville County, the City of Mauldin and Laurens Electric Cooperative.

“It’s exciting to see a company like Siemens bring a new manufacturing operation to the Palmetto State. Every one of these jobs will have impact locally. Announcements like this are made possible by a strong team effort from state and local officials,” said Secretary of Commerce Bobby Hitt.

Local Siemens officials are currently working with readySC and Greenville Technical College on workforce development and training needs. Siemens plans to begin hiring in October and individuals interested in learning more may visit the Siemens career web site at www.usa.siemens.com/careers.

Siemens Mechanical Drives Business Unit manufactures mechanical and electrical drive equipment typically used in mechanical designs, including processing, transport and conveying systems, power generation and many off-shore applications. This portfolio particularly concentrates on gear technology, ranging from geared motors to industrial gear units and couplings as well as large gears for power stations and wind turbines. This portfolio of products and solutions are the mechanical foundation to Siemens’ Totally Integrated Automation (TIA) platform.

For more information visit: http://www.usa.siemens.com/answers/en/#683050?stc=usidt100004&sp_source=usidt100004.

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue reading

New Simotion Scout version 4.2, a visualization tool for parameter configuration of Simotion, the Siemens motion control system for production machines.

CHICAGO, PACK EXPO — The motion control business of Siemens Industry, Inc. has announced that Simotion Scout, the engineering system used for configuring Simotion motion controllers, has been updated with a wide range of usability improvements. As more and more demands are put on modern production machines, this system enables all of the application functions and tasks to be implemented within one uniform user interface.

Simotion is the scalable motion control system that quickly and easily handles increasing machine demands by enabling central machine functions to be implemented with just one controller.

It is available in three variants: drive-based, PC-based and controller-based.

Simotion Scout facilitates the configuration, programming, testing and commissioning of applications. With its graphical-based programming, Scout further facilitates system configuration for new users. Users of Scout 4.2 will also benefit from new features such as automatic drive integration and detailed comparisons for graphics-based programming languages.

The most significant innovation of Scout 4.2 is its simplified interface to the Siemens Sinamics drive system. This feature provides users with an automated means of integrating drives and components into the Simotion system. Using the new symbolic assignment of technology objects (TOs) and I/Os to drive objects, users no longer manually configure communication with message frames and addresses because Simotion Scout now automates this task. Object-to-object assignment takes place via a new inter-connection screen. In this screen, all compatible partners are listed hierarchically and the symbolic connection of the components to be inter-connected takes place by simple selection.

For more information about motion control solutions and services from Siemens, point your web browser to www.usa.siemens.com/motioncontrol.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications

or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Continue reading

The new Simotion D motion controllers for production machines cover all levels of performance, from simple positioning tasks to demanding applications with extremely short cycle times or large numbers of axes, up to 128.

CHICAGO, PACK EXPO — Siemens Industry, Inc. announced today the extension of the upper performance range of its popular Simotion D motion controllers. The new generation of Simotion D445-2 multi-axis controllers has new features such as onboard Profinet interfaces, high-speed I/O, and with three times the performance, a single controller can support up to 128 axes of motion.

Simotion D motion controllers are the ideal solution for production machines covering all levels of performance — from simple single-axis positioning tasks to complex synchronous applications — with extremely short cycle times on a large numbers of axes. Thanks to its scalability, Simotion D offers users a high degree of flexibility for the ever-changing demands on machine automation. The Simotion D drive-based multi-axis control not only offers PLC, motion control and advanced technology functions, but also an integrated drive control based upon Siemens Sinamics S120 drives.

Today, with the new Simotion D445-2 DP/PN and D455-2 DP/PN versions, the performance range has been extended even higher. Compared to the previous generation, the maximum quantity has been doubled to 128 axes and the memory capacity significantly expanded. This has increased the PLC and motion control performance by a factor of three. With Simotion D445-2 DP/PN and D455-2 DP/PN, the previously optional Profinet I/O interface has now been integrated on the modules as standard. This frees up the option slot for other expansion cards. The onboard interface is equipped with an integrated three-port switch and facilitates different network topologies such as line, star or tree structures, without the need for additional external switches. The interface not only supports real-time (RT), but also isochronous real-time (IRT) data exchange and can be operated as a controller and / or device of another controller.

In addition to the Profinet interface, Simotion D445-2 DP/PN and D455-2 DP/PN also have two Profibus and two Ethernet interfaces, as well as 28 digital I/Os, of which 16 can be used for technology tasks such as output cams and measuring inputs with micro-second resolution.

For more information about motion control solutions and services from Siemens, point your web browser to www.usa.siemens.com/motioncontrol.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Continue reading