Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

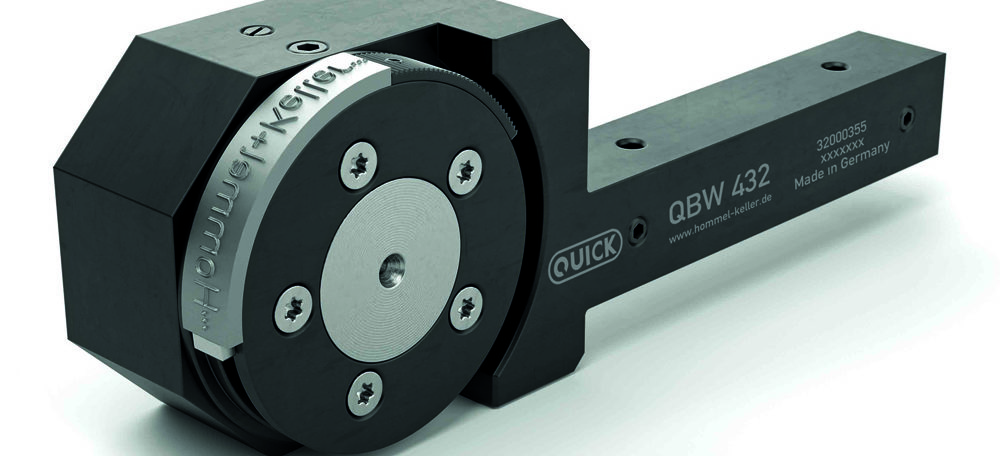

Catalog features cut and form knurling, knurling wheels and marking tools

Hommel & Keller manufactures the QUICK line with a combination of function and innovation. Quality, precision and stability are the key principals used to make QUICK® tools successful. Furthermore, the company prides itself on a rich history of providing customized solutions for its customers.

Benefits of cut knurling include maximum precision and surface quality, knurling of thin-walled components without deformation and time savings due to faster cutting speed and feed rate. Additional advantages are machining of virtually all materials (including gray cast iron and plastic), zero or only minimal alternation of the workpiece diameter and minimal surface compaction.

Among its offering, QUICK also has knurling tools with interchangeable jaws and knurling wheels available from stock. Wheels with special dimensions and pitches can be customized.

QUICK marking tools can mark workpieces in seconds and on a wide variety of geometries independent of workpiece diameter. They are ideal for machines with small installation space and can mark up to a shoulder.

To download the full catalog, click: https://platinumtooling.com/catalog/quick-catalog/

For further information, please contact:

Preben Hansen, President

PLATINUM TOOLING TECHNOLOGIES, INC.

16 E. Piper Lane

Suite 128

Prospect Heights, IL 60070

Phone: 847-749-0633

Fax: 847-749-2445

Email: phansen@platinumtooling.com

Platinum Tooling Technologies, Inc. in Prospect Heights, IL, near Chicago, serves its growing North American customer base with an extensive inventory of machine tool accessories. Its experienced staff is dedicated to providing the most innovative tooling and technology. Platinum Tooling Technologies, Inc. serves the auto, aero, medical, woodworking, composites and other industries, as well as an ever-increasing number of machine tool OEMs, through its network of manufacturers’ representatives. Platinum Tooling is the importer of Heimatec, Henninger, Tecnicrafts, Hommel + Keller QUICK tools and REV broaching tools in North America. In addition, Platinum Tooling represents Rineck Shrink Fit Tooling in the United States and Mexico.

Brings additional technology and customer base to leading manufacturer

Wardwell Braiding Company announces its acquisition of Cobra Braiding Machinery and the company assets, effective immediately. The announcement was made by Wardwell Vice President John Tomaz at the company’s headquarters in Rhode Island (USA).

According to Mr. Tomaz, “Wardwell and Cobra have been friendly competitors for many years on the global market in wire and cable harnessing and when this opportunity for acquisition arose, we knew it was a great fit for our company and our customers. I have the highest respect for the Cobra line of braiders and especially the company’s managing director, Neil Hyde.” Mr. Hyde will remain active in the company as general manager for a period of time yet to be determined, according to Mr. Tomaz.

Established in the UK in 1981, Cobra is a family-run company now in its fourth generation. Innovation, quality and service have allowed Cobra to develop a strong reputation as a leading manufacturer of wire harness and cable harness braiding machinery.

Cobra manufactures and supplies braiding machines and equipment for a wide range of wiring harness markets including heavy vehicles, agricultural equipment, construction and mining equipment, military and defense vehicles, marine engines and aerospace. 95% of the braiding machines Cobra manufactures are exported overseas to countries including the USA, Mexico, Europe, China, Japan and Australia. “Teaming up with Wardwell gives us the confidence that our customers will continue to receive the performance and support they are accustomed to getting from Cobra,” said Neil Hyde.

Wardwell is a member of the Wilms Group which includes other major equipment manufacturers around the world such as SKET, Henrich and Spirka-Schnellflechter. This global network of suppliers to the industry has improved each member’s market position. The Wardwell braiding machine offerings will now include the entire Cobra line, highlighted by the industry-recognized Cobra 450, according to John Tomaz. “We see the Cobra line, when joined with ours, creating a positive synergy in sales and marketing for us on a global scale.”

For more information on this development, please contact:

John Tomaz, Vice President

Wardwell Braiding Co.

1211 High Street

Central Falls, Rhode Island 02863

USA

Phone: 401-724-8800

Web: www.wardwell.com

Email: sales@wardwell.com

Wardwell is a world-leading supplier of braiding equipment. Since its founding in 1911 by Simon Wardwell, the Company’s engineers have continually introduced advancements in machine technology that have made Wardwell braiders the industry standard for overall value.

Wardwell machines are entirely designed, engineered, manufactured, tested and shipped from its factory in Central Falls, Rhode Island, near Providence. Our global network of partner companies reaches all industrialized countries.

Continue reading

With the FZU/FZP42 machine line, Zimmermann Inc. offers users efficient 5-axis portal milling machines for heavy workpiece machining. The specific aspect of these improved machines is a thermo-symmetrical design, incorporating a centrally-guided Z-slide. This particular construction, as well as the guide layout, increases machine stability, while also saving weight – resulting in a more dynamic, productive and energy-efficient machine.

“We have developed suitable machine designs for light processing, such as composite materials or aluminum used in aerospace, as well as for highly dynamic heavy machining,” reports Cornelius Kiesel, president at Zimmermann Inc. in Detroit, the U.S. operation of F. Zimmermann in Germany. While further developing its machine portfolio in the last several months, heavy machining for automotive, other transportation and off-highway are gaining an even higher priority in the company’s market targets. At the same time, Zimmermann is on the cutting-edge in its traditional segments, explains Frieder Gaenzle, CEO of F. Zimmermann. “We are focusing less on classic heavy machining, using large tools and high material removal rates per cut. Instead, the FZU/FZP42 model range provides tool and mold makers with a 5-axis system for highly complex components, which enables more dynamic milling of free-form surfaces.”

Dynamic heavy machining is precisely the challenge in this new market segment. Because the more difficult it is to process the materials, the higher the requirements for rigidity in the machine, Kiesel further notes. Weighting in at several tons on average, the machines are quite massive. How can this massive design deliver great dynamics, so that users can work even more productively?

“Our machines mill out contours with a maximum speed of 60 m/min and may accelerate with 3 m/s2, if needed. “This resembles a motorcyclist, accelerating in a curve to run it more dynamically,” says Kiesel. Despite the acceleration, the machines must be able achieve very high accuracy as well as high-quality surfaces. “This connection of dynamics and heavy machining may be compared to a truck, loaded with stones, performing in a Formula 1 race,” Kiesel muses.

Thermo-symmetry for more precision

In order to achieve this result, Zimmermann is setting up its complete machine portfolio thermo(load)-symmetrically. This occurs because changing ambient temperatures, as well as processing temperatures, inevitably influence machine geometry featuring a portal design. The idea behind a thermo-symmetrical design is based on the ability to substantially absorb incurring thermal influences, achieved by the design of the machine structure itself. Considering this factor, Zimmermann engineering has appropriately designed and intelligently arranged the machine structure and drive unit components and guides, as well as other components responsible for accuracy, for all machines in this newly developed portfolio. In this way, the machine structure may expand in directions that are non-critical.

The centrally guided Z-slide of the portal in double-bridge construction has a large cross-section which makes it especially stable. Using this design, Zimmermann achieves a very high degree of rigidity. Since there is no possible one-sided temperature rise, accuracy is greatly increased, as well. With this structural design, the machine manufacturer constructively reduces the effects of error-inducing variables to a minimum. Due to the fact that less leverage forces apply in comparison to a serial design with a classic guide layout, Zimmermann has increased rigidity of the FZU/FZP, without having to increase the cross- sections of the components. Because less mass needs to be moved, the machine works faster and more dynamically. “Moving less mass also requires less energy. This results in clear cost benefits”, states Kiesel. Additionally, the thermo-symmetrical design makes it possible to omit complex cooling circuits, which also has a positive impact on cost reduction.

By offering the new FZU/FZP42 machine lines, Zimmermann seeks to gain a better foothold in heavy machining. For a long time, the machine manufacturer only occasionally sold systems in this market segment. This has changed following these new developments. “We are already seeing the first successes in the market, says Kiesel. “We were able to sell three ‘heavy’ machines in the first quarter alone.” The company’s customers are equally convinced about the technical data and the price-performance ratio. “A particular customer only wanted to purchase one of our machines for post-processing, since they were already using a heavy machining system provided by a competitor. During the discussions, they then spontaneously decided on a second machine from Zimmermann,” notes Kiesel.

Among the new customers for this line is an automotive manufacturer, who required a new machine for their tool making, in order to process large sheet-metal forming tools and to replace older systems. In the end, Zimmermann was able to successfully assert itself against the competition with its FZU42 machine. The customer realized that this innovative machine concept will enable them to meet their requirements to a high machining accuracy with excellent surfaces on their tools. The high tool weights of up to 40 tons do not pose a problem for the FZU42 system, because the components are not being moved. The movement system, consisting of the portal, Z-slide and milling head, can operate with consistently high dynamics, regardless of the tool weight.

Flexible setup

“We were able to successfully impress the customer with our concept and our price-performance ratio,” says Kiesel. Another important aspect adds to this scenario. The FZU system does not require a solid machine foundation and can therefore be placed flexibly on the factory floor. Extensive construction, which creates high costs and disrupts manufacturing, are completely eliminated.

“We continue to develop and are able to find the right answers for many applications, concludes Frieder Gaenzle. “We have the right overall package. We offer these improved machine concepts in all market segments. Besides the machine structural upsides, these improvements include fitting mounts for the spindles, milling heads for the tools and an extensive service package for our customers.”

About the company

F. Zimmermann GmbH in Germany is a leading global high-tech builder of portal milling machines. These machines are characterized by large workspaces, substantial machine dynamics and cutting performance. The company, founded in 1933 by Friedrich Zimmermann, now has over 250 employees worldwide. With its product range, this innovative company has one goal above all: to offer the right solution for its customers and to be able to guarantee high economic efficiency. “Quality made in Germany” is its motto. Zimmermann special machines are used worldwide in the automotive, aerospace, off-highway, moldmaking and transportation sectors. The company has its North America headquarters in Wixom, Michigan, near Detroit, where it operates a full tech center, offering engineering assistance, commissioning, parts and retrofit services, as well as multiple machines for demonstration purposes.

For more information, please contact:

ZIMMERMANN INC.

30587 Century Drive

Wixom, MI 48393

Phone: 248-956-8511

www.zimmermann-inc.com

Ms. Lena Kiesel, Marketing Manager

lena@zimmermann-inc.com

Guill Tool, global leader in extrusion tooling, recently announced the hire of two new employees. Nick Comeau and Brandon Ribeiro join Guill as Design Engineers. The announcement was made by Chuck Paull, Chief Marketing Officer, at the company’s West Warwick, Rhode Island headquarters.

Nick Comeau obtained his Mechanical Engineering degree from the University of Hartford, Connecticut, where he worked part-time as a senior machine shop manager. As a Design Engineer at Guill, he has several responsibilities including new product design concept generation and research and defining customer requirements using job quotations, purchase orders and customer interactions (emails, phone calls, conference calls). He also develops the design concept for customer requirements, works on the detailed design using SolidWorks (Computational Fluid Dynamics (CFD) and Computer-Aided Engineering (CAE) programs), database searches, along with proprietary design tools. Next, Comeau prepares the design to release it to operations for manufacture by ensuring accurate and complete drawings and Bill of Materials (BOMs), performs project reviews to define and implement process/product improvements and presents to customers at trade shows.

Brandon Ribeiro received his Mechanical Engineering degree from Roger Williams University, in Bristol, Rhode Island. Before joining Guill, Ribeiro held several positions including metal fabricator, press brake operator, design engineer and automation engineer. His work at Guill involves creating extrusion die assemblies to the requirements specified by the customer. The details are acquired by the sales team along with reference assembly previously created. Once the assembly is completed, Ribeiro contacts the customer to get approval before sending the job to the shop floor for production.

Asked what he likes about working at Guill, Comeau said he’s enjoyed the hands-on-experience and that operating and cleaning assemblies shows the strengths and area for improvement of the current assemblies Guill uses. Discussing what he’s looking forward to learning he said, “I’m looking forward to learning more about CFDs and how similarly we can replicate real world application within a simulation.”

Ribeiro appreciates seeing the friendly faces at Guill that are always ready to lend a helping hand. He’s enjoyed learning how to create complex geometry using the company’s 3D CAD software, SolidWorks.

Commenting on the new hires, Paull said, “We are excited to have Nick and Brandon join the Guill family. They are young professionals eager to learn all they can about the extrusion process to better serve our customers.”

For more information, please contact:

Tom Baldock, Sales Manager, Extrusion

Guill Tool & Engineering

10 Pike Street

West Warwick, RI 02893

USA

Phone: 401-465-5526

tbaldock@guill.com

Partnering with ANCA gave a boost of confidence to the Bengaluru-based company, which extensively uses ANCA machines to make precision cutting tools, prepare blanks, and regrind tools

Journey of growth with ANCA

Kumar started SST Cutting Tools in the middle of the global recession in 2008 with a single tool and cutter grinding machine. The company now has four ANCA machines and many delighted customers.

“I had absolutely no idea about CNC grinding machines, as I had never operated one before. All I knew was that I wanted the best one. I evaluated several global brands and found ANCA to be best suited for my application. More than anything, I needed a user-friendly machine, as none of the team members, including me, had any experience with CNC grinding machines,” adds Kumar.

Enhanced output, efficiency, accuracy

SST Cutting Tools added an ANCA FX3 with linear scale technology, which can produce tools with an accuracy of three microns. “We were amazed by the machine’s output and speed. Our efficiency and accuracy went up. This provided a boost to our much-needed confidence and now we’re out in the market looking for precision cutting tools requirements,” says Kumar.

The company started taking precision cutting tool orders, with many happy customers. “We received several repeat orders and a lot of new inquiries. We needed to enhance our efficiency further by reducing the setup time. I discussed this challenge with the ANCA team, and they suggested the ANCA FX5 fully automatic linear machine. I saw the demo, observed all the features, and opted for it in March 2018. It was the perfect match for my requirements. The machine is equipped with a 2-wheel changer that helps us reduce the number of setups,” informs Kumar. SST added one more advanced version of the ANCA FX5 in 2019. It is fully automatic and provides high accuracy and an in-process measuring camera.

It’s all about meeting requirements

The CPX Linear is capable of achieving a surface finish better than 0.2Ra with a run out of less than two microns. “With the addition of a CPX Linear, we can make tools in a few hours, thereby meeting urgent requirements,” he adds.

Focus on quality, accuracy for applications

Talking about his vision, Kumar says, “I want to be a world-class manufacturer of cutting tools and provide services to the customer’s speculated time with zero defects and a high degree of accuracy.”

The company specializes in customized cutting tools such as drills with sizes ranging from Ø1 to Ø25 with the L/D ratio of Ø X 12; endmills with sizes ranging from 0.8mm to 25mm and 2flutes to 12flutes; and reamers and holemills, with sizes ranging from 1mm to 25mm, within the tolerance of 0.002 mm. Additionally, the company works with threading tools, boring tools, ID and OD grooving tools, pico bars, and angle grooving tools.

“I wanted to learn the fundamentals of mechanical engineering, the functionality of the latest machines, and various advantages of grinding applications. I used to work for 10-12 hours during the day and attend classes in the evening,” he recalls.

SST Cutting Tools’ drive and versatility is also highlighted in their multiple #ANCATooloftheYear entries, showcasing their skill and creativity with ANCA software as well as an enthusiastic commitment to the community of cutting tool manufacturers.

More growth ahead at home and abroad

After close to 15 years of operations and many happy customers in India, the company is now eyeing exports, and expanding their infrastructure to accommodate more machines. “We are looking forward to adding more ANCA machines in the coming days,” says Kumar.

He adds, “We have big plans for the future. However, it is worth looking back at the journey and remembering all that has worked in our favor. Choosing ANCA was one of the best decisions in my career. ANCA has not only enhanced the efficiency and productivity of SST Cutting Tools, it has also given our confidence the much-needed boost.”

“The ANCA team is well-versed with the technical know-how and their service is nothing short of excellent. Whenever we faced any technical hurdles, the team would quickly respond. We never had to face any major delays in our projects thanks to their prompt support. In fact, there have been instances of executives from ANCA flying down to Bengaluru from Australia only to help us better understand the machine’s features. I am looking forward to working with ANCA; they are our growth partner and not just a vendor,” concludes Kumar.

For further information, please contact:

Amanda Bakun

Marketing & Communications Manager – Americas

248-497-1168

amanda.bakun@anca.com

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

Using MX7 Linear, the Canadian company helps automotive company make tools within spec and regrinds 1,100-1,500 tools each year

In the ‘80s and ‘90s, business was made up entirely of aerospace customers. However, events like 9/11 and the global financial crisis, showed how temperamental that sector could be and prompted diversification beyond it. With its high-performance holemaking tools, including drills and special end mills, Clortech expanded into the automotive industry. It also provides drills for rail and tie installers, as well as tools (reaming, milling and holemaking) to help the Canadian Armed Forces in the maintenance and overhaul of tanks and other military equipment. Besides MRO tooling services, they also offer regrinding and reconditioning services to old tools and kit inventory services. Their 360° Approach is aimed at companies that don’t have the necessary resources or workforce to make their own tools, while the AOG 911 service produces or modifies aircraft tools with the shortest lead times.

Currently, the job shop is equipped with CNC lathes, milling machines, cylindrical grinders, tool and cutter grinders and six 8-axis NC ANCA grinding machines (two TG7 Plus grinders, two TX7 machines and two TX7 Linear machines).

Discussing what features stand out on the MX7 Linear, Patrick mentioned the Toolroom software, which allows them to simulate a tool before making it. This greatly reduces scrap. The program’s integrated 3D graphics make on-machine programming easy, as grinding simulation is performed after any parameter change providing instant feedback. When they are satisfied with the geometry, operators take that program and put it on the machine to run it. “The simulation software and offline programming is a very strong feature allowing the machine to run while [operators] work on other programs for different parts that they will be running later. The versatility with lots of axes allow them to make the most intricate type parts.” The importance of the software is further evidenced by the fact that raw materials are very expensive and hard to come by so the ability to run a 3D model of the tool beforehand makes a big difference. Most of the company’s tools are designed from A to Z, offering a turnkey solution. The 3D model can be taken to the customer, and they can simulate the cutting conditions in their machine tool. Thus, Clortech can give the customer something before the actual part is delivered.

Before they started using ANCA, Patrick mentioned they were doing a lot of work on conventional machines. Challenges they encountered included capacity and precision. The machines ran continuously but couldn’t match the speed and efficiency of a CNC grinder. Another challenge was having enough people to work the machines. With the integrated automation on ANCA machines, one operator can run more than one machine at once, making the company more profitable and efficient. Additionally, Clortech used to regrind 500-1,000 tools conventionally each year. With CNC machines, they are regrinding 1,100-1,500 each year. This is an efficiency improvement of 1000%. Although the set-up time on a CNC machine is longer, the output efficiency outweighs the time it takes.

The company’s first ANCA machine, a TG7 Plus Grinder, was purchased in 1997 after meeting Russell Riddiford at a trade show. At the time, Clortech was looking to purchase a machine and they chose ANCA because of its software features. Patrick believes ANCA machines symbolize efficiency and reliability, as the first one he purchased is still running smoothly.

For further information, please contact:

Amanda Bakun

Marketing & Communications Manager, Americas-ANCA

M: +1 248 497 1168

amanda.bakun@anca.com

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

Suhner recently introduced the ROTOmax 2.2, a powerful and universal system unit in which the drive and the tool are run separately using a flexible shaft.

Since the ROTOmax 2.2 can be used almost anywhere, it is put to work in foundries, tool production, the pharmaceutical industry, food tech processing plants, aviation technology, boiler making and in mechanical workshops.

The Suhner ROTOmax 2.2 offers applications in cutting machining, grinding, rust removal, brushing or polishing.

For more information, please contact:

Zach Mann, Sales Manager, Abrasives Division

Suhner USA, Inc.

zach.mann@suhner.com

www.suhner.com

One important strategy in remaining competitive in your business today is ensuring you have the tools to adapt to your shifting markets; having the flexibility to adopt new technologies and reap the benefits that they offer. Punch manufacturers around the world know this fact and are seeing the benefits of using ANCA TX7 Linear and TXcell Linear for their production needs.

To begin with, TX7 Linear or TXcell Linear needs to be kitted up with the right tools and accessories to do the job. ANCA has developed several accessories and options that explicitly meet the needs of the punch grinding application.

These accessories are necessary for any good punch grinding machine. So, what makes punch grinding on ANCA TX7 Linear so different? Starting with the basics, TX7 Linear is a 5-axis grinding machine, compared to the 3-axis grinder more traditionally used for punch manufacture. Having these extra degrees of freedom on your grinding machine translates to greater freedom in what applications you can put through it.

In the case of punch manufacture, a traditional punch grinding machine would have been capable of grinding only the outside form of the punch with a single wheel. The TX7 Linear now offers you so much more. Punches will typically have a series of separate machine operations that need to be performed to complete the tool.

So, what operations on the tool require all the additional investment and effort? After OD grinding a punch may require a roof-top or whisper shear on the punch. Additionally, a tool index mark or feature may also need to be included near the shank of the tool. Typical punches include a single radius dressed into the grinding wheel to create a gentle transition between punch section of the tool and its shank, but in some cases, additional reinforcement radii are added. Finally, there is the inclusion of ejector holes in the end face of the punch that requires not grinding but drilling operations. With two-wheel packs available on the 5-axis TX7 Linear, undertaking several of these operations in a single set-up is now possible. But take the next step to a TXcell, with its offering of nine up to 24-wheel packs, and all these operations can now be done in a single set-up, something that was never possible on a standard punch grinding machine.

The TXcell robot used for changing wheel packs is also used for automated loading of tools, which means you can keep it running for those unattended shifts. Having more than one wheel pack on the machine brings other benefits too. By using different roughing and finishing wheels, grinding operations can now be optimized for stock removal or fine surface finish. The TX7 Linear and TXcell Linear are also ideally suited to the use of CBN grinding wheels. Using a much smaller wheel diameter (up to 200 mm (8”). on TX7 Linear and 300 mm (12”) on TXcell Linear), CBN not only delivers superior grinding feed rates compared to conventional abrasives, but also requires less frequent wheel dressing. Both properties ultimately save you time and money.

Many of our customers manufacturing punch tools can demand the highest possible accuracy in terms of dimensional tolerances and surface finish quality. The TX7 Linear and TXcell Linear machines can meets these demands easily to grind punches within 2-3 microns with a surface finish of less than 0.1 Ra (Roughness Average).

Keyhole punches – a key benefit of ANCA’s premium TX machines

One important strategy in remaining competitive in your business today is ensuring you have the tools to adapt to your shifting markets; having the flexibility to adopt new technologies and reap the benefits that they offer. Punch manufacturers around the world know this fact and are seeing the benefits of using ANCA TX7 Linear and TXcell Linear for their production needs.

To begin with, TX7 Linear or TXcell Linear needs to be kitted up with the right tools and accessories to do the job. ANCA has developed several accessories and options that explicitly meet the needs of the punch grinding application.

These accessories are necessary for any good punch grinding machine. So, what makes punch grinding on ANCA TX7 Linear so different? Starting with the basics, TX7 Linear is a 5-axis grinding machine, compared to the 3-axis grinder more traditionally used for punch manufacture. Having these extra degrees of freedom on your grinding machine translates to greater freedom in what applications you can put through it.

In the case of punch manufacture, a traditional punch grinding machine would have been capable of grinding only the outside form of the punch with a single wheel. The TX7 Linear now offers you so much more. Punches will typically have a series of separate machine operations that need to be performed to complete the tool.

So, what operations on the tool require all the additional investment and effort? After OD grinding a punch may require a roof-top or whisper shear on the punch. Additionally, a tool index mark or feature may also need to be included near the shank of the tool. Typical punches include a single radius dressed into the grinding wheel to create a gentle transition between punch section of the tool and its shank, but in some cases, additional reinforcement radii are added. Finally, there is the inclusion of ejector holes in the end face of the punch that requires not grinding but drilling operations. With two-wheel packs available on the 5-axis TX7 Linear, undertaking several of these operations in a single set-up is now possible. But take the next step to a TXcell, with its offering of nine up to 24-wheel packs, and all these operations can now be done in a single set-up, something that was never possible on a standard punch grinding machine.

The TXcell robot used for changing wheel packs is also used for automated loading of tools, which means you can keep it running for those unattended shifts. Having more than one wheel pack on the machine brings other benefits too. By using different roughing and finishing wheels, grinding operations can now be optimized for stock removal or fine surface finish. The TX7 Linear and TXcell Linear are also ideally suited to the use of CBN grinding wheels. Using a much smaller wheel diameter (up to 200 mm (8”). on TX7 Linear and 300 mm (12”) on TXcell Linear), CBN not only delivers superior grinding feed rates compared to conventional abrasives, but also requires less frequent wheel dressing. Both properties ultimately save you time and money.

Many of our customers manufacturing punch tools can demand the highest possible accuracy in terms of dimensional tolerances and surface finish quality. The TX7 Linear and TXcell Linear machines can meets these demands easily to grind punches within 2-3 microns with a surface finish of less than 0.1 Ra (Roughness Average).

Keyhole punches – a key benefit of ANCA’s premium TX machines

The TX7 Linear and TXcell Linear have one final trump card to offer the punch grinding application: keyhole punches. These punches typically feature much more complicated OD profiles including concave forms and require a fundamentally different approach to grinding them. Small diameter wheels with form profiles and run at high RPM; the TX Linear machines handle this with ease. Dedicated keyhole punch software allows you to control every detail of the keyhole punch geometry and grinding process. This means the possible punch applications on TX7 machines have been opened to an entirely new segment of the punch-grinding market, giving you more opportunities to be making money from your investment. In fact, if business in the punch-grinding industry turns down to such a point the machine has spare time available, then re-tooling your machine to ANCA’s bread and butter application of drill or endmill manufacture is a simple exercise. ANCA’s TX7 Linear and TXcell Linear offer you a complete step forward in enhanced punch production flexibility and automation. Diversity like this not only opens new markets and business opportunities, but also delivers future commercial security.

For further information, please contact:

Amanda Bakun

Marketing & Communications Manager – Americas

248-497-1168

amanda.bakun@anca.com

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

World Leader in Extrusion Tooling Design & Manufacturing Releases Newly Designed, Informative Website

Guill Tool & Engineering, West Warwick, Rhode Island (USA), world leader in extrusion tooling design and manufacturing, has unveiled a new website at www.guill.com.

The new site offers a detailed look at the company’s entire product line, which offers a wide-range of standard and custom designed extrusion tooling, including crossheads, in-line heads, rotary heads and extrusion tips & dies. Highlight among the new products is the inline Spiderless Pipe Die, unique in the world market currently for its design efficiency and process performance on small to medium sized plastic pipe.

The site includes a full listing of all products and specifications with calculation tools to compute annual cost of lengthy concentricity adjustments and crosshead replacement analysis, plus calculators to compute draw-down, feet per minute and pounds per hour, making extrusion production scheduling and estimating far more accurate and efficient. The website also includes charts and tables with detailed data and a full library of downloadable literature organized by industry and tool type. Guill markets its equipment worldwide and is currently seeking new representatives in select countries.

The Guill website is mobile phone friendly and offers the convenience of allowing users to request a quote online.

For more information, please contact:

Tom Baldock, Extrusion Sales Manager

Guill Tool & Engineering

10 Pike Street

West Warwick, RI 02893

USA

Phone: 401-828-7600

sales@guill.com

www.guill.com

Guill Tool, the global leader in extrusion tooling, recently announced the purchase of a CNC grinder and a CT scanner.

The company’s rheology lab measures the flow characteristics of plastics and rubber to better predict how the customer’s material will flow through the extrusion dies before they’re made. Together with the scanner, simulation greatly reduces the number of physical reworks needed.

Sold by DMG Mori, the TAYIYO KOKI, is a CNC vertical multi-process machine grinding ID, OD and face by one-time chucking. The ATC unit stores up to six tools. Features of the wheel spindle include HSK-E100 single spindle and a 2-position turret with indexing angle 0 and 22.5.” An optional touch sensor for measuring ID, OD and face is available, as well as a scale feedback control for the X-axis. Control for the Z-axis is also available upon request. Additional features include a single point dresser (rotary dresser as an option) and a work spindle fixed-position stop. Vertical Mate 85 is ideal for applications such as: planetary gears, spindle housings and bevel gears.

In the job shop, Guill offers CNC grinding technology with full automation in lights-out mode as well as custom service for dies and superior material quality, including stainless steel manufacturing and fabrication.

Capable of high-definition imaging, the IM-8000 Series Image Dimension Measurement System has triple the detection performance without sacrificing its simple operation. With a 20-megapixel CMOS sensor and a new algorithm for stable, edge detection high-accuracy measurement on up to 300 features within seconds is available. Newly developed, optional automated rotary fixture allows 360° multi-surface measurement on diverse part sizes and shapes. Accurate and repeatable measurements are instantly achieved with the ‘place and press’ operation. The fast, accurate and easy-to-use interface solves several measurement-related problems.

For more information, please contact:

Tom Baldock, Sales Manager, Extrusion

Guill Tool & Engineering

10 Pike Street

West Warwick, RI 02893

USA

Phone: 401-465-5526

tbaldock@guill.com