Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Additionally, the tooling section features quadrant heating. Guill’s crosshead stand is equipped with an integral alignment station and concentric role guide. The stand is also an integral cleaning station, so clients don’t need to remove the crosshead for cleaning. Lastly, this crosshead has “on-the fly” catenary adjustment and can be easily maintained with simple hand tools.

For more information, please contact:

Bill Conley, Sales Manager

Guill Tool & Engineering

10 Pike Street

West Warwick, RI 02893

USA

Phone: 401-828-7600

www.guill.com

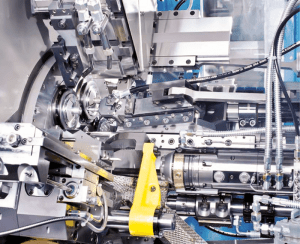

Often, manufacturers need automatics that have greater capabilities. These include the machining of non-ferrous metal or steel, a combination of heavy roughing and accuracy, simple programming combined with versatility and a single machine that performs several production processes. The answer to these challenges is Schütte’s PC series.

Automatics in the PC series are machining centers. They are used whenever classic cam-controlled automatics reach their limit. Besides turning, PC multi-spindle automatics perform tapping, mill cutting, polygon cutting and eccentric drilling operations. Six or eight work spindles, endworking and cross slides can be controlled independently of each other. Rear-side machining can have up to three tools. Over 56 CNC axes can be easily programmed with Schütte’s SICS 2000 system.

PC multi-spindle automatics are designed for material removal of geometrically sophisticated parts made of hard solid materials. The machines are designed to be robust, durable and technically flexible for complex drilling operations. Furthermore, they provide ready-to-install precision parts in large and small batch sizes. Machines in the PC series feature short setup, non-production and part production times.

These machines are used by automobile manufacturers and suppliers, the fittings, pneumatics and hydraulics sector, as well as in the production of precision parts.

For further information, please contact:

Brittany Oulch

SCHUTTE USA, LLC

4055 Morrill Road

Jackson, MI 49201

Phone: 517-782-3600 ex.10

www.schutteusa.com

boulch@schutteusa.com

Huissel utilizes MSP servo presses for high production of complex stampings

Canton, Michigan – Huissel, well-known as a reliable die and sheet metal part supplier for the European automotive and supplier industry, looked to Schuler presses to help expand their market.

“We examined suppliers from Spain and Italy to Germany,” says Peter Busalt. “But only the MSP series from Schuler currently has the functions we need.” Gerald Schug adds, “The ease of operability of the machine was important for us, for example, because this aspect helps even inexperienced employees quickly achieve good results in regard to taking advantage of the full potential of the servo press.”

The commissioning of the new press is also considerably faster thanks to a digital twin. Here, the virtual system model is connected to the real control system with the machine and system visualization system. All functions of the MSP 800 can be simulated on the computer in this manner. The functionality and operation of the system can therefore be tested and trained on the real machine.

Huissel will set up a new building in its Enkenbach-Alsenborn factory for the MSP 800. As a whole, this project is the largest single investment in the company’s 100-year history. Huissel also intends to attach dies that it has manufactured in its Frankenthal factory 25 miles away to the new servo press. The tie rod structure of the MSP 800, which offers particularly high rigidity, also guarantees the quality of the parts production.

Schuler presented the MSP 400, a smaller version of the MSP 800, to the general public at the EuroBLECH trade fair in Hanover for the first time. The smallest members of the group, the single-rod automatic blanking press CSP 100 and the double-rod automatic blanking press MSP 200, are already in use at stamping companies. What all these presses have in common is the innovative knuckle-joint drive with highly dynamic servo motors and additional smart functions, such as condition monitoring.

Schuler is currently in development and will soon offer a press force of 1,250 tons.

www.schulergroup.com/servopresses

For further information on Schuler Inc., North America, please contact:

Jeferson Valerio, Director of Sales

Schuler Incorporated

7145 Commerce Blvd.

Canton, MI 48187 USA

734-207-7200

info@schulerinc.com

www.schulergroup.com

The HCB hoist attachment safely lifts steel, fiber and plastic drums weighing up to 2000 lbs. using Liftomatic’s exclusive “Parrot-Beak®” drum handling attachment. The model HCB-BC attaches to any overhead hoist, crane or boom and engages drums automatically. Liftomatic’s exclusive mechanical clamping system engages the top lip of the container, assuring a safe and reliable pick-up each time.

An adjustable counter-balance on the main frame of the unit allows for safe handling of all drums from 15 to 27 inches in diameter. A padded belt cradle protects the drum sidewall during transport. The model HCB is available in 1 or 2 drum configurations, including stainless steel units for food grade and pharmaceutical applications.

Liftomatic Material Handling, Inc. is an acknowledged leader in the design and manufacture of drum handling equipment. Headquartered in Buffalo Grove, Illinois, Liftomatic maintains manufacturing, engineering and sales facilities around the globe. Liftomatic currently sells products in over 40 countries and sells to more than 400 of the Fortune 500 companies.

For more information, please contact:

Liftomatic Material Handling, Inc.,

700 Dartmouth Lane, Buffalo Grove, IL 60089,

Sales Dept. 847-325-2930

Web: www.liftomatic.com

Email: info@liftomatic.com

For more product information, please contact:

George Gambini

Liftomatic Material Handling

700 Dartmouth Lane

Buffalo Grove, IL 60089

sales@liftomatic.com

847-325-2930 ext. 1226

www.liftomatic.com

By Gerhard Flores, Manager of Technology Development and Intellectual Property

Gehring, Farmington Hills, Michigan

Note to editor: Information in this article was derived from the presentation given by Gerhard Flores at AGMA’s Fall Technical Meeting between September 24th and 26th in Chicago.

Gerhard Flores discusses the need for flat and curved surfaces with the functionality of high static friction for force-fitted nonslip power transmissions. This need is especially true for con rod and cam structuring for high torque resistance or front face connections of sprockets, gears or cam shaft adjustments. He details that expensive solutions like diamond layers, coatings or form fitting design are being substituted. Instead, innovative manufacturing is now performed by a modified laser process with defined exposed micro structures. The prerequisite for high friction is exposed micro melting burrs of smaller micrometer height with martensitic material structures. As a result, high static friction surfaces can be produced economically with repeatability of small tolerances in high-volume productions.

The principal feature of the adhesive system was revealed in a stress test. In it, hardened and structured contact surfaces are loaded against non-structured and unhardened ones with an axial force of 80 kN over 60 seconds for a twist angle of 4 degrees. The course of torque was indicated as target value. The contact areas (di= 15 m, da= 30 mm) were dry and free of grease. At the junction of adhesive and sliding friction, there is a maximum of adhesive value.

Using the adhesive friction bench or the functional aggregate, the effects of structure can be evaluated. Every structure that increases adhesive friction is characterized by a raised profile contour that has influence on the counter body. Next, manifold micro form profiles are produced to absorb shearing forces. Furthermore, the micro form profiles result in a frictional connection with high adhesive friction value. Due to the thermal effect of the laser beam, hardness is generated due to the short heating time.

There are significant differences in the laser structured adhesive friction surfaces of cams, connecting rods, front face connections and pre-treated substrate surfaces. Cam topographies can be raised with low profile elevations and without deepening. Material melts evenly. The structure lines of connecting rods are equidistant superposed. Both cam shafts and connecting rods can absorb torque of shaft hub joints. Between the structures of front face connections, there are often deepenings caused by material transfer. Lastly, pre-treated substrate surfaces display a squamous structure with micro recesses and are suitable to join layer materials to substrates.

Laser structuring of adhesive friction surfaces in rigid friction type connections can substitute positive locking design connections or other expensive friction type connections like diamond interlayers. The achievable adhesive value depends on the depth of the height, the profile shape of the laser structured roughness profile, the arrangement of the structure density, the martensitic properties of lasered materials, the normal force and whether the lubricant is embedded in the contact surfaces or not.

Different connections with torsional strength have different cylindrical contact surfaces. A shrinking connection with the laser structured inner surface of the cam and the shaft, enables the cost effective built cam shaft in serial production. In the case of the clamping connection shaft and the hub, the laser structured contact surfaces are engaged by clamping. This replaces the costly alternative of positive connections. In this way, pin or fitting connections can be replaced by friction type contact surfaces with high adhesive friction generated by the laser structured process.

Another category is the frictional connections of plain functional surfaces for the transmission of shearing forces of torques. The laser structured front surface, often designed with an alignment element replaces cost-intensive solutions like form-locked joint coupling with frontal tooling or inserted diamond or SiC interlayers as slices for the increase of the friction value. Applications related to the combustion engine like pinion, cam shaft adjuster, ball bearing or related to the chassis frame are becoming frequently demanded alternatives to the expensive solutions with slices and interlayers.

Laser structuring of the connecting rods is realized by means of the crank pin, which joins the connecting rod and the crankshaft. The design of the bearing consists of the rod eye, the bearing shell and the crank pin of the crankshaft. There is a rotational relative movement between the crank pin and the inner side of the bearing shell. The joint is laid out as a sliding bearing and works with low friction. However, there is no movement allowed between the outer side of the bearing shell and the connecting rod bore. Here, a sufficient high adhesion is required to absorb the frictions within the sliding bearing. Next, a frictional connection is necessary to deliver the suitable torque strength by means of the elevated topography of the connecting rod and the resulting adhesion.

For the process of laser structuring, a solid body laser with scanning optics is used. The two beam sources are arranged above the connecting rod eye laterally, the connecting rod bore. The beam sources work simultaneously and structure each of the two areas with the connecting rod bore. In each unit, the pulsed beam is guided by the galvanometer scanners with two galvanometer mirrors each. There is no mechanically actuated displacement or positioning of the beam and the focal movement is carried out quickly, line by line, with the highest precision and simultaneously by the movable optics of the integrated scanning heads.

The laser structuring of cams takes place after the shaft and cams are machined as single parts and are assembled by thermal friction type connected processes. In order to achieve sufficient torque strength of the cams, their bores are structured for enhanced adhesion.

Friction type connections are applied in several sectors of mechanical engineering and vehicle design for the transmission of shearing forces and torque. Frontal face connections with plain contact surfaces are laser structured in serial production. Cam shaft adjuster, chain pinions or gears are the focus of the central valve of Schaeffler with the cam shaft in serial production. This valuable technology reduces carbon dioxide emissions. By laser structuring of the main bearing, a high torsion strength of the bearing shell can be realized by the roughly structured areas of a cylindrical type connection as well as heat transfer by the smooth unstructured areas.

In conclusion, the advantage of laser structuring with integrated scanning is that the structuring segments on curved and plain surfaces can be freely dimensioned and positioned. In addition, the structure data and the tolerances of the different surface values can be adjusted by the beam parameter. The structuring process is completely automatable and can be integrated in a production line. Laser structuring allows an increase of static friction up to 5 times. Compared with diamond interlayers, the costs and number of parts is significantly lower.

For more information, please contact:

Jacqueline Fette

Marketing Manager

Gehring

24800 Drake Road

Farmington Hills, Michigan, 48335

Cell: +1 248 954 8383

Email: Jacqueline.fette@gehring-group.com

250 aerospace supply company representatives enjoy hospitality, educational presentation and exclusive movie showing at Colossus de Laval in the Cosmodome

On Friday, October 12, approximately 250 suppliers to the bustling Montreal aerospace community gathered at the Colossus de Laval theater and entertainment complex for a premier showing of “First Man,” the new movie which traces the history of the first moon landing in 1969. The film focuses on the life of Neil Armstrong, the American astronaut who took that “one small step for man, one giant leap for mankind.”

This event was sponsored jointly by Maya HTT and Siemens PLM, partners in service to the aerospace industry in Montreal. Hosting the event was Ms. Rita Azrak, marketing director for Maya, who began the technical presentation portion of the day by musing that the actual “first foot” on the moon was Canadian, as the landing leg cones on the lunar excursion module Eagle were fabricated in Canada, a comment which aroused the crowd’s enthusiasm.

The three main speakers gave insights on their companies’ involvement in the industry and were quite optimistic for the future, as funding for renewed space exploration by both Canada and America is in the works with the respective countries’ governments. Before the first speaker, a recorded message was shown from the first Canadian astronaut, Marc Garneau, now Minister of Transport in Canada and a veteran of three flights on the Space Shuttle. He was followed by Mike Greenley, group president for MDA Corporation, a major aerospace supplier, George Rendell, senior director at Siemens and Marc Lafontaine, vice-president of Maya. All spoke of the longtime benefits derived in our daily lives from the space program, over the decades, as well as the next major project now under way, the Lunar Orbital Platform-Gateway, a lunar orbit space station which, according to NASA documents, will serve as a solar-powered communications hub, science lab, short-term habitation module and holding area for space rovers and other robots. They detailed some of the advancements and planned developments in artificial intelligence.

The program also included a variety of successes achieved with Siemens PLM products, especially NX CAD and NX CAM through the Teamcenter of product lifecycle management. Maya is the Siemens partner in Montreal and brings further value to these products and others in the Siemens suite as a Platinum Level VAR, serving a broad spectrum of industries, including aerospace, defense, automotive, marine and commercial building.

Many in the audience were quite moved by the touching story of Neil Armstrong and his Apollo journey to the moon and back.

For more information on this interesting event or the sponsoring companies, contact:

Ms. Rita Azrak, Marketing Director

Maya HTT Ltd

4999 Ste-Catherine Ouest, Suite 400

Montreal, Quebec QC H3Z 1T3

Canada

Phone: 514-369-5706, ext. 236

Rita.Azrak@mayahtt.com

www.mayahtt.com

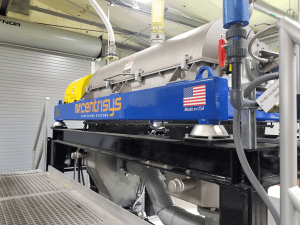

Centrisys/CNP, located in Kenosha, Wisconsin, is collaboratively working with the Milwaukee Metropolitan Sewerage District (Milwaukee, Wisconsin), the Metro Wastewater Reclamation District of Denver (Denver, Colorado), the Madison Metropolitan Sewerage District (Madison, Wisconsin) and the Massachusetts Water Reclamation Authority (Boston, Massachusetts).

Together, they will perform Tailored Collaborative Research (TCR), a program of The Water Research Foundation (WRF), to demonstrate phosphorus removal and recovery potential of the CalPrex™ process at the Madison Metropolitan Sewerage District from September to November.

The TCR will collect high-quality data from the CalPrex™ process and allow the participating utilities to evaluate high-rate phosphorus recovery prior to anaerobic digestion and its positive effects on operations and maintenance. This will help the utilities better meet stringent biosolids regulations and simultaneously mitigate operations and maintenance issues related to phosphorus levels in sludge. A peer review of the findings will be conducted and the results will be disseminated to industry professionals through the WRF LIFT Link platform.

Phosphorus (P) removal and recovery is one of the hottest topics in the wastewater biosolids industry today. Tightening regulations for both land applications and the sale of biosolids have water reclamation professionals eager to evaluate technologies that remove nuisance phosphorus from biosolids in a cost-effective and sustainable manner.

CNP – Technology Water and Biosolids designs and supplies nutrient recovery and biosolids treatment optimization systems. CNP’s key technologies are: AirPrex® and CalPrex™, phosphorus recovery technologies, and PONDUS™, a Thermo-Chemical Hydrolysis Process (TCHP). CNP is a division of Centrisys Corporation. Centrisys Corporation is a U.S.A. manufacturer of dewatering centrifuges, sludge thickeners and complete dewatering systems for municipal and industrial wastewater. The company’s focus is centrifuge equipment, including the award-winning THK sludge thickener. Centrisys provides global service, repair and parts for all brands of centrifuges.

For more information, please contact:

Centrisys/CNP

9586 58th Place

Kenosha, WI 53144

262-654-6006

Jessie Jones, Marketing Associate

Email: Jessie.jones@centrisys.us

Website: www.cnp-tec.com

With eight purchase orders in the last 3 months, the company’s sludge thickener has been used in several wastewater treatment facilities and wineries.

The basis of the THK design highlights what Centrisys is best known for – centrifuges. This sludge thickener is not a modified dewatering centrifuge, which is typically what happens when a conventional dewatering centrifuge is used for thickening sludge. The THK sludge thickener is designed and built specifically to thicken both primary and waste activated sludge using the fundamental principles of a centrifuge, DAFT and Rotary Drum Thickener.

According to Centrisys/ CNP’s CEO, Michael Kopper, “Equipment in this industry should last for decades. Those decision makers who understand the increasing importance of lower lifecycle costs and higher process efficiencies are clearly making the right choices for their plants and ultimately rate payers and our environment.”

Centrisys Corporation is a U.S.A. manufacturer of dewatering centrifuges, sludge thickeners and complete dewatering systems for municipal and industrial wastewater. The company’s focus is centrifuge equipment, including the award winning THK sludge thickener. Centrisys provides global service, repair and parts for all brands of centrifuges. CNP – Technology Water and Biosolids designs and supplies nutrient recovery and biosolids treatment optimization systems. CNP’s key technologies are: AirPrex® and CalPrex™, phosphorus recovery technologies, and PONDUS™, a Thermo-Chemical Hydrolysis Process (TCHP). CNP is a division of Centrisys Corporation.

For more information, please contact:

Centrisys Corporation

9586 58th Place

Kenosha, WI 53144

262-654-6006

Jessie Jones, Marketing Associate

Email: Jessie.jones@centrisys.us

Website: www.centrisys.com

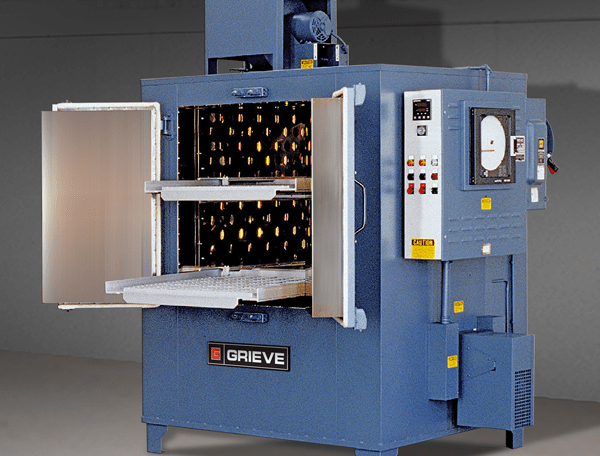

This Grieve cabinet oven has 6” insulated walls and an aluminized steel exterior. Features include Type 430 stainless steel interior and two (2) rollout shelves, 28” wide x 37” long rated 150 lbs. loading each. Additional features include safety equipment for handling flammable solvents.

Controls on the No. 903 include a digital indicating temperature controller, manual reset excess temperature controller with separate contactors, recirculating blower airflow safety switch, 10” diameter circular chart recorder and fused disconnect switch.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, Illinois 60073-2835

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

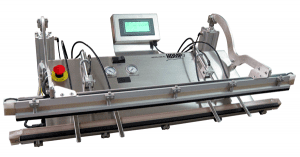

Attention: Frank Calabrese

Davis Olney, the Sales Manager of Accu-Seal, comments, “Recognizing the value that Viking Plastic Packaging offered and serving a region currently not well served for Accu-Seal, we initiated discussions with Viking.” He added, “A visit was made to meet with their team and it became evident to us that Viking offered all the capabilities and characteristics we were seeking in a distribution partner, namely, a knowledgeable and experienced sales team, broad industry experience, technical support capabilities and an understanding of the value of the Accu-Seal brand. Lastly, Viking Plastic Packaging was eager to forge a long-term relationship with Accu-Seal and they believe the relationship will prove extremely beneficial for both parties.”

Prior to establishing the formal terms of the distribution agreement, Viking and Accu-Seal had been working closely together on new opportunities and they had already been seeing positive results from the collaborative partnership.

Viking Plastic Packaging has locations in Minnesota and Wisconsin, serving the upper Midwest.

About Viking Plastic Packaging / Reliable Packaging Systems

Since 1967, Viking Plastic Packaging/RPS has continued to meet and exceed its goal of providing customers with the best solutions for bringing products to market at the lowest possible price. A premier full-service distributor of packaging products, Viking offers the finest in flexible packaging equipment, materials, parts, service and training. Skilled technicians, armed with over 100 years of experience, assist in setup, testing, training, plus system integrations, rebuilds, troubleshooting and machine repair. The Viking clientele spans from individual proprietorships to Fortune 500 companies.

SencorpWhite, a Connell Limited Partnership portfolio company, is a leading provider of unique end-to-end solutions for the packaging and management of high-value inventory. The company’s products and services – which range from innovative thermoformers and other packaging technologies to automated storage and retrieval systems plus inventory management software – cover the entire supply chain spectrum, from the point-of-manufacture through distribution and point-of-use.

For more information on this development, please contact:

Brian Urban, President/CEO

SencorpWhite

400 Kidds Hill Rd

Hyannis, MA 02601 USA

Phone: 508-771-9400

Email: burban@sencorpwhite.com

www.sencorpwhite.com