Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

The C1D1-DCM power drum transporter is a completely powered and self-contained handling device for lifting, lowering and moving all types of steel, plastic and fiber drums.

The unit incorporates a completely electrically enclosed and spark-free power drive, as well as power lift and lower for moving drums quickly and efficiently by any operator in all plants, warehouses and laboratories. Weight capacities up to 1000 pounds are available.

The models offer users a number of benefits, including protection for “EE” and “EX” rated environments. Features include a steering/throttle handle for forward/reverse drive, lift and lower features and tight turning radius for tight aisle and restricted workspace facilities. The transporter offers a standard lift height of 20” to allow for palletizing on standard or spill pallets and handles up to 1000# per drum. The power system can negotiate inclines and offers the ability to load/unload trucks and shipping containers. Additional features include a fully counterbalanced configuration for “head-on” work with pallets, cabinets, etc., and heavy-duty deep-cycle industrial grade battery. The C1D1-DCM uses Liftomatic’s proven “Parrot-Beak®” clamping system for safe handling of steel, plastic and fiber drums. An optional charger is available.

Liftomatic Material Handling, Inc. is an acknowledged leader in the design and manufacture of drum handling equipment. Headquartered in Buffalo Grove, Illinois, Liftomatic maintains manufacturing, engineering and sales facilities around the globe. Liftomatic currently sells products in over 40 countries and sells to more than 400 of the Fortune 500 companies.

For more information, please contact:

Liftomatic Material Handling, Inc.,

700 Dartmouth Lane, Buffalo Grove, IL 60089,

Sales Dept. 847-325-2930

Web: www.liftomatic.com

Email: info@liftomatic.com

For more product information, please contact:

George Gambini

Liftomatic Material Handling

700 Dartmouth Lane

Buffalo Grove, IL 60089

sales@liftomatic.com

847-325-2930 ext. 1226

www.liftomatic.com

This Grieve bench oven has a modified roof which provides 7 slots with adjustable covers and 2” insulated walls. Additional features include Type 304, 2B finish stainless steel interior and Type 304, #4 brushed finish, stainless steel exterior.

Controls on the No. 1024 include a digital indicating temperature controller.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, Illinois 60073-2835

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese

Suhner’s North American service center has larger capacity, new equipment, better organization and more staff

Suhner proudly announces the opening of its new North American center. Located immediately next to the existing repair center on the company campus in Rome, Georgia, this facility offers customers several benefits. While the actual size is about the same as the previous repair center, there is 40% more workspace, thanks to better storage and materials handling operations. The center’s repair area has increased by 50% and there are new repair function areas, as well as new repair equipment. Suhner’s new center also features improved training facilities and a test area. The North American center has substantial room for expansion, as well, according to company sources.

This new factory service center repairs spindles, multiple spindle heads, slides and live tooling. In the near future, Suhner will also service rotary index tables for CNC machines. Additionally, Suhner repairs its own line of abrasive power tools and competitive brands of spindles, multi-heads and live tooling.

For more information, please contact:

SUHNER Industrial Products Corp.

Lee Coleman, National Sales Manager-Machining Division

43 Anderson Road SW

Rome, GA 30161 USA

Phone: 706-314-2927

Fax: 706-235-8045

lee.coleman@suhner.com

www.suhner.com

Unlike fixed inlet structures for secondary clarifiers, the Passavant hydrograv adapt System consistently and continuously adjusts to current loading in a clarifier. If the loads are low, the hydrograv adapt automatically shifts the inlet elevation and opening height to a low position, introducing the mixed liquor below the sludge blanket. As the loads increase, the hydrograv adapt system shifts itself to a higher elevation and opening height, ensuring ideal hydraulic conditions for the operation of the secondary clarifiers and avoiding sludge overflow.

Benefits of the Passavant hydrograv adapt System include improved process stability of secondary clarification, a reduction of effluent suspended solids to usually less than 3 mg/L, improved particulate phosphorus removal, improved clarification capacity from hydraulic optimization and overall low maintenance requirements.

At WEFTEC 2018, Dr. Martin Armbruster, the Managing Director and founder of hydrograv GmbH and the inventor of the hydrograv adapt system, will co-present on the topic of “Stress Testing of a Secondary Clarifier with an Adaptive Inlet Structure.” His expertise in the field of clarifier CFD simulation includes optimization and practical engineering for more than 1,000 clarifiers in 200+ treatment plants worldwide. His experience in improving hydraulic efficiency of water management systems is based on 500+ hydrograv® with CFD simulations installations. The seminar will take place on Wednesday, October 3 at 1:50 p.m. in room 239.

Centrisys Corporation is a U.S.A. manufacturer of dewatering centrifuges, sludge thickeners and complete dewatering systems for municipal and industrial wastewater. The company’s focus is centrifuge equipment, including the award winning THK sludge thickener. Centrisys provides global service, repair and parts for all brands of centrifuges. CNP – Technology Water and Biosolids designs and supplies nutrient recovery and biosolids treatment optimization systems. CNP’s key technologies are: AirPrex® and CalPrex™, phosphorus recovery technologies, and PONDUS™, a Thermo-Chemical Hydrolysis Process (TCHP). CNP is a division of Centrisys Corporation.

For more information, please contact:

Centrisys Corporation

9586 58th Place

Kenosha, WI 53144

262-654-6006

Jessie Jones, Marketing Associate

Email: Jessie.jones@centrisys.us

Website: www.centrisys.com

Centrisys will introduce their new CS6-4 dewatering centrifuge, their smallest centrifuge to date. The CS6-4 bridges the gap between benchtop studies and full-scale installations. The CS6-4 continuously treats flows from 4 to 10 gpm, making this centrifuge a better alternative to a conventional laboratory centrifuge, which processes samples in batches. The CS6-4 provides scalable solid-liquid separation data to move R&D projects forward.

“We introduced the CS-6 into our equipment portfolio because so many of our customers requested it; there was a need and we simply provided a solution” Michael Kopper, CEO Centrisys/CNP.

Additionally, Centrisys will discuss their latest exclusive distributorship for the Passavant® hydrograv® adapt System in North America (U.S. patent pending). Unlike traditional inlet structures for secondary clarifiers, with the hydrograv adapt System, mixed liquor is introduced near the bottom of the clarifier, below the sludge blanket. The inlet elevation and opening height adjusts to flow conditions so it is always operating in ideal hydraulic conditions.

Centrisys will hold an in-booth discussion with Dr. Armbruster, the Managing Director and founder of hydrograv GmbH and the inventor of the hydrograv adapt system, on Tuesday, October 2 at 2 p.m. Additionally, Centrisys/CNP equipment and processes will be highlighted in the following seminars at WEFTEC 2018:

Visit Centrisys/CNP at WEFTEC 2018, booth #4921.

Centrisys Corporation is a U.S.A. manufacturer of dewatering centrifuges, sludge thickeners and complete dewatering systems for municipal and industrial wastewater. The company’s focus is centrifuge equipment, including the award winning THK sludge thickener. Centrisys provides global service, repair and parts for all brands of centrifuges. CNP – Technology Water and Biosolids designs and supplies nutrient recovery and biosolids treatment optimization systems. CNP’s key technologies are: AirPrex® and CalPrex™, phosphorus recovery technologies, and PONDUS™, a Thermo-Chemical Hydrolysis Process (TCHP). CNP is a division of Centrisys Corporation.

For more information, please contact:

Centrisys Corporation

9586 58th Place

Kenosha, WI 53144

262-654-6006

Jessie Jones, Marketing Associate

Email: Jessie.jones@centrisys.us

Website: www.centrisys.com

Joint venture for “press shop of the future”

Canton, Michigan, September 5, 2018 – Porsche and Schuler announce plans to build an innovative press shop together for the car factory of the future. Representatives of both companies signed the contract on Tuesday, September 4, 2018 for the foundation of a corresponding joint venture. The European Commission has already green-lighted the joint undertaking. Approval from further anti-trust authorities is still pending. The objective of this Schuler and Porsche joint venture is to create what is termed the “Smart Press Shop” as part of a networked Industry 4.0 approach. The new press shop’s pioneering technologies will enable the highly flexible production of complex car body parts, where the focus will be on aluminum body panels and small batch production.

“Porsche wants to use the joint venture to lay the foundations for the future of sports car manufacturing,” says Albrecht Reimold, Member of the Executive Board for Production and Logistics at Porsche AG. “We plan to exploit future technologies and innovations in order to make our processes even more efficient. By dovetailing design, development, car body planning, toolmaking and production within the Porsche Group, we can significantly influence the quality of our sports cars.”

Schuler CEO Domenico Iacovelli stated, “Porsche and Schuler will be using a press shop that sets new standards in two respects – in terms of manufacturing performance, as well as the digital networking and readability of data streams along the entire production process. Not only Porsche will benefit from this major step forward, but ultimately other manufacturers as well.”

The systematic further development of process know-how in the field of metalforming will be achieved in part by the end-to-end networking of production data and the use of machine learning. Porsche and Schuler aim to set new standards in the field of predictive maintenance and intelligent production control.

The joint venture will utilize Schuler’s new Servo 20 Technology. It raises maximum output from 18 to 20 strokes per minute while reducing energy consumption per stroke and per part. A newly developed die-changing concept makes it possible to produce small batch sizes with a high degree of economic efficiency. Further features of the new line include an optimized servo drive in the downstream presses plus a reduced footprint.

The joint venture will operate as an independent company (GmbH & Co. KG) held in equal proportions by Schuler AG and Porsche. Each of the two companies will invest a double-digit million Euro amount in the joint venture. Over 100 highly skilled jobs are to be created. The location of the new company has not been finally decided yet. However, its location is expected to minimize logistics distances for car body parts – thus significantly reducing CO2 emissions.

For further information on Schuler Inc., North America, please contact:

Jeferson Valerio, Director of Sales

Schuler Incorporated

7145 Commerce Blvd.

Canton, MI 48187 USA

734-207-7200

info@schulerinc.com

www.schulergroup.com

About the Schuler Group – www.schulergroup.com

Schuler is the world market leader in metal forming technology. The company supplies presses, automation solutions, dies, process know-how, and services for the entire metalworking industry and lightweight automotive design. Customers include automobile manufacturers and suppliers as well as companies from the forging, household appliances, packaging, energy, and electronics industries. Schuler is the leading supplier of minting presses and supplies system solutions for aerospace, rail transport, and large pipe manufacturing. In 2017, Schuler posted sales of € 1,233 million. Following the acquisition of toolmaker AWEBA and a majority stake in Chinese press manufacturing company Yadon, Schuler employs around 6,600 members of staff in 40 countries. The Austrian ANDRITZ Group holds a majority share in Schuler.

Continue readingBuffalo Grove, IL Liftomatic Material Handling, Inc., an industry leading material handling equipment manufacturer, recently introduced a new 4-wheel hand truck, the Liftomatic 10HT-4W.

The drum truck has two 10″ main wheels with full roller bearings, and two 4″ swivel casters to support the drum while moving through plants and warehouses, in addition to Liftomatic’s exclusive “Parrot-Beak®” clamping mechanism. Other features include a clamping mechanism that can be adjusted to handle all drum sizes from 10 to 85 gallons.

Liftomatic Material Handling, Inc. is an acknowledged leader in the design and manufacture of drum handling equipment. Headquartered in Buffalo Grove, Illinois, Liftomatic maintains manufacturing, engineering and sales facilities around the globe. Liftomatic currently sells products in over 40 countries and sells to more than 400 of the Fortune 500 companies.

For more information, please contact:

Liftomatic Material Handling, Inc.,

700 Dartmouth Lane, Buffalo Grove, IL 60089,

Sales Dept. 847-325-2930

Web: www.liftomatic.com

Email: info@liftomatic.com

For more product information, please contact:

George Gambini

Liftomatic Material Handling

700 Dartmouth Lane

Buffalo Grove, IL 60089

sales@liftomatic.com

847-325-2930 ext. 1226

www.liftomatic.com

This Grieve oven holds one stainless steel tray 6″ wide x 18″ long x 6″ deep with perforated bottom. The tray sets on drip trap/air diffuser which is removable for cleaning. Features include 2” insulated walls and Type 304, 2B finish stainless steel interior.

Controls on the No. 861 include a digital indicating temperature controller, manual reset excess temperature controller with separate contactors and a recirculating blower airflow safety switch.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, Illinois 60073-2835

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese

Acquisition designed to deliver advanced logistics software offerings for manufacturing and distribution

ISSUED UNDER EMBARGO until Sept 1, 2018 – SencorpWhite (Hyannis, Massachusetts) announces the acquisition of Minerva Associates, a strategic merger designed to expand SencorpWhite’s complete warehouse logistics system solutions for the global market.

Minerva Associates, based in San Diego, CA, has provided warehouse management, warehouse control, and asset management system software since 1987. Serving a base of regional distributors to Fortune 500 customers, Minerva’s WMS, WCS, and AMS products are field-proven in distribution, manufacturing and 3PL billing & order management.

This merger complements SencorpWhite’s inventory storage and retrieval products and extensive field-service options. It strengthens SencorpWhite’s expanding software resources and allows the SencorpWhite family to offer comprehensive, turn-key hardware and software solutions; solutions that improve accuracy and efficiency, and satisfy unique customer needs with increased configuration choices. This acquisition further strengthens the company’s overall value proposition in the market, in tandem with the 2017 acquisition of Intek warehouse software and the partnership with ICAM for vertical lift modules.

“We are excited to be a part of this strategic merger,” said Lisa Minerd who will remain Minerva’s President. “SencorpWhite shares our dedication to provide customers with the highest level of service, and comprehensive system solutions that improve the customer’s bottom line.”

“Our strategy is to be a great solutions company, and Minerva reinforces our position as a world-class provider of complete solutions for warehouse and storage automation,” said Frank Doyle, CEO of Connell Limited Partnership and chairman of its subsidiary SencorpWhite. “Minerva has a 31-year track record of providing great solutions to some of the world’s most recognizable companies, including large manufacturers and tech companies. This acquisition adds to our recently acquired Intek software bench strength multiple times over, and together we offer customers the strongest and most experienced WMS people in the business,” said Stan McLean, Intek’s VP System Sales & Implementation.

SencorpWhite, a Connell Limited Partnership portfolio company, is a leading provider of unique end-to-end solutions for the packaging and management of high-value inventory. The company’s products and services – which range from innovative thermoformers and other packaging technologies to automated storage and retrieval systems and inventory management software – cover the entire supply chain spectrum, from the point-of-manufacture through distribution and to the point-of-use. For more information, call (508) 771-9400 or visit hwww. sencorpwhite.com and www.intek.com.

Minerva Associates was founded in 1987 and is the sole owner, designer, developer, and provider of the Advanced Warehouse Logistics software platform, AWL. AWL provides measurable accuracy and efficiency improvements for distribution, manufacturing and 3PL billing & order management, from small regional distributors to Fortune 500 manufacturing enterprises. AWL installations can be found in North America, Western Europe, and the Pacific Rim. Minerva’s product offering and passionate talent are what make them stand out from other WMS software companies. For more information, call (858)-792-8626 or visit http://minerva-associates.com/.

SencorpWhite

400 Kidds Hill Rd | Hyannis, MA 02601 USA

508.771.9400 | info@sencorpwhite.com

www.sencorpwhite.com

Attention: Brian Urban

Minerva Associates

5910 Pacific Center Blvd. #330 | San Diego, CA 92121

858.792.8626 | info@minerva-associates.com

www.minerva-associates.com

Attention: Lisa Minerd

Software solution combines maximum performance with minimal implementation time

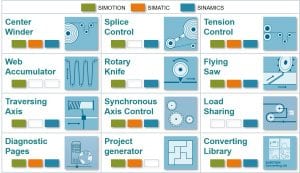

The toolbox enables machine builders to achieve considerably faster time to market by reducing the time required for engineering, programming, commissioning and documentation as much as 80%.

The Siemens Converting Toolbox has separate modules for each of the Siemens product categories typically found on converting machines, including SIMOTION motion controllers, SINAMICS drives and SIMATIC PLCs. SIMOTION is designed for high-performance motion control applications with centralized control in conjunction with the SINAMICS S120 drive system. SINAMICS is ideal for drive-based applications with process-related control implementation in the SINAMICS S120 drive system with graphical drag-and-drop programming. Lastly, the SIMATIC platform applies to centralized converting applications implemented in the PLC control to work in tandem with the SINAMICS S120 drive system.

Additional features of the Converting Toolbox include converting base applications such as: center winder, unwind flying splice control, sectional drive with tension/draw control, accumulator, rotary knife with print mark correction, flying saw, traversing control, synchronized multi axis drive control, load sharing, diagnostics Web pages, project generation tools and converting library process and logistic functions. These function blocks can literally be cut and pasted into a new design, with minimal programming time.

Other specialized application blocks are available upon request.

For more information, please contact:

William Gilbert, Converting Market Manager

Siemens Industry Inc.

5300 Triangle Parkway

Norcross, GA 30092-2538, USA

Tel: +1678 314-4222

William.gilbert@siemens.com

www.usa.siemens.com/converting

Siemens Digital Factory (DF) offers a comprehensive portfolio of seamlessly integrated hardware, software and technology-based services in order to support manufacturing companies worldwide in enhancing the flexibility and efficiency of their manufacturing processes and reducing the time to market of their products.

Siemens Corporation is a U.S. subsidiary of Siemens AG, a global powerhouse focusing on the areas of electrification, automation and digitalization. One of the world’s largest producers of energy-efficient, resource-saving technologies, Siemens is a leading supplier of systems for power generation and transmission as well as medical diagnosis. With approximately 351,000 employees in 190 countries, Siemens reported worldwide revenue of $88.1 billion in fiscal 2016. Siemens in the USA reported revenue of $23.7 billion, including $5.4 billion in exports, and employs approximately 50,000 people throughout all 50 states and Puerto Rico.

Continue reading