Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Siemens expands its SINUMERIK Run MyRobot platform with the CNC allowing cost-effective KUKA robot part handling and articulation functions directly on the control screen of a SYIL machine tool

Automation for every shop size

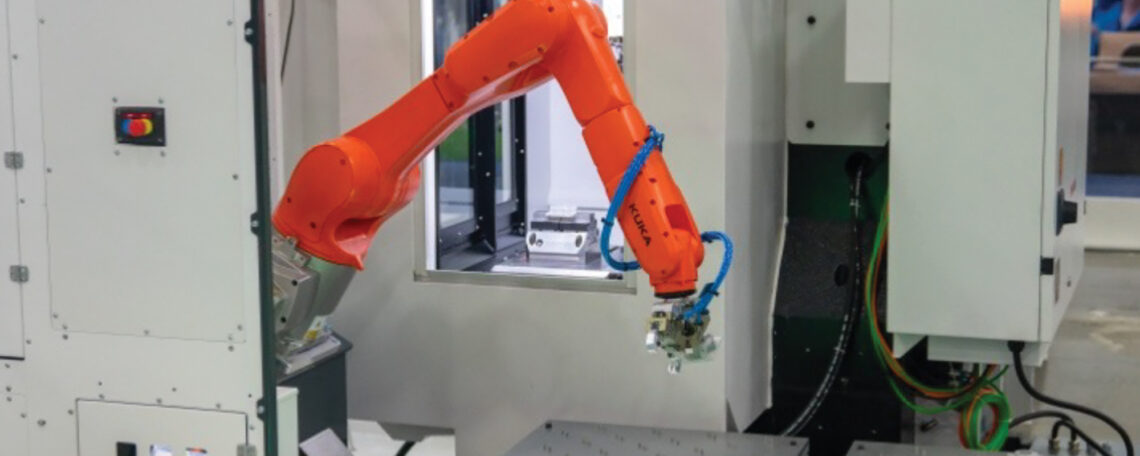

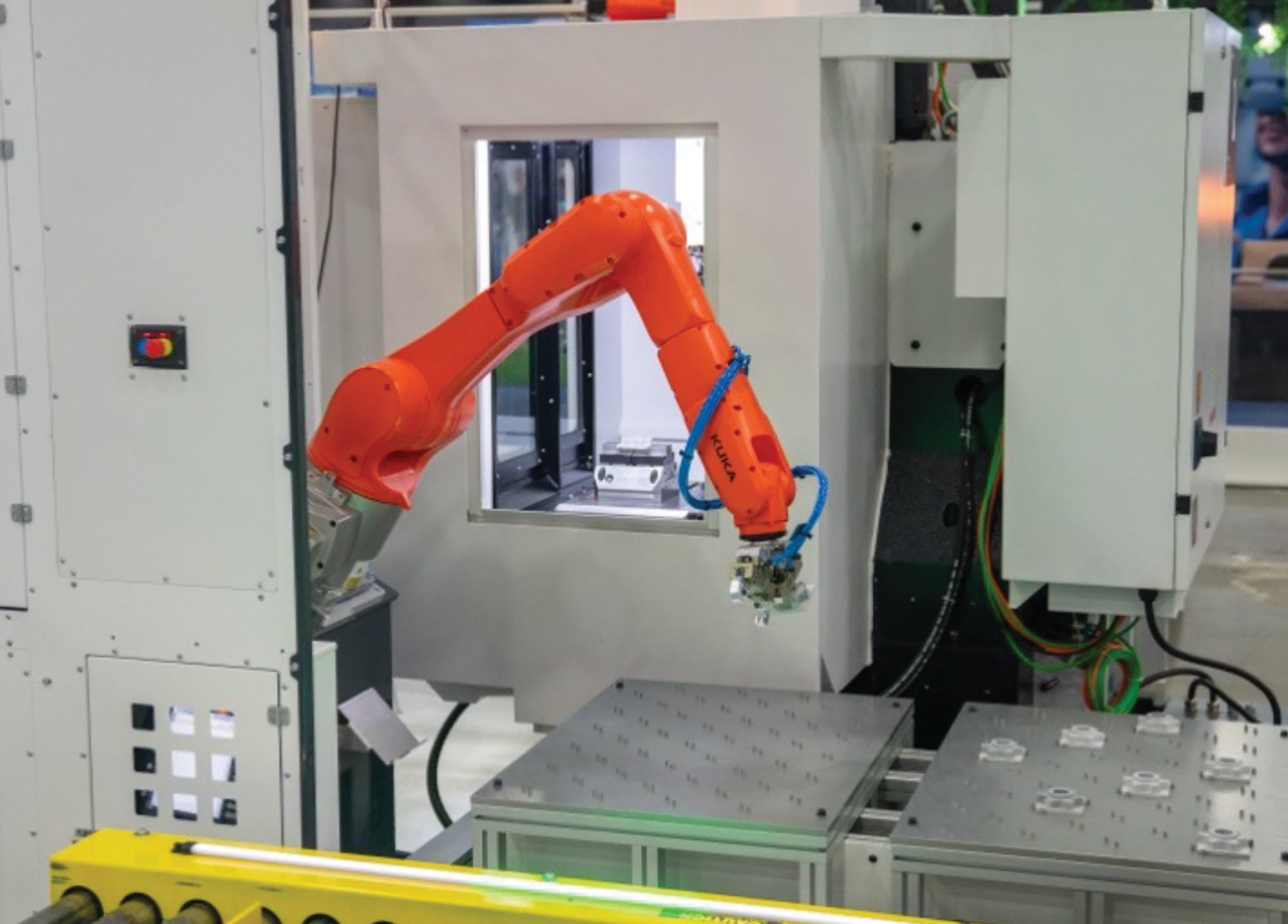

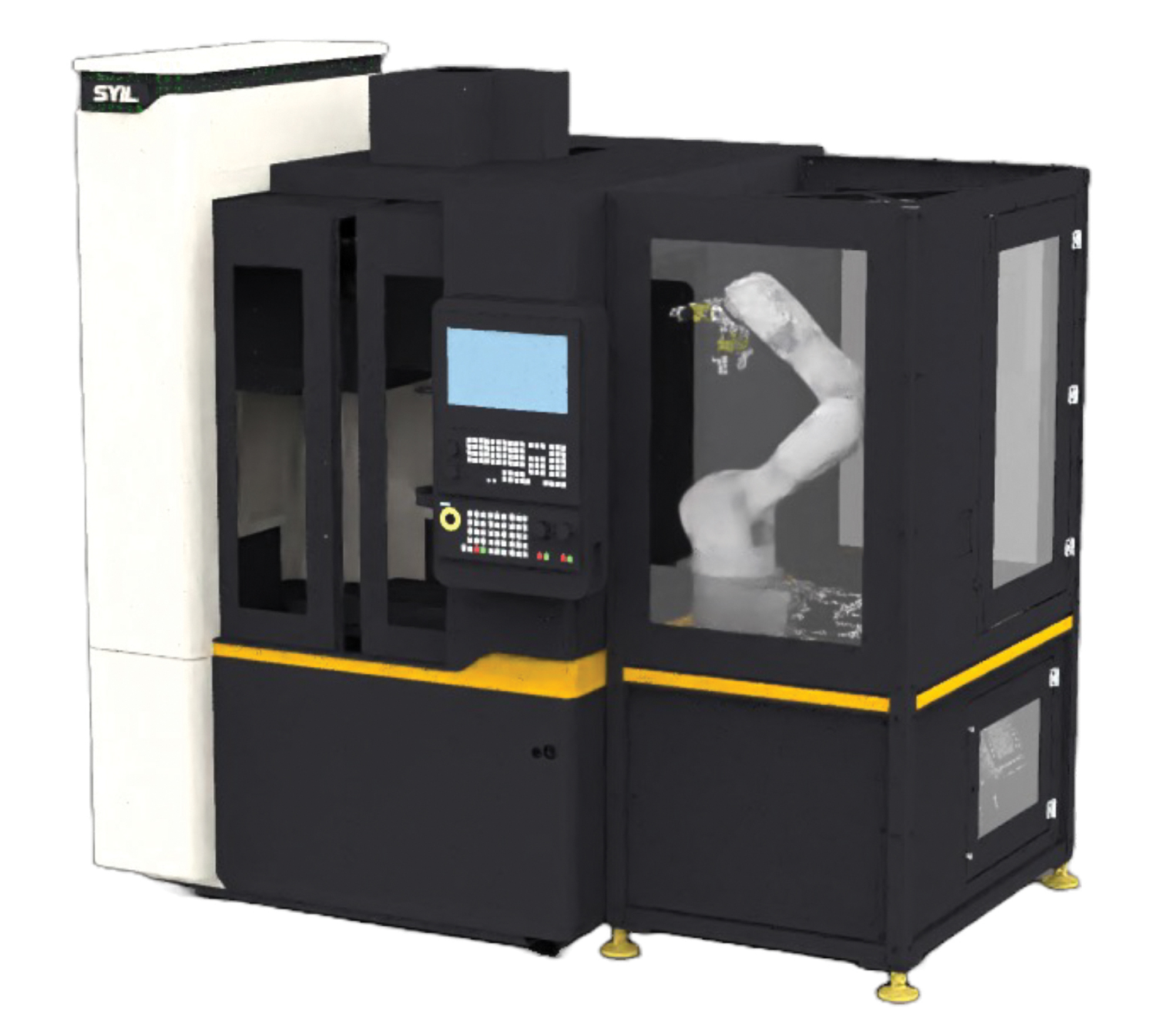

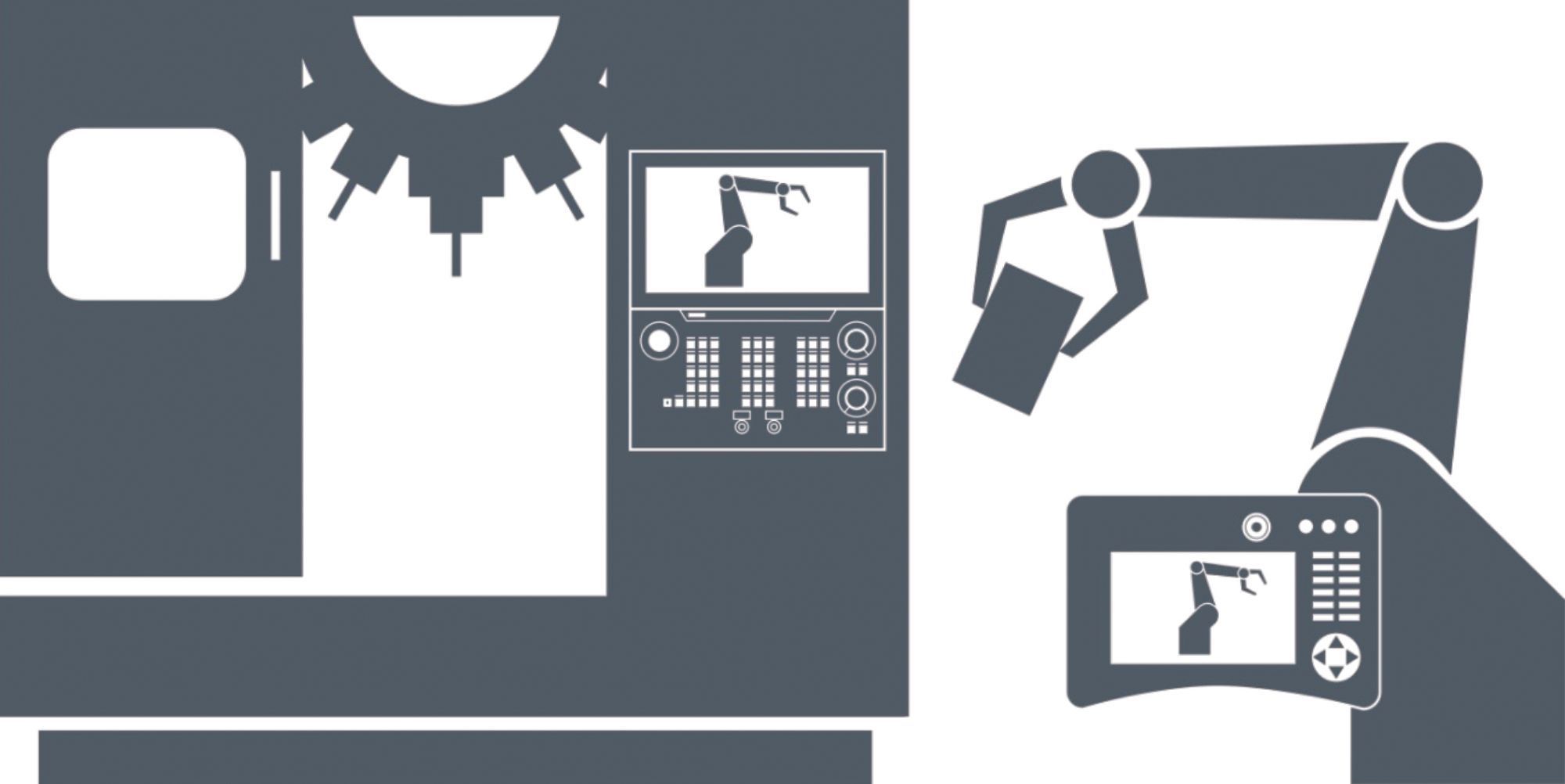

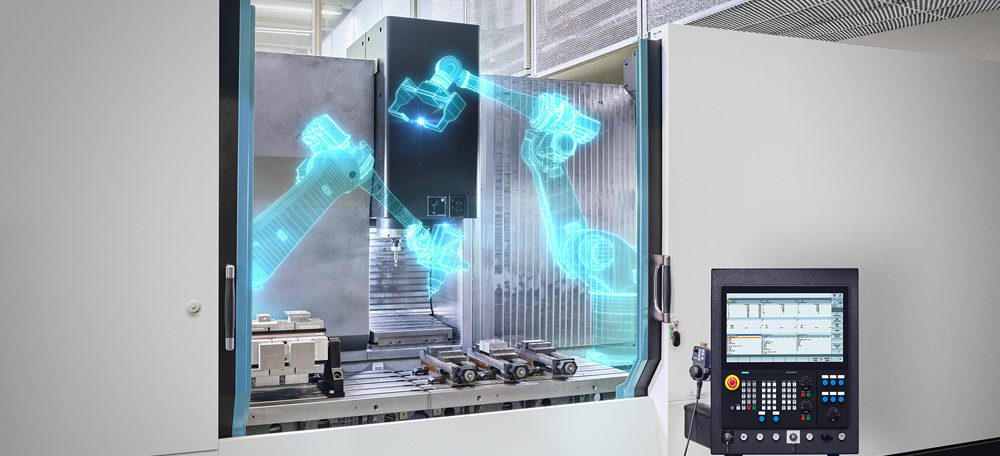

Through a technology partnership that breaks new ground in the machine tool industry, Siemens presents an automation solution for the busy, multi-tasking, small to mid-sized machine shop, as it combines a digital twin of the software and programming of its popular SINUMERIK 828 CNC, working in tandem with a KUKA robot, to simplify the operation and programming in part handling for the machine tool operator. Bringing the concept to life during a recent tradeshow, KUKA Robotics Corporation demonstrated the same control and its robot working in tandem with a SYIL vertical milling machine. The machine featured the SYIL R1 machine-tending automation package, developed with one of KUKA’s System Partners, Waybo, which seamlessly integrates the pick-and-place, part articulation and communications with the CNC onboard, all at a very attractive price point.

The goal of the program, according to Frans Buikema, Chief Marketing Officer at SYIL, is to offer the small and mid-sized shops an entry point into automation without major capital investment. Likewise, as Ron Bergamin, Key Technology Manager for Machine Tool Automation at KUKA, adds, the ROI can be very short, as this automation advancement allows the addition of a lights-out second or third shift at job shops of almost any size. Automation is the key and this cooperative engineering venture has opened a new chapter for small to mid-sized machine shops.

Simplifying robotics through the CNC

A bit of history. Only a decade ago, the integration of a robot with a machine tool required a separate learning curve for the shop, as robotics required special programming and teach-in communications, a separate pendant for operation and other challenges that often required outside consultants to implement. For small and mid-sized machine shops, this barrier, combined with the cost involved, resulted in today’s market condition, where less than a quarter of the smaller job shops in America today utilize automation and especially robotics in their workday.

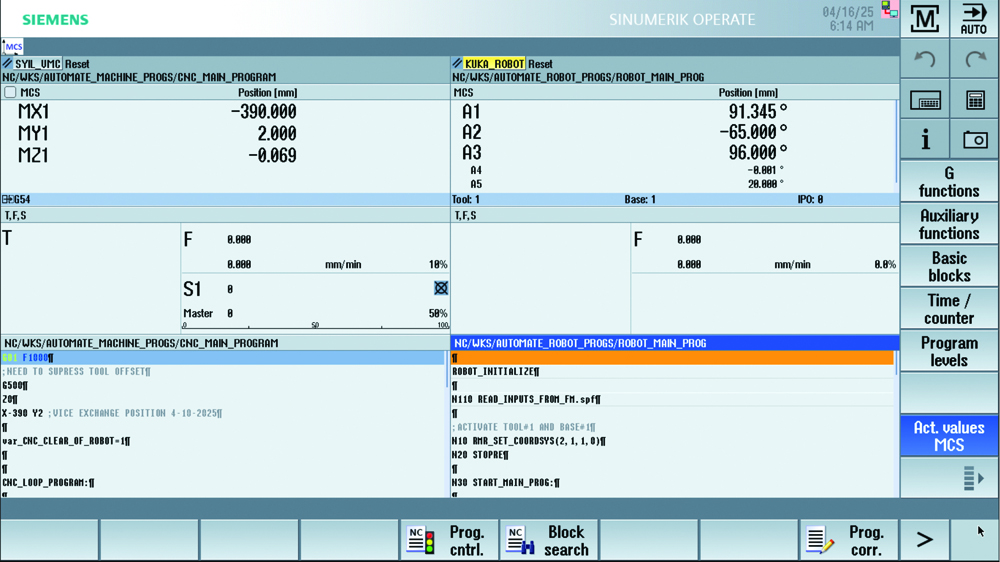

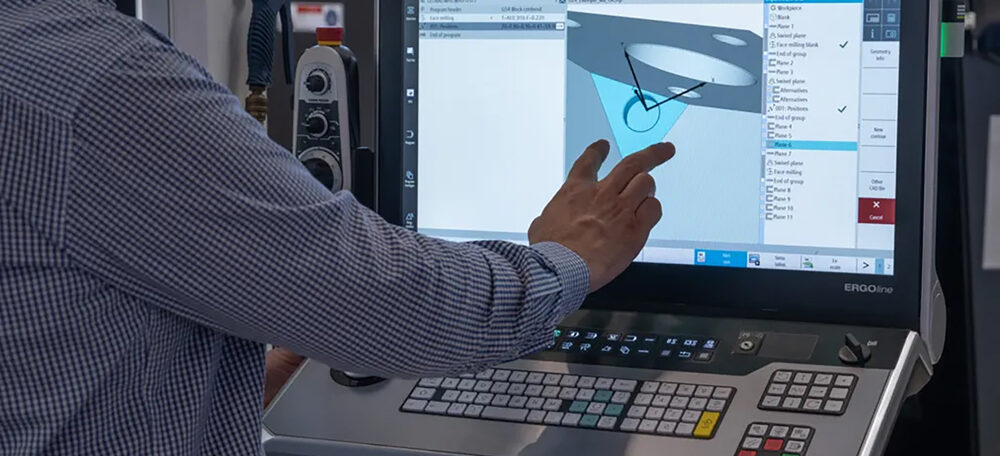

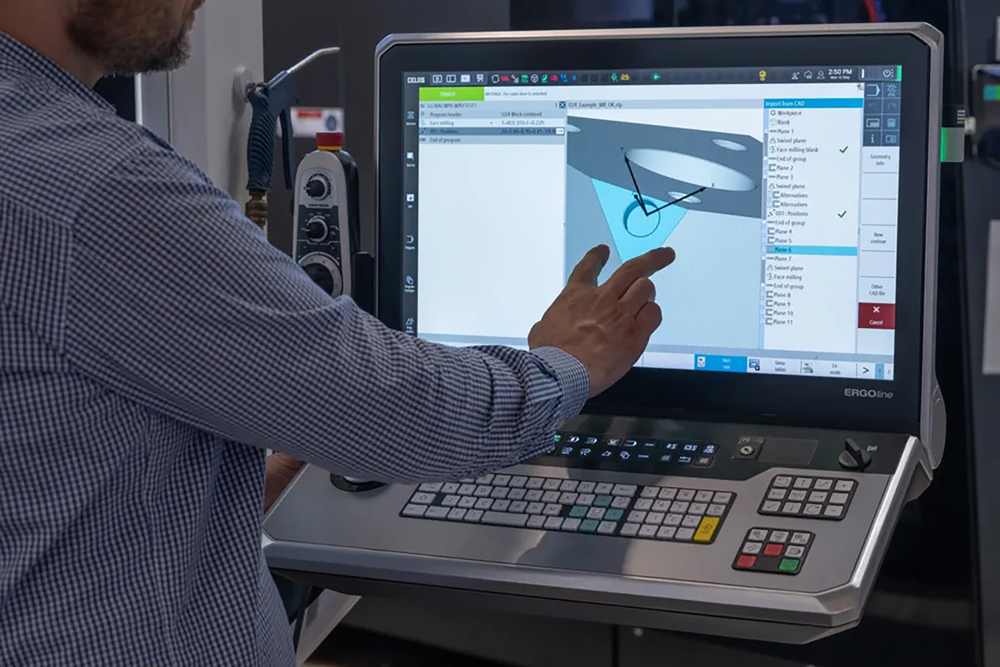

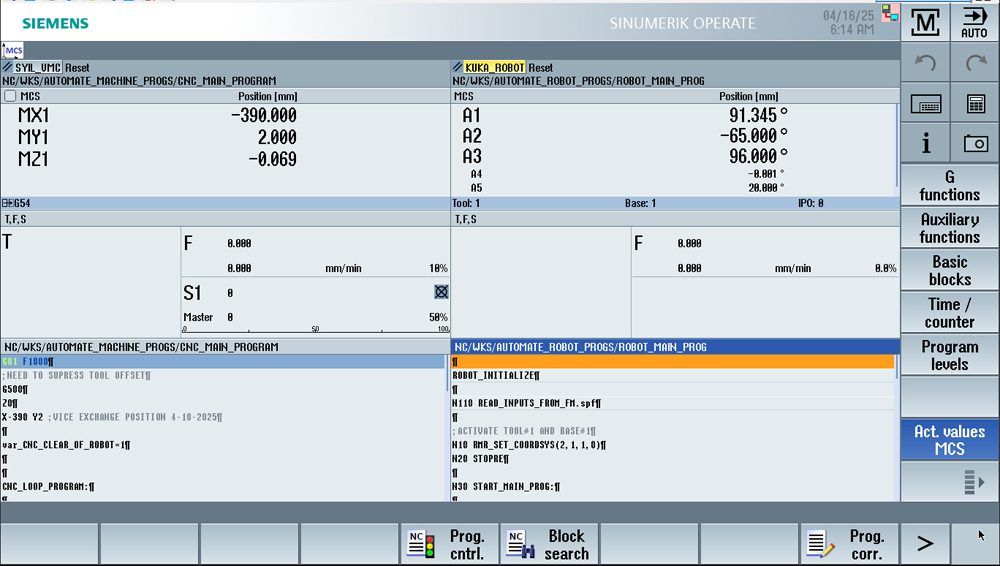

History has advanced. As Tiansu Jing, Product Manager, SINUMERIK CNC systems, explains, “The benefits of this development for the busy job shop are many. Setup, programming, operator interface and diagnostics are all improved with the SINUMERIK Run MyRobot /Handling application, as it easily incorporates the KUKA robot with the SYIL machine tool.” The teach-in functions are implemented through the SINUMERIK Operate HMI system on the control, while the proprietary SINUMERIK Run MyRobot /Handling capability of the CNC seamlessly integrates with the KUKA robot control. Jing further noted that, since there is no need to learn robotic programming, start-up time is reduced and the robot’s separate control pendant is eliminated, simplifying the operator’s task. The SINUMERIK control’s HMI is used to operate both the machine tool and the robot tender, with all commands and operating conditions displayed on a single screen. He also added that the greatest value for the busy job shop comprised the system’s ability to integrate robots on all its machines, while economizing the learning curve for all the operators. This entire cooperative venture between Siemens, KUKA and SYIL made this advancement possible, Jing noted.

From complexity to clarity

The SINUMERIK 828D CNC utilized in this application is designed for the job shop market’s use of turning centers, milling machines and Vertical Machining Centers (VMCs), but it also offers machine builders and end-users the flexibility to enhance the productivity of those machines with this new robotic automation, integrated directly into the control. As Jing points out, “The 828 is scaled to the functionality of the standard machines sold to the smaller job shops. With Run MyRobot /Handling included, programmers can use the same G-code for the robot and the machine tool.”

Designed for the job shop including affordable lights-out manufacturing

As Ron Bergamin of KUKA notes, “Machine builders can now offer robotics from KUKA PLC mxAutomation, a universal PLCopen-certified PLC interface. It allows the user to program and operate all important robot functions directly in a busy shop’s familiar control environment.”

Jing further adds that the Run MyRobot /Handling application allows the machine builder to offer robotics as another option, at a far more affordable price than in the past, as all the engineering effort has been substantially reduced. With the connection of Ethernet and safety cables to the robot, the SYIL customer finds it’s much easier to connect the robot. Bergamin adds that the robot can be up and running in a day, in most cases. “With the addition of a lights-out second or third shift at the shop, the spindles keep turning and the shop makes more money. Plus, the ROI is very fast with this setup.”

Jing concludes, “The machine builder can easily add their own robot specific screens to display the robot tasks and improve the usability. This solves long-time challenges for both the machine builder and end-user alike. Machine tool builders like SYIL can now offer robotic packages to their customers with less price pain and more advantages in the shop.”

Philip Peloso, Business Development Manager for Machine Tool Automation at KUKA, expands, “We saw a resident robotic talent gap as well as price resistance in the smaller machine shop sector and decided we needed to pursue a solution. We turned to our Official System Partner, Waybo, presenting them with the facts. This solution would be an entry-level venture, addressing the 75% of the job shops who currently have no robotic automation on their floors. We sought to present them an easy-to-use, robust system that allowed quick changeover for the busy shop doing multiple jobs or families of parts during the day.”

As KUKA has a longtime relationship with Siemens, their combined support in the field would bring a further benefit to the solution. Once developed, this new system was presented to SYIL, who adopted it as their SYIL R1 solution for the job shop market. Peloso cites the key value proposition. “All meaningful controls and diagnostics were to be displayed on the CNC, thereby reducing or eliminating all the previous roadblocks for the shop personnel.” All the motion control of the grippers, pick-and-place functionality and communications with the CNC on workholding are seamlessly transmitted from an application layer on the KUKA robot, so all commands are configured and programmed to take instructions directly from the CNC.

Ron Bergamin further notes, “Working with Waybo, we developed the automation around the robot. A new interface layer, run through our standard mxAutomation software, allowed the robot control from the Siemens CNC, so a single pendant is all that’s required to run the SYIL machine tool and the robot package. All diagnostics are under the hood,” Bergamin muses.

A new benchmark for machine tool builders

On the tactical business level, Siemens had been providing CNC technology to SYIL globally and brought the concept of robotic integration to KUKA, who worked closely with their partner Waybo to design and implement the package that became SYIL R1 automation.

Frans Buikema of SYIL details this development from the machine builder perspective.

“We’ve long had automation in our company’s vision and road map for the future. As we focus on the small and mid-sized machine shop world, we constantly encounter the lack of skilled labor, the price resistance and the shortage of robotic knowledge in this sector of the machine tool market.”

Wesley Wang, Managing Director for SYIL in North America, adds, “We have recently partnered with Titans of CNC to market our machines here and we feature the SINUMERIK 828D CNC on most of our equipment, as it offers great motion control, monitoring and communications capability, plus the onboard capacity to engage machine tending robotics, which opens the 24/7 running option to our customers in ways they have not imagined in the past.

Real results on the shopfloor

Buikema cites some hard numbers. “We believe we can tell our customers that automation is accessible today in new and exciting ways. It is decidedly not too complicated nor is it a major capital investment. For a $60,000 package, they can be looking at a payback period of a year or less.” Wang adds, “It’s all about knowing your options today and how different they are from the not-too-distant past in the machine tool world.”

Expanding the vision

SYIL currently designs and builds CNC milling machines, CNC turning centers and CNC Swiss type lathes. According to Buikema, “This development with Siemens and KUKA represents our own entry into robotics and we plan to expand the use of such packages onto all our machine offerings very soon.” He calls the implementation of the SINUMERIK 828D CNC with Run MyRobot/Handling “… a real game changer, because it enables us to start creating more automation packages and make them accessible to our audience, the small to mid-sized machine shops.” The SYIL R1 automation package utilizes the same technology integration shown by Siemens and KUKA during recent tradeshows in the industry.

Commenting on the relationship between SYIL and Siemens, Buikema observes, “It grew from supplier to strategic partner very quickly. The engineering support at Siemens collaborates with our own machine tool engineers at SYIL on virtually all new machine developments at our company. This enables us to expand our machine range much faster and better than we could do on our own. That’s true synergy.”

Of equal importance, Buikema cites the support his company gets from Siemens in the North American market. “The help they provide to our dealers in Canada, the United States and Mexico is invaluable. It allows our dealers not only the ability to sell a higher level of machine and automation, but also the software support to fulfill the needs of all our end-users.”

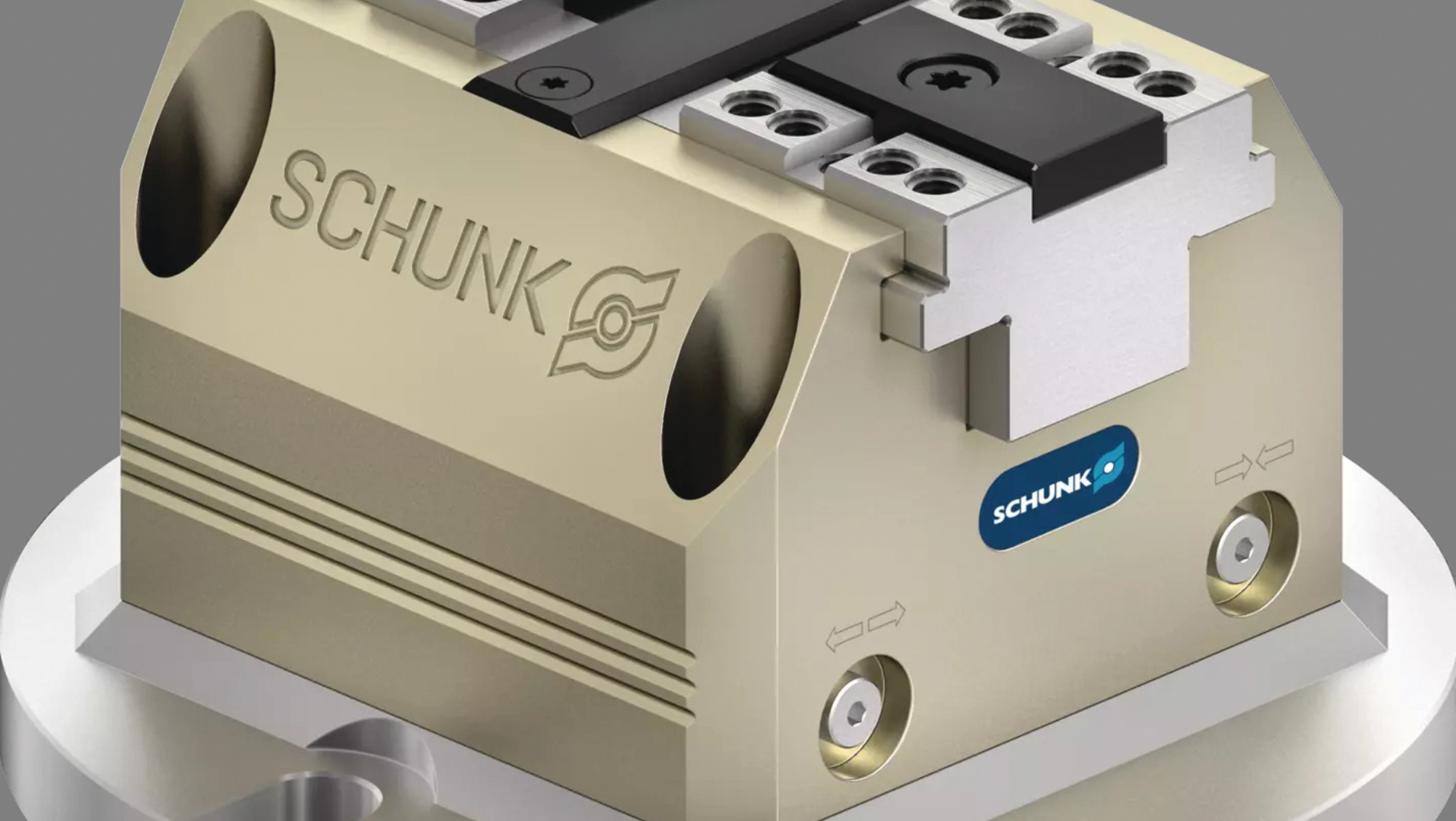

The SYIL R1 machine tending system, incorporating the KUKA robotic technology, is currently offered as a standard package by the machine builder, for parts up to 3kg (6.61 lbs.), a payload of 6.7kg (14.77 lbs.) and a reach of 901 mm (35.47 in). It offers an IP65/67 rating for harsh operating environments. It facilitates the loading and unloading of metal parts from the cutting zone and workholding devices being utilized, plus it is quick to install and easy to operate from the SINUMERIK 828D control. The R1 system from SYIL removes the manual and repetitive tasks for a CNC machine operator by automating the load/unload process. It is an ideal solution for high-mix, low-volume tasks and can be fully integrated with parts conveying systems, bins and pallets. The R1 system is offered with a standard workholding package, featuring pneumatic clamping force block design, as well as a dual gripper option when the finished part has a differing final shape from the blank.

In addition, the SYIL R1 system features an “everything on one screen” format, integrating the robot’s programming and operation in the SINUMERIK 828D control, using NC G-code and robot teach-in function for programming. This makes it very easy for machine tool operators to learn and use. All the robot diagnostic data is shown on the same HMI as the machine, allowing the entire automation cell to be monitored without the need for a second pendant.

According to Buikema, the SYIL R1 automation package can be installed and fully operational in less than one day. The system is expandable with custom solutions and various pallet drawers provided.

The future of shopfloor automation

Increasingly more job shops and machine operators are seeing that automation is an important asset when striving to achieve consistent workpiece quality and more flexibility on the shopfloor. Digitalization facilitates the higher level of automation needed and the networking

of the components involved. With this new development, Siemens is offering a cost-effective solution that incorporates the KUKA robot functionality with a line of affordable machine tools, in this case, the SYIL brand of machining centers and lathes for small to medium job shops.

From the KUKA perspective, Ron Bergamin comments, “KUKA offers machine tool builders and end-users alike the ability to incorporate advanced robotics into their equipment and onto their shopfloors, with the goal of optimizing productivity and reducing operator workload. Our partnership with Siemens has resulted in the synergy that brought this development to life.

It substantially expands the ability of the small and mid-sized shops to utilize robotics in their work environment.”

To watch a video of this system in action, please visit:

http://usa.siemens.com/kuka-syil

For more information on this technology story, please contact:

Siemens

Tiansu Jing or John Meyer

tiansu.jing@siemens.com

john.meyer@siemens.com

KUKA

Ron Bergamin or Philip Peloso

ron.bergamin@kuka.com

philip.peloso@kuka.com

SYIL

Frans Buikema or Wesley Wang

frans@syil.com

wesley@syil.com

Powered by the SINUMERIK ONE CNC platform and Ingersoll’s MasterPrint® industrial 3D printer, a new generation of deployable machines is bringing additive and subtractive manufacturing directly to the point of use.

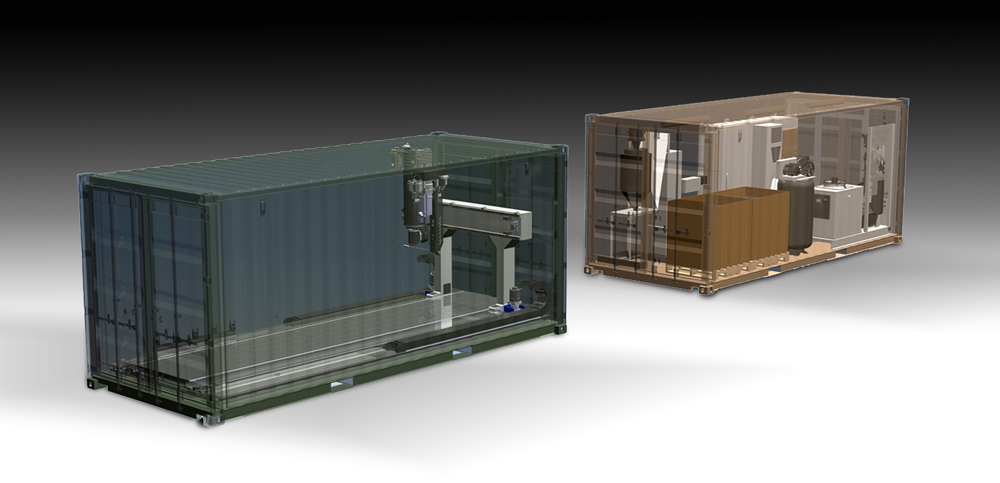

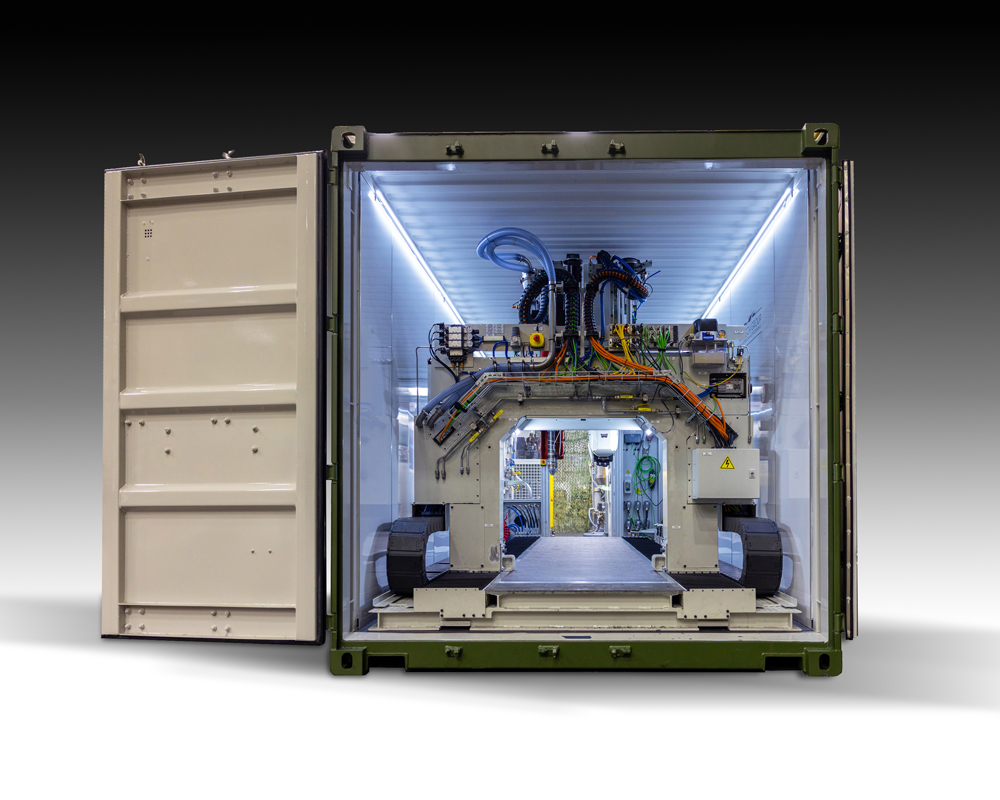

Siemens and Ingersoll, a 133-year-old Rockford, Illinois builder of high-quality, large-format machine tool solutions, have enjoyed a long-standing relationship of business cooperation, engineering dynamism and executed achievements in automated machine technology. That tradition continues today with Ingersoll’s new generation of its “machine in a box” concept, the MasterPrint® Deployable, designed to be an application-specific, portable machine tool, featuring the company’s unique combination of high-speed additive manufacturing and precise 5-axis milling. MasterPrint® Deployable is compactly housed in two 20-foot containers and allows Ingersoll’s customer to send the unit to its point of use as a free-standing manufacturing entity, with all the necessary hardware, software and tools onboard to complete a specific function.

Powered by the digital-native SINUMERIK ONE CNC, MasterPrint® Deployable “opens the possible,” as Zach Gray, Additive Business Development Manager at Siemens, notes. “We were challenged by Ingersoll, as we always are, to think outside the box and yes, that’s a pun, in this case, given the nature of the final machine.” For the initial project, the machine needed to incorporate an additive material extruder, designed by a third party, with full environmental and motion control, plus a gantry and milling head for material removal and finishing, with full capability for onsite adaptation to various conditions and climates.

As Jason Melcher, Vice President and Sales Director of Composite and Additive Technology at Ingersoll, comments, “On the first project, we knew very little about the application, as it was confidential, so we had the empty space of a Conex box as our starting point.” The Conex box is a commercially available item, heavily altered by Ingersoll. The innovation comes with the alterations to make this structure and space a plausible environment capable of carrying a large industrial 3D printer, CNC milling machine, controls and power supply to the point of use. Melcher continues, “Cooperation with our key suppliers was vital on this project and we knew we could rely on our years of experience with Siemens to assist us. As usual, our Siemens partners had less concern about the end-product and put greater emphasis on the process. This gave us confidence that we could journey together in the creation of this unique machine.”

In future applications, the same MasterPrint® Deployable technology might be used with thermoplastic or metal additive materials, applied through cold spray, Directed Energy Deposition (DED), blown powder, Wire Arc Additive Manufacturing (WAAM), friction stir or other technologies, then milled on the same machine to produce the final part. A Deployable Automated Composite solution is also possible. Applications could range from aerospace and defense to energy, R&D and even disaster relief uses in very hostile environments. Also, through the power of the CNC, robotics can also be integrated and controlled. Keeping the machine technically competent under all such circumstances is a challenge for both the Ingersoll and Siemens teams. That’s where the “future ready” technology of SINUMERIK ONE really shine. With its high-fidelity digital twin technology, the entire process can be programmed and visualized with real time operation virtually, before the machine is built. This provides Ingersoll the ability to offer the MasterPrint® Deployable solution for various applications, across a wide range of industries, including the marine industry and residential construction.

Andrew Ramirez, Siemens Account Manager for Ingersoll, adds, “Our relationship with this customer presents us new and exciting challenges all the time, and that’s very rewarding … and fun, because we can leverage our technical knowledge and collaborate with our engineering teams to address the job at hand. When it works as well as it does on MasterPrint® Deployable, that’s very satisfying as an account manager who gets to see innovative solutions come to life.”

Melcher echoes that thought, “We know Siemens has decades of experience in CNC, software development and problem-solving in the machine tool world. They bring a very open-ended attitude to our needs and, together, we produce solutions that benefit our Ingersoll customers in many ways.” In this case, it was necessary to have modifications made to the process and the combination of Ingersoll machine technology and engineering, with the Siemens control environment helps to produce a functional and flexible ecosystem for manufacturing in the field. The Siemens SINUMERIK ONE CNC, Melcher notes, incorporates all the variables and can work up solutions, prove them out virtually, then produce a functioning machine, with the added benefit of accepting variables onsite and adapting the control parameters to manage them.

A further testament to the Siemens value at Ingersoll, is training, according to Jason Melcher. “We’ve worked with all the major CNC control manufacturers and we’ve seen Siemens expand its technology, but also its training mindset. Today, they provide us training both on the operation of the control and the integration of it into the manufacturing process, something we can then share with our customers to get them running more efficiently from the start.”

On the MasterPrint® Deployable application, Zach Gray cites three key concerns.

SINUMERIK ONE plays a central role in the transformation of machine tools in the age of Industry 4.0, outperforming previous generations of controllers in terms of PLC and CNC machine operation, cutting speed, data capture and processing power. With its integrated SIMATIC S7-1500F PLC, the SINUMERIK ONE control offers up to 10 times faster PLC cycle times. Thanks to the PLC, SINUMERIK ONE is now fully integrated into the Siemens TIA Portal engineering framework, enabling standardization of all engineering tasks for operators of larger format machines. This generation of Siemens CNC is fully compatible with the previous SINUMERIK 840D sl controller generation in terms of programming and operation. This made the changeover to SINUMERIK ONE more seamless for Ingersoll and, as Jason Melcher notes, the training supplied by Siemens made the process faster and easier for Ingersoll and its first customer for MasterPrint® Deployable.

With SINUMERIK ONE, Siemens offers CNC technology that easily creates and works with digital twins of machine tools. Work preparation teams and engineering departments can also benefit from the digital twin. Siemens offers a comprehensive user interface for SINUMERIK ONE that enables convenient, flexible and efficient operation of machine tools across all machining technologies, including additive, subtractive and, in this case, both, as well as composites with chopped carbon fibers.

While under development at Ingersoll, the unit was powered by standard factory 480V power. The transformer supplied “in the box” connected to the customer’s on-site generator in the field for immediate startup, according to Jason Melcher.

On the topic of the overall benefits of the relationship with Siemens, Jason Melcher says, “We wanted to produce the largest possible workspace in the footprint provided by our customer. Siemens was very helpful, as they always are, in not letting us overreach the capabilities of the control and its processes. That’s the optimum contribution a partner can make and, combined with their technology and training, we are confident we derived the best solution for the customer’s application and their logistics.”

From the Siemens side, Zach Gray concludes, “This MasterPrint® Deployable application was an exciting challenge for Andrew (Ramirez) and me. With all the other technologies we know we can incorporate into this Ingersoll concept, including robotics, it really does open the possible up for our customer and us.”

Website:

usa.siemens.com/ingersoll

At EMO 2025, Siemens will introduce Optimize MyProgramming /3D Scanner, a groundbreaking software solution that will fundamentally transform shop floor-oriented CNC programming. This innovative software combines cutting-edge 3D analysis technologies with programming right on the CNC control, maximizing efficiency, precision, and quality in production. Optimize MyProgramming /3D Scanner is part of the Siemens Xcelerator portfolio and enhances it with advanced technologies for process optimization in manufacturing.

Programming right on the control

The solution is distinguished by its direct integration into Sinumerik Operate, which allows users to create and optimize programs on the control. Seamlessly transferring geometric information from 3D CAD models into programs eliminates the need for cumbersome and error-prone manual input. This function saves significant time and costs while minimizing sources of error.

Efficiency and quality thanks to automatic data transfer

The 3D Scanner offers customized suggestions for manufacturing strategies based on geometric features. This function not only leads to enormous time and cost savings, but it also allows better parameterization of machining cycles. This prevents programming errors, which means consistently high quality in production. By integrating Optimize MyProgramming /3D Scanner, machine manufacturers can increase the attractiveness of their products in a competitive market and convince customers through measurable efficiency and quality advantages in production.

Collaboration with DMG MORI

The software’s successful pilot with machine manufacturer DMG MORI demonstrated that the 3D Scanner is a powerful complement for optimizing manufacturing processes and can be seamlessly integrated into existing systems. Optimize MyProgramming /3D Scanner is integrated as a standard option in all DMG MORI machines equipped with Sinumerik One. The software will be available for purchase starting in autumn.

Availability and support

Optimize MyProgramming /3D Scanner is offered as a perpetual license for real machine tools and also as an option for their digital twin based on Run MyVirtual Machine. Experienced service providers offer support with comprehensive consulting as well as implementation. This ensures seamless integration of the software into modern production environments.

With Optimize MyProgramming /3D Scanner, Siemens reinforces its commitment to shaping the future of the manufacturing industry with advanced technologies and efficient solutions. The software sets new standards in CNC programming and enables manufacturing companies to make higher-quality products with more efficient production processes.

Follow us on social media

X: www.x.com/siemens_press and https://x.com/siemensindustry

Blog: https://blog.siemens.com/

Siemens Digital Industries (DI) empowers companies of all sizes within the process and discrete manufacturing industries to accelerate their digital and sustainability transformation across the entire value chain. Siemens’ cutting-edge automation and software portfolio revolutionizes the design, realization and optimization of products and production. And with Siemens Xcelerator – the open digital business platform – this process is made even easier, faster, and scalable. Together with our partners and ecosystem, Siemens Digital Industries enables customers to become a sustainable Digital Enterprise. Siemens Digital Industries has a workforce of around 70,000 people worldwide.

Siemens AG (Berlin and Munich) is a leading technology company focused on industry, infrastructure, mobility, and healthcare. The company’s purpose is to create technology to transform the everyday, for everyone. By combining the real and the digital worlds, Siemens empowers customers to accelerate their digital and sustainability transformations, making factories more efficient, cities more livable, and transportation more sustainable. A leader in industrial AI, Siemens leverages its deep domain know-how to apply AI – including generative AI – to real-world applications, making AI accessible and impactful for customers across diverse industries. Siemens also owns a majority stake in the publicly listed company Siemens Healthineers, a leading global medical technology provider pioneering breakthroughs in healthcare. For everyone. Everywhere. Sustainably.

In fiscal 2024, which ended on September 30, 2024, the Siemens Group generated revenue of €75.9 billion and net income of €9.0 billion. As of September 30, 2024, the company employed around 312,000 people worldwide on the basis of continuing operations. Further information is available on the Internet at www.siemens.com.

Continue reading

At this year’s AUTOMATE, Siemens is announcing the launch of its enhanced motion control portfolio, featuring SINAMICS servo-drive systems and the new SIMATIC S7-1200 G2 controller, delivering unprecedented performance and flexibility for basic automation applications including handling, moving, positioning and processing.

The new solution combines three key innovations:

“This holistic system approach represents a significant leap forward in basic automation capabilities,” said Craig Nelson, Product Manager, Motion Control, Siemens Industry, Inc.

Key features and benefits include:

The new portfolio offers scalable solutions with various power options:

This cost-optimized solution includes comprehensive safety features, wireless diagnostics capabilities, and seamless integration with the Siemens TIA Portal, making it ideal for manufacturers seeking to modernize their automation systems.

For more information about this new motion control system for basic applications, visit usa.siemens.com/servo-drives and usa.siemens.com/efficient-motion-control.

Siemens Digital Industries (DI) is an innovation leader in automation and digitalization. Closely collaborating with partners and customers, DI drives the digital transformation in the process and discrete industries. With its Digital Enterprise portfolio, DI provides companies of all sizes with an end-to-end set of products, solutions and services to integrate and digitalize the entire value chain. Optimized for the specific needs of each industry, DI’s unique portfolio supports customers to achieve greater productivity and flexibility. DI is constantly adding innovations to its portfolio to integrate cutting-edge future technologies. Siemens Digital Industries has its global headquarters in Nuremberg, Germany, and has around 75,000 employees internationally.

Siemens Corporation is a U.S. subsidiary of Siemens AG, a technology company focused on industry, infrastructure, transport, and healthcare. From more resource-efficient factories, resilient supply chains, and smarter buildings and grids, to cleaner and more comfortable transportation as well as advanced healthcare, the company creates technology with purpose adding real value for customers. By combining the real and the digital worlds, Siemens empowers its customers to transform their industries and markets, helping them to transform the everyday for billions of people. Siemens also owns a majority stake in the publicly listed company Siemens Healthineers, a globally leading medical technology provider shaping the future of healthcare. In addition, Siemens holds a minority stake in Siemens Energy, a global leader in the transmission and generation of electrical power. In fiscal 2022, which ended on September 30, 2022, Siemens Group USA generated revenue of $18.6 billion and employs approximately 45,000 people serving customers in all 50 states and Puerto Rico.

Siemens expands its Run MyRobot platform to allow cost-effective part handling and articulation functions of a KUKA robot directly on the control of the machine tool

In Booth 3232 at this year’s AUTOMATE show in Detroit, Siemens is presenting an automation solution for the busy, multi-tasking job shop, as it demonstrates a digital twin of the software and programming of its popular SINUMERIK 828 CNC, working in tandem with a KUKA robot, to simplify the operation and programming in part handling for the operator. Meanwhile, in nearby booth 4032, KUKA Robotics Corporation will demonstrate the same control and its robot working in tandem on a SYIL vertical milling machine.

Advantages of this development include:

As automation continues to impact the machine tool industry, robots and CNC machines are collaborating even more closely. The number of handling and machining robots (machine tools with robotic kinematics) is continually on the rise and Siemens is leading this movement, as the only automation manufacturer in the world that equips its CNC with the necessary interfaces for robotic integration.

Increasingly more machine shops and operators are seeing that automation is an important asset when striving to achieve consistent workpiece quality and more flexibility on the shopfloor. Digitalization facilitates the higher level of automation needed and the networking

of the components involved. With this new development, Siemens is offering a cost-effective solution that incorporates the KUKA robot functionality with a line of affordable machine tools, in this case, the SYIL brand of machining centers and lathes for small to medium job shops.

As Tiansu Jing, Product Manager, SINUMERIK CNC systems, explains, “The benefits of this development for the busy job shop are many. Setup, programming, operator interface and diagnostics are all improved with this system, as it easily incorporates the KUKA robot with

the machine tool.” The teach-in functions are implemented through the SINUMERIK Operate system on the control, while the proprietary SINUMERIK Run MyRobot capability of the CNC seamlessly integrates with the KUKA robot control. He further noted that, since there is no need to learn robotic programming, start-up time is reduced and the robot’s separate control pendant is eliminated, making the operator’s task simplified. The SINUMERIK CNC’s HMI is used to operate both the machine tool and the robot.

From the KUKA perspective, Ron Bergamin, Key Technology Manager, Machine Tool Automation, comments, “KUKA offers machine tool builders and end-users alike the ability to incorporate advanced robotics into their equipment and onto their shopfloors, with the goal of optimizing productivity and reducing operator workload. Our partnership with Siemens has resulted in the synergy that brought this development to life. It substantially expands the ability of the small and medium-sized shops to utilize robotics in their work environment.”

Siemens Digital Industries (DI) is an innovation leader in automation and digitalization. Closely collaborating with partners and customers, DI drives the digital transformation in the process and discrete industries. With its Digital Enterprise portfolio, DI provides companies of all sizes with an end-to-end set of products, solutions and services to integrate and digitalize the entire value chain. Optimized for the specific needs of each industry, DI’s unique portfolio supports customers to achieve greater productivity and flexibility. DI is constantly adding innovations to its portfolio to integrate cutting-edge future technologies. Siemens Digital Industries has its global headquarters in Nuremberg, Germany, and has around 75,000 employees internationally.

Siemens Corporation is a U.S. subsidiary of Siemens AG, a technology company focused on industry, infrastructure, transport, and healthcare. From more resource-efficient factories, resilient supply chains, and smarter buildings and grids, to cleaner and more comfortable transportation as well as advanced healthcare, the company creates technology with purpose adding real value for customers. By combining the real and the digital worlds, Siemens empowers its customers to transform their industries and markets, helping them to transform the everyday for billions of people. Siemens also owns a majority stake in the publicly listed company Siemens Healthineers, a globally leading medical technology provider shaping the future of healthcare. In addition, Siemens holds a minority stake in Siemens Energy, a global leader in the transmission and generation of electrical power. In fiscal 2022, which ended on September 30, 2022, Siemens Group USA generated revenue of $18.6 billion and employs approximately 45,000 people serving customers in all 50 states and Puerto Rico.

Complete enterprise-grade solution accelerates Industry 4.0 adoption through hands-on technology demonstration center at MxD

CHICAGO, IL – In a milestone for manufacturing innovation, Betacom, a pioneer in private wireless networks, today announced a groundbreaking partnership with Siemens Industries. The companies have deployed a first-of-its-kind private 5G network platform at MxD (Manufacturing x Digital), the National Center for Cybersecurity in Manufacturing in Chicago. The platform is the first complete private wireless network to operate behind a Siemens firewall, demonstrating the future of secure enterprise connectivity.

“Manufacturing enterprises need more than just network connectivity – they need a complete solution that seamlessly enables Industry 4.0 applications while maintaining total control of their data and operations,” said Johan Bjorklund, CEO of Betacom. “By partnering with Siemens at MxD, we’re providing manufacturers with a blueprint for digital transformation, combining our private 5G expertise with Siemens industrial automation leadership to create a truly comprehensive platform for smart manufacturing innovation.”

The platform demonstrates how enterprises can:

Developed specifically for Siemens U.S. manufacturing initiatives, the solution features:

“This deployment represents a significant milestone in manufacturing innovation,” said Joel Green, Wireless Business Development at Siemens Industries. “The platform gives our customers the security and control they need while enabling the full spectrum of Industry 4.0 applications that drive operational excellence.”

Industries benefiting from this complete private 5G solution include manufacturing, logistics, defense contractors and supply chain operations. The MxD facility showcases practical applications including:

About Betacom

Betacom offers the first fully managed private 5G network service in the U.S., building on decades of expertise as a trusted wireless infrastructure provider for major carriers such as AT&T, T-Mobile, and Verizon. Founded in 1991 and headquartered in Bellevue, Washington, Betacom has established a reputation for delivering high-performance connectivity solutions to meet complex enterprise needs. With its secure, high-speed and scalable 5G services, Betacom continues to lead innovation in private wireless networks. For more information, visit http://www.betacom.com.

About Siemens Industries

Siemens Corporation is a U.S. subsidiary of Siemens AG, a global technology powerhouse that has stood for engineering excellence, innovation, quality, reliability and internationality for more than 170 years. Active around the world, the company focuses on intelligent infrastructure for buildings and distributed energy systems and on automation and digitalization in the process and manufacturing industries. Siemens brings together the digital and physical worlds to benefit customers and society. Through Mobility, a leading supplier of intelligent mobility solutions for rail and road transport, Siemens is helping to shape the world market for passenger and freight services. Via its majority stake in the publicly listed company Siemens Healthineers, Siemens is also a world-leading supplier of medical technology and digital health services. In addition, Siemens holds a minority stake in Siemens Energy, a global leader in the transmission and generation of electrical power that has been listed on the stock exchange since September 28, 2020. In fiscal 2020, Siemens Group USA generated revenue of $17 billion and employs approximately 40,000 people serving customers in all 50 states and Puerto Rico. For more information, visit http://www.siemens.com.

About MxD

MxD (Manufacturing x Digital) is where innovative manufacturers go to forge their futures. In partnership with the Department of Defense, MxD equips U.S. factories with the digital tools, cybersecurity and workforce expertise needed to begin building every part better than the last. As a result, our more than 300 partners increase their productivity, win more business and strengthen U.S. manufacturing.

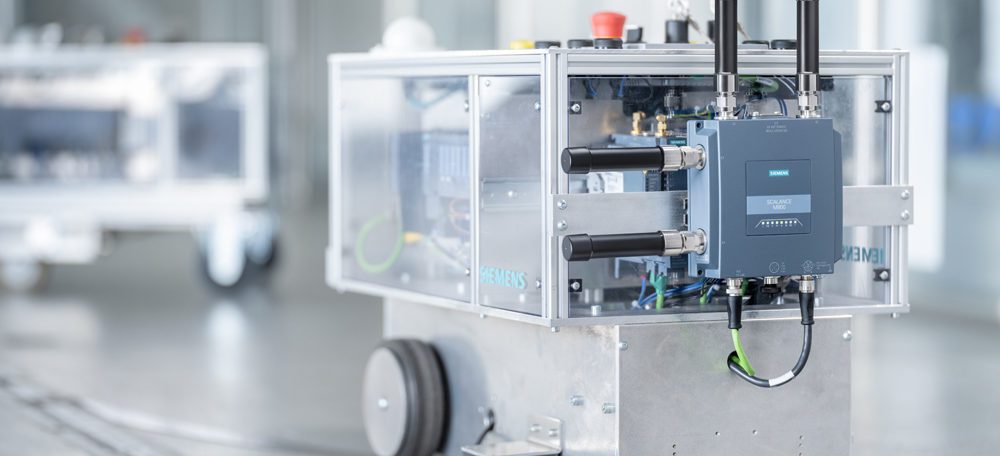

The Scalance MUM856-1 – the first industrial 5G router from Siemens – is now available for the U.S. market. The device connects local industrial applications to public 5G and 4G (LTE) mobile wireless networks. The router can be used to remotely monitor and service plants, machines, control elements and other industrial devices via a public 5G network flexibly and with high data transmission rates. Demand for this type of solution is growing in all industries. The device also integrates into private 5G networks. The Scalance MUM856-1 supports future-oriented applications such as mobile robots in manufacturing, autonomous vehicles in logistics or augmented reality applications for service technicians. Featuring a robust IP65 housing, this Siemens router can also be used outside the control cabinet, for example, under harsh conditions in production or in outdoor facilities in the water industry.

To ensure the powerful connection of Ethernet-based subnetworks and automation devices, the Scalance MUM856-1 supports Release 16 of the 5G standard. This device offers high bandwidths of up to 1000 Mbps for the downlink and up to 500 Mbps for the uplink providing high throughput for data-intensive applications such as remote implementation of firmware updates. Thanks to IPv6 support, the device can also be implemented in modern communication networks. Best-in-class security functions are included to monitor data traffic and protect against unauthorized access in, for example, an integrated firewall as well as authentication of communication devices and encryption of data transmission via VPN.

Where there is no available 5G network, the device switches automatically to 4G networks. The first release version of this new Siemens router has support for U.S. Mobile Network operators as well as the CBRS spectrum; other versions with different licenses are currently in development. With the SINEMA Remote Connect management platform for VPN connections, users can securely access remote plants or machines easily – even if they are integrated in other networks. The software also offers easy management and auto-configuration of the devices.

Successful use of prototypes for private 5G networks

Along with connectivity to public networks, Scalance MUM856-1 also supports integration into private 5G campus networks. Siemens is testing this use case in its own Automotive Showroom and Test Center in a prototype of a standalone 5G test network, which is based on Siemens components. The 5G infrastructure used here comprises a 5G core, a distributed unit and several radio units. Siemens has also built another prototype of a private 5G infrastructure in its plants in Amberg and Karlsruhe, Germany. In these systems, Siemens is relying exclusively on its own independently developed products and solutions, which will be available in the U.S. market in the future. Today, Siemens has private 5G systems running in a customer digital experience center known as MxD in Chicago.

Background info

In today’s industrial landscape in addition to the need for local wireless connectivity, there is an increasing demand for secure remote access to machines and plants. In these cases, communication is usually over long distances. Public mobile networks can be used to access devices that are located at a considerable distance.

Service technicians can connect to the machines they need to service via the mobile network while traveling, making public 5G networks an important element of remote access and remote servicing solutions. The public networks can be used to provide users with very high bandwidths in urban areas with small radio cells and high frequencies.

In rural areas, radio cells need to cover a large area, which is why lower frequencies are used. Particularly at the edges of radio cells such as LTE, there are often significant losses in terms of both the bandwidth and stability of the communication connection. “For companies requiring reliable service in remote areas, such as in water stations or electric power sub-stations, there is a need for solutions with stable bandwidth transmission for remote servicing or video transmission,” explains Joel Green, Business Development Manager for Wireless and Remote Networks at Siemens Digital Industries. “With innovative 5G communications technologies, considerably more bandwidth with greater reliability is available at the edges of radio cells, while the average data rate for users within a radio cell increases.”

Siemens Digital Industries (DI) is an innovation leader in automation and digitalization. Closely collaborating with partners and customers, DI drives the digital transformation in the process and discrete industries. With its Digital Enterprise portfolio, DI provides companies of all sizes with an end-to-end set of products, solutions and services to integrate and digitalize the entire value chain. Optimized for the specific needs of each industry, DI’s unique portfolio supports customers to achieve greater productivity and flexibility. DI is constantly adding innovations to its portfolio to integrate cutting-edge future technologies. Siemens Digital Industries has its global headquarters in Nuremberg, Germany, and has around 75,000 employees internationally.

Siemens Corporation is a U.S. subsidiary of Siemens AG, a global powerhouse focusing on the areas of power generation and distribution, intelligent infrastructure for buildings and distributed energy systems, and automation and digitalization in the process and manufacturing industries. Through the separately managed company Siemens Mobility, a leading supplier of smart mobility solutions for rail and road transport, Siemens is shaping Siemens USA reported revenue of $23.7 billion, including $5.0 billion in exports, and employs approximately 50,000 people throughout all 50 states and Puerto Rico.

The Siemens Machine Tool Business sadly announces the death of Randy Pearson, 70, on May 21, 2024 in Reno, Nevada, following a long battle with lung cancer. Randy had recently retired after more than 20 years with Siemens, where he served as dealer support manager … and much more.

As Motion Control group VP Rajas Sukthankar notes, “When I think of Randy, I think of my good fortune in life to work with an individual that cared as passionately and deeply about his work as I do. I first met Randy when he was hired as an application engineer at Hyundai Machine Tools in 1995. Our association went back over two decades. I had the chance to work with him as both a customer and a valued Siemens employee. As a skilled machinist himself, Randy trained and educated a generation of new machinists in his career. I treasure the time I spent working with Randy and will miss his infectious laugh and energy.”

Randy’s associate in machine tool training at Siemens, Chris Pollack, recalls, “I was always amazed how he remembered everyone’s name. Walking around a trade show with Randy was like being with the mayor of the town. Everyone knew him and, more importantly, he knew everyone. He was always there to help others and he surely helped me a lot in my career.”

Marion Kica, executive assistant at the Siemens Machine Tool headquarters in Elk Grove Village, IL adds, “He always brightened my day with his humor and good cheer, plus he was there to handle all the engineering questions callers would have. He was a kind, supportive friend who took his responsibilities very seriously but could still find humor in life’s ups and downs.”

John Meyer, head of marketing communications for the motion control group, was a close associate of Randy’s throughout all his years at Siemens. He notes, “As a marketer, when I came to Siemens, I had a challenge to learn about machine tools and manufacturing technologies such as CNC. I wasn’t an engineer, so Randy took me under his wing to teach me what I needed to know to be successful in my career. It became a technical education over 20+ years and I’m very thankful for the knowledge Randy instilled in me.”

During his long career in the machine tool industry, Randy served as an applications engineer or sales manager at such leading companies as Bridgeport, Toyoda, ROMI, Kitamura and Hyundai, as well as machine tool dealer Iverson & Company.

Always willing to share the talents he possessed, Randy authored regular CNC expert advice columns that appeared in several machine tool magazines, over the years. He brought a wealth of technical expertise in CNC technology along with his hands-on practical experience as a machinist, when giving his help to the industry.

A native of Chicago, Randy and his wife Susan, whom he met when they both worked at Bridgeport, were married 34 years and had two children.

Following in his dad’s footsteps, Randy’s son Jeremy has now been with DMG machine tools for 10 years.

After his retirement from Siemens, Randy and Susan decided to “go west” and landed in Reno.

A memorial service for Randy Pearson will be held at 11 AM Central on July 13 at United Methodist Church in Roselle, IL. Donations can be made to the American Cancer Society at www.cancer.org or the American Lung Association at www.lung.org.

Bringing together a number of its hardware automation, digitalization software and services, Siemens will present the new path towards digitalization for machine tool users and machine builders

At the upcoming IMTS 2024 in Chicago, September 9–14, Siemens will present its extensive machine tool CNC portfolio and digitalization software technology, highlighted by the digital native SINUMERIK ONE control platform for machining applications. Also, using a sports theme of “Speed, Agility and Endurance,” aimed at the machine shop on its path to digitalization, Siemens will introduce MACHINUM to the North American market. MACHINUM brings together machine tool controls, digitalization software and machine shop services from Siemens to help manufacturers optimize their production processes, to provide agility for quick adaptation to changing customer requirements and calculated uptime needs, plus enable digitally proven endurance to maximize the productivity of the entire machine shop or production department.

Detailing the elements of MACHINUM:

Speed

Siemens adaptive feedrate control reduces cycle times, while maintaining a stable machining process. This results from instantaneous and continuous analysis of the current cutting conditions on a machine tool in real time, automatically optimizing the feedrate.

Agility

Through strategic digitalization and software that seamlessly integrates the machine tool CNC systems and a shop’s internal communications, MACHINUM can significantly boost the agility of a machine shop or production department to accommodate changes in design, quantity output and even machining characteristics, based upon customer input and overall production and workflow landscape characteristics.

Endurance

Continuing the sports theme, over the long “run”, MACHINUM enables a heightened level of maintenance capability with leading “edge” machine monitoring that anticipates potential issues before they escalate. This results in reduced cost and substantially less downtime on machines, due to unplanned maintenance. This feature is especially useful for linked and sequential production lines.

MACHINUM also offers substantial benefits to machine builders, as Siemens integrated digital twin technology allows more streamlined off-machine programming and machining simulation in an office environment. This approach facilitates faster prep time, more accurate design specs on the final machine, faster component acquisition near the build time and a reduction in costly downtime, due to last-minute design changes, as those are anticipated, simulated and resolved, all in a virtual world. MACHINUM also represents the integration of existing Siemens digitalization software such as Create MyVirtual Machine, Run MyVirtual Machine, Adaptive Control and Monitoring (ACM), Analyze MyWorkpiece and Manage MyMachines.

Under the theme “Empowering the Digital Machine Shop”, Siemens will display its digital threads, from blueprint to finished part, digital twin to simulation, part production, as well as the total integration of these processes into the digital factory for job shops and production departments, all brought to life by Siemens hardware automation and digitalization software.

eRod Continues Its Path

Building off the successful rollout of its eRod “electric buggy” at IMTS 2022, Siemens will further demonstrate the end-to-end production of the aluminum wheel rim and gear housing for this electric vehicle on display in the booth. The wheel rim is made by traditional 5-axis and multi-technology machining (mill-turn, turn-mill) and the gear housing is manufactured through additive/subtractive machining processes. At every stage of each part’s development, including machining, displays will take visitors through the digital manufacturing process. From the popular Siemens NX CAM software, which enables the use of 3D models, data and processes to seamlessly connect planning and shopfloor operations, to the powerful SINUMERIK ONE, the digital-native CNC that permits a digital twin of the machine tool and its full operation in production, Siemens has streamlined machine shop operations as well as leading automotive, aerospace, off-highway, medical part and myriad consumer durable production facilities worldwide.

Additional highlights of the Siemens booth will include:

Aimed at developing a complete eco-system for the machine tool builder and end-user, the Siemens Xcelerator portfolio brings together the breadth of engineering and manufacturing to provide the optimum solution for customers of any size in any industry.

Digitalization solutions will shorten the machine tool builder’s time-to-market through Digital Twin technology, where all machine design and operational kinematics are simulated prior to the machine being built. This development enables substantial savings for the builder and end-user alike — not only in the design, building and commissioning, but also during the startup and training phases of machine implementation.

With SINUMERIK ONE, Siemens is accelerating the digital transformation of the machine tool industry. The new CNC control platform works with software to create the machine controller and the associated digital twin from a single engineering system and thus contributes to the total integration of hardware and software. Thanks to its seamless interaction between the virtual and real worlds, including high-performance PLC, drive and motor hardware, SINUMERIK ONE is setting new standards in terms of productivity, performance and digitalization. It is the future-proof machine controller in the increasingly digital world of manufacturing.

With Create MyVirtual Machine and Run MyVirtual Machine, SINUMERIK ONE is provided with software to create the universal concept of the digital twin, powerful hardware and integrated IT security, making it a forward-looking CNC.

Using Mcenter, the open and modular platform for efficient shopfloors, end-users can seamlessly link all their machine tools and network with company’s IT landscape.

Finally, a fun highlight at this year’s show, Siemens will hold a golf putting contest and raffle two putters twice daily during IMTS 2024. The putter heads will be machined utilizing Siemens CNC hardware automation and digitalization software and feature custom engraving.

For more information about Siemens at IMTS 2024, please visit: https://usa.siemens.com/imts

For more information about the new MACHINUM portfolio, please visit: https://usa.siemens.com/machinum

Siemens Digital Industries (DI) is an innovation leader in automation and digitalization. Closely collaborating with partners and customers, DI drives the digital transformation in the process and discrete industries. With its Digital Enterprise portfolio, DI provides companies of all sizes with an end-to-end set of products, solutions and services to integrate and digitalize the entire value chain. Optimized for the specific needs of each industry, DI’s unique portfolio supports customers to achieve greater productivity and flexibility. DI is constantly adding innovations to its portfolio to integrate cutting-edge future technologies. Siemens Digital Industries has its global headquarters in Nuremberg, Germany, and has around 75,000 employees internationally.

Siemens Corporation is a U.S. subsidiary of Siemens AG, a global powerhouse focusing on the areas of power generation and distribution, intelligent infrastructure for buildings and distributed energy systems, and automation and digitalization in the process and manufacturing industries. Through the separately managed company Siemens Mobility, a leading supplier of smart mobility solutions for rail and road transport, Siemens is shaping the world market for passenger and freight services. Due to its majority stakes in the publicly listed companies Siemens Healthineers AG and Siemens Gamesa Renewable Energy, Siemens is also a world-leading supplier of medical technology and digital healthcare services as well as environmentally friendly solutions for onshore and offshore wind power generation. For more than 160 years, the company has innovated and invented technologies to support American industry spanning manufacturing, energy, healthcare and infrastructure. In fiscal 2018, Siemens USA reported revenue of $23.7 billion, including $5.0 billion in exports, and employs approximately 50,000 people throughout all 50 states and Puerto Rico.

Production facilities are increasingly the targets of cyberattacks. Industrial companies are therefore required to identify and close potential vulnerabilities in their systems. To address the need to identify cybersecurity vulnerabilities on the shop floor as quickly as possible, Siemens has launched a new cybersecurity software-as-a-service.

The cloud-based SINEC Security Guard offers automated vulnerability mapping and security management optimized for industrial operators in OT environments. The software can automatically assign known cybersecurity vulnerabilities to the production assets of industrial companies. This allows industrial operators and automation experts who don’t have dedicated cybersecurity expertise to identify cybersecurity risks among their OT assets on the shop floor and receive a risk- based threat analysis. The software then recommends and prioritizes mitigation measures. Defined mitigation measures can also be planned and tracked by the tool’s integrated task management. SINEC Security Guard is offered as cybersecurity software-as-a-service (“SaaS”), is hosted by Siemens and will be available for purchase in July, 2024 on the Siemens Xcelerator Marketplace and on the Siemens Digital Exchange.

Increasing protection by reducing manual effort

“With SINEC Security Guard, customers can focus their resources on the most urgent and relevant vulnerabilities, while having full risk transparency in their factory. It is unique because it takes the specific situation of the customer’s operational environment into consideration while providing a single pane of glass for security- relevant information in the OT area,” says Dirk Didascalou, CTO of Siemens Digital Industries. “When developing the SINEC Security Guard, we drew on our extensive experience with cybersecurity in our own factories.”

Today, industrial operators are tasked with continuously safeguarding their production assets on the shop floor. They need to analyze vendor security advisories, manually match them to the asset inventory of their factory and prioritize mitigation measures. Because this process is time-consuming and error-prone using the existing tools, factories are running the risk of missing critical vulnerabilities in their assets or producing false-positives. This can lead to incorrectly configured plant components and inadequately allocated resources. With the SINEC Security Guard, industrial operators can tackle these challenges without needing in-depth cybersecurity knowledge.

Attack detection at scale with Microsoft Sentinel

For a comprehensive view of IT and OT cybersecurity, SINEC Security Guard will also offer a connection to Microsoft Sentinel, Microsoft’s Security Information and Event Management (SIEM) solution for proactive threat detection, investigation and response. Once connected, SINEC Security Guard can send alerts for security events including attacks to Sentinel, enabling a security analyst to incorporate SINEC Security Guard insights and conclusions in investigations and responses with Microsoft Sentinel powered Security Operations Centers.

“As information technology and operational technology systems continue to converge, a holistic cybersecurity architecture is key to protecting IT and OT

capabilities alike. By combining our domain knowledge, Siemens and Microsoft make it easier for industrial operators to efficiently detect and address cybersecurity threats at scale,” says Ulrich Homann, Corporate Vice President, Cloud + AI at Microsoft.

SINEC Security Guard also supports the manual upload of existing asset information for asset inventory. Siemens recommends, however, that industrial operators use the Industrial Asset Hub, the Siemens cloud-based Asset Management solution, to enable continuous automated asset inventory management.

Functionalities also include signature-based network intrusion and attack detection via the SINEC Security Guard Sensor, an Industrial Edge app, which gives users live information about their industrial network. The SINEC Security Guard Sensor App is available at the Siemens Industrial Edge Marketplace.

The initial release of SINEC Security Guard only supports Siemens OT assets but third-party device support is planned in the future. SINEC Security Guard will expand the existing Siemens software portfolio for OT network security consisting of SINEC Security Inspector and SINEC Security Monitor.

SINEC Security Guard is a cloud-based cybersecurity software that provides full risk transparency and cybersecurity management of OT assets.

Further details on the new SINEC Security Guard can be found at: www.usa.siemens.com/sinec-security-guard

Siemens Digital Industries (DI) is an innovation leader in automation and digitalization. Closely collaborating with partners and customers, DI drives the digital transformation in the process and discrete industries. With its Digital Enterprise portfolio, DI provides companies of all sizes with an end-to-end set of products, solutions and services to integrate and digitalize the entire value chain. Optimized for the specific needs of each industry, DI’s unique portfolio supports customers to achieve greater productivity and flexibility. DI is constantly adding innovations to its portfolio to integrate cutting-edge future technologies. Siemens Digital Industries has its global headquarters in Nuremberg, Germany, and has around 75,000 employees internationally.

Siemens Corporation is a U.S. subsidiary of Siemens AG, a global powerhouse focusing on the areas of power generation and distribution, intelligent infrastructure for buildings and distributed energy systems, and automation and digitalization in the process and manufacturing industries. Through the separately managed company Siemens Mobility, a leading supplier of smart mobility solutions for rail and road transport, Siemens is shaping the world market for passenger and freight services. Due to its majority stakes in the publicly listed companies Siemens Healthineers AG and Siemens Gamesa Renewable Energy, Siemens is also a world-leading supplier of medical technology and digital healthcare services as well as environmentally friendly solutions for onshore and offshore wind power generation. For more than 160 years, the company has innovated and invented technologies to support American industry spanning manufacturing, energy, healthcare and infrastructure. In fiscal 2018, Siemens USA reported revenue of $23.7 billion, including $5.0 billion in exports, and employs approximately 50,000 people throughout all 50 states and Puerto Rico.

Continue reading