Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

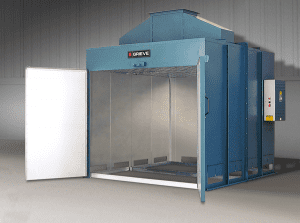

This Grieve modified shelf oven has 4” insulated walls, an aluminized steel exterior and Type 430 stainless steel interior. Features include two (2) shelf trucks with supports on 9” centers to correspond to wheel supports in oven and two (2) tiers of wheel tray supports to aid in loading trays from oven to trucks. Additional features include 350,000 BTU/HR installed in a modulating natural gas burner.

This Grieve oven includes all safety equipment required by IRI, FM and National Fire Protection Association Standard 86 for gas-heated equipment, including a 325 CFM 1/3-HP powered forced exhauster.

Controls on the No. 879 include adjustable, thermocouple actuated, manual reset excess temperature interlock, electronic flame safeguard protection, exhauster airflow safety switch, recirculating blower airflow safety switch and purge timer.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, Illinois 60073-2835

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese

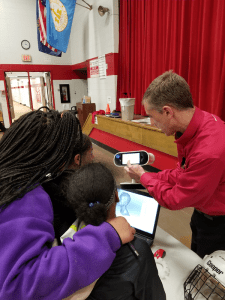

On March 28, 2019, Exact Metrology was among several companies who came to Latonia Elementary Career Day. This event was meant to introduce students to a variety of careers in health, law, manufacturing, engineering, technology and other fields. Fifth grade students spent three weeks researching different careers that interested them. They learned information concerning future salary, education and job skills. Then, students had the opportunity to speak with professionals in their chosen fields and ask questions.

Geomagic Design X is the industry’s most comprehensive reverse engineering software-combining history-based CAD with 3D scan data processing and enables users to create feature-based, editable solid models compatible with existing CAD software. Geomagic Design X provides an easy way to integrate CAD models from a 3D scanner into an existing engineering design workflow. This software permits the re-use of designs without manually updating old drawings or re-measure/rebuild a model in CAD.

Jason Kleinhenz commented, “Exact Metrology was happy to participate in this career event because we are committed to giving back by partnering with schools for educational purposes and career enhancements.”

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

Artec 3D is an international company, headquartered in Luxembourg, with subsidiaries in the United States (Santa Clara, California) and Russia (Moscow). Artec develops and produces innovative 3D solutions and products. Artec has a team of professional experts in the collection and processing of 3D surfaces as well as biometric facial recognition. Artec’s products and services can be used in many industries, such as in engineering, medicine, media and design, entertainment, fashion, historic preservation, security technology and more.

For more information, please contact:

Steve Young

Exact Metrology, Inc.

11575 Goldcost Drive

Cincinnati, OH 45249

Phone: 614-264-8587

Local: 513-831-6620

www.exactmetrology.com

stevey@exactmetrology.com

Derek Williams, National Sales Director at REP Corporation, was recently featured in an article on Industrial Careers. REP Corporation is the world leader in injection molding presses for rubber and TPE.

For more information, please contact:

REP Corporation

8N740 Tameling Court

Bartlett, IL 60103-8146

Phone: 847-697-7210

www.repinjection.com

Attention: Tim Graham or Jim Wirtz

This new and improved addition to the Accu-Seal family is suitable for the medical and pharmaceutical industry

Accu-Seal, a wholly-owned subsidiary of SencorpWhite, the recognized global leader in high quality, end-to-end solutions for automated packaging, integrated AS/RS systems, and warehouse automation software, announced the immediate availability of its 6300P Series.

The seal lengths/width are 15, 20 and 25 inches/0.375 inches. The series features heavy-duty linear pneumatic seal actuation and high strength stiffened seal bar construction. A digital high-speed PLC controller is included with an LCD touchscreen. Optionally, users can choose to have a data acquisition system with the sealer. This would include seal parameter collection and reporting, as well as peripheral interface capability such as a barcode scanner.

Seal and temperature and pressure limit alarm settings are part of the 6300P Series. In addition, the sealer has thermal overload protection and is ISO 11607 compliant.

About SencorpWhite:

SencorpWhite, a Connell Limited Partnership portfolio company, is a leading provider of unique end-to-end solutions for the packaging and management of high-value inventory. The company’s products and services–which range from Sencorp brand innovative thermoformers, CeraPak and Accu-Seal brand packaging technologies to White brand automated storage and retrieval systems and Intek and Minerva inventory management software–cover the entire supply chain, from the point-of-manufacture through distribution and point-of-use. For more information, call (508) 771-9400 or visit http://www.sencorpwhite.com.

About Connell Limited Partnership:

Connell Limited Partnership is a family-owned business headquartered in Boston, Massachusetts. Connell has a history of owning and operating industry leading manufacturing companies that provide superior products, exceptional customer service and operational excellence to market leading OEMs. The Connell family is dedicated to supporting a wide range of philanthropic endeavors, with a large commitment to the medical field, including the William F. Connell School of Nursing at Boston College, the Connell and O’Reilly Families Cell Manipulation Core at the Dana Farber Cancer Institute, the Connell Nursing Research Scholars Program at Massachusetts General Hospital and the William F. Connell Emergency Department at St. Elizabeth’s Hospital. More information is available at http://www.connell-lp.com.

For more information, please contact:

Accu-Seal SencorpWhite, Inc,

225 Bingham Drive, San Marcos, CA 92069 USA | 760-591-9800 | sale@accu-seal.com

Attention: Davis Olney

E-commerce and retail sales continue to grow each year, yet warehouse operators struggle to find and recruit enough warehouse associates to keep up with the work. The Wall Street Journal recently reported that U.S. warehouses need to hire an additional 452,000 workers between 2018-19 amid record-low unemployment nationwide, just to meet the growing demand. Mobile Sort is designed to help operators rise to meet peak demands and challenges.

“Each-picking operations are under bigger-than-ever market pressure to pick faster and scale for peak seasons with fewer seasonal hires,” Jerome Dubois, 6RS co-CEO and co-founder said. “6 River Systems’ Mobile Sort improves throughput with a picking and sorting solution that is mobile and flexible, helping operators who are crunched for time, capital and resources balance performance and cycle times.”

Equipped with product images and put lights, Mobile Sort stations further assist associates to sort items into customer orders at industry-leading speed and accuracy. The entire solution, from robots to sortation and packout stations, is powered by 6RS’ machine learning that drives efficient picking and system performance. Not only does Mobile Sort improve pick rates, but it is also used to consolidate picks across different areas or automation into discrete orders; for example across mezzanine levels or from goods-to-person automation solutions.

“Mobile Sort is quick to setup and break down, and doesn’t require any permanent infrastructure,” Gillan Hawkes, 6RS VP of Product said. “Unlike traditional automation, Mobile Sort can be easily scaled up or down to handle seasonality and to reclaim precious floor space.”

With the addition of Mobile Sort, 6RS extends the value that their solutions offer customers—from their collaborative mobile robots, to order allocation, picking, sorting and pack-out. These solutions address existing gaps in the market today, specifically for third party logistics, B2B, fast-growing e-commerce and omni-channel retail operations.

“Autonomous mobile robots have done a great job of attacking the low-hanging fruit in fulfillment processes— movement of material” said John Santagate, Research Director for Commercial Service Robotics at IDC. “As the innovative vendors in this space have begun to scale deployments, they are now also developing complementary products that extend the value of the AMRs in the fulfillment process. Mobile Sort from 6 River Systems is a good example of an AMR vendor extending the capabilities and value of their products and offerings”.

The Mobile Sort solution will be deployed across leading 3PL and retail warehouse operations in time for peak 2019.

Attending ProMat 2019? Schedule time to view a demonstration of Mobile Sort from April 8-11 at Booth #S3983.

About 6 River Systems

6 River Systems was founded in Boston, Massachusetts in 2015 by Jerome Dubois, Rylan Hamilton and Chris Cacioppo. Jerome and Rylan were previously executives at Kiva Systems (now Amazon Robotics). The 6 River Systems engineering team has decades of automation, software and operations experience and has designed, built and deployed the world’s largest warehouse automation solutions. Leading 3PLs, retailers and manufacturers including DHL, XPO Logistics and Office Depot are using 6RS to fulfill millions of units a week.

6 River Systems is supported by world-class venture capital firms and strategic investors, including Menlo Ventures, Norwest Venture Partners, Eclipse and iRobot. Amy Villeneuve, former president and COO of Kiva Systems, is a member of the board.

Contact

Fergal Glynn, VP of Marketing, +1.866.602.4825

6 River Systems, Inc.

fglynn@6river.com

www.6river.com

More media

Mobile Sort Photo Gallery (Google Drive)

Mobile Sort Video Demo (Google Drive)

Continue reading

Leading supplier of fast hole EDM renews commitment to industry, seeks continued expansion of machine line and markets

The FH Series offers up to seven-axis fast hole EDM drilling capability for many applications, including aerospace, power generation, semiconductor manufacturing and more. Machines are entirely designed, engineered and built in the USA.

As company president Ed Beaumont explains, “We needed a fresh start and we were committed to making it happen, on every level, from our physical location to the machine offerings to the markets served and more.” And Beaumont Machine has done exactly that.

The company today announces the opening of its new manufacturing facility in the Cincinnati area, at 4001 Borman Drive, Batavia, Ohio 45103. Phone number is 513-701-0421. Website remains www.beaumontmachine.com.

Ed Beaumont continues, “I started the company over 25 years ago, had success in the aerospace industry here in Cincinnati and elsewhere. After five years of semi-retirement, I returned to run the company, with three goals in mind. I wanted to relocate the business to a larger facility, expand the machine line to offer more companies the benefits of our unique designs and, lastly, grow our consumables business, a key to long-term relationships with EDM customers, precisely because the wire, guides, electrodes, dielectric resin, filters, rotary unions, seal kits and more are critical components to keep the machines up and running.”

New building in Batavia, OH (Cincinnati) houses Beaumont Machine design, engineering, machine building, sales and service operations for the company.

As of today, all three goals have been met, resulting in more business for the company and an expansion into new markets such as semiconductor materials processing and land-based power generation, particularly turbine blades.

The consumable sales have ramped up, owing to Beaumont securing reliable partners and having the warehouse capacity to carry expanded inventories. Customers can now call on Beaumont for all their consumables needs.

“Though Beaumont machines are available with Fanuc or Siemens CNC controls,” Ed Beaumont explains, “our newest platform with Siemens allows us to create even more shapes with Realtime EDM. We bring them some pretty complex specs and they can always meet the challenges.”

Beaumont EDM machines are used primarily for precision placement of the cooling and gas flow holes in various products, from metering and diffuser holes on a jet engine turbine blade to large blade, seals, vanes and transition ducts on power gen equipment and more.

The company also provides customers fixture design, training, part programming assistance, engineering, turnkeys and vision system integration.

Ed Beaumont concludes, “It’s good to be back in the day-to-day operation of the business. It’s a passion for me and my team. We love solving EDM problems for our customers and will continue to push the envelope in machine performance.”

For more information, please contact:

Ed Beaumont

President

BEAUMONT MACHINE

4001 Borman Drive

Batavia, OH 45103

Phone: 513-701-0421

Web: www.beaumontmachine.com

Email: beaumach@msn.com

From L to R: Salvation Army Kenosha Board Chairman Tim Leach; Salvation Army Kenosha Auxiliary Captain Marie Lewis; Receiving the award on behalf of the Centrisys/CNP employees Jan Mosele & Carlos Contreras; President of Celebrate Our Town Cindy Nicoletti; Kenosha County Sheriff David Beth; Mayor of Kenosha John Antaramian.

Centrisys/CNP, Kenosha, Wisconsin is proud to announce that they have been recognized for their charitable contributions by the Kenosha Salvation Army. Centrisys was awarded the 2019 Other’s Award Recipient in the category of “Resources Supporting Others.” Jim Andresen, the company’s COO said, “By May 2019, the Centrisys/CNP employees will have contributed over $15,000 to the Salvation Army and the company matches match all of our employees’ contributions dollar-for-dollar.”

Established in 2017, Centrisys Cares is the company’s charity. They support the Salvation Army through two programs, Youth Program and Recreation Program and the Disaster Relief Services. Every year in May, the company hands over checks to the Salvation Army for the two programs.

The award ceremony, entitled “2019 Other’s Luncheon,” was held March 9, 2019 at 12 pm at the Bristol Oaks Country Club. Each award recipient received two complimentary tickets. Centrisys was represented by Jan Mosele, marketing assistant and Carlos Contreras, the HR manager at the company. All the winners received a plaque and had their picture taken. Commenting on the award, Mosele said, “We were thrilled to accept this award on behalf of our generous employees at Centrisys Corporation. For the past 20 years, Centrisys has been very proud to call Kenosha home, so we knew we wanted to sponsor a local charity and selected the Salvation Army.” She concluded, “It is truly an honor to call the Salvation Army our partner in giving.”

Centrisys Corporation is a U.S.A. manufacturer of dewatering centrifuges, sludge thickeners and complete dewatering systems for municipal and industrial wastewater. The company’s focus is centrifuge equipment, including the award winning THK sludge thickener. Centrisys provides global service, repair and parts for all brands of centrifuges. CNP – Technology Water and Biosolids designs and supplies nutrient recovery and biosolids treatment optimization systems. CNP’s key technologies are: AirPrex® and CalPrex™, phosphorus recovery technologies, and PONDUS™, a Thermo-Chemical Hydrolysis Process (TCHP). CNP is a division of Centrisys Corporation.

For more information, please contact:

Centrisys/CNP

9586 58th Place

Kenosha, WI 53144

262-654-6006

marketing@centrisys.com

www.centrisys.com

Leader in 3D and CT scanning for industrial, commercial concerns now representing premier German builder of CT scanner

The computed tomography scanner GOM CT provides 3D data of internal and external component geometries in exceptionally high resolution. The GOM CT produces the finest details visible throughout the component, simplifying initial sampling, tool correction and inspection tasks during production. It captures complex components including the “inner workings” in a single scanning process, so that the user receives a complete image of the test specimen for form and position analysis or nominal/actual comparisons. The system shows its greatest strengths when digitizing smaller plastic and light metal parts.

High-contrast X-ray detector and 5-axis kinematics

Data acquisition and evaluation in one software package

As with all GOM metrology systems, the control of the device, data acquisition and evaluation are combined in a single software package. This means that no further software is required; the chain from recording the raw data to creating the measurement report is greatly simplified.

Exact Metrology will house a GOM CT scanner at their Brookfield, Wisconsin location. Once there, it will be used for customer demonstrations and educational purposes, as well as contract scanning.

For more information, please see:

https://www.exactmetrology.com/metrology-equipment/gom-ct-scanner

Exact Metrology is an ISO 9001, AS9100 and ITAR Certified Company.

Exact Metrology, Inc.

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the country, is a comprehensive metrology services provider, offering customers 3D scanning, reverse engineering, quality inspection and product development. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

GOM GmbH

GOM develops, produces and distributes software, machines and systems for 3D coordinate measuring technology, 3D computed tomography and 3D testing based on latest research results and innovative technologies. With more than 60 sites globally and more than 1,000 metrology specialists, GOM guarantees professional advice as well as support and service. More than 14,000 system installations improve the product quality and manufacturing processes in the automotive, aerospace and consumer goods industries.

For more information on this development or to arrange a demonstration of the equipment, please contact:

EXACT METROLOGY, INC.

Steve Young

20515 Industry Avenue

Brookfield, WI 53045

Phone: 614-264-8587

Local: 866-722-2600

www.exactmetrology.com

stevey@exactmetrology.com

This Grieve cooling chamber has aluminized steel construction, ¼” plate floor and is sectioned to pass through a 72” wide doorway.

No. 807 has twelve (12) 24” x 24” x 6” thick HEPA filters installed at top of workspace to filter exhausted air.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, Illinois 60073-2835

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese

Minnesota CNC shop uses Heimatec speed increaser to up RPM and feed rate; significantly reduces cycle time on aluminum engraving application

On a recent project, where 5000 pieces of 6060 aluminum were to be engraved on a Hwacheon horizontal turning center, Kurt Engineering Manager, Shawn Eisenshank, had concerns over the cycle times. He turned to his local tooling distributor, Abrasive Specialists, Inc. (ASI) and their tooling partner, Platinum Tooling, for suggestions. Leigh Kinnan of ASI worked with the local Platinum Tooling representative, Cody Papenfus, to test run a Heimatec speed increaser, with the goal of increasing RPM on the machine and decrease part cycle time, with a documentation of the potential savings. After performing the calculations in consultation with Preben Hansen, president of Platinum Tooling and exclusive importer for Heimatec products in North America, it was determined a significant savings could be realized.

As Shawn Eisenshank notes, “This is one of those classic scenarios, where the theoretical has proven out in practice, as we’ve seen exactly the results ASI and Platinum Tooling proposed in their test calculations.”

Kurt Machining performs both vertical and horizontal milling and turning, complex assemblies and weldments, delivering with rapid lead times. CAD compatibility is offered for web-based communications and fully interactive manufacturing engagement for its customers. The company performs contract manufacturing in high quantity as well as prototyping for new designs. Kurt also performs impact extrusion, heat treating and cleanroom operations including ultrasonic cleaning of stainless steel and aluminum components and assemblies, with cleaning to Class 1000 with 100 protocol. The company is ISO 9001:2015 and AS9100D plus NADCAP Certified. Kurt Machining is quality certified by the U.S. Government to MIL-Q-9858 and MIL-I-45208.

For further information on the application discussed in this story, please contact:

Shawn Eisenshank, Engineering Manager

KURT MACHINING

5280 Main Street NE

Minneapolis, MN 55421

Phone: 763-572-1500

Fax: 763-572-9878

Web: www.kurtmachining.com

or

Preben Hansen, President

PLATINUM TOOLING TECHNOLOGIES, INC.

16 E. Piper Lane

Suite 128

Prospect Heights, IL 60070

Phone: 847-749-0633

Fax: 847-749-2445

Web: www.platinumtooling.com

Email: phansen@platinumtooling.com

Platinum Tooling Technologies, Inc. is the exclusive importer for North America of quality tooling from around the globe. The company currently represents Heimatec live tools and angle heads, Tecnicrafts collets and guide bushings for Swiss machines, Henninger spindle speed increasers for machining centers, AMF marking and cleaning tools plus Suzuki Swiss speed increasers. In addition, Platinum Tooling engineers application-specific specialty tools at its location in the Chicago area. The company is led by its president, Preben Hansen, a longtime veteran of the tooling industry and an acknowledged authority on machine tooling and accessories.

Continue reading