Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

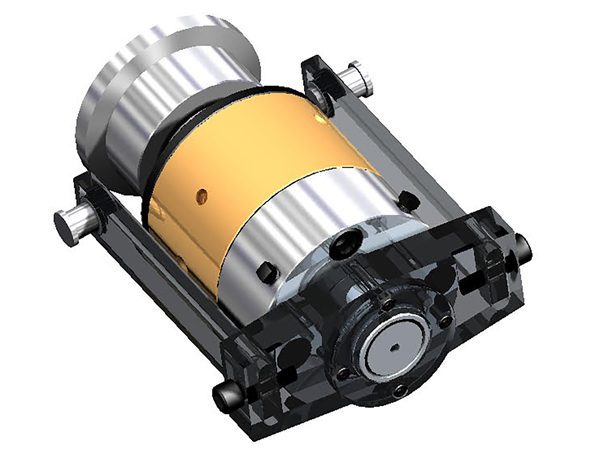

Guill Tool, the global leader in extrusion tooling, offers its Series 1000. This series of blow molding extrusion dies, features a core diameter between 8.5″ (219.5 mm) – 10″ (254.0 mm). Model 1025 uses material blends which are ideal for medical, automotive and specialty packaging.

Series 1000 is available as single layer, co-extrusion or triple extrusion. It adapts to existing extruder layout and, in most cases, accepts existing tooling. Features include fixed center or adjustable, built-in cartridge heaters, low inventory, expandable to multi-layer, heated core pin, one-piece body/flow diverter and split feed balanced flow.

Most products should be run fixed. Users need to change only one component to become fully adjustable. The cartridge heaters offer even heat for better flow and ensure there aren’t any cold spots. Low inventory produces no burning or stagnation, resulting in quick color change. Since it’s expandable to multi-layer, the crossheads run a variety of products. Benefits of the heated core pin and one-piece body/flow diverter are better temperature control and easy cleaning/quick change over, respectively. Lastly, the split feed balanced flow achieves concentric walls at all speeds.

For more information, please contact:

Tom Baldock, Sales Manager, Extrusion

Guill Tool & Engineering

10 Pike Street

West Warwick, RI 02893

USA

Phone: 401-465-5526

tbaldock@guill.com

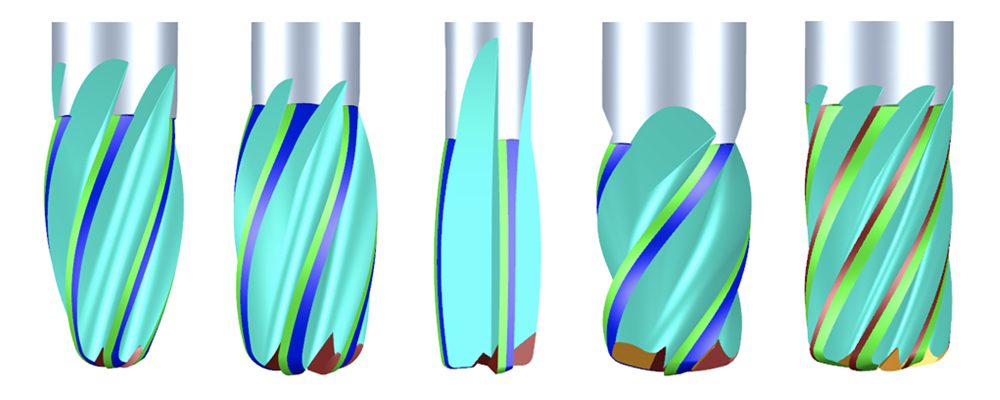

Industry 4.0 connectivity and AI-assisted guidance on ANCA’s new edge preparation machine revolutionizes edge preparation for cutting tool performance

Renowned for launching industry-first tool and cutter grinding technologies, ANCA continues its legacy of innovation with the EPX-SF, guaranteeing productivity, quality, and profitability in edge preparation. The new EPX-SF stream finishing machine was debuted at GrindingHub in Stuttgart, coinciding with the company’s 50-year anniversary.

Armando Manzano, EPX-SF Product Manager said, “More than just an edge preparation machine, the EPX-SF is a strategic business asset. Its high level of precision will help manufacturers to secure more contracts by meeting the rigorous standards of industries that demand clean and consistent cuts. Its ability to deliver flawless quality in a single pass enhances operational efficiency, eliminating the need for extensive post-processing and ultimately saving costs for businesses.”

Key highlights of the EPX-SF:

The EPX-SF is a future-ready solution, designed with advanced functionalities to meet the evolving needs of manufacturing. Its performance-driven design with 11 axes, delivers predictable nano-smooth surfaces and micron-honed edges within a minute per tool. The Advanced Cyclic Mode allows users to adjust angles, optimizing chip flow and effectively combatting surface burrs. It utilizes AI-assisted guidance to provide tailored recommendations, enhancing tool geometries and streamlining process efficiency. With Industry 4.0 connectivity, advanced safety features, and remote technical assistance, the EPX-SF seamlessly integrates into production lines.

Contact your local ANCA representation for more information on how the EPX-SF is redefining edge preparation, or visit https://machines.anca.com/Products/Machines/Edge-Preparation/EPX-SF

About ANCA CNC Machines

ANCA CNC Machines is a global leader in the design, manufacture, and service of advanced CNC grinding machines. With an illustrious history spanning over 50 years, ANCA is renowned for its cutting-edge technology, innovative solutions, and exceptional customer support. ANCA’s comprehensive range of products includes tool grinders, CNC grinding machines, software, and automation solutions, catering to diverse industries such as aerospace, automotive, medical, and general manufacturing.

With the FZU22, Zimmermann enters the lighter weight 5-axis gantry mill applications at an attractive price point

With the introduction of FZU22, Zimmermann has added a 5-axis portal milling machine for the machining of various workpiece shapes, sizes and materials. Aluminum, plastic, wood and other substrates can be processed, plus the machine is ideal for the finishing of carbon fiber reinforced and other composite materials. The overhead gantry provides precise production of models and molded parts. The standard machine includes a toolchanger for 24 tools and a CNC from Siemens or Heidenhain for full motion control and tracking. A specially developed 5-axis milling head with 15kW spindle is suitable for machining contours and tight pockets in large molds.

As Zimmermann Inc. President Cornelius Kiesel observes, “With this new machine, being introduced in our booth at IMTS to the North American market, Zimmermann enters a new arena, that is, the lighter weight machining applications for large structures at an economical price. Our recent acquisition of a company in Germany allows us to partner with a reliable source for this type of machine, enhanced by the unique features which have made Zimmermann a standard in the aerospace and large mold market segments.”

The FZU22 boasts a substantial working range, from 71”-98” in the X-axis, 118”-138” in the Y-axis and 49” in the Z-axis. A feed rate of 2756 ipm in the X- and Y-axes is standard while the acceleration on the machine is max. 118-197 in/sec2. With a compact footprint of 11’ x 15’, the machine fits in the corner of any shop. ISO 230-2 accuracy is provided. A choice of milling heads is offered on the machine to suit a variety of applications.

Optional equipment is offered on the FZU22, including touch probe, tool measuring system, work area cover, tool changer, chip conveyor, mist/dust extraction system, minimum quantity lubrication and a vacuum system.

The machine to be displayed at IMTS also features an ultrasonic system for cutting aerospace insulation.

About the company

Zimmermann is based in Germany and is a leading global high-tech supplier of portal milling machines. These are characterized by huge workspaces, substantial machining dynamics and cutting performance. The company, founded in 1933 by Friedrich Zimmermann, now has over 200 employees worldwide. With its product range, our innovative company has one goal above all: to offer the right solution for our customers and thus be able to guarantee high economic efficiency. “Quality made in Germany and supported locally” is our motto. The company’s special machines are used worldwide in the automotive, aerospace, moldmaking, transportation, off-highway and mechanical engineering sectors. The company has its North American headquarters in Wixom, Michigan, near Detroit, where it operates a full tech center, offering engineering assistance, commissioning, parts and retrofit services, as well as multiple machines for demonstration purposes. Zimmermann Inc. is headed by President Cornelius Kiesel. This year, Zimmermann Inc. is celebrating 20 years in business.

For more information, please contact:

ZIMMERMANN INC.

30587 Century Drive

Wixom, MI 48393

Phone: 248-956-8511

www.zimmermann-inc.com

Ms. Lena Kiesel, Marketing Manager

lena@zimmermann-inc.com

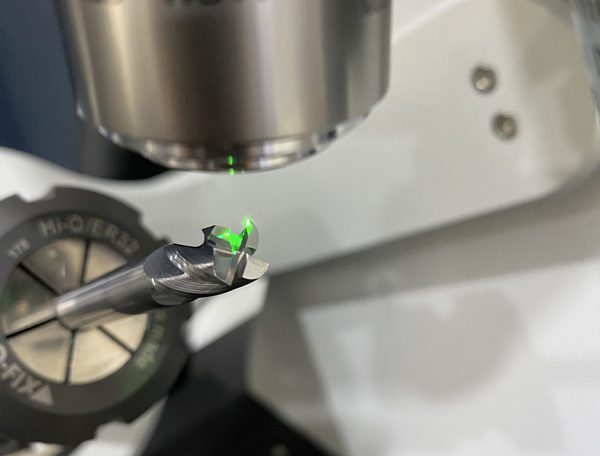

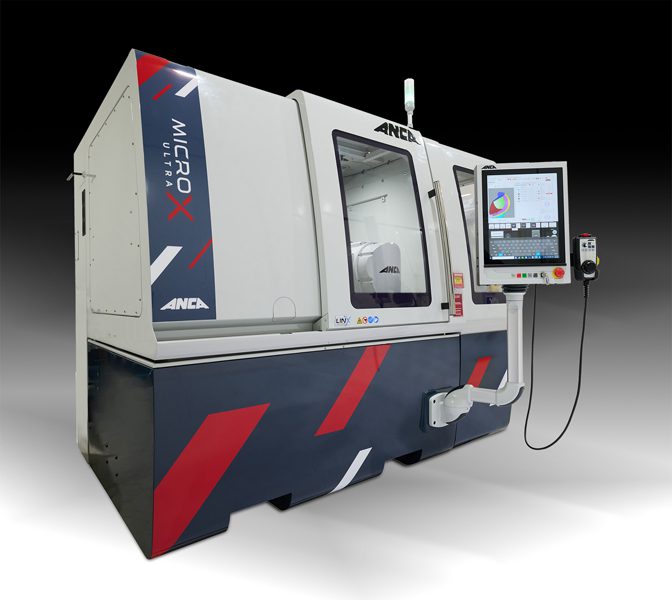

ANCA’s newest ULTRA machine makes micro tool grinding easier, more precise and more productive as the only nano-level resolution micro tool grinder

ANCA CNC Machines, a leading manufacturer of precision grinding machines, have launched the highly anticipated MicroX ULTRA.

This innovative six-axes grinding machine is meticulously designed for volume production of nano and micro cutting tools down to D0.03mm. Offering a superior solution for manufacturing high-quality, high-performance micro cutting tools, the MicroX ULTRA introduces groundbreaking technologies exclusive to the cutting tool industry.

The brain behind the machine is Pat McCluskey, a passionate machine tool designer, who is this year celebrating the 50th anniversary of ANCA, the company he co-founded with Pat Boland in 1974.

Pat McCluskey remarked, “I have been designing ANCA machines for 50 years – always with the goal of making machines better, more efficient, and user-friendly. It is a trademark of ANCA that you just have to do it differently, and the latest machine, the MicroX ULTRA, is the only micro tool grinder with nanometer resolution. This nano-level precision is a significant advancement in the field, utilizing the very best of ANCA’s technology developed over five decades to offer superior micro tool production.”

Key features of the MicroX ULTRA:

With nanometer resolution and control over the tool grinding path, the MicroX ULTRA delivers a high level of surface and edge quality. This achievement is made possible through intelligent algorithms that operate collaboratively and in synchrony.

The C-axis refers to the wheel swivel axis centerline, which is aligned with the wheel’s 9 o’clock grind point. This specific design is critical in the grinding of ballnose, corner radius and profile tools. In the case of a ballnose tool, the X and Y interpolations during the grinding process will be nearly equal to the radius of the ballnose tool.

Advanced algorithms ensure precise nanometer-level control of tool grinding paths, guaranteeing superior surface and edge quality. These algorithms collaborate and synchronize to reject disturbances swiftly, enhancing axis stiffness and robustness. They actively mitigate disturbances from spindle speed variations caused by imbalanced or runout grinding wheels. Encoder subdivision error compensation automatically detects and corrects inherent encoder errors on both linear and rotary encoders.

The LaserUltra takes process stability to an even higher level by closely controlling tolerances and incorporating in-process compensation mechanisms. This advanced system adapts to factors like wheel wear, resulting in superior precision and reliability.

Seamless integration with ANCA Integrated Manufacturing System (AIMS) facilitates effortless transition to automated, lights-out production, enhancing operational efficiency and productivity.

For more information, visit https://machines.anca.com/MicroX

For further information, please contact:

Amanda Bakun

Marketing & Communications Manager – Americas

248-497-1168

amanda.bakun@anca.com

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil, Korea and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

Continue reading

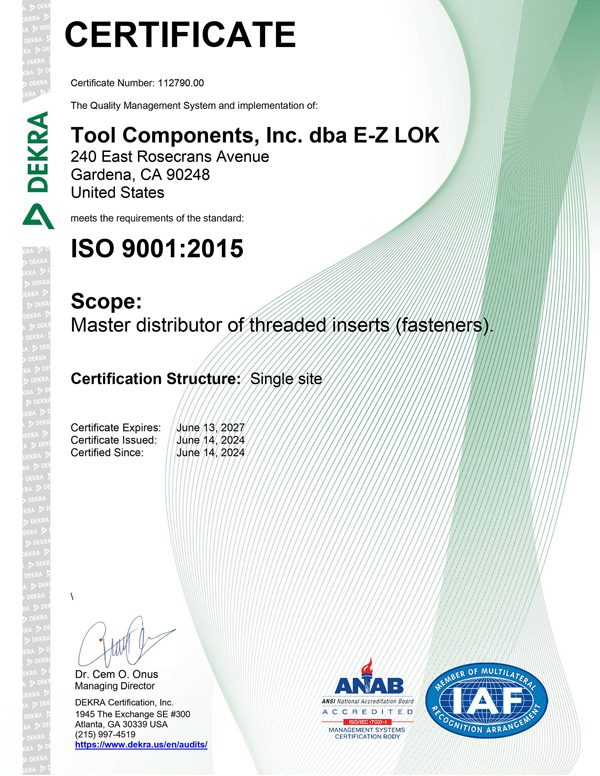

E-Z LOK, a leading manufacturer and master distributor of threaded inserts for metal, plastic and wood, just announced it has received ISO 9001 certification. The announcement was made by Kyle Lindsly-Roach, Director of Sales & Marketing at the company’s Gardena, California headquarters.

With a quality management system that confirms to ISO 9001 standards in place, the company can now meet customer and other stakeholder needs within statutory and regulatory requirements related to their products.

The company started the certification process in January of this year because they saw the need for ISO certification to better support current and future customers. To do so, E-Z LOK partnered with a consulting company to design and build out their quality management system (QMS). Then, they implemented the QMS within their company. Lastly, the QMS was audited by an external company, thus verifying that the QMS was in place and effective.

Commenting on the benefits of the certification, Lindsly-Roach said, “This gives us the potential to work with OEMs and distributors who need a robust quality system in place for their vendors. It opens up additional business opportunities for us with those customers who require an ISO certification for their suppliers.”

For more information, please contact:

Kyle Lindsly-Roach, Director of Sales & Marketing

E-Z LOK

240 E. Rosecrans Ave

Gardena, CA 90248

USA

Phone: 310-323-5613 x 221

klindsly@ezlok.com

www.ezlok.com

As ANCA celebrates 50 years of advancing tool manufacturing technology, Edmund Boland, General Manager of ANCA CNC Machines, (Bayswater North, Australia), looks ahead 5 to 10 years.

Just a person and a dog?

The old story about the factory of the future being populated by one human and a dog—the human’s role limited to feeding the dog, while the dog is in charge of keeping the person away from the machinery—will be close to reality for tool grinding.

At a minimum, said Boland, the entire production process will be linked digitally, “from the intake of the raw material, to palletizing, laser etching, and blank preparation…to the tool and cutter grinding, edge prep, coating, and right through to shipping the finished goods.” So, for example, when a particular job transitions from OD prep to the 5-axis grinders, the machines will automatically call up the correct program to finish grinding the tools. Everything will also be linked to a company’s ERP and MES system, providing “very good data analytics, to help make the right decisions and improve your processes.”

It’s already the case that individual processes, such as OD grinding or stream finishing, are often highly automated once they’re setup. So, what will differ among thriving companies, as Boland sees it, is the degree to which those processes have been automated and the degree to which the transfer of material between stations has also been automated.

“A small to medium shop will probably have a person who’s physically moving and scanning let’s say, a pallet from the OD machine to the five-axis machine. But digitally, the five-axis machine receives a file that says it’s getting these blanks, and it’s all tied in with the ERP system. The same thing would happen if they’re subcontracting the coating. Digitally, they’re sending that information to the coater, but somebody is manually moving tools from the five-axis to the shipping department. Whereas in a large shop, a robotized cart would make the physical moves.” That’s the case with ANCA’s Integrated Manufacturing Systems (AIMS).

Improving setups and quality

The more automation a shop achieves, says Boland, the more consistent its output quality and the more its workers can concentrate on solving isolated problems and improving the entire process, aided by AI. “Invariably, there will be tools that are out of tolerance. And someone will need to ask ‘Why? What do we need to tweak? Is there an issue with one of the production steps? Is the program wrong?’”

Competitive companies will therefore rely on a relatively small number of highly skilled problem solvers. These people will in turn rely on the kind of advanced training available at the ANCA Academy.

Boland also envisions a continuing role for skilled people to set up machines, though changes are coming there too. “As an example, technology like steadyrests will have sensors and the ability to make automatic adjustments.”

Automatic compensation to correct errors detected in-process is already a reality, and this capability will only improve, Boland adds. For example, with today’s technology, if the machine loads a blank askew, the probe detects the error and the grinding problem automatically adjusts to produce a satisfactory tool. But, “you still need to manually check the first piece, especially if it’s a new type of tool. After that, the system can take over. ‘First tool right’ is already our big mantra. You should be able to measure the first tool, and if wrong, be able to compensate.”

One contributing factor is the ever increasing capability of internal measurement devices. Boland observes that their new generation lasers can measure in the presence of coolant mist and even some residual oil on the tool itself. Vision systems still require manual placement and removal after use, but “that will change. Camera systems require better ventilation than lasers, but there are solutions. A robot can blow out the debris from the environment within the machine right after grinding. Or you could use a robot to bring the camera into the machine from an external location.”

At the same time, the list of features that can be measured internally and automatically compensated will grow. Today it’s “things like OD, tool profile, and flute depth. In a short time we’ll be able to do more. The threads within a thread mill or a tap, as an example. A K-land. Or the gash. As long as it can be measured within the system, it can be compensated.”

Boland doesn’t think we’ll eliminate the need for stand-alone measuring machines like the ZOLLER Genius, especially when it comes to measuring complex features. But he foresees improvements in the interplay between such systems and tool grinders.

The key, he explains, in the establishment of standardized measurement protocols for specific geometric features. “Until these measurement protocols are created, no tool grinder can compensate for a measured deviation. At the moment, ANCA has a standard set of measurements available for simpler end mills and drills. But as we install AIMS throughout our customer base, we’re also working with these customers to expand the range of measurements we can compensate. We’re getting into quite complex profile tools, and complex end mills, for example.”

Sub-micron tolerances

It’s no secret that tolerances are getting tighter. Boland says achieving micron, and even sub-micron, levels of precision will be the key to capturing many future applications. Demand for such accuracy “will grow, because of the benefits of these cutting tools. Whether it’s the surface finish of the workpiece that’s being machined, tool life, or other factors. Removing all the small inaccuracies within the cutting tool lifts its performance significantly.”

This is also why the market is moving more toward solid round tools, versus indexable cutters. “Customers want the rigidity of a solid round tool and the advantages of being able to push the tool while also achieving an excellent surface finish,” reports Boland.

Maintaining higher levels of precision will take more than the highly functioning automation, in-process measuring, and closed-loop compensation functions covered earlier. “Simple, though expensive, things like air conditioning,” lists Boland. “The coolant systems. The types of wheels you buy… It’s not just the tool and cutter grinder. It’s the whole system around it.

“Eliminating vibration is going to be absolutely critical. No longer will you be able to attach a mist extractor directly under the canopy. The air conditioning unit within a machine tool will become very important. Because if it vibrates, it will cause problems.” Thus, a central coolant system and central mist extraction become requirements.

Although Boland predicts a growing demand for even more accurate tools, he also thinks there will continue to be demand for lower cost tools. That, plus the inherent cost and difficulty of meeting the tightest tolerances, will limit the adoption of the improvements just discussed.

Material trends

Carbide continues to be the dominant cutting tool material, but PCD use is growing faster, according to Boland. Thus, PCD may reach 30% of the market in 10 years or so. Ceramics are also getting more interest, but remain a small part.

Likewise, the need for material removal technologies other than grinding will grow. Wire and rotary EDM are now predominant for PCD, but laser ablation bears watching, says Boland. “It is definitely an emerging technology. Customers with early machines are using them not only for PCD, but also for carbide. In particular, micro tools are now seen as a potential for laser ablation, and tool makers are getting interesting results.

“In terms of PCD, laser ablation definitely has its advantages over erosion. It doesn’t require coolant or consumable copper electrodes.” So, though the machines might remain 40-50% more expensive than competing technology, they might save money over time due to lower consumable costs. Laser ablation also has the ability to produce shapes that can’t be created with erosion, including surface features. Conversely, it doesn’t make sense for fluting larger diameter tools. Boland therefore remains uncertain of laser ablation’s near term future being more than a niche solution.

Similarly, additive machining is not likely to replace more than a few material removal applications in industry. And its applicability to the production of cutting tools appears to be limited. “I don’t see it becoming efficient enough in ten years. But potentially, it has a place in producing special tools, with otherwise impossible internal coolant channels and those kinds of things. It might also have a role in creating big, expensive, cutting tools. But even if it does take off, I don’t believe it will be accurate enough to eliminate the need for finish grinding.”

Other market considerations

Given the production efficiencies Boland envisions, you might expect regrinding to die. But not only will the automation solutions discussed earlier also apply to regrinding, Boland surmises that sustainability concerns will continue to make it a viable business.

At the same time, the greater efficiencies achieved by forward leaning tool producers will create expectations in the market for faster turnaround times, even for small quantities of special tools. As Boland put it, “the ability to easily produce optimized special tools for a specific job is what will be important to our customers.”

Unsurprisingly, the move to electric vehicles is reducing cutting tool demand in the automotive sector by as much as 50%. This varies around the globe, with the U.S. lagging in EV adoption. There are also “growing applications outside of the EV area which might be compensating,” Boland states, though the total impact of EVs will undeniably be large.

“And then there’s the question of where the technology will land. But it’s almost a philosophical discussion rather than a factual one. Will hydrogen take over? Will ultra clean fuel come back and give the combustion engine another lease on life? Who knows?”

Changes to service & support

Boland predicts that AI will “be a huge productivity improvement mechanism for the future,” in part because it contributes to accurately warning of component failures in advance. It can even automatically order the replacement part. Thus, preventative maintenance becomes targeted and efficient while ensuring nearly seamless uptime.

Conversely, Boland points out that multi-machine automation makes any downtime intolerable. “Customers can live without a single machine for a day or two. But if a fully automated system is not up within a couple of hours, that’s a big problem. So, being able to respond rapidly and around the clock is going to be important. There will be different technologies to allow that.” This includes remote and predictive diagnostics, “to reduce the necessity of having a service person on site.”

Whatever the future holds, it’s sure to be interesting. And if Boland turns out to be wrong about anything, you can always count on your dog.

For more information, visit https://machines.anca.com.

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil, Korea and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

Continue reading

E-Z LOK, a leading manufacturer and master distributor of threaded inserts for metal, plastic and wood now offers E-Z Hex™ (Hex Drive) inserts along with drive thread insert kits.

Generically referred to as Type D (flanged) or Type E (flush) insert nuts, E-Z Hex™ inserts provide sturdy machine threads in soft woods. These hex drives are an ideal solution for any application where assembly or disassembly could lead to thread erosion or stripping. This threaded insert for wood features broad external threads that provide superior holding power in materials like pine, composition board, MDF and plywood. E-Z Hex™ internal thread sizes range from #8 to ⅜-16, plus M6 and M8. Die-cast from a durable zinc alloy, these threaded inserts install quickly with an Allen wrench or optional drive tool.

Threaded inserts for wood are used in ready-to-assemble (RTA) furniture, drawer pulls, display cases, crating and anywhere threaded inserts are installed in softwood.

E-Z Hex™ threaded insert kits offer the parts needed to provide solid reinforcement to threaded holes in softwood materials. Depending on project requirements and available tools, the company offers standard hex drive threaded insert installation kits with the drive tool, drill bit and specific size inserts in both flanged and flush designs. Another option is threaded insert assortment kits that provide a variety of different insert sizes without the drive tool and drill bits.

FREE SAMPLE ON REQUEST

CAD files on this product can be downloaded in over 100 file formats from the E-Z LOK website at https://www.ezlok.com/cad-downloads

For more information, please contact:

Kyle Lindsly-Roach, Director of Sales & Marketing

E-Z LOK

240 E. Rosecrans Ave

Gardena, CA 90248

USA

Phone: 310-323-5613 x221

klindsly@ezlok.com

www.ezlok.com

E-Z LOK is a leading manufacturer and master distributor of threaded inserts for metal, plastic and wood. Inserts for metal include solid wall and helical wire-thread inserts, while inserts for plastic feature press-

in ultrasonic/heat stake designs. Those for wood are die cast zinc alloy hex drives for soft wood and brass knife threads for hardwood. A variety of kits for the above inserts are available and feature installation tools, drill bits, etc.

E-Z LOK is a third-generation family owned and operated company. Founded in 1956, it primarily sells through local, regional, and national industrial distributors.

Guill Tool, the global leader in extrusion tooling, now offers a wide variety of extrusion equipment specifically for food processing. Extrusion is increasingly becoming one of the primary methods of producing a variety of traditional and innovative food products, and the company’s extrusion tooling is designed to accommodate producing all of them. From pastas, hot dogs, and snack foods to chewing gum, licorice, and pet food, Guill’s balanced flow designs control dimensional tolerances in order to increase product quality while reducing waste.

Custom-made extrusion tooling and dies make it easy to efficiently and consistently manufacture a variety of food products. More precise tooling allows for considerably reduced wasted extrudate. Furthermore, Guill’s extrusion tooling enables precise temperature control, allowing food to be manufactured under both high and low temperatures.

Intended to increase tube wall strength, the 300 Series heads achieve concentric heads at all speeds. Additional features include low inventory/quick color change and elimination of secondary stage processing. The company’s 600 Series crosshead offers flexibility in design and extruder orientation with split balanced flow, while the 700 Series is fully adjustable and accepts existing tooling.

Guill’s 800 Series simple crosshead can be configured to be fixed center or adjustable, featuring built-in cartridge heaters and a low volume split feed balanced flow. The 900 Series Spiderless in-line head offers simplicity and fewer parts with a low volume split balanced flow. Lastly, the Bullet™ is suitable for high and low-volume applications and is accommodated with the simple, easy changing of just one component.

For more information, please contact:

Tom Baldock

Sales Manager, Extrusion

Guill Tool & Engineering

10 Pike Street

West Warwick, RI 02893

USA

Phone: 401-465-5526

Email: tbaldock@guill.com

ANCA’s RN35 release delivers advanced features to help manufacturers reduce cycle time by 20%

ANCA, a global leading manufacturer of CNC tool and cutter grinders, proudly introduces RN35, the latest version of its cutting-edge ToolRoom software. This significant launch coincides with the celebration of ANCA’s 50th anniversary, marking a half-century contribution to industrial progress through precision cutting tools.

The RN35 release presents a range of advanced features designed to boost productivity and ensure consistent tool quality, resulting in superior surface finishes. By enabling faster cycle times and enhancing tool performance, manufacturers can drive up their profits effectively.

ANCA’s ToolRoom RN35 software offers:

Thomson Mathew, Software Product Manager at ANCA says: “It is no secret that flexibility, user-friendliness and application diversity have always been key strengths of ANCA software. With our RN34 release, we launched high performance cutting tools of different tool types. Continuing from this, our RN35 release focuses on elevating the user experience, enhancing performance, boosting productivity, and minimizing cycle times – all without compromising quality.”

“ANCA is the only tool and cutter grinder manufacturer in the world that designs and produces the complete machine in-house, including building the CNC, precision motors and spindles, and polymer concrete bases. Our dedicated Software Engineering team is focused on developing software with innovative enhancements, with the goal of making tool production easier, faster and more efficient for our customers. This level of vertical integration means we can consider the entire machine as a single system when developing new solutions,” Thomson concludes.

Established in 1974, ANCA has consistently delivered industry-first solutions that have reshaped cutting tool manufacturing. The introduction of the System 32 CNC software in 1991 marked a groundbreaking moment as ANCA applied advanced robotic software to the machine world, introducing novel concepts in tool grinding, including the innovative soft axis or soft machine kinematics, which simplified the grinding process for cutting tools. In 1998, ANCA was the first to introduce true 3D simulation technology for CNC tool and cutter grinding with the launch of CIM3D software.

Key Highlights of RN35:

Feedrate optimization: RN35 includes feedrate optimization, ensuring improved cycle time and increased productivity. The software facilitates stable tool quality with a superior surface finish, offering enhanced performance for CNC tool manufacturing.

Improved cycle time and wheel life: With RN35, manufacturers can experience improved cycle time and extended wheel life. The software provides uniform wheel wear on the surface of the grinding wheel, contributing to cost savings and enhanced operational efficiency.

SPC (Statistical Process Control): ANCA’s revamped SPC software empowers users with comprehensive control of the production process during high-volume manufacturing. Key features include:

Profile fluting: RN35 introduces profile fluting, providing the ability to control and maintain hook/rake angle along the trajectory of the cutting edge on a given profile. This enhancement increases cutting performance and extends the life of the tool due to uniform hook/rake angle along the edge.

I3dg improvements: ANCA has enhanced i3dg features, allowing for faster comparison of tools on the machine during small changes. The software also enables the measurement of features after changes, providing a seamless validation process.

Profile software improvements: RN35 introduces a new and easy way to define and modify profiles, saving time in the design stage. This improvement makes it easy for new starters to adapt to the software.

LaserUltra enhancements: LaserUltra enhancements allow for the measurement and compensation of more complex tools with line and arcs inside the machine. This feature saves customers cycle time and reduces the scrap rate, ensuring better tool quality independent of operator skills.

Double corner radius enhancements: RN35 brings advancements in manufacturing complex geometry tools for various industries, enhancing the versatility of CNC tool production.

VRML import: The ability to import VRML models in RN35 gives users a strategic advantage by facilitating the easy import and matching of competitor tools.

For further information, please contact:

Amanda Bakun

Marketing & Communications Manager – Americas

248-497-1168

amanda.bakun@anca.com

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil, Korea and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

Continue readingThe Siemens Machine Tool Business sadly announces the death of Randy Pearson, 70, on May 21, 2024 in Reno, Nevada, following a long battle with lung cancer. Randy had recently retired after more than 20 years with Siemens, where he served as dealer support manager … and much more.

As Motion Control group VP Rajas Sukthankar notes, “When I think of Randy, I think of my good fortune in life to work with an individual that cared as passionately and deeply about his work as I do. I first met Randy when he was hired as an application engineer at Hyundai Machine Tools in 1995. Our association went back over two decades. I had the chance to work with him as both a customer and a valued Siemens employee. As a skilled machinist himself, Randy trained and educated a generation of new machinists in his career. I treasure the time I spent working with Randy and will miss his infectious laugh and energy.”

Randy’s associate in machine tool training at Siemens, Chris Pollack, recalls, “I was always amazed how he remembered everyone’s name. Walking around a trade show with Randy was like being with the mayor of the town. Everyone knew him and, more importantly, he knew everyone. He was always there to help others and he surely helped me a lot in my career.”

Marion Kica, executive assistant at the Siemens Machine Tool headquarters in Elk Grove Village, IL adds, “He always brightened my day with his humor and good cheer, plus he was there to handle all the engineering questions callers would have. He was a kind, supportive friend who took his responsibilities very seriously but could still find humor in life’s ups and downs.”

John Meyer, head of marketing communications for the motion control group, was a close associate of Randy’s throughout all his years at Siemens. He notes, “As a marketer, when I came to Siemens, I had a challenge to learn about machine tools and manufacturing technologies such as CNC. I wasn’t an engineer, so Randy took me under his wing to teach me what I needed to know to be successful in my career. It became a technical education over 20+ years and I’m very thankful for the knowledge Randy instilled in me.”

During his long career in the machine tool industry, Randy served as an applications engineer or sales manager at such leading companies as Bridgeport, Toyoda, ROMI, Kitamura and Hyundai, as well as machine tool dealer Iverson & Company.

Always willing to share the talents he possessed, Randy authored regular CNC expert advice columns that appeared in several machine tool magazines, over the years. He brought a wealth of technical expertise in CNC technology along with his hands-on practical experience as a machinist, when giving his help to the industry.

A native of Chicago, Randy and his wife Susan, whom he met when they both worked at Bridgeport, were married 34 years and had two children.

Following in his dad’s footsteps, Randy’s son Jeremy has now been with DMG machine tools for 10 years.

After his retirement from Siemens, Randy and Susan decided to “go west” and landed in Reno.

A memorial service for Randy Pearson will be held at 11 AM Central on July 13 at United Methodist Church in Roselle, IL. Donations can be made to the American Cancer Society at www.cancer.org or the American Lung Association at www.lung.org.