Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

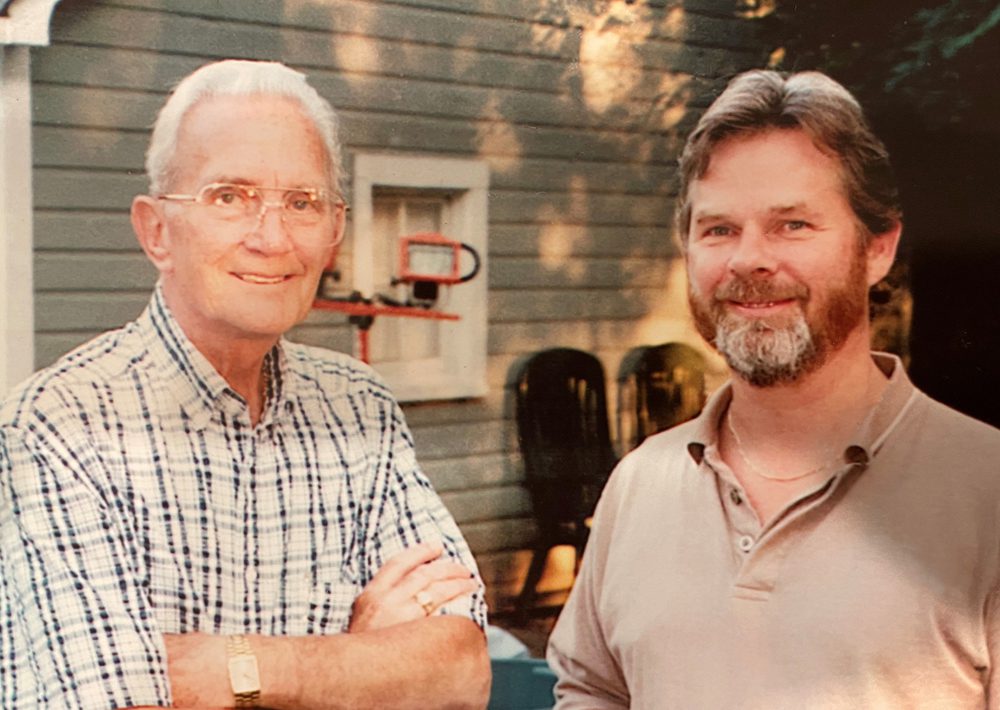

In a world where machine shops are struggling to stay open and maintain their business and in a day when “going into dad’s business” is not what it once was, Platinum Tooling is an exception to the rule. Located in Prospect Heights, Illinois, the company is set to reach an important milestone. In 2022, company President Preben Hansen and his family will celebrate 100 years working in metal cutting and four generations of Hansen men in the industry. How cool is that?

The story began with Preben’s grandfather, Louis Eckart Hansen, who learned his trade in Copenhagen, Denmark in the early 1900s. Louis worked as a machinist in the Danish Navy’s repair facility. Preben’s father, Svend Eckart Hansen, honed his skills under the guidance of Louis. In 1958, Svend emigrated with his family, including young Preben, to the U.S. Despite not knowing English, he found employment within days of arriving in Chicago, because of his skill as a tool maker. Svend began his career as a machinist and ended it in the 1990s as a master tool maker at Ramcel Precision Stamping and Manufacturing LLC in Northbrook, Illinois.

With manufacturing and tooling in his DNA, Preben worked in the machine shop of the former Fulton Machine Company in downtown Chicago, while attending the University of Illinois/ Chicago and pursuing a degree in engineering. Following college, he worked in the shop at Oakley Industries building custom machinery. After several years in the shop, Preben moved to the front office and into an inside sales position. Later, at Jemco Tool & Die, he learned programming and set-up on their CNC lathes and machining centers which was his introduction to machine tools and their accessories. His next job was at HPI, now known as Pioneer Heartech Precision Inc., a distributor of tool holders and related products, in Elk Grove Village, Illinois. Preben started as an Outside Sales representative of tool holders and rotary tables, then became the company’s Sales Manager. This was followed by work at Lyndex-Nikken, another machine tool accessory supplier in Mundelein, Illinois. Here, Preben was introduced to live tools and once again worked as Sales Manager. In 2010, Preben started a joint venture with heimatec GmbH, becoming the President of Heimatec, Inc., a company specializing in live tools, angle heads and multi-spindle drill heads. In 2018, Heimatec, Inc. was purchased by Platinum Tooling Technologies, Inc. with headquarters located in Prospect Heights, Illinois. Preben Hansen is the COO and President at Platinum Tooling.

In total, Preben has over 30 years of experience in the machine tool accessory market and over 40 years in the manufacturing industry. Given his credentials, it’s no surprise that Preben has established himself as a leading authority on these topics in the North American machine tool accessory market. He often hosts knowledge bars at trade shows to SRO crowds.

In keeping with this family tradition, Preben’s son, Luke Hansen, joined his dad’s company in 2018 as a Technical Sales Specialist for several of the product lines sold by Platinum Tooling, including Tecnicrafts collets and guide bushings for Swiss machines. After graduating from high school, Luke joined the army in search of his calling and received great training there. Upon his discharge, he decided to put into practice the motivational and goal orientation skills he had learned in the military. In his current position at Platinum Tooling, Luke continues to expand his knowledge of the machine tool accessory market as well as build valuable relationships with the North American sales and distribution network of the company.

Reflecting on 100 years as a family in the manufacturing industry, Preben Hansen says, “The machine tool industry has been and continues to be an extremely vital part of our country’s continued success. My son Luke and I are proud to be 3rd and 4th generation professionals involved in this exciting industry.”

For more information, please contact:

Preben Hansen, President

Platinum Tooling Technologies, Inc.

16 East Piper Lane, Suite 128

Prospect Heights, IL 60070

847-749-0633

www.platinumtooling.com

phansen@platinumtooling.com

Platinum Tooling Technologies, Inc. in Prospect Heights, IL, serves its growing North American customer base with an extensive inventory of machine tool accessories. Its experienced staff is dedicated to providing the most innovative tooling and technology. Platinum Tooling Technologies, Inc. serves the auto, aero, medical, woodworking, composites and other industries, as well as an ever-increasing number of machine tool OEMs worldwide, through its network of manufacturers’ representatives. Platinum Tooling is the importer of Heimatec, Henninger, Tecnicrafts and AMF Tooling for North America.

Continue reading

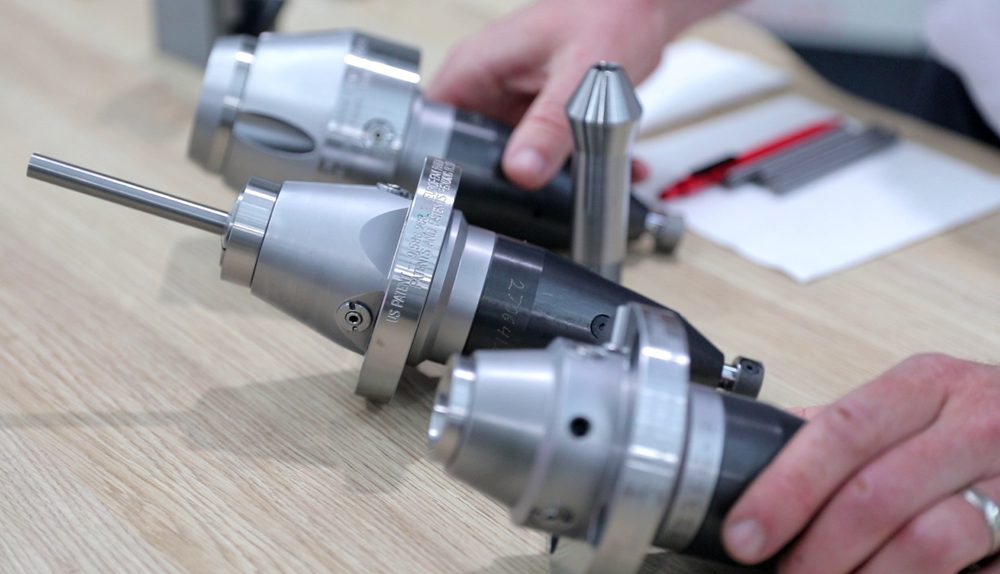

Learn how to set up a collet adaptor, a fundamental skill that all operators need to grind accurate tools and maintain stability of batch grinding

Each month, the ANCA Academy show will cover a different technical topic – from set up through to grinding. The educational videos will help ANCA machine users understand new applications and features.

Hugh Ingham, ANCA Mechanical Engineer hosts the new show and said: “I love working at ANCA because we design and apply really interesting and effective technology. It is important that we make sure we are helping our customers and those interested in getting into cutting tool grinding produce the best possible product faster, more accurately and at the lowest possible cost. The first episode will explain a PCA adaptor, how they work and how you can set your machine up for long and stable batch runs.”

“ANCA already has our Tool Tip Tuesdays, monthly newsletter, The ANCA Club, face to face training, social media and YouTube channel but we think there is so much to learn about our technology that we decided to start our own dedicated TV show. Make sure you send in any ideas or topic suggestions because this show is entirely dedicated to help our customers get even more out of their investment in ANCA. That way we both succeed.”

“The first episode covers the fundamentals of these types of collet adaptors, what makes them unique and how with some simple tricks, you can reduce your setup time and increase your productivity. After watching this episode, you will be able to confidently set up your ANCA PCA for reduced radial and axial runout and enjoy the benefits of long and stable batches.”

“If you have a brand new or an older ANCA machine and want to get right into accurate and repeatable grinding, then you definitely don’t want to miss this.”

Topics covered will include:

Sign up to our customer dedicated newsletter and don’t miss an episode: https://machines.anca.com/E-Sharp-News/Sign-up

For further information, please contact:

Johanna Boland

Group PR and Communications Manager, ANCA

M: +61 407799779

Johanna.Boland@anca.com

https://machines.anca.com/

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

Continue reading

Poly Crystalline Diamond (PCD) products are widely used in industry for their superior abrasion resistance and longevity when machining non-ferrous materials. By virtue of their uniform carbon lattice structures, diamond is the hardest material available and therefore lends itself well to manufacturing processes requiring high speeds, feed rates and extended wear behaviors. PCD is not typically used to machine ferrous materials such as iron or steel due to a chemical reaction that occurs between the diamond and the iron molecules. The Carbon atoms in the diamond react with the Iron (Ferrous) atoms of the iron or steel to produce Iron Carbide (Fe3C), causing the tool edges to collapse. However, it can tackle bimetal applications involving aluminium and cast iron.

The areas that PCD tooling excels in is the machining of non-ferrous materials, composites, electronic components, timbers and precious metals.

| Non-ferrous Metals | Polymers and Other Materials | Precious Metals |

| Aluminum | Composites | Platinum |

| Carbide | Carbon Fibers | Gold |

| Titanium | Glass Fibers | Silver |

| Nickel | Ceramics | Bronze |

| Lead | Polyether (PEEK) | |

| Copper | Timber and wood | |

| Brass | PCB |

When machining these materials, PCD tooling exhibits superior wear resistance, heat tolerance and tool longevity.

Using PCD in tooling is not new, however, the explosion of lightweight materials used in all industries as manufacturers race to create lightweight and durable products highlights how versatile PCD tooling is becoming. Aluminium and composite products continue to grow quickly with the rapid expansion of consumer electronics, light-weight transportation and more efficient power generation.

Linked to the growth in non-ferrous componentry and PCD tooling is the downward pressure being applied to machine tool builders. Lowering cycle times and increasing surface finishes enables a profitable business proposition for PCD tooling manufacturers by reducing manufacturing costs per tool and increasing quality and durability for the end user.

To enable ANCA’s customers to create high-quality, low-cost tooling the new ANCA Motion SparX Generator has been designed and built using the latest power electronics. Power Electronics allows the creation of a wide band-gap generator to achieve high current and high frequency simultaneously. This enables higher mega-amp per second Nano and Pico-pulses and far greater control of the erosion process. These combine for a much faster and controllable erosion process than conventional electronics and allow for the complete manufacture of PCD tooling using nano grade PCDs (example: Element Six CMX850 with 0.85µm diamond grains and CTX002 with 2µm grains) through to very large diamond grades (example: CTH025 with average grain size of 25µm and CTM302 a multi-modal PCD with grain sizes of 2µm to 30µm)

Additionally, by virtue of the 5-axis kinematics of the ANCA EDG machines utilizing a rotary copper electrode, almost infinite tool geometries can be created including complex end-face and fluting geometries. This linked to very aggressive pricing and performance with supreme flexibility enables tooling manufacturers to create high quality PCD tools competitively. Additionally, with the increase in performance, decrease in cycle time and increase in surface finish specification, users are able to purchase arguably the most technologically advanced erosion machine available. ANCA is the only supplier of EDG erosion machines in the market that has a synchronized, adaptable, intelligent and controllable erosion process suited perfectly to the vast array of non-ferrous materials.

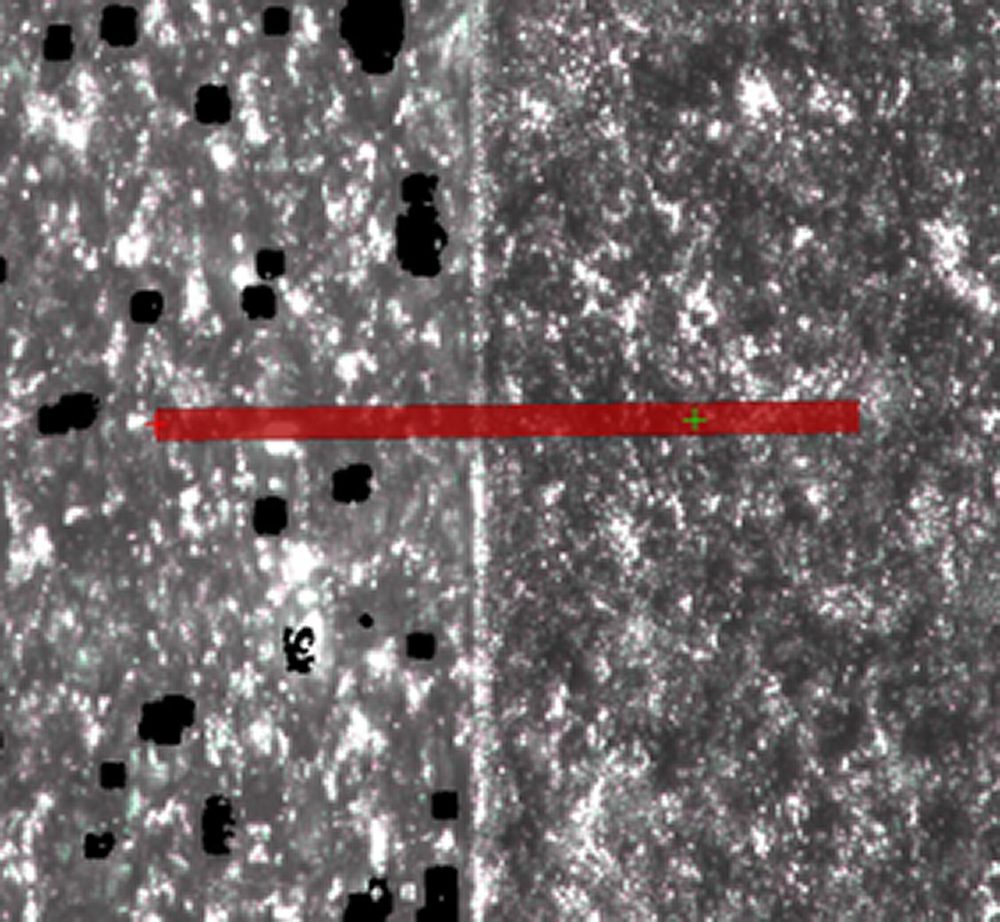

To highlight these benefits, ANCA conducted testing between tools created on an ANCA EDG, tools created on a competitor laser machine and lastly on a competitor erosion machine. Testing utilized a 12mm 2D shear brazed (neutral rake face) tool due to laser ablation systems being unable to create large fluted tools. The PCD material was Element Six CTM302.

Testing showed definitively that not only did the ANCA EDG match the quality and cycle time of laser created tools, but it was vastly superior to the like-for-like erosion results.

| Laser Competitor | Erosion Competitor | ANCA EDG | |

| Settings | – | Standard Finish | Standard Finish |

| Surface Finish (µm Ra) | 0.200 | 0.400 | 0.200 |

| Cycle Time | 26m : 24s | 56m : 00s | 26m : 20s |

| Edge Corner Radius (µm) | 9.45 | 6.25 | 3.22 |

Additionally, the cutting edges were 3x keener on the ANCA created tools as opposed to the laser ablated tools. Keen cutting edges are very important in the manufacture of aluminium and composites as they reduce burring while increasing surface finishes. In composites, keen cutting edges also reduce the risk of delamination during machining.

The key take-away from this testing was that not only is the ANCA EDG with the new ANCA Motion SparX Erosion Generator well suited to all types of PCD and the varying associated industries, but that erosion processes utilizing power electronics with high current and high frequency simultaneously positions the ANCA EDG squarely in the sights of both traditional erosion and laser technologies.

For further information, please contact:

Johanna Boland

Group PR and Communications Manager, ANCA

M: +61 407799779

Johanna.Boland@anca.com

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

Continue readingI’ve previously written about the top ten do’s and don’ts at shows. The basics remain:

Bring people, including your reps, dealers and distributors. Some large machine dealers are exhibiting again, showing all their lines on a co-op cost basis. Bring your good tech people, as attendees want answers on the spot and they will appreciate the learning experience. Don’t say “I’ll check the guys at the factory and get back to you.” YOU are the guy from the factory the attendees came to see.

Bring your product, whatever it may be. THAT’S what people attend shows to see, in addition to those experts noted above. An obvious exception would be our client who builds machines the size of a basketball court. Show ‘n tell has as much value today as it did when the nuns had us do it in grammar school.

Be open about pricing. I know that’s difficult but even a ballpark number will lend clarity to the conversation.

Engage the media. At large shows with 1000+ exhibitors, use your agency (or us) to corral the media for meetings, a presser or other event. It’s simply putting your head above the crowd. (Tim has an Irish town crier in his family tree!)

Look sharp. I was a rarity in a suit and tie, but that’s a personal choice. My father went to work every day of his life in a suit, as my son does. Restaurant and hotel moguls.

And, lastly, bring candy…even when it’s not Halloween! Our friends in other countries make shows much more of a social event than we do in America, but that’s a personal choice, too.

Take time, talk to your agency or us to learn from our experience at many shows in many industries, each year. You’ll be better prepped to max up the value of the events for your company.

Make sense?

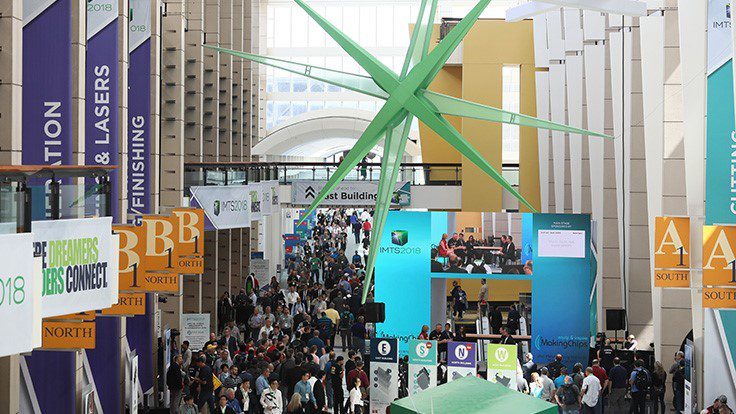

Tim Daro

Continue readingJust returned from my 12th trade show since Labor Day. So good to be back in touch with clients, media and industry associates. The kids at the agency tell me we’re in constant contact (sic) with our clients and the industry. That’s true, if you consider blasts, zooms, roundtables, lunch ‘n learns, webbies, social media and the other electronic forms of communications sufficient. Those tactics got us through the depths of Covid, to be sure, but as that landmark SME study proved loudly, the top sources industrials still use today to gather information to do their jobs are trade magazines (yes, Virginia, they’re still alive and well) and trade shows.

Some call me Pollyannish for this view. Anybody who knows me knows that simply ain’t so. (copywriter privilege for grammar)

We have identified seven ways you need to communicate and shows are high on the list. Why? In the case of our machine tool clients with average prices over a million bucks, it should be obvious. For consumable seller clients, the supply chain has been changing rapidly and shows maintain contact with the ultimate buyers. For custom crafted live tools and tool grinders, for example, not only are our clients a pair of wizards in engineering, but they also solve problems on the spot for people at shows. I’ve stood at their booths and watched them work their magic. When the customer or soon-to-be customer’s eyes light up at the suggested solution or unique feature on a machine that will significantly enhance their production, the battle is practically won.

Branding, of course, is enhanced by shows and by print advertising in ways no digital tactic can match, save perhaps the powerful video, which is now an integral part of our agency’s communication strategy in both advertising and PR.

Best of all…and this may seem sappy…there’s the clear benefit of personal contact. Here again, the youngsters who live in their digital worlds tell me such encounters are overrated. They’re wrong. The value of listening to a smart person IN PERSON who can help your business thrive and prosper, plus establish that esoteric but very real credibility only an industry expert can sustain, is never out of fashion.

On the numbers, some shows were roaring, others were dead, due largely to poor planning on the part of the organizers. I’d peg 65% as an average turnout at the shows I’ve attended, compared to pre-Covid days.

Continue reading

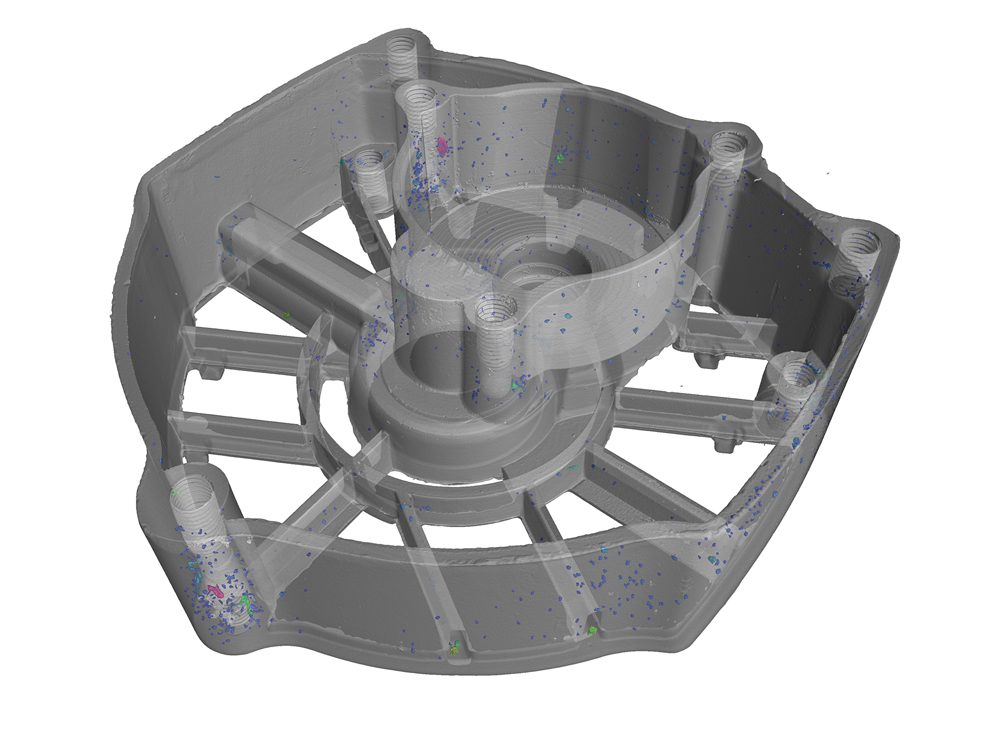

Greg Groth, the Brookfield, Wisconsin Division Manager, was part of a panel discussing additive manufacturing, its challenges and opportunities

Exact Metrology: A Division of In-Place Machining Company and a comprehensive 3D metrology service provider and hardware sales company, had one of their employees give a presentation on 3D scanning and how to use it. Greg Groth, the Division Manager at the company’s Brookfield, Wisconsin location, presented at Rapid+TCT, North America’s largest additive event. Held recently at McCormick Place in Chicago, Illinois, Groth was part of a panel discussion entitled “3D Scanning: Why do it and how.”

He discussed Exact Metrology’s capabilities, with an emphasis on CT technology. Groth also cited how CT fits into the company’s business model and how it supplements additive technology. In addition, the discussion covered the challenges that arise with complex additive parts and the need to incorporate 3D scanning into the quality process that validates parts. He also shared several examples of complex projects Exact has performed over the years.

When talking about additive manufacturing today, Groth said that there is a growing need for evaluation of additive parts once they are made. “We are naïve to the thought that even though additive circumvents the traditional manufacturing restrictions (draft/shrink) when making parts, the end result part is not perfect.” He added that these parts need to be validated. Due to the fact that additive parts are so complex, inspecting them is a challenge. Thanks to CT scanning, this has become easier.

Even though CT technology has helped capture internal geometry for additive manufacturing better than other methods, there are still limitations of material penetration. Part design should think about the way the part will be inspected, whether using contact or non-contact measurement techniques.

Depending on the complexity of the part, most additive substrates can be scanned using structured light or laser scanning. However, complex powered metal substrates are feasible for CT scanning if their material properties and scale don’t impede the penetration of the X-rays on the CT scanner. The denser the material, the more power is required.

In conclusion, Greg Groth said, “I think all additive markets can find value in the scanning and validation process. With the wide variety of scanning technology available, I don’t think any market is untouchable.”

Exact Metrology: A Division of In-Place Machining Company, is ISO9001, AS9100 Certified as well as ITAR Registered.

Exact Metrology: A Division of In-Place Machining Company, with facilities in Cincinnati, Ohio, Moline, Illinois and Milwaukee, Wisconsin, plus affiliated offices throughout the country, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

In-Place Machining Company: On-Site Machining Solutions In-Place, Any Place in the World.

In-Place Machining Company, with facilities in Wisconsin, Washington, Virginia, Ohio, California, and Ontario, Canada, is the premier provider of high-precision engineered on-site machining, metrology, and large scale cutting & drilling services for a wide range of renewable energy, aerospace, industrial, and military customers throughout the world.

For more information, please contact:

Greg Groth

20515 Industry Avenue

Brookfield, WI 53045

Phone: 262-533-0793

www.exactmetrology.com

gregg@exactmetrology.com

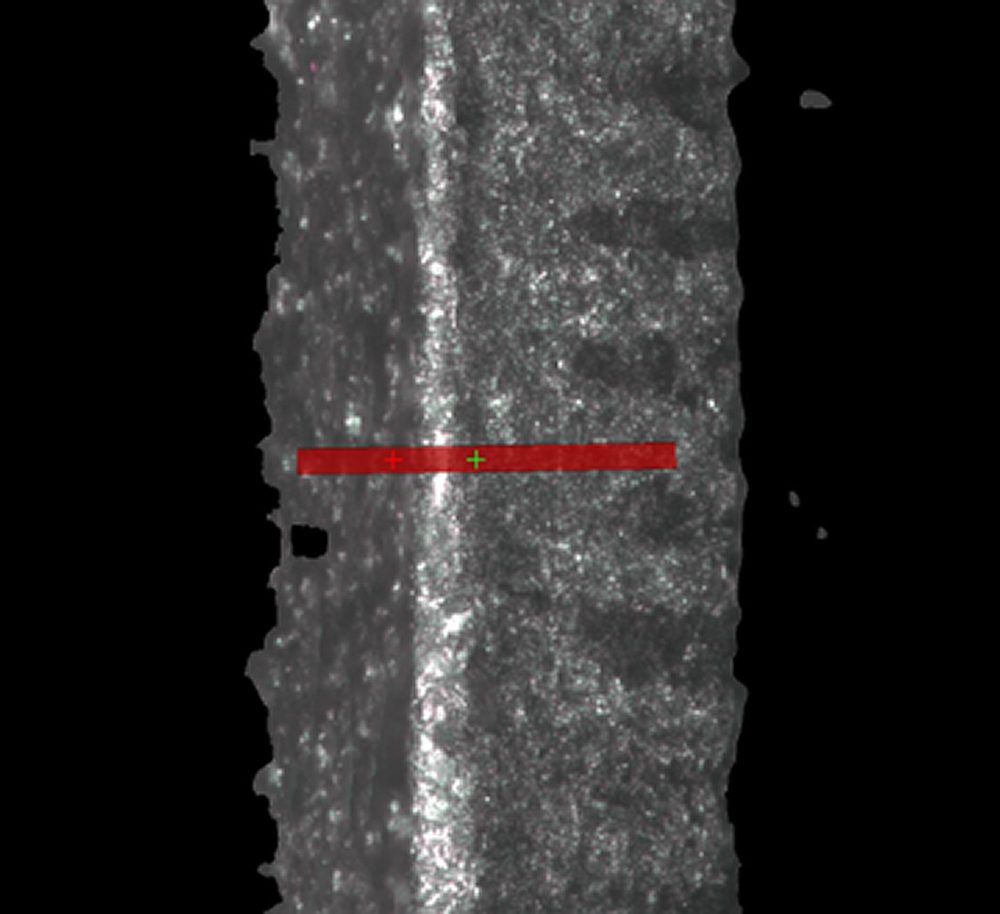

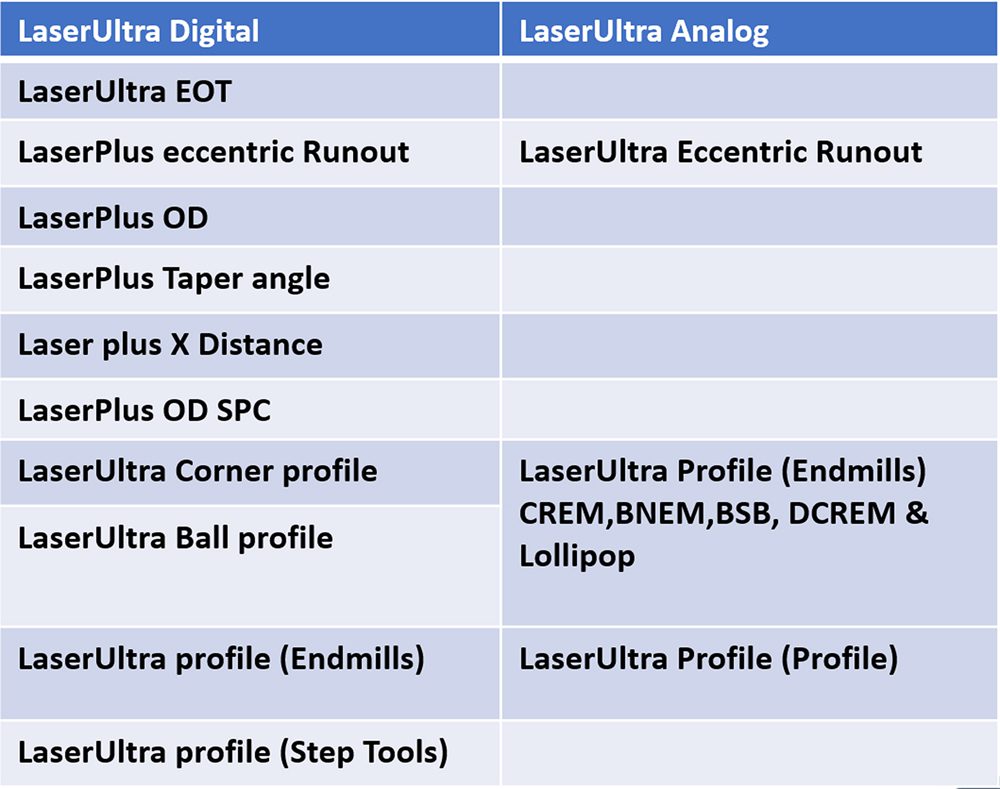

Recently launched at Eastec 2021, LaserUltra dramatically increases capacity and reduces waste through highly accurate and fast in-process measurement and compensation

ANCA leads the market in inventing, developing, and offering its customers the latest technology to realize the benefits of automation and lights out manufacturing. LaserUltra is the next generation of the highly popular LaserPlus, an in-process measurement technology only available with ANCA that gave customers the power to operate unmanned overnight with confidence they could retrieve their finished tools the next day within specification. LaserPlus was itself a game changer for the industry and already significantly faster than external tool measurement processes.

The 70% reduction in measurement time compared to Laser Plus is achieved through the new Analog measurement. The Analog measurement is a continuous edge scan instead of number of digital points along the cutting edge. This process also eliminates variations caused by machine standing idle, errors due to manual wheel corrections and the requirement of skilled operators. In its place LaserUltra has increased accuracy, productivity, and reduction of scrap.

ANCA’s LaserUltra allows the measurement of tool geometries to tolerances of 0.002mm without removing the tool from the grinder, saving time in the manufacturing process, and ensuring maximum accuracy in measurement is maintained over large batch grinding.

Pat Boland, ANCA Co-Founder said: “The intersection of 5 axis milling machines, advanced CAD/CAM software and advanced profile geometry cutting tools is revolutionizing the Die and Mold and Aerospace machining industries. ANCA’s Laser Ultra tool measurement system together with RN34 software gives tool manufacturers all they need to manufacture complex profile endmills productively to outstanding accuracy.”

LaserUltra offers customers:

Thomson Mathew, ANCA Software Product Manager said: “gone are the days of manual or external measurement and compensation for critical dimensions or profile forms due to wheel wear or other grinding factors as LaserUltra can measure and compensate within a couple of microns. All this is done in process without taking the tools out of the machine with complete control of process stability and capability. These measurements are displayed at various locations to give our customers complete visibility and trust in their grinding process.”

LaserUltra is an automatic OD, profile measurement and compensating system for ANCA’s TX, MX and FX machines. It is ideal for measuring and compensating tools to maintain tight tolerances (0.002mm) in unmanned production grinding. The in-process measurement is available in both digital and analog for fast and accurate measurements to enable productivity and performance improvements.

It is permanently mounted inside the machine and will not interfere with typical grinding processes and accessories. Using the laser, the operator can perform accurate in-process measurement and compensation without removing tools from the machine.

Thomson continues: “It gives customers flexibility to service multiple markets, supporting a large range of cutting tool applications, for example, all types of endmills or step tools — including profile, compression routers and Threadmills and several more. Furthermore, different versions of LaserUltra can cover large diameter ranges and various lengths depending on user cases. And finally, LaserUltra can generate reports which can be configured depending on customers’ requirements.”

For further information, please contact:

Johanna Boland

Group Strategy and Communications Manager, ANCA

M: +61 407799779

Johanna.Boland@anca.com

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

Continue reading

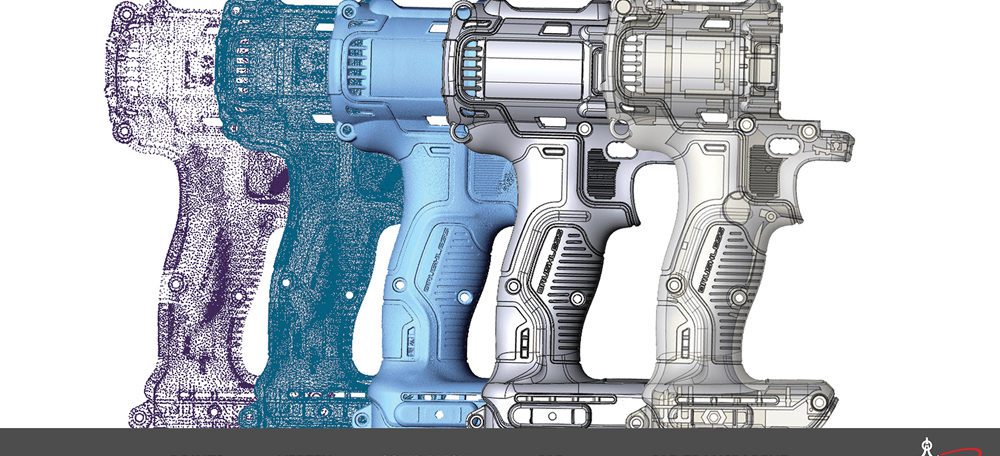

Exact Metrology: A Division of In-Place Machining Company and a comprehensive 3D metrology service provider and hardware sales company, recently reverse engineered an impact driver body.

Reverse engineering involves digitally deconstructing products to extract design information from them. Thus, users can determine how a part was designed so that it can be recreated. Although the process tends to imply that 3D scanning will be used solely for product design, it can be used to address many other engineering functions. These include product design and manufacturing, facilities maintenance and plant engineering, architectural and civil engineering and custom manufacturing.

While there are many ways to reverse engineer, CT scanning was used due to plastic nature of the impact driver body. CT excels in digitalizing small plastic parts. This impact driver body was scanned using the ZEISS METROTOM 6 scout. This CT scanner digitizes complex parts including the internal geometries at the finest level of detail. Users obtain a complete 3D image for GD&T analysis or nominal-actual comparisons. The combination of a 3k detector and 225 kV X-ray enables ZEISS METROTOM 6 scout to provide high contrast, high-resolution measurement results and exceptional sharpness of detail. As a result, even the smallest defects in the part become visible and can be analyzed to the last detail. Furthermore, CT scanning quickly captures data and one scan can be used for void analysis, inspection, volume porosity, etc. A 5-axis kinematics with integrated centering table helps clients optimally position the part in the measuring volume and the control of the device and the metrological evaluation of the data are combined in a single software package, making additional software or intermediate steps redundant.

Greg Groth, the Division Manager at the company’s Brookfield, Wisconsin office explained that the impact driver body although relatively ubiquitous, presents many challenges in the digital modeling process. One of these challenges includes the complex geometry. The smooth outside ergonomics can be difficult to duplicate and interpret with traditional CAD functionality. According to Groth, “We used a combination of hybrid NURBS (Non-Uniform Rational B-Splines) modeling to duplicate the smooth, sculpted surfaces and combined them with traditional mechanical CAD features to create the part shape.” Another challenge with plastics components is replicating complete parting lines from the original tooling to make the part. These can zig-zag around the part depending on the geometry and are sometimes omitted or cleaned up at the factory. The final challenge involves compensating for warp and shrink during manufacturing, as injection molding is used. Once the formed part starts to cool, it may change its shape. Predicting the movement and compensating it back to the intended design was time consuming.

Exact Metrology: A Division of In-Place Machining Company, is ISO9001, AS9100 Certified as well as ITAR Registered.

Exact Metrology: A Division of In-Place Machining Company, with facilities in Cincinnati, Ohio, Moline, Illinois and Milwaukee, Wisconsin, plus affiliated offices throughout the country, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

In-Place Machining Company: On-Site Machining Solutions In-Place, Any Place in the World.

In-Place Machining Company, with facilities in Wisconsin, Washington, Virginia, Ohio, California, and Ontario, Canada, is the premier provider of high-precision engineered on-site machining, metrology, and large scale cutting & drilling services for a wide range of renewable energy, aerospace, industrial, and military customers throughout the world.

For more information, please contact:

Exact Metrology: A Division of In-Place Machining Company

Dean Solberg

20515 Industry Avenue

Brookfield, WI 53045

Local: 262-533-0800

www.exactmetrology.com

deans@exactmetrology.com

Exact Metrology: A Division of In-Place Machining Company

Steve Young

11575 Goldcoast Drive

Cincinnati, OH 45249

Local: 513-831-6620

Toll Free: 866-722-2600

www.exactmetrology.com

stevey@exactmetrology.com

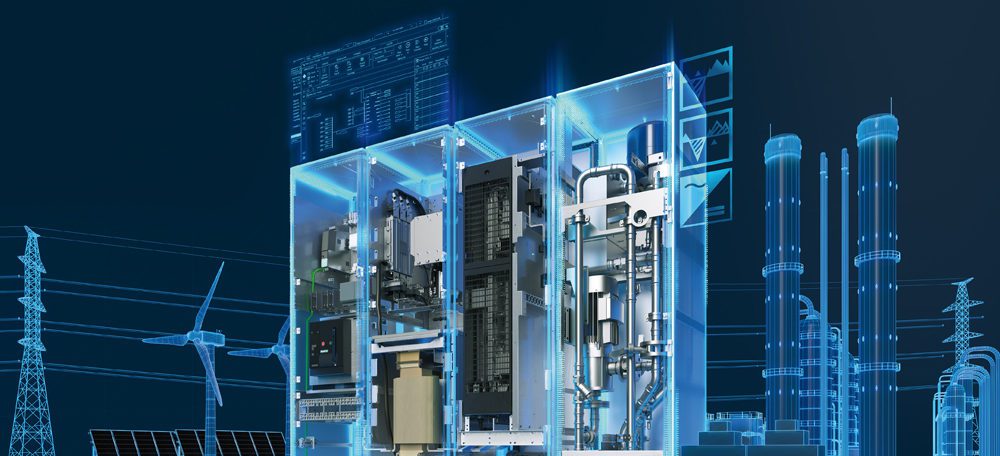

With SINAMICS PCS, Siemens presents a new power conversion system for battery storage applications. The SINAMICS PCS grid converter makes locally generated batter power usable for industrial and public power grids. SINAMICS PCS controls the charging and discharging process of the battery and helps to handle load peaks and grid disturbances via the battery storage, to store the electricity in an energy- and cost-efficient manner, and to bring the energy stored in batteries efficiently and reliably into the grid.

The grid converter is based upon the industry proven technology of the SINAMICS S120 drive platform and works very energy-efficiently thanks to liquid-cooling. The compact and robust power conversion system includes connection technology and control, line filter, drive and liquid-cooling, and can be easily integrated as a complete system in control rooms or containers.

SINAMICS PCS is certified in accordance with the “Technical Connection Rules” VDE-AR-N 4110, which is valid in Germany. This means that stationary battery storage units can be connected to the public medium-voltage grid with minimal system certification effort.

A validated Matlab/Simulink simulation model simplifies and accelerates the planning, optimization and grid integration of the power conversion system — and thanks to the SINAMICS Startdrive tool in the TIA Portal engineering framework, the grid converter

can be easily integrated into the drive world. Operating states and system parameters can be read out via the Profinet communication interface, which allows data from operation to be monitored and analyzed and makes precise statements about upcoming service work possible.

For specific product information and inquiries, send an e-mail to:

mc.us@siemens.com

Siemens presents SINAMICS PCS, a liquid-cooled, robust power conversion system for battery storage systems.

For more information about SINAMICS PCS, please visit: http://siemens.com/sinamics-pcs.

Siemens Digital Industries (DI) Siemens Digital Industries (DI) is an innovation leader in automation and digitalization. Closely collaborating with partners and customers, DI drives the digital transformation in the process and discrete industries. With its Digital Enterprise portfolio, DI provides companies of all sizes with an end-to-end set of products, solutions and services to integrate and digitalize the entire value chain. Optimized for the specific needs of each industry, DI’s unique portfolio supports customers to achieve greater productivity and flexibility. DI is constantly adding innovations to its portfolio to integrate cutting-edge future technologies. Siemens Digital Industries has its global headquarters in Nuremberg, Germany, and has around 72,000 employees internationally.

Siemens Corporation is a U.S. subsidiary of Siemens AG, a global technology powerhouse that has stood for engineering excellence, innovation, quality, reliability and internationality for more than 170 years. Active around the world, the company focuses on intelligent infrastructure for buildings and distributed energy systems and on automation and digitalization in the process and manufacturing industries. Siemens brings together the digital and physical worlds to benefit customers and society. Through Mobility, a leading supplier of intelligent mobility solutions for rail and road transport, Siemens is helping to shape the world market for passenger and freight services. Via its majority stake in the publicly listed company Siemens Healthineers, Siemens is also a world-leading supplier of medical technology and digital health services. In addition, Siemens holds a minority stake in Siemens Energy, a global leader in the transmission and generation of electrical power that has been listed on the stock exchange since September 28, 2020. In fiscal 2020, Siemens Group USA generated revenue of $17 billion and employs approximately 40,000 people serving customers in all 50 states and Puerto Rico.

Continue reading

For over 55 years, Guill Tool has been providing tooling for the aerospace, extrusion, medical, consumer and commercial, defense, wind, oil and energy industries. Due to its years of experience, the company has a highly skilled team of expert machinists engineers trained in the latest CAD, CAM, CFD and FEA programs. Besides being experts in extrusion tooling, Guill is a major industrial manufacturer who can provide customers with one-stop shopping for their tooling and other select machine shop needs.

Today, the company announces its intent to offer merchant machining services to the global aerospace industry. Tom Baldock will lead this effort at Guill. He is based at the company’s headquarters in Rhode Island.

The Guill high quality standards are evidenced by the company’s many certifications, including ISO 9001:2015. Defense certifications include AS9100:2016 (aerospace manufacturing), MIL-I-45208A (inspection system), MIL-STD-45662A (calibration system), JCP Certified (government contracting), ITAR Registered (export compliant), NIST SP800-171 (cyber security) and others.

As part of this new merchant machining program, Guill offers 5-axis machining centers, high precision machining and full wire EDM capabilities, highlighted by a .008” hole popper. Guill machines super alloys and exotic metals to close tolerances. They offer state of the art precision machining of many materials including aluminum, aluminum bronze, HY-80, HY-100, Hastelloy, Inconel, K-Monel, nickel copper, stainless and carbon steel and titanium. Guill continues to invest in utilizing innovative machine tools with the most advanced automation controls and operated by experienced technicians. Guill Tool endeavors to be a cost efficient manufacturer while adhering to a continuous improvement quality program.

Guill CNC milling machines offer resources needed to successfully fulfill the most challenging aerospace parts and tooling to keep aircraft running efficiently and precisely. The precision of CNC turning is offered for quicker production that meets rigorous standards on short and medium runs, regardless of the complexity of the parts. Guill multi-axis machines can produce a variety of sizes, complex engineering and geometric intricacies. Prototype machining and rapid manufacturing enable engineering to develop and innovate solutions with the ability to respond quickly and modify parts. Super alloys and other materials are offered to benefit customers who need new solutions to remain competitive. Finally, wire EDM eliminates the force put on part surfaces. This protects intricate and fragile tooling, plus it provides higher tolerances and accuracy.

Machining capabilities range from small hole machining of .008” in diameter and machining material measuring up to 15 inches in all axes.

Typical products produced are brackets, latches, engine components, fine hole cooling channels and structural mechanisms.

For more information, please contact:

Tom Baldock

Guill Tool & Engineering

10 Pike Street

West Warwick, RI 02893

USA

Office: 401-828-7600

www.guill.com/aerospace