Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

By Kevin Koval

More and more companies are looking for effective ways to gain additional exposure for their respected brands. One of the best ways that Bernard & Company has been helping clients achieve this is by using Google’s Geotargeting and Retargeting. Many of our clients have had great success with one or both of these types of advertising.

We encourage our clients to use our Geotargeting service during their trade shows or any events that they will be attending. Geotargeting or Geo-fencing is a way to have ads appear within a city, region or country. One of the best features is that you can pinpoint a very small and precise location where you want your ads to show up. We create stunning ads with your company branding, a call-to-action, high-res images of tools or machines, a logo of the trade show and the booth number. We put this kind of information on the ads to entice customers, prospects and editors that are attending the show. By setting these ads up, you will see an increased amount of traffic to both your booth and website.

A great example that we have done for many of our clients in the past is to run Geotargeting ads during the highly anticipated trade show, IMTS that happens every 2 years in Chicago, IL. We create 12 ads that appear within a 5-mile radius around the McCormick Place Convention Center. All of our clients receive thousands of clicks on their ads which are linked to specific landing pages. Your results may vary depending on the size of the trade show. When people show up to your booth, be sure to ask them how they heard of your company and why they decided to come to your booth. You will hear from time to time that they saw your ad online.

Bernard & Company assures all clients that none of their ads will appear on any unwanted sites such as sexual content, racist groups and other inappropriate sites. We work very hard to make sure this never happens and we are diligent to find ways for future prevention.

Have you ever been searching online for a product and later noticing that ads of a similar product appeared on another site? Have you ever visited a website of a company and later seen ads of the same company follow you around the internet? Have you ever searched on Google and seen ads for what you are searching for at the top of the page? These are all examples of Retargeting. How it works is we create two different campaigns. One is a search and the other is a display.

With the search campaign, we must ask ourselves what will our customers or prospects type to search online and what kind of keywords will they be using? When you go to Google and type anything into the search engine, this is considered a keyword. We link keywords with ads that will appear at the top of Google search results. The great thing about these kinds of ads is we have total control of what the ads will say. The ads will have a call-to-action and will link to a landing page on your website. We can set up as many keywords as you would like, target a specific audience and run the ads for as long as you would like. With a Retargeting display campaign, we create 12 similar ads that will appear but since this won’t be linked to a trade show, we can take out the booth number and the event logo.

These ads will activate after the prospect visits your site. An ad will then follow their behavior and it will appear on the thousands of Google friendly websites. How it works is we provide a Global Site Tag that is generated and it will need to be added to every page of code on your website. Without this, the ads will not follow any of your visitors.

At Bernard & Company, we had a client that ran this program for 6 months. By the end of the campaign, they got hundreds of thousands of clicks on their ads, increased their sales, raised brand awareness and improved their Google ranking from page seven to number one.

In both Retargeting and Geotargeting, your ads can appear when people are searching on mobile devices, desktop computers and tablets. This is a Cost Per Click (CPC) type of advertising, where a portion of the budget is billed every time someone clicks on these ads. We manage your ads’ performances and the bidding system. We will make sure you get fantastic results within your budget. For more information, please reach out to Bernard & Company if you are interested to get started on one of these fantastic opportunities.

Continue readingIn these trying times, marketers must get even more creative. Creative? Hmmm. Whom do you know who does that for a living? And knows your company? And your market?

That’s right, your ad/PR agency, who daily brings its clients’ messages to markets, far and wide…or, in the case of some of you, who sell to a limited audience, very narrowly. That’s the upside of our method. We’re not one-size-fits-all, even for our many machine tool clients who might appear to be marketing in the same direction. They’re not and we don’t, for them.

Our agency, precisely because we’re strictly industrial and bring creative solutions to your specific marketing challenges, is your perfect partner in these Covid times, as we will be when we can once again get in your face, literally.

We’re designing and implementing a lot of new and innovative tactics for our clients…and they’re working.

Last piece of advice…don’t be Chicken Little and cut your budget because the sky is falling. It ain’t. The clients we serve who actually INCREASED spending in Covid times have done quite well. It’s the textbook “smaller pie, bigger slice” theory. Stopping your ad and PR efforts in down times only makes it worse. This is a long-proven fact in business marketing. I know it’s all about budget, but every marketing dollar you invest will bring a positive ROI.

Give us a call…we’re doctors of marcom…and we’re ALWAYS on call.

Stay safe,

Tim Daro

President

The first to market ANCA Integrated Manufacturing System (AIMS) uses smart automation and IT integration to connect tool production processes and systems.

ANCA’s launch of integrated solutions with AIMS, connects sequential processes in tool manufacturing, to bank the benefits of automation and integration. AIMS facilitates streamlined tool production, linking separate processes to each other and factory IT systems. The future of toolmaking is here, with AIMS providing versatile, modular options for common manufacturing challenges to optimize cutting tool production.

AIMS offers functionality that is adaptable to each factory’s needs; from smaller scale, data-based options to the full AIMS setup across a series of machines with endless possibilities. Central to any AIMS system is the AIMS Server that manages data flows between the elements of the AIMS system and established IT platforms, such as your ERP system. Building on this, customers can choose from a suite of “auto” solutions for reducing production costs, resolving labor challenges and integrating systems to improve product and process quality. From transferring tools between operations with AutoFetch robot options; fully automated tool measurement and process compensation using AutoComp; and managing data via the AutoSet hub – AIMS delivers streamlined manufacturing, with connected tool production processes integrated to IT systems that takes tool production to the next level.

“ANCA is here to provide tool manufacturers with solutions to support production that work across all industries and applications and expand to complete tool production needs. This is a new landscape for interconnected technology, working end to end,” said Chris Hegarty, ANCA Group CEO.

“Integration and automation solutions provide infrastructure to manufacture tools with increased productivity and higher quality. ANCA has the industry-leading software and control capabilities to deliver a system for production management that tackles time, cost and labor inefficiencies where it counts.”

“We are delighted to be accelerating into the fourth industrial revolution with advanced, smart factory solutions for cutting tool makers – intelligent automation for connecting processes and data management.”

Connect, automate and create with AIMS

AIMS Project Lead, Duncan Thompson said: “Automated options that can be applied in the real world and tailored to a machine shop’s challenges, mean that tool manufacturers can reap the advantages of integrated processes and systems in a practical way.”

Over 70% of ANCA customers seek machines with robotic functionality. ANCA’s world-first technology developments utilize automation to gain efficiencies and have helped reduce production costs by 50%.

Duncan Thompson explains: “Our customers continue to look for custom solutions for increased automation in their operations and AIMS is ANCA’s holistic response; a tangible option for a smarter factory. Automation that works best is targeted to repetitive processes that can occur alongside value-adding individual skills. AIMS slots in to seamlessly automate routine processes.”

“Seeing this level of integration in action is pretty amazing. Our easy to view, virtual demonstration really highlights the ways that AIMS works to boost tool production. AIMS can be deployed to a single process or across an entire production line, towards end to end tool manufacturing.”

The AIMS online demo exhibits interconnected grinding technology solutions that eliminate wasteful manual handling, reduce machine downtime in between batches and take away the need to have operators constantly monitoring and adjusting production machines.

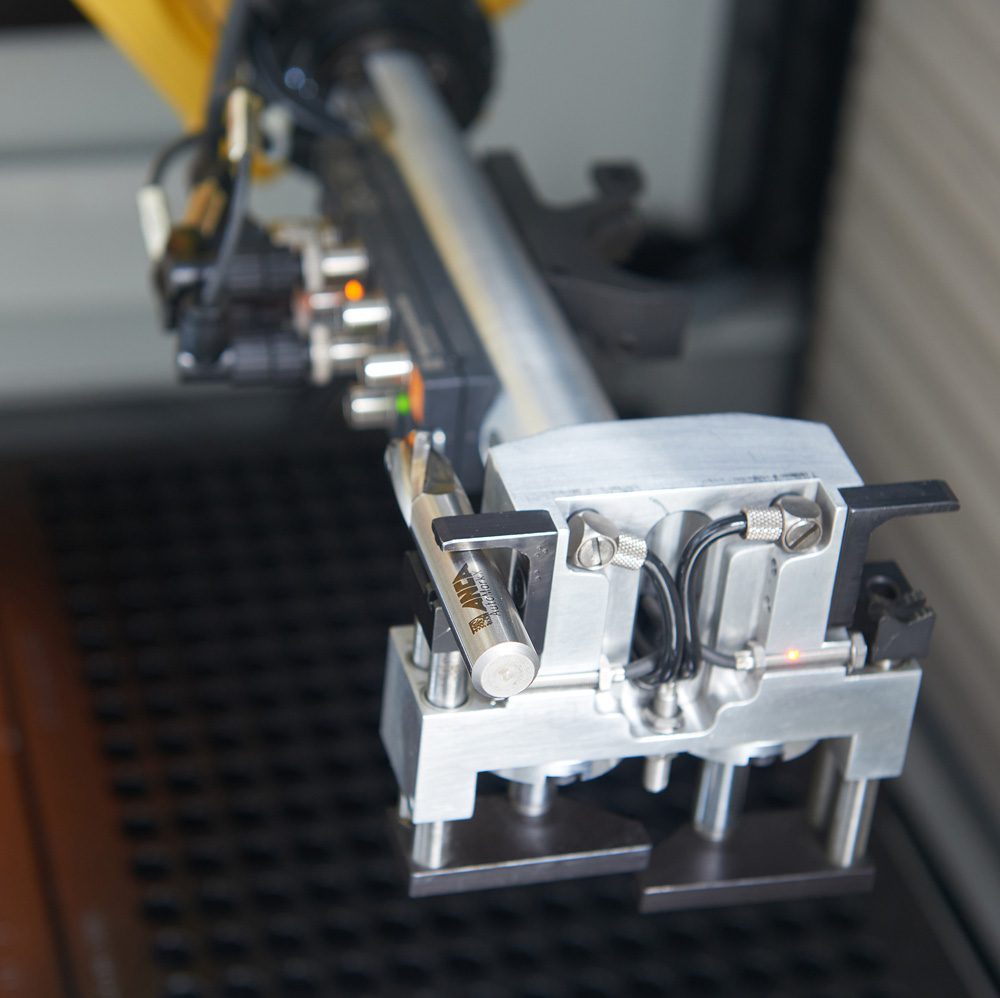

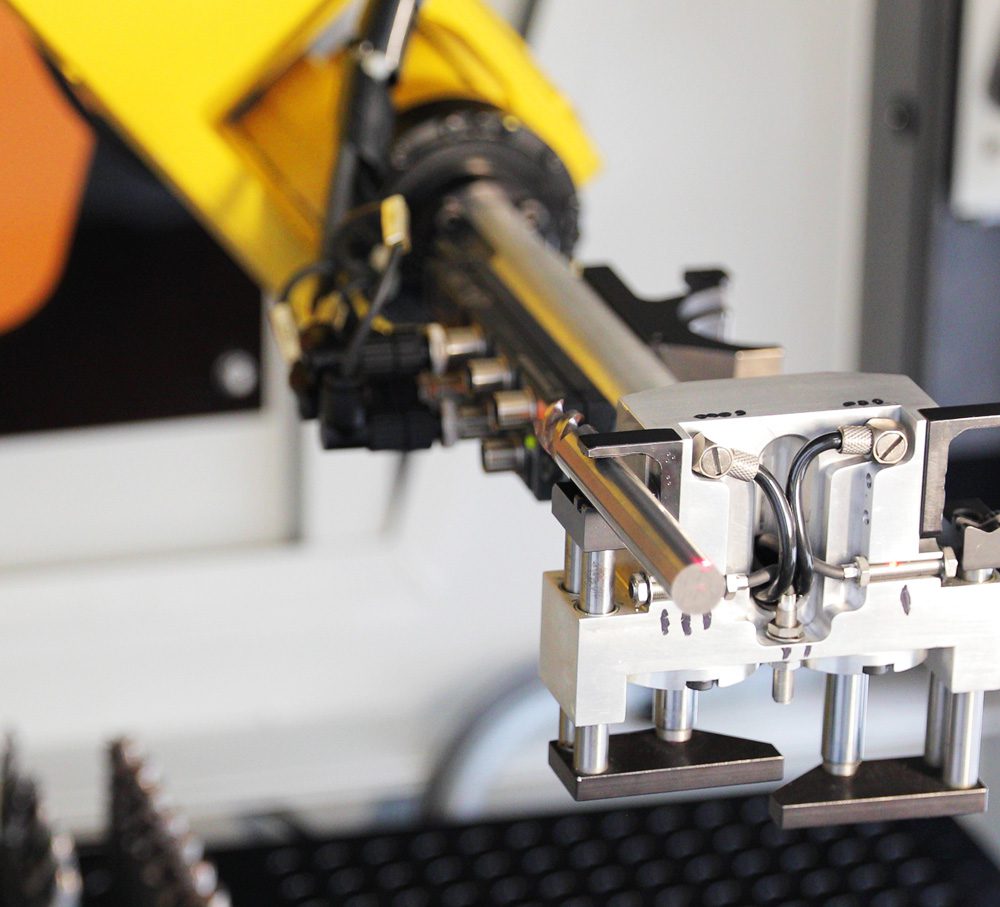

For complete tool production, AutoMarkX offers automated laser tool marking

The new AutoMarkX is ANCA’s tool marking solution designed particularly for the needs of cutting tool production. ANCA already has you covered with critical tool grinding processes; CPX for blank preparation, and tool grinding on ANCA’s TX, MX and FX tool and cutter grinders. AutoMarkX will work seamlessly alongside ANCA CNC grinders and automates the tool marking process, further extending unmanned production operations.

Tool manufacturers are seizing options that streamline processes and save labor costs. AutoMarkX is capable of automated pallet loading and takes care of the tool laser marking process, freeing up operators to perform more value-adding tasks. AutoMarkX is designed for integration with AIMS, being able to automatically receive and dispatch pallets from AutoFetch, while connectivity to the AIMS Server provides details of the message to be marked on the tools.

Product Manager, Jan Irzyk said: “This machine is efficient and compact – but more than that, it can be integrated with your ERP and AIMS, so that technology can work together. Removing the need for manual handling, our new laser marking solution pushes tool marking capabilities into lights-out production.”

“For full production, flexibility is important. This system accommodates a variety of tool sizes as well as mixed batches. With an easy to use interface and customizable marking, it is a complete solution that boosts labor efficiency.”

With over 45 years’ experience delivering CNC grinders to customers around the world, ANCA carries a reputation for delivering customer-focused innovations that meet market needs. Products that use smart automation for every day applications offer increased productivity and profitability. Integrated manufacturing, and machines that work together for complete tool production provide comprehensive options for manufacturers across multiple industries.

For further information, please contact:

Sepideh Zandieh

PR and Communications Manager, ANCA

M: +61 439 316 131

Sepideh.Zandieh@anca.com

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

ANCA website: www.anca.com

Continue reading

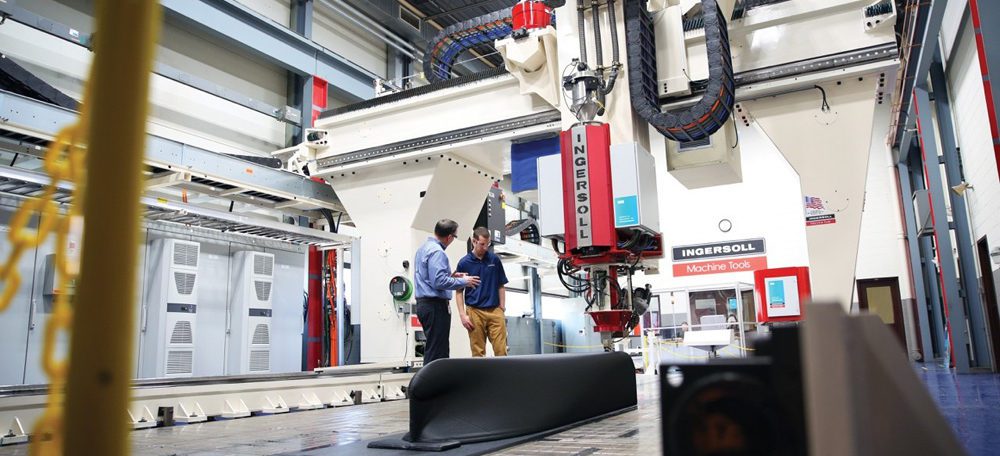

Robotic fiber placement and 3D printing enable disruptive breakthroughs in today’s manufacturing processes thanks to the advantages promised by Industry 4.0, the Digital Twin, higher robotic intelligence and complex motion control.

Siemens and Ingersoll Machine Tools have expanded their decade-long partnership to support the Rockford, IL-based machine tool company of Camozzi Group on its digital journey of creating digital twins of its products and expanding into new markets. Based upon extensive experience in heavy machine tool building, Siemens cutting-edge technologies in hardware complement Ingersoll Machine Tools’ successful journey into the new market of additive manufacturing and have pushed the boundaries for industrial robots for the aerospace market with its entry-level robotic platforms MasterPrint Robotic™ and MasterPrint Continuous Filament™

For example, Ingersoll developed the mammoth 3D printer MasterPrint™, the world’s largest device that prints with thermoplastics. The MasterPrint at the University of Maine — included in the Guinness Book of World Records — is able to 3D-print objects up to 100 feet long, 20 feet wide and 10 feet tall. It is designed mainly to make tools for the aerospace, space and marine industry. MasterPrint™ cuts cost and streamlines the manufacturing process. Large parts are printed and then machined to final their shape with the same machine. Manufacturing costs can be reduced by 75% and lead times shortened from months to days.

“As a key supplier of high-tech manufacturing equipment to all the major players of the aerospace industry, Ingersoll has strategic technology goals that push CNC products capabilities and performance beyond their OEMs’ intentions, conception and scope in term of accuracy, reliability, ease of integration and seamless programming experience. Ingersoll has found a CNC and software partner in Siemens who is willing to develop and encompass these advanced capabilities into their products and to enable Ingersoll to achieve its strategic goals and service the needs of our customers by shortening their time-to-market and increasing their profitability”, said Piergiorgio Assandri, Business Director, Ingersoll Machine Tools.

“Ingersoll Machine Tools’ ambitious plans for becoming a leading digital enterprise in the machine tool market are impressive. Their successful additive manufacturing and industrial robot products are a proof point for this. Ingersoll Machine Tools’ entrepreneurial spirit and innovative approach has pushed us to the limits, what our technology is capable of and inspired us to go even further”, said Rajas Sukthankar, Vice-President of Siemens Digital Industries Motion Control Business (US).

Ingersoll Machine Tools is using cutting-edge CNC automation hardware and software from Siemens to transform their business for the digital age. With the Siemens Virtual NC Kernel (VNCK), the company was able embed the real CNC kernel into a virtual machine, allowing Ingersoll Machine Tools to completely emulate real machine tool control and directly import the commissioning archive of the actual machine. That helped Ingersoll Machine Tools to save time with faster commissioning and to get the machine to their customers faster. From an end-customer perspective, users will be able to simulate the manufacturing of their product and shorten their time-to-market while increasing their production quality.

“Composite production processes such as the increasingly popular robotic applications can have quite complex machine motions and tight manufacturing tolerances, as well as the ever present need to reduce production times. Having a virtual version of the CNC kernel directly integrated within the programming and simulation software environment allows a customer to more reliably validate their production processes and timing before physically running anything on the machine.” said John Dreher, Software Engineering Manager, Ingersoll Machine Tools.

To handle the complex machining applications, Ingersoll Machine Tools chose the modular, scalable and open Sinumerik 840D sl CNC system from Siemens, which is considered to be

the control of choice in high-end machining segments like aerospace. High CNC machining performance, along with flexibility and openness, represent the basis for almost every machine tool concept.

Engineers from aerospace and other large-part industries come to Ingersoll Machine Tools

to collaborate on breakthroughs in additive and subtractive manufacturing

The promised advantages of digitalization are being implemented by Ingersoll Machine Tools.

Having removed the boundaries to large-format robotic fiber placement and 3D printing,

expectations now rise toward making breakthrough improvements across the entire part

production process.

Run MyRobot is a key feature on the Siemens Sinumerik 840D sl CNC, bringing precision control to the robotic machines at Ingersoll.

Contact for journalists:

John Meyer

Phone: +1 847 952 4158

E-mail: john.meyer@siemens.com

Follow us on Social Media:

www.twitter.com/siemens_cnc_us www.facebook.com/Siemens.CNC.US

Siemens Digital Industries (DI) is an innovation leader in automation and digitalization. Closely collaborating with partners and customers, DI drives the digital transformation in the process and discrete industries. With its Digital Enterprise portfolio, DI provides companies of all sizes with an end-to-end set of products, solutions and services to integrate and digitalize the entire value chain. Optimized for the specific needs of each industry, DI’s unique portfolio supports customers to achieve greater productivity and flexibility. DI is constantly adding innovations to its portfolio to integrate cutting-edge future technologies. Siemens Digital Industries has its global headquarters in Nuremberg, Germany, and has around 75,000 employees internationally.

Siemens Corporation is a U.S. subsidiary of Siemens AG, a global powerhouse focusing on the areas of power generation and distribution, intelligent infrastructure for buildings and distributed energy systems, and automation and digitalization in the process and manufacturing industries. Through the separately managed company Siemens Mobility, a leading supplier of smart mobility solutions for rail and road transport, Siemens is shaping the world market for passenger and freight services. Due to its majority stakes in the publicly listed companies Siemens Healthineers AG and Siemens Gamesa Renewable Energy, Siemens is also a world-leading supplier of medical technology and digital healthcare services as well as environmentally friendly solutions for onshore and offshore wind power generation. For more than 160 years, the company has innovated and invented technologies to support American industry spanning manufacturing, energy, healthcare and infrastructure. In fiscal 2018, Siemens USA reported revenue of $23.7 billion, including $5.0 billion in exports, and employs approximately 50,000 people throughout all 50 states and Puerto Rico.

Ingersoll Machine Tools Inc is a leader in advanced manufacturing processes and a global supplier of additive and subtractive machine tools for the aerospace, defense, energy and all heavy industrial sectors. The Ingersoll product lineup includes MasterMill™, PowerMill™ and SuperProfiler™ for accurate, reliable, high-speed milling and trimming of large, complex-geometry parts made of aluminum, titanium and hard metals; Mongoose™ and Mongoose Hybrid™, for the composite manufacturing of aircrafts’, rockets’ and vessels’ structures; MasterPrint™, the largest existing thermoplastic 3D printer, capable to produce extra-large, hollow, parts in a single piece for the aerospace and the marine sectors. Ingersoll runs these very same machines at its Development Center to manufacture key-components for many aerospace and defense programs. Together with Innse-Berardi (Lombardy, Italy), Ingersoll is part of the Camozzi Machine Tools division of the Camozzi Group. With 30 subsidiaries in 75 countries, 2600 employees, 5 operating divisions and 18 production sites, the Camozzi Group is a global leader in the supply of components and systems for industrial automation and operates in other strategic sectors: Automation, Manufacturing, Digitalization and Textile Machinery

Continue reading

This Grieve oven is a 400°F (204°C) electrically heated shelf oven, currently used for heat treating parts at the customer’s facility. Workspace dimensions of this oven measure 56” W x 30” D x 60” H. 15 KW are installed for heat input, while a 1000 CFM, 1 HP blower provides side-to-side horizontal airflow to the workload.

This Grieve shelf oven features 6” insulated walls, integrally welded construction, channel shelf supports and nickel-plated wire shelves. Additional features include 304 stainless steel interior and Trilite Green enamel painted aluminized steel exterior.

Controls on this Grieve oven include a digital indicating temperature controller, manual reset excess temperature controller and separate heating elements control contactors.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, Illinois 60073-2835 USA

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese

Tool end-users bank cost and time savings with BSB cutters with exceptional large-radii geometry

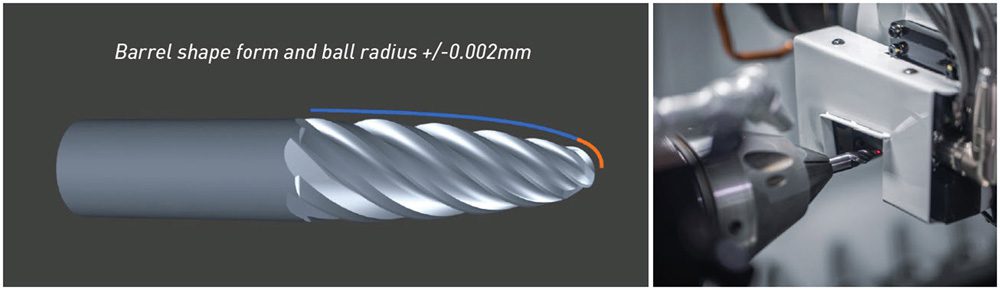

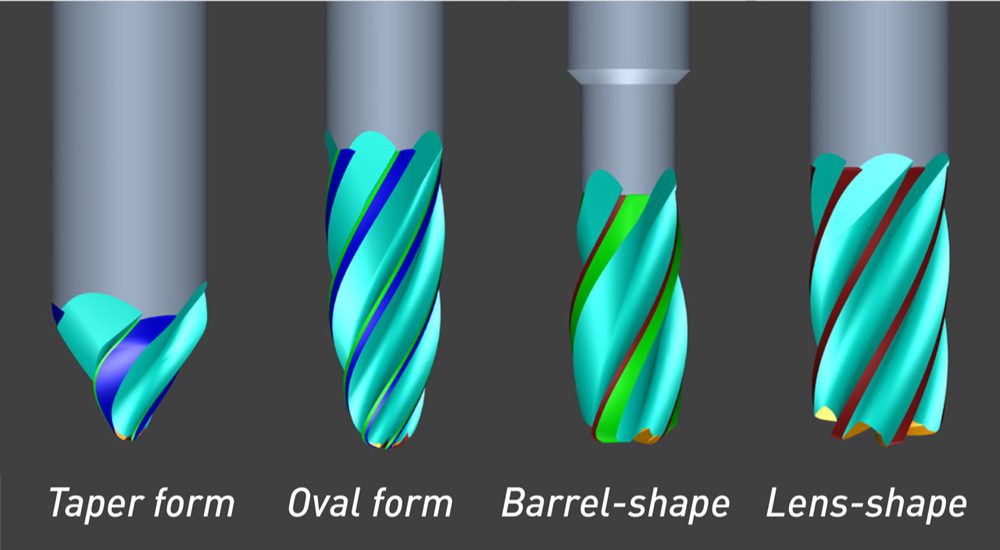

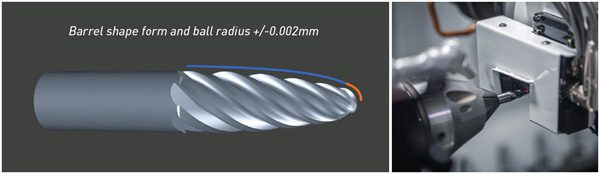

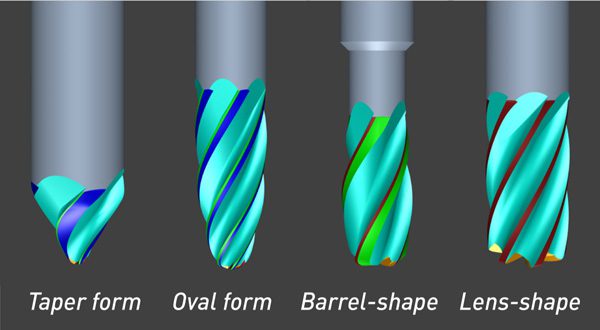

Discover new possibilities in machining with the latest Barrel Shape Ballnose (BSB) tooltype in ANCA’s up-to-the-minute ToolRoom software. The latest enhancement also includes revamped Double Corner Radius (DCR) Endmills. These endmills constitute a new tool class for machining excellence. Barrel and lens shapes and taper and oval forms are relative market newcomers and are predominantly used in the die mould, aerospace, general machining and power generation industries.

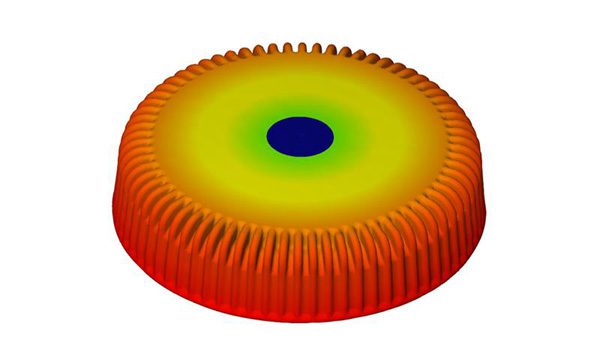

ANCA Software Product Manager, Thomson Mathew said: “The ability to create endmills with a larger-radius edge, permits greater stepover increments. This enables machining with a larger crossover pitch during pre-finishing and finishing operations – improving productivity.”

Shorter cutting distances mean it’s almost like a two for one coupon for longer tool life and faster cycle times.

Thomson adds: “Replacing conventional ballnose and corner radius applications with the large tangential form radius simulates these applications but the outsized cutting diameter is what saves cycle time and cost; and the resulting surface finish is better as well.”

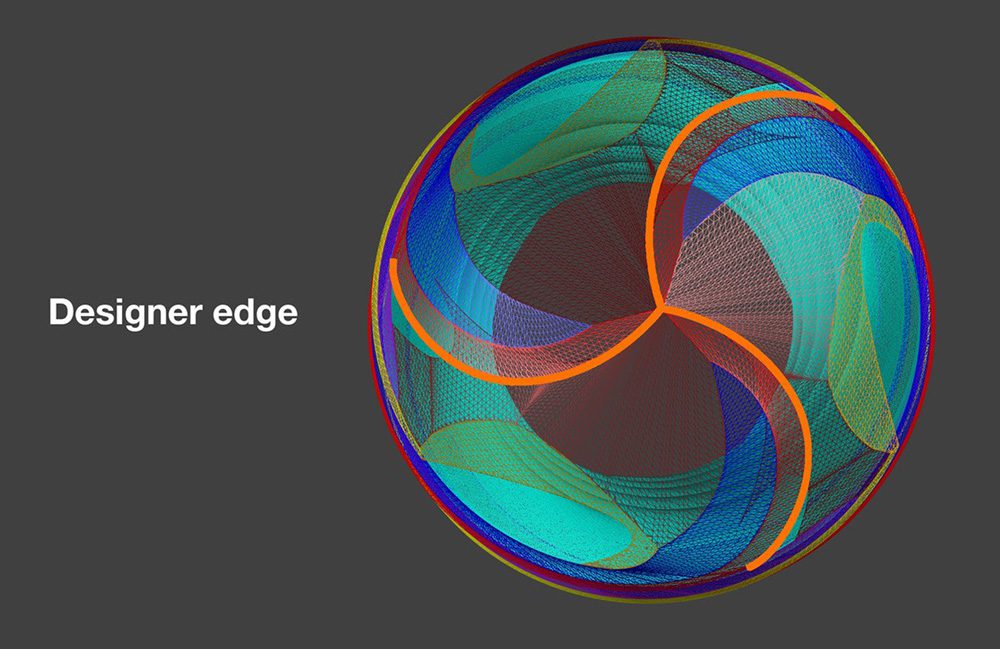

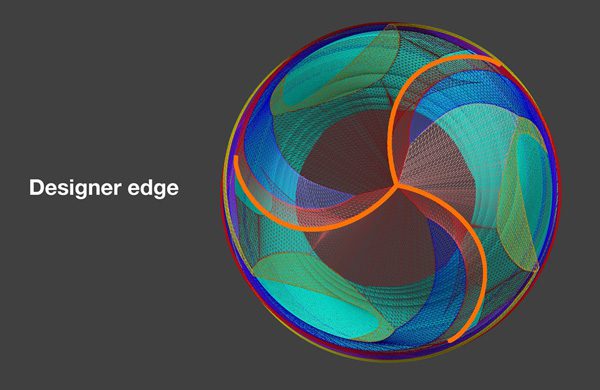

“Bringing these new endmills together with the expert advantages of ToolRoom such as iView and laser compensation, designer edge ballnose, variable helix and tool balancing sets tool manufacturers up with a complete solution and is unique to ANCA software. In addition, a special fluting operation ensures a constant hook angle all the way along the trajectory of the cutting edge resulting in vibration-free tools, with less wear and tear during machining.”

Innovation and flexibility in ANCA’s software has always been an intrinsic partner to tool machines’ functionality. With a legacy of first-to-market software features, this enhancement continues to advance the sophistication and application diversity of ANCA’s dedicated cutting tool software package. Clever features offer customers the machining capabilities needed for today’s market.

Thomson adds: “ANCA has been leading the industry in terms of new features, cycles, cutting tool geometry and functionality in our cutter grinder software for over two decades and this latest release extends this further.”

The upgrade offers wizard-based design for user-friendly operation

Manufacturing complex, sophisticated endmills is made easy with wizard-based BSB design in ToolRoom, suitable also for catalog production.

BSB and DCR tool types are high performance endmill cutters, mainly used for finishing requiring high accuracies. They may be more familiar to some as circular segment or high feed endmills. In the current market, cutting tool manufacturers may be looking to enter new markets and this software release makes diversification with high-quality specialist tools attainable.

This sought after enhancement retains ANCA’s renowned software user-friendliness and completes the ToolRoom RN34 endmill package.

The features of the new market release encompass compensation and accuracy

Compensation methods are covered as ANCA supports manual, iView and LaserPlus compensation for all geometry, as these tools are highly accurate. Both ball radius and tangential barrel form radius can be maintained within +/-0.002 mm using LaserPlus. This accuracy can also be maintained in batch grinding with automatic in-process compensation for large volume production on machines with LaserPlus.

The wizard-based design also provides the option to scale tools and add various other operations like roughing or chip breakers. Wizard support is available for oval form, taper form and also a custom form for specials. A static view gives parameter inputs for geometry description and there is also a dynamic view available to visualize the geometry as and when parameters are entered.

There are multiple practical advantages of ToolRoom software for cutting tool manufactures

For further information, please contact:

Sepideh Zandieh

PR and Communications Manager, ANCA

M: +61 439 316 131

Sepideh.Zandieh@anca.com

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

Continue reading

Exact Metrology, a comprehensive 3D metrology service provider and hardware sales company, recently celebrated the opening of their newest location in Moline, Illinois with a ribbon cutting ceremony. On September 29, 2020, members of the Quad Cities Chamber joined Exact Metrology for the ceremony to officially welcome the company at their new location.

The Quad Cities Chamber is a diverse group of influential business leaders in Western Illinois and Eastern Iowa that work to advance local businesses through advocacy, business connections, financial assistance, business intelligence, promotions, regional marketing, placemaking and leadership development.

Present at the event were Larry Makoben, Jan Mohr, Tushar Patel, Brian Williams, Scott Naumann, Amanda Hess, Ron Crouch, Mark Carlson and Terri Smith. Also present was the mayor of Moline, Stephanie Acri. The team at Exact Metrology included co-president Dean Solberg, general manager Joe Wright and applications engineers Patrick Wigans and Kris Bowers. Besides attending the ribbon cutting ceremony, the guests received a tour of the facility and witnessed product demonstrations.

Dean, Joe, Patrick and Kris scanned a sample part using the Hexagon Absolute Arm 8525 and the Leica Absolute Tracker AT960. The Hexagon Absolute Arm 7-axis delivers tactile probing and laser scanning in a uniquely ergonomic package. It is ideal for high-end portable measurement applications. The articulating arm offers ease of movement and ease of measurement. The Leica Absolute Tracker AT960 is a robust, all-in-one laser tracker that fits in a single flight case and offers high-speed dynamic measurement as standard. Besides offering six degrees of freedom (6DoF), the tracker offers probing, scanning, automated inspection and reflector measurement. The AT960 laser tracker can be easily transported, unpacked quickly and powered up in minutes to deliver high-performance measurement almost anywhere. Dynamic features and flexible functionality give users absolute speed, accuracy and portability.

Speaking about this event, Dean Solberg said, “We were pleased to have members of Quad Cities Chamber visit us at our new location and we’re happy to be part of the local business community. Our hope is to develop a strong collaboration within this community.”

Exact Metrology is ISO, AS9100 Certified as well as FFL and ITAR Registered.

Exact Metrology, with facilities in Cincinnati, Ohio, Moline, Illinois and Milwaukee, Wisconsin, plus affiliated offices throughout the country, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

For information, please contact:

EXACT METROLOGY, INC.

Dean Solberg

20515 Industry Avenue

Brookfield, WI 53045

Local: 262-533-0800

www.exactmetrology.com

deans@exactmetrology.com

Tool end-users bank cost and time savings with BSB cutters with exceptional large-radii geometry

October 2020: Discover new possibilities in machining with the latest Barrel Shape Ballnose (BSB) tooltype in ANCA’s up-to-the-minute ToolRoom software. The latest enhancement also includes revamped Double Corner Radius (DCR) Endmills. These endmills constitute a new tool class for machining excellence. Barrel and lens shapes and taper and oval forms are relative market newcomers and are predominantly used in the die mould, aerospace, general machining and power generation industries.

ANCA Software Product Manager, Thomson Mathew said: “The ability to create endmills with a larger-radius edge, permits greater stepover increments. This enables machining with a larger crossover pitch during pre-finishing and finishing operations – improving productivity.”

Shorter cutting distances mean it’s almost like a two for one coupon for longer tool life and faster cycle times.

Thomson adds: “Replacing conventional ballnose and corner radius applications with the large tangential form radius simulates these applications but the outsized cutting diameter is what saves cycle time and cost; and the resulting surface finish is better as well.”

“Bringing these new endmills together with the expert advantages of ToolRoom such as iView and laser compensation, designer edge ballnose, variable helix and tool balancing sets tool manufacturers up with a complete solution and is unique to ANCA software. In addition, a special fluting operation ensures a constant hook angle all the way along the trajectory of the cutting edge resulting in vibration-free tools, with less wear and tear during machining.”

Innovation and flexibility in ANCA’s software has always been an intrinsic partner to tool machines’ functionality. With a legacy of first-to-market software features, this enhancement continues to advance the sophistication and application diversity of ANCA’s dedicated cutting tool software package. Clever features offer customers the machining capabilities needed for today’s market.

Thomson adds: “ANCA has been leading the industry in terms of new features, cycles, cutting tool geometry and functionality in our cutter grinder software for over two decades and this latest release extends this further.”

The upgrade offers wizard-based design for user-friendly operation

Manufacturing complex, sophisticated endmills is made easy with wizard-based BSB design in ToolRoom, suitable also for catalog production.

BSB and DCR tool types are high performance endmill cutters, mainly used for finishing requiring high accuracies. They may be more familiar to some as circular segment or high feed endmills. In the current market, cutting tool manufacturers may be looking to enter new markets and this software release makes diversification with high-quality specialist tools attainable.

This sought after enhancement retains ANCA’s renowned software user-friendliness and completes the ToolRoom RN34 endmill package.

The features of the new market release encompass compensation and accuracy

Compensation methods are covered as ANCA supports manual, iView and LaserPlus compensation for all geometry, as these tools are highly accurate. Both ball radius and tangential barrel form radius can be maintained within +/-0.002 mm using LaserPlus. This accuracy can also be maintained in batch grinding with automatic in-process compensation for large volume production on machines with LaserPlus.

The wizard-based design also provides the option to scale tools and add various other operations like roughing or chip breakers. Wizard support is available for oval form, taper form and also a custom form for specials. A static view gives parameter inputs for geometry description and there is also a dynamic view available to visualize the geometry as and when parameters are entered.

There are multiple practical advantages of ToolRoom software for cutting tool manufactures

For further information, please contact:

Sepideh Zandieh

PR and Communications Manager, ANCA

M: +61 439 316 131

Sepideh.Zandieh@anca.com

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

Continue reading

Exact Metrology, a comprehensive 3D metrology service provider and hardware sales company, performed a recent inspection on molded caps to showcase the power and capability of multi-part inspections at its Brookfield, Wisconsin office.

Computed tomography (CT) scanning is an x-ray methodology yielding 3D results by placing an object on a rotational stage between an x-ray tube and an x-ray detector, rotating the object 360 degrees and capturing images at specific intervals. Furthermore, CT scanners can easily scan multiple parts at the same time. To render the 3D x-ray model of the object or part, the series of images is reconstructed. CT visualization software can slice in any direction to produce optimal views and images required for the analysis of internal configuration and instant CAD comparison. This software can segment multiple scanned parts, creating individual files for each component. These can be analyzed independently, and all statistics can be evaluated.

The GOM CT scanner used by Exact enables the inspection of complex parts based on volume. It produces the finest details visible throughout the component, simplifying initial sampling, tool correction and inspection tasks during production. It captures complex components including the “inner workings” in a single scanning process, so that the user receives a complete image of the test specimen for form and position analysis or nominal/actual comparisons.

This scanner features a 225 kV X-ray source and a high-contrast 3k X-ray detector that generates a very fine pixel grid (3008 x 2512 pixels), laying the foundation for high-precision detection of the measured components. 5-axis kinematics with an integrated centering table make it easier for the user to position the component optimally in the measuring volume, so that the measurement is always performed with the best possible resolution. Additional features include temperature balancing for metrology applications, an I/O port and photogrammetric calibration. Within the measuring volume (diameter: 240 mm, height: 400 mm) several objects can be measured simultaneously in one scan, further reducing processing times. Thanks to the proven GOM technology, the CT ensures high precision and repeatable measurement results. As with all GOM metrology systems, the control of the device, data acquisition and evaluation are combined in a single software package. This means no additional software is required; the chain from recording the raw data to creating the measurement report is greatly simplified.

Using both the scanner and the software, 30 individual inspection reports were generated on these injection molded caps. Statistical results compared all measurements. Sean Plastine, an Exact Metrology Application Engineer and Greg Groth, Division Manager, were involved in this process. They believe it is significant for the company because it reduces the amount of time needed to get results for customers, thus eliminating the need for measuring 30 parts individually with conventional methods such as CMM, laser or structured light.

Exact Metrology is ISO9001, AS9100 Certified as well as FFL and ITAR Registered.

Exact Metrology, with facilities in Cincinnati, Ohio, Moline, Illinois and Milwaukee, Wisconsin, plus affiliated offices throughout the country, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

GOM GmbH

GOM develops, produces and distributes software, machines and systems for 3D coordinate measuring technology, 3D computed tomography and 3D testing based on latest research results and innovative technologies. With more than 60 sites globally and more than 1,000 metrology specialists, GOM guarantees professional advice as well as support and service. More than 14,000 system installations improve the product quality and manufacturing processes in the automotive, aerospace and consumer goods industries.

For information, please contact:

EXACT METROLOGY, INC.

Dean Solberg

20515 Industry Avenue

Brookfield, WI 53045

Local: 262-533-0800

www.exactmetrology.com

deans@exactmetrology.com

Kodlin Motorcycle customizes motorcycles based upon bikes from the legendary American brand Harley-Davidson. Sophisticated technology and an easy-to-use control system are essential—which is why the company chose the Sinumerik 828D CNC from Siemens.

There is no denying it: the Kodlin family has motorcycles in its blood. Master blacksmith Fred Kodlin gave his son Len his first motocross bike for his fifth birthday. There was never really any question about what Len would do when he grew up. Today, the father-and-son team runs the Fred Kodlin Motorcycle workshop, founded by Fred Kodlin back in 1984, in the small town of Borken in the German state of Hessen.

The company is highly specialized: together, father, son and 10 employees customize Harley-Davidson motorcycles. Up to 50 motorcycles leave their shopfloor each year, to the great excitement of their new owners. Many customers simply want to have their series-produced bikes adjusted to suit them better, or to look more individual. Other customers come to the company looking for bigger modifications, such as the installation of a big front wheel, which has a very striking effect and is popular among Harley-Davidson fans.

The most passionate bikers, however, want their bikes to be completely personalized. “These unique bikes cannot be beaten in terms of exclusivity. When it comes to design and technology, we make the virtually impossible possible,” explains junior manager Len Kodlin. In some of these models, the only thing that’s left is the engine, with its unmistakable Harley-Davidson sound: the rest of the bike is made up of components that have been developed and produced entirely by Kodlin. Customers’ budgets are the only thing limiting their imagination. Enthusiasts pay up to $130,000 for these unique cycles. And then, of course, there are also the technical approval restrictions (TÜV, for example).

Avoiding imitations

When fulfilling a customer’s dream of owning a personalized motorcycle, the customizers at Kodlin Motorcycle not only adapt parts, they also manufacture many individual parts themselves. Various styles of footboards, footpegs, turn-signal trim, air filters, engine covers, hand grips and mirror brackets are manufactured individually or in very small series. Outsourcing production could be cheaper in many cases, but for Kodlin, this is not an option. Len Kodlin explains the reasoning behind the decision. “Unique pieces are the basis of our whole company. The risk of copies appearing is simply too great. Our customers pay for something unique and that’s what we give them. This is why we do everything ourselves, from sheet-metal work and welding to milling, turning, painting and assembly,” Kodlin says.

Kodlin has an extremely large range of manufacturing capabilities to prevent imitations and rival products, thus safeguarding its competitive edge. The company invests heavily in production expertise and machinery. Kodlin even has a world manufacturer identifier. This official designation signals that Kodlin is officially a manufacturer that can build and approve motorcycles.

An integrated process from the design to the machine

Anyone who wants to survive the competition as a small, independent customizer needs top-quality CNC machines. That’s why the core of Kodlin’s production process is a PreMill VL 1000 CNC machining center from MMD Werkzeugmaschinen with a Sinumerik 828D CNC system. Len Kodlin, a trained precision mechanic himself, explains what matters to him and his father, “MMD was extremely cooperative and, with the PreMill VL 1000, gave us a machine that meets our needs perfectly. The price/performance ratio was good and with the Sinumerik 828D control—including the intuitive Sinumerik Operate graphical user interface—our core requirement, namely ease-of-operation, was met to our utmost satisfaction.”

The demands on the machine tool and control system are high and diverse. Many simple parts are programmed directly on the machine. For this type of application, it is important for the shopfloor programming to be as simple as it is reliable and efficient. Jan Rosenkranz, a mechanic on the Kodlin team, gets straight to the point, “The ShopMill menu-based navigation makes everything really quick and easy.” He also appreciates the convenient setup functions.

The production of custom parts, which often involves extremely complex contouring, is entirely different. The junior manager creates the programs for these parts separately at an external CAD/CAM workstation and then transfers them to the machine, using a USB stick. This means the machine can remain in operation while the junior manager can design parts for his spectacular creations, far away from production noise, in peace and quiet. Once the blank is in place, the entire machining process itself goes very quickly. With the help of various Sinumerik CNC cycles, the workpiece and the tool are set up quickly and machining on the PreMill VL 1000 can begin.

Len Kodlin specifically mentions the clearly organized folder structure in Sinumerik Operate, which is designed in a similar way to that found on a traditional PC. Meaningful names—such as “Handlebar1-Customer3”—with up to 28 characters can be assigned to the programs. This improves the ability to maintain an overview and products that have already been made can be clearly identified and accessed again at a later date.

The entire production spectrum covered

In terms of production technology, the PreMill VL 1000 offers everything needed for bike parts. The machine gets extra points for its framework construction, which makes it very stable and easily accessible. The majority of the components are less than 500 mm long. However, there are exceptions, such as long fork tubes. With travel paths of X = 1020 mm, Y = 510 mm, and Z = 560 mm, plus a 1200 x 500 mm clamping table, the machine comprehensively covers the spectrum. The 10-kW milling spindle provides the power needed to quickly and precisely machine the parts, which are usually made of aluminum or steel. The changer can be equipped with up to 30 tools and the linear guides on all three axes ensure utmost precision. According to Jens Bubenheim, a sales consultant at MMD, the PreMill VL 1000 achieves a repeat accuracy of ± 3 µm and a positioning accuracy of ± 5 µm, which means that the desired quality is always guaranteed.

A special feature on the Sinumerik 828D CNC scores additional points for high quality, namely the Sinumerik MDynamics technology package with integrated Advanced Surface motion control. The program sequence can be set or adjusted at any time, ensuring that the machine generates an optimal ratio of speed, accuracy and surface quality. Take the turn signal trim, for example. In this case, production accuracy is of less significance. Corresponding settings in MDynamics and the activated Advanced Surface therefore ensure that the machine works with a focus on both surface quality and speed of production.

Contact for journalists and product information:

John Meyer

Marketing Communications Manager

Siemens Industry, Inc.

390 Kent Avenue

Elk Grove Village, IL 60007

T: +1 847 640 1595

E: john.meyer@siemens.com

Website: usa.siemens.com/cnc