Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

With its ability to scan both expansive areas and fine details, Artec LEO can scan a variety of objects, from small mechanical parts to the human body, cars, boats or crime scenes.

The scanner has a 3D reconstruction rate of 80 frames per second, making it the fastest professional scanner on the market. With its large field of view, Artec LEO can scan and process large objects and scenes quickly and accurately.

LEO has the ability to scan in sunlight, as well as capture dark and shiny objects. As will all Artec scanners, LEO uses advanced hybrid technology and texture tracking. Therefore, you can point at your object and shoot. There is no need to stick targets and remove them. The texture resolution is 2.3 mp.

This handheld scanner is equipped with a 4” LCD screen to capture images of the data. The 3D light source is provided by state-of-the-art VCSEL (Vertical-Cavity Surface-Emitting Laser) technology. With no need to connect to a computer or to plug in to a main power source, users can hold the scanner and walk around freely, scanning without worrying about wires or additional equipment. Artec LEO’s battery pack allows users to scan for 3.5 to 4 hours. Supplementary battery modules permit unlimited 3D scanning on expeditions or in remote areas. There are 2 cameras on this scanner. One is a range camera for 3D geometry and another is a color camera. The color camera captures color texture data. Besides built-in battery and wireless connectivity, Artec LEO can stream to a second device and upload the data.

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

For information, please contact:

EXACT METROLOGY, INC.

Dean Solberg

20515 Industry Avenue

Brookfield, WI 53045

Phone: 262-533-0800

Local: 866-722-2600

www.exactmetrology.com

deans@exactmetrology.com

Steve Young

Exact Metrology, Inc.

11575 Goldcoast Drive

Cincinnati, OH 45249

Phone: 614-264-8587

Local: 513-831-6620

www.exactmetrology.com

stevey@exactmetrology.com

In the 2018 fiscal year, Schuler increased its order intake by ten percent with successful sales in new markets and digitized applications. However, ongoing pressure to make business adjustments in Germany, international trade conflicts and special effects had a significant negative impact on the Göppingen-based press manufacturer’s sales. “We will consistently focus Schuler on new markets, digital business models and profitable core businesses,” said CEO Domenico Iacovelli, in office since April 2018, when speaking to journalists on Wednesday, March 6. In mid-2019, Schuler and Porsche plan to start building their joint high-tech press plant, which has now finally been approved for construction.

Order rise but 2018 sales down slightly compared to previous year

Schuler’s incoming orders rose to € 1,255 billion in 2018 (previous year: € 1,141 billion). Despite the rather low order backlog at the end of 2017, Group sales remained virtually unchanged at € 1,212 billion (previous year: € 1,220 billion). The regions of Europe and China grew, while business in North America suffered some losses.

Sales margins were subject to multiple burdens. The challenges posed by the new WLTP test procedure for automobile manufacturers led, particularly in Germany, both to the abandonment of new capacities and to the postponement of already agreed projects. At the same time, costs rose due to the collective wage agreements from recent years. Customer business in China suffered from the trade conflict between China and the USA.

In 2018, Schuler had extraordinary expenses in the low double-digit million Euro range due to capacity adjustments within the Group and write-downs on the capitalized goodwill of the die manufacturing subsidiary AWEBA. EBITA fell to € 45.3 (111.9) million. Schuler achieved consolidated earnings after tax of € 13.5 (67.4) million.

Cautious optimism for 2019 and beyond

At the end of 2018, Schuler’s equity capital ratio of 40.1 (38.1) percent of the balance sheet total was still above average in the German mechanical and plant engineering sector. The company employed 6,575 (6,570) people worldwide, 4,195 (4,237) of them in Germany – which is barely any fewer than in the previous year.

CFO Norbert Broger said, “2018 was a very challenging year in terms of operation and strategy. This is why it was all the more important that we were able to reverse the negative trend in incoming orders and achieve an increase of ten percent for the first time. We therefore entered the new year with a decent order backlog of € 926 million. Therefore, and thanks to the cost reduction measures already initiated, we are confident that we will be able to show medium-term earnings improvements.”

Concentration on the profitable core business

Irrespective of the positive order development, the pressure to adapt remains high, especially in Germany, said CEO Iacovelli. “In 2018, we therefore began making Schuler more dynamic and bringing customer-driven innovations to market more quickly. The aim is to concentrate on the Group’s profitable core business and increase profitability in the coming years. This includes the consistent segregation of loss-making business areas, wherever necessary.”

In recent months, Schuler has developed new product strategies for each business division. Expensive “over-engineering” needs to be a thing of the past. Schuler has already decided to withdraw from the unprofitable production of packaging machines and lines for the production of large-diameter pipes in 2019.

Expansion of service business and value creation in China

Cost benefits in production in China and Brazil are to be exploited to a greater extent and the global service network is also to be expanded in Germany. The locations in China will receive additional engineering positions.

“Smart Press Shop” with Porsche sets new standards

The new press shop as part of the joint venture with Porsche will set new standards for the automotive industry both in terms of performance in industrial manufacturing and in the digital networking of data streams in the production process.

Beginning in 2019, Schuler and Porsche will build what is said to be the world’s most modern press plant for the digitized automobile production of the future in Germany. Operation is scheduled to go on line in 2021. “The establishment of the corresponding joint venture between the two companies under the name ‘Smart Press Shop’ is perfect,” said Schuler CEO Iacovelli. “The new press shop will set globally high standards for the automotive industry, both in terms of performance in industrial manufacturing and in the digital networking of data streams in the production process,” he explained.

The new Smart Press Shop will supply the Porsche plant in Leipzig in particular with body parts at low logistical cost and with the lowest possible ecological impact. For Schuler, this joint venture is an example of close cooperation with the world’s leading automobile manufacturers. “At the same time, we are focusing on new markets and digital business models,” said CEO Iacovelli. Schuler intends to gain additional market shares in 2019 with new mechanical presses in the mid-price segment and consistent digitization of the main product lines. “For Schuler and our customers, digitization is not a vision, but a reality. And it is, above all, a great opportunity for all of us – not a risk,” explained the Schuler CEO.

For further information on Schuler Inc., North America, please contact:

Guido Broder, VP

Schuler Incorporated

7145 Commerce Blvd.

Canton, MI 48187 USA

734-207-7200

info@schulerinc.com

www.schulergroup.com

About the Schuler Group – www.schulergroup.com

Schuler offers customer-specific cutting-edge technology in all areas of forming technology – from networked presses to press shop planning. In addition to presses, the product portfolio also includes automation and software solutions, dies, process know-how and service for the entire metalworking industry. Its customers include automobile manufacturers and automotive suppliers, as well as companies from the forging, household appliance and electronics industries. Presses from the Schuler Group also mint coins for more than 180 countries. As a provider of innovative system solutions, we support our customers worldwide in the digital transformation of forming technology. In the 2018 fiscal year, Schuler generated sales of € 1,212 billion. Schuler AG, founded in 1839 at its headquarters in Göppingen (Germany), has approx. 6,600 employees at production sites in Europe, China and America, as well as service companies in over 40 countries. The company is majority-owned by the Austrian ANDRITZ Group.

Continue readingThe following interview was conducted with Platinum Tooling’s President, Preben Hansen, at the company’s headquarters in Prospect Heights, Illinois. Hansen discusses the beginnings of Platinum Tooling, the transition period, changes, product lines and the future.

Regarding future changes at Platinum Tooling, Hansen isn’t going to change his main goal: making sure customer needs are met. He explained “As always, I will continue to look for new products to complement our current product offering in an effort to satisfy the growing needs of our customers. Since the transition to Platinum Tooling, we have done our best to assure our customers that we will continue to promote and support the Heimatec tooling lines as we did in the past.” Hansen clarified by saying “Heimatec tooling will always be our core business. We have several other complimentary lines including Tecnicrafts collets & guide bushings for the Swiss market, Henninger spindle speed increasers for machining centers, AMF marking tools, cleaners, and radio sensors plus Suzuki IB spindle speeders for Swiss machines.”

As for custom tooling, Hansen assures customers that Platinum Tooling will continue offering this service. “Our current manufacturers are all excellent at engineering solutions for special applications.”

Lastly, Hansen expressed excitement about the future of Platinum Tooling, saying “We are eager to see how the company will grow and evolve.”

For more information, please contact:

Preben Hansen, President

Platinum Tooling Technologies, Inc.

16 East Piper Lane, Suite 128

Prospect Heights, IL 60070

847-749-0633

www.platinumtooling.com

phansen@platinumtooling.com

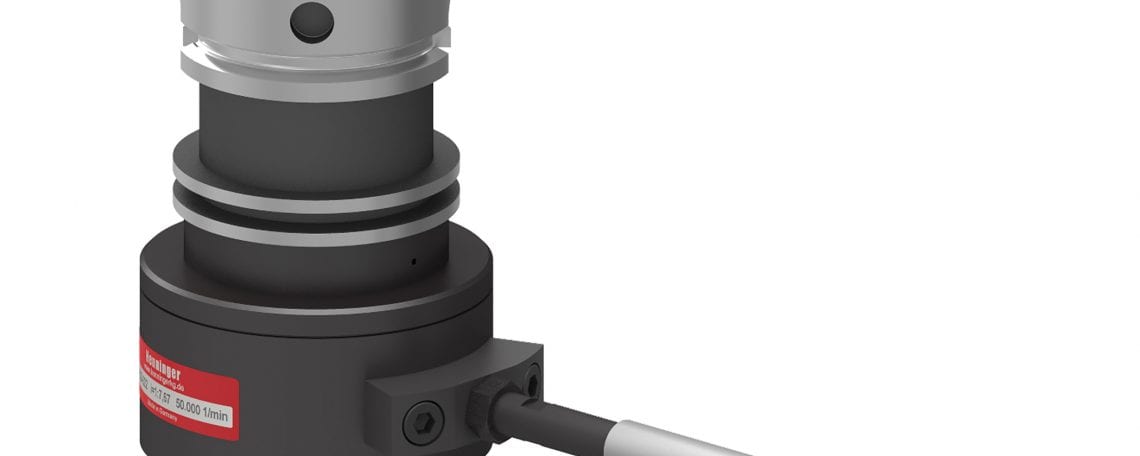

Henninger is a manufacturer of specialized equipment and precision machine tool accessories. Spindle speeder types including mechanical, air and electric motor driven styles are all available.

These speed increasers help maximize productivity by achieving a higher spindle rpm that is required for certain applications in today’s marketplace. Small diameter tools require rpms that are sometimes not possible to reach with existing machine tools. In addition, they allow for less wear and tear on the machine’s spindle when it is not required to run at its maximum rpm.

Mechanical speeders are available with up to a 1:8 gear ratio and a maximum speed of 50,000 rpm. Air speeders can run continuously at up to 80,000 rpm and high frequency motor spindles can maintain up to 80,000 rpm with high torque, and have variable speed options.

Many of the speeders have automatic tool change capabilities and are modular in design to offer the customer greater flexibility.

Henninger also manufactures custom angle heads, live centers, face drivers, and live chucks. In addition, Henninger is the premier manufacturer for center grinding machines.

To learn more about these Henninger products as well as the Heimatec, Tecnicrafts, and AMF lines available through Platinum Tooling, please visit the company website.

For more information, please contact:

Preben Hansen, President

Platinum Tooling Technologies, Inc.

16 East Piper Lane, Suite 128

Prospect Heights, IL 60070

847-749-0633

www.platinumtooling.com

phansen@platinumtooling.com

This Grieve cabinet oven has 4” insulated walls, an aluminized steel exterior and Type 430 stainless steel interior.

Controls on the No. 828 include a digital indicating temperature controller, manual reset excess temperature with separate contactors and a recirculating blower airflow safety switch.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, Illinois 60073-2835

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese

This new office has sample models of Suhner’s products such as their tapping and drilling units. In addition, they have real-world examples on the walls that show where the tapping and drilling units can be used and what they’re used in.

Mike Ricketts, the regional manager of the machining division, feels that the new office offers a more professional environment. He believes that “Customers can come into my office or sit down in the conference room and we can go through a presentation showing them what Suhner offers. Likewise, they can come in with their own presentation and let us know what their needs are.” This setup promotes open communication between the company and its customers.

In this location, Suhner runs two divisions. These are the machining division led by Mike Ricketts and the transmission division, led by Tom Dunn, the company’s national account representative. Dunn is a specialist in the field of orthopedic surgical tools. Suhner’s flex shafts have particular advances in the medical industry, as they do in the company’s primary automotive market for power windows, seats, side view mirrors and roof retraction.

The new office is only 30 minute away from O’Hare International Airport, a central location that allows Suhner to better serve its current and future customers.

For more information, please contact:

Mike Ricketts

Suhner Industrial Products

Regional Manager – Machining Division

777 Lake Zurich Road

Suite 110G

Barrington, IL 60010

Mobile: 224-545-2014

Email: mike.ricketts@suhner.com

Brands of the Schuler Group provide customers with a wide range of products and services to meet their needs

Bliss Clearing Niagara technical services offer a complete range of related products — including spare parts, repair, inspections, remanufacturing, rebuilds, and modernizations.

Modernization services include complete press teardown and analysis, engineering analysis, repair or manufacture of parts and assembly that shows the original OEM specs. Also available are field service, on-site repair, trouble shooting, press relocations and press inspections.

Remanufacturing is offered on all brands of mechanical presses/hydraulic presses and some forging presses.

OEM users can quickly receive their needed parts, thanks to a unique parts record that contains over 300,000 parts. These include clutches, brakes, gears, bearings, conversions/upgrades, perishable parts, frames, and connections. In addition to the brands that make up BCN, they also carry USI, Toledo, Consolidated Press, Wilkins and Mitchell and Warco.

No matter the age of your part, BCN can provide you with timely and high quality retrofits, repairs, modernizations, replacements and services. Interested parties can contact Tony DeMerle, BCN’s Director of Sales.

For further information, please contact:

Tony DeMerle, Director of Sales

Bliss Press Systems

1004 East State Street

Hastings, MI 49058 USA

734-865-0949

Anthony.DeMerle@blisspressusa.com

www.blisspressusa.com

About the Schuler Group – www.schulergroup.com

Schuler is the technology and global market leader in the field of forming technology. The company provides presses, automation solutions, dies, process expertise and service for the entire metalworking industry and lightweight automobile construction. Its customers include automobile manufacturers and automotive suppliers, as well as companies from the forging, household appliance, packaging, energy and electronics industries. Schuler is a leader in coin minting presses and implements system solutions for the aerospace, rail transport and large-dimension pipe manufacturing sectors. In the 2016 fiscal year, Schuler generated sales of 1.174 billion euros. After acquiring toolmaker AWEBA and a majority stake in Chinese press manufacturer Yadon, Schuler has a presence in 40 countries with roughly 6,600 employees. Schuler is majority-owned by the Austrian ANDRITZ Group.

Continue reading

The entire process of scanning and data processing was done in a couple of hours. The captured data was used to create a six foot statue replica. At present, the statue is being painted and will be displayed in front of the museum.

For more information, please contact:

Dean Solberg

Exact Metrology, Inc.

20515 Industry Avenue

Brookfield WI, 53045

262.533.0800

www.exactmetrology.com

deans@exactmetrology.com

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

Continue readingWith power range from 1–700 hp (0.75–630 kW), Sinamics G120X is optimized for pump,

fan and compressor applications

Siemens is introducing the new Sinamics G120X drive, a simple, seamless and easy-to-use drive, designed for use in pump, fan and compressor applications in industries such as water/wastewater, HVAC/R, irrigation/agriculture and in industrial environments. Sinamics G120X has a power range of 1–700 hp (0.75–630 kW) and can operate in a temperature range from -4 to +140° F (-20 to +60° C) with any standard motor, including synchronous reluctance motors (SRM). It has an integral DC choke which improves harmonics and EMC performance. Sinamics G120X meets all the latest and upcoming UL, NEMA and EN/IEC standards for 2019 and beyond and offers up to 100 kA short-circuit current rating (SCCR) ensuring enhanced product safety and energy efficiency.

Siemens is introducing a totally new drive series for the U.S. market. Sinamics G120X drives are especially suited for use in pump, fan and compressor applications in industries such as water/wastewater, building technology and in industrial environments.

Sinamics G120X easily integrates into existing applications and is configured for cost-optimization and resource-saving operation, which ultimately helps reduce total cost of ownership.

The compact design of the G120X saves space in the control cabinet and can also be easily integrated in to MCC solutions (including plug-in buckets). Even without an additional output reactor, Sinamics G120X drives enable motor cable lengths of up to 492 ft. (150 m) with category C2 or C3 filter and up to 1476 ft. (450 m) without filter and have hardware-based SIL3-certified safety functions built-in.

“The Sinamics G120X offers outstanding ‘out-of-the-box’ ease of use and is simple to commission and operate using its high-resolution graphical color keypad, known as IOP-2 (intelligent operator panel), as well as the optional Wi-Fi-enabled Smart Access wireless module — both optimized for pump and fan applications,” states Nikunj Shah, product manager, Siemens, Digital Factory, US.

Shah continues, “Sinamics G120X drives offer an automatic restart function after power failures and the multi-pump/staging operation mode allows the user to control several pumps using just one drive. Its energy-saving mode automatically switches the motor on and off to save energy and reduce wear. G120X also has built-in energy functions which display energy consumed as well as energy saved.”

The G120X has Class 3C3 coating which is suitable for harsh environments where the presence of corrosive gases such as Hydrogen Sulfide (H2S) is present. A high C2 or C1 EMC category ensures the drive can be reliably used in any kind of industrial and public networks.

Sinamics G120X is compliant with all relevant EU and upcoming NEMA energy-saving standards and offers an operating efficiency level of over 98% (efficiency class IE2). Its comprehensive range of integrated application-specific functions for pumps and fans ensures improved energy efficiency through amount of actual energy needed in line with the actual load which ensures the best possible performance and minimal energy losses.

Sinamics G120X is fit for digitalization and can be linked to Mindsphere by using Sinamics Connect 300 and the Mindsphere app Analyze MyDrives. This offers users the opportunity to analyze valuable operating data gathered from the drive and enables the visualization and analysis of status information, providing users with valuable data which can be used as the basis for process optimization and maintenance strategies. Mindsphere is the cloud-based, open IoT operating system from Siemens that connects products, plants, systems and machines, while enabling a user to harness the wealth of data generated by the Internet of Things (IoT) with advanced analytics.

Siemens Digital Factory (DF) offers a comprehensive portfolio of seamlessly integrated hardware, software and technology-based services in order to support manufacturing companies worldwide in enhancing the flexibility and efficiency of their manufacturing processes and reducing the time to market of their products.

Contact for journalists:

Siemens

Hollie Davis

(678) 313-7256

hollie.davis@siemens.com

Contact for product information:

Siemens

John Meyer

(847) 640-1595

john.meyer@siemens.com

For specific product information and inquiries, send an e-mail to: mc.us@siemens.com

Siemens Corporation is a U.S. subsidiary of Siemens AG, a global powerhouse focusing on the areas of electrification, automation and digitalization. One of the world’s largest producers of energy-efficient, resource-saving technologies, Siemens is a leading supplier of systems for power generation and transmission as well as medical diagnosis. With approximately 379,000 employees in 190 countries, Siemens reported worldwide revenue of $94.0 billion in fiscal 2018. Siemens in the USA reported revenue of $23.7 billion, including $5.0 billion in exports, and employs approximately 50,000 people throughout all 50 states and Puerto Rico.

Continue readingby TJ Terrell, Business Development Manager,

Siemens Industry, Inc., Machine Tool Business

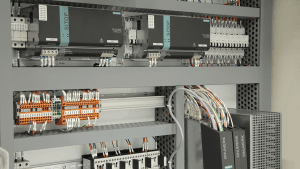

Given the multiple challenges associated with in-house panel building such as quality design, expertise, support and technology, outsourcing quickly becoming a viable option

A single source that can provide the design data, digitalization expertise, hardware, engineering, panel build and installation assistance, with factory warranty coverage, can yield myriad advantages for the builder.

Panel building on machine tools is no longer as simple as wiring a few components and calling it a day. Now, there are more deadlines, cost pressures, standards, new directives, plus an increasing pressure to innovate. Besides commonly encountered problems related to time, cost, compliance and quality, there is also an increased degree of automation in the pre-fabrication of cables and the automated production of sheet metal parts. In addition to the mechanical design and development of the automation concept, planning of the electrical power supply and distribution is the third engineering discipline involved in the production of a new machine. Electrical planning provides the framework for the automation engineer, as it involves specifying basics such as communication, topology and the control concept.

Increasingly, the daily work of electrical designers isn’t limited to planning activities. It now includes downloading, storing, processing and backing up data. These data management activities are an important part of the process, yet they occupy substantial time. To save time, machine tool companies need to create and implement a plan for handling data. If a machine tool builder has more than one electrical designer, it is worthwhile to relocate the product databases to a central server. Data only need to be maintained and imported once, then every user can access it. Since the engineering process is closely tied to other processes like procurement, storage, project-specific provisioning, assembly and inspection, it is useful to connect these processes electronically. All ECAD, or electrical drawing systems, are able to connect to typical Enterprise Resource Planning (ERP) systems. This makes it easier to calculate the price of a control panel. Prices are transferred from the ERP system to the product database of the ECAD solution.

Even though clients expect manufactured products to be high-quality, costs need to be kept to a minimum in order for companies to remain competitive. When machine tool builders think of cabinet costs, they typically think of costs originating from engineering, devices and materials, assembly and wiring. Engineering costs typically comprise 45% of the overall cost, devices and materials make up another 45% and assembly and wiring are the remaining 10%. However, there are also hidden costs like costs to order material, store it, the value of time from procurement, the time spent by engineering coordinating with suppliers or redesigning the cabinet and payment terms dictated when you order material.

Simplified designs are made possible by the expertise of custom panel builders, who bring experience in component clustering, footprint and enclosure space utilization to the task.

Increasing cost pressures stem from various sources. In general, the complexity of the documentation to be created is constantly increasing. End-users and machine builders want a high level of detail for better and more independent production. The communication portion of the integrated components is continuously increasing. A basic controller now has measuring and monitoring devices for tasks such as energy usage or machine condition monitoring. This makes planning more complex and time consuming. Demands on service personnel have also increased, as maintenance personnel must receive all necessary information for component replacement quickly and efficiently.

Although a favorable purchase price is desired, this doesn’t automatically lead to an economical control panel. The electrical planner works with a product log before it is purchased or integrated. Unfortunately, the burden placed by a component on electrical planning is often overlooked in the purchase decision. The manual creation of a complete dataset for a new project in the ECAD software often takes more than 2-½ hours. Therefore, the ability to use existing data is very important. Fortunately, ECAD systems often offer complete data packages that can be downloaded via data portals.

The use of tools for daily work is also changing. Only a few years ago, a “drawing” was the main way electrical plans were created. ECAD programs offered functions for easy and precise placement of circuit diagram placement and their interconnection. Then, the concept of object orientation was added to the software. A placed symbol is no longer simply a collection of drawn lines, but one of many views of a device that’s integrated into the control panel. With object orientation and automation functions in every ECAD software, users can take advantage of these benefits in their daily work. This “toolbox” concept has been popularized in various industries such as packaging, printing, converting and metal forming machinery. It allows slightly modified and next gen machine builds without the need to redo the entire electrical landscape. This evolution represents a significant potential savings for builders and integrators alike.

In-house projects often lead to delayed deadlines, wasted money and wasted effort. In fact, a significant number of machine tool builders often can’t afford building panels in-house. Occasionally, in-house cabinet building is done to keep a workforce employed. However, in today’s highly competitive business environment, the builder must evaluate whether or not overall cost could be lowered by reallocating resources? Often, this is not considered by machine builders, but could prove advantageous. Outsourcing to companies who specialize in electrical control and cabinet builds can establish milestones with contract manufacturers for timeline-based pricing, thus eliminating project management uncertainties and reducing time-to-market for the builder, beyond the time and materials costs.

Innovative projects or highly complex automation or robotic integration schemes often rely on multiple concepts to ensure they stand out in the market. Companies may lack the ability to have more staff working on developing projects. By working with another company, machine tool builders can use diverse teams of technologically advanced engineers to develop projects while eliminating the excess labor and engineering costs devoted to panel and cabinet builds.

As new software, automation technologies and tools continue to evolve, companies are placed in a competitively disadvantageous position. Tools and software programs can require a license or an expensive user fee. By outsourcing to a dedicated partner, machine builders can utilize the newest and most appropriate technologies for projects, in a cost-effective manner.

Problems with the equipment or the software can also lead to inactivity and unplanned expenses for a builder. An outsourced support staff monitors equipment efficiencies, diagnoses problems and repairs equipment in a more effective and economical manner.

Flexible set-up permits on-the-fly adaptation of control hardware, when design changes are required or subsequent iterations of a machine are produced.

By partnering with Siemens, for example, the process of panel building is streamlined and simplified. The company offers a unique product and system portfolio of CNC, PLC, drive, motor and other components in the control loop, backed by many years of expertise, data communications, software and tools. We further help the machine tool builder on the path to digitalization and also offers comprehensive support throughout each of the panel building stages including design, quoting, order, build and support. This achievement is often accomplished in tandem with a Solution Partner, authorized electrical distributor and job shop located in close proximity to the machine tool builder.

In the design stage, our company can assist with UL/EC standards and sizing optimization. Furthermore, the company offers component optimization, expert know-how and content-neutral devices. Additionally, the company can evaluate specification requirements and provide support regarding the application of standards and certifications, based upon the end-user’s market, physical location etc.

When quoting, Siemens and its partners can offer competitive pricing and fast response times to meet application-specific needs.

Ordering is likewise simplified, without complicated purchase orders and numerous line items, once the project details are set. One of the key reasons for outsourcing the cabinet build is to simplify the procurement process through time reduction. For a typical package, there may be more than 200 line items on the bill of material, each of which must be entered and tracked by someone in procurement. Outsourcing allows that procurement person to focus on obtaining better pricing instead of needless administrative work. In addition, there is no need to store pieces and parts for the panels in-house, as the partners maintain that carrying cost.

The building of the panel takes place in a UL-Certified production facility. There is a dedicated project manager onsite to handle engineering change notices (ECN) and communication. Our company and its partners provide quality control and assurance, along with clear scheduling and resource management. Continuity testing is performed, as well as automatic routing of the wiring and custom painting, per customer specification. All control panels feature a one-year warranty, pre- and post-purchase consultations, a communication log and a transparent ECN process.

There are several additional benefits when choosing Siemens to outsource panel and cabinet production. The company acts as the builder’s single source for all ordering, service, support and delivery, with comprehensive project management. Using a third-party to build a control panel greatly reduces the builder’s time-to-market. The total cost of ownership for the machine tool builder, which includes engineering, electrical and manufacturing engineering costs, is significantly lower when outsourcing, as well. In addition, our company has invested in a variety of panel shops to develop a “best practices” protocol for various machine categories.

Machine builders further receive competitive pricing by leveraging Siemens global agreements and enjoy extended payment terms, that is, terms at the completion of the project vs. when the order is placed.

Despite being implemented in the market presently for only one year, several machine tool companies are already realizing substantial savings with this new control panel initiative.

The company utilizes a global network of trusted partners with panel design and build expertise. These partners have years of experience and can optimize the overall design, cabinet heating and cooling, footprint, Siemens content, third-party content and more, thereby further enhancing the machine builder’s benefits.

For more information on this new approach to machine tool control panels, please contact:

TJ Terrell

Machine Tool-Business Development

Siemens Industry, Inc.

390 Kent Avenue

Elk Grove Village, IL 60007

770-653-9612

tyran.terrell_jr@siemens.com