Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Global distributor Wesco and Siemens team up with local integrator to enable major Tennessee tire manufacturer achieve consistent tension, save money

As Chad Garner, a Nashville-based application engineer with distributor Wesco, relates, “We were presented with a significant challenge by one of our great customers, a tire manufacturer in the area. They needed to upgrade their multiple wire drawing machines for tire cord production in the plant.”

Garner goes on to explain in detail. “They were faced with very specific challenges. The machines needed to hold a very tight and consistent tension to meet the wire specifications. The company was using a ‘black box’ solution that had been custom-developed for them by a small local company that was no longer in business. The black box, in this case, originally allowed the user to dial in the tension on the wire without making any adjustments to the drive parameters. However, the system was now only able to hold +/- 500 grams of tension on the line, even after the customer had tested nine different control schemes to find a solution. Ideally, their goal was to replace the black boxes with off-the-shelf products, but their current drive and control supplier was not able to help satisfactorily. Wesco, in tandem with a local integrator and Siemens, was able to devise a solution, using standard Siemens components for the first line.”

The full solution to this challenge comprised a SIMATIC S7-1500 PLC plus remote I/O racks, SCALANCE wireless switches, SIMATIC HMI panels and, the heart of the solution, the SINAMICS S120 drive system, running 30 axes of motion control, plus various servo motors and other control products. All these components were supplied as a total solution to the integrator and the tire cord manufacturer by Wesco.

Thanks to the success on the first machine, three more wire drawing lines at the facility were upgraded with the Siemens solution, with more planned for future installation. A total of 120 axes of motion run by the SINAMICS S120 drives are currently in operation. The key to success here was the tight tension control programmed into the S120 drive control unit.

Chad Garner of Wesco further observes, “A major financial aspect of this project was the amount of money invested in the controls cabinet on each machine. The legacy PLC and Ethernet cards, if purchased from the previous supplier, would have cost approximately $30,000 and we were able to supply our better solution for about one-third that amount. This was not only a significant reduction in cost from the previous solution, but it also resulted in component reduction, as we were able to combine functions in fewer parts. The Siemens solution offered the customer integrated Ethernet on the PLC, so there was a reduction in expensive hardware, also achieving a smaller footprint in the plant.”

Matt Wagner, a Drives and Motion Consultant on the Siemens team, comments, “By replacing the old black box solution for tension control on these wire drawing machines at the tire manufacturer, our team, working in tandem with Wesco and the local integrator, was able to achieve all the required wire draw specs and do it with off-the-shelf solutions from the Siemens product lines. It’s exciting when we can exceed the goals of the customer, retrofit a substantial part of the manufacturing operation and save them a lot of money in the process. Can’t do much better,” he mused.

Using ANCA technology, SJ Tools can manufacture complicated tools for their clients with a reduction in cost and delivery time

Founded in 2015, SJ Tools is a Mexican company in Saltillo, Coahuila state that designs and manufactures cutting tools, tooling, special and standard inserts. SJ Tools offers solutions for milling, reaming, interpolations, drilling, endmills (spherical, toric, flat, double radius and barrel), drill bits (standard, step and shape) and reamer. A wide range of products are manufactured for the automotive, aerospace, medical, dental and agricultural industries. They offer services in Mexico and in the United States.

Recently, the company won the ANCA Tool of the Year competition with a cutting tool that combined multiple features into a single tool, all with very precise surface finishes.

Speaking about how SJ Tools developed their capabilities, CEO Edwin Juarez said they didn’t have the experience they now have at first and thanks to the customer with which they started with, they were able to create their first two-step combo drill tool carrier. Two inserts in the first diameter and four more in the second. Since they started supplying tools, the company wanted to demonstrate to its customers that tools are not always to blame for issues during production and that is why they have state-of-the-art quality machines to guarantee repeatability. In 2017, SJ Tools started sharpening and manufacturing carbide tools and purchased an ANCA FX5 Linear. Impressed by the results from the machine, SJ Tools decided to expand the number of ANCA Machines. Currently, they have four ANCA machines to manufacture and sharpen carbide tools. Two of them are MX7’s with robot, one is an FX5 with the AR300 Robot and one without. They use RoboMate for high volume tool production or FastLoad-MX for low-volume. Very soon, they will buy an ANCA machine for the sharpening of PCD. He added that “the great team around us makes SJ Tools grow day by day.”

The ANCA MX7 Linear is a powerful, versatile CNC tool grinder designed for production grinding. It is built to meet the demands of high output, high precision manufacturing. The 38 kW (51 HP) permanent magnet spindle provides high torque at lower RPM which is ideal for carbide grinding and a wide range of other applications. The MX7 Linear is a hard-working, high productivity system with unique features that enable it to handle varied batch sizes with minimum set-up time. The new cylindrical linear motor design increases reliability further and ensures a superior surface finish.

The FX5 Linear features increased spindle power provided by the new 12kW standard spindle and an additional option of 19kW, adding more flexibility in the tool room. Furthermore, the high-powered spindle reduces the production cost and increases net output across a wider range of tools.

Thirteen years ago, the director of SJ Tools heard about ANCA and five years ago, he requested a meeting with Mr. Russell Riddiford, the president of ANCA for North America, to present him with an ambitious project. Riddiford believed in the project and helped the company buy their first machine. Juarez explained that they decided to use ANCA because “SJ Tools is an innovative company that likes to have the best technology and ANCA is always innovating. We like that because we are walking the same path.”

Russel Riddiford said, “Since I first met Edwin and spoke with him about the initial project with SJ Tools, I’ve been thrilled about the partnership! SJ Tools is an exciting company, with a team full of innovators that are pushing the boundaries and the art of toolmaking in Mexico. Under Edwin’s leadership, SJ Tools continues to invest in new Tool and Cutter Grinding technology, allowing them to expand into new industries and to continue to push the limit of toolmaking.” He added that as expertise grows and word of mouth gets out, SJ Tools’ demand for products continues to grow and that ANCA is honored to be one of their partners.

The company uses a wide variety of ANCA products and software but the ones they like the most are ANCA Tool Compensation and ANCA Wheel Compensation. This helps a lot to reduce adjustment times. In addition, automation allows machines to continue working on weekends without an operator.

Thanks to ANCA, “We have manufactured complicated tools with customers who themselves are surprised that they are manufactured in Mexico since large companies have not wanted to manufacture or sharpen since very tight tolerances are required. We are very happy with our machines and our customers are as well as we have helped them reduce costs and delivery times.”

Juarez praises ANCA for several reasons, including its software, service, and staff. He commented that “The simple form of their software, the attention of their technical service in the United States and Mexico has been captivating us more and more.” He also highlighted the help of Russell Riddiford, stating that he is grateful for his support from the first moment.

Benefits of tools that have multiple functions in a single tool include reduction in cycle times, as well as reducing and optimizing the use of inventory space. Referring to the increase in the number of tools with multiple functions, he concluded, “In such a competitive market each and every one of the companies that manufactures seeks savings. This is why we need to innovate, develop, design tools and look for processes that give better performance to our clients’ tools.”

For further information, please contact:

Amanda Bakun

Marketing and Communications Manager, Americas

M: +1 248 497 1168

Amanda.bakun@anca.com

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

Edwin Juarez

CEO, SJ Tools

T: +52 8441226437

E.juarez@sjtools.mx

By Rich Guillemette, CEO, Guill Tool & Engineering

Guill is analyzing the latest market demands, combined with its extrusion die design expertise, to deliver solutions to its customers. Guill’s new Spiderless Pipe Die is an alternative solution, utilizing precision tooling to provide material savings vs conventional Basket Dies.

The global market for pipes used in irrigation systems, sewage systems and industrial applications is expected to grow in the coming years. According to a report by MarketsandMarkets™, the global market for pipes is projected to reach USD 23.5 billion by 2025, growing at a CAGR of 6.1% from 2020 to 2025.

The demand for pipes is driven by the increasing need for water and wastewater infrastructure, as well as the growth in industrialization and urbanization. These factors are expected to drive demand for pipes in emerging economies such as China, India and Brazil, as well as in developed markets such as the United States and Europe. The U.S. government has announced several infrastructure improvement plans aimed at revitalizing the country’s aging infrastructure, including its water and wastewater systems.

In March 2021, President Biden proposed the American Jobs Plan, a $2 trillion infrastructure plan that includes funding for a wide range of infrastructure projects, including the modernization of water infrastructure. The plan proposes to invest $111 billion in drinking water infrastructure, $45 billion in reducing lead exposure in drinking water and $56 billion in modernizing water infrastructure, including wastewater treatment plants and stormwater management systems.

What differentiates Guill’s Spiderless Pipe Die design over a basket die is Guill’s focus on precision tooling, developed from decades of experience in medical tubing, flow analysis and Guill’s ISO 9001 and AS9100 (Aerospace) quality systems. The significance of Guill’s Spiderless Pipe Die becomes clear when one considers material savings.

In general, the cost of the polymer raw material can range from 50% to 70% of the total cost of producing polymer pipes. The cost of other materials such as additives, fillers and reinforcements, “as well as the cost of energy, labor, equipment and overhead also contribute to the total production cost.

In some cases, the cost of energy, particularly electricity and natural gas, can be a significant part of the total cost of production, especially for large-scale production facilities. In other cases, labor costs in regions with high labor costs, can significantly impact the cost of production. Also a factor is that the cost of the raw polymer can be affected by market fluctuations in the price of oil, impacting the cost of petrochemicals used in the production of polymers. Additionally, the cost can also be influenced by supply and demand factors and global trade dynamics.”

Guill’s Spiderless Pipe Die is now available to meet the needs of its customers, as they consider all these factors required to be competitive in the production of pipes from 2” to 15” OD. This product was entirely conceived, designed, engineered, manufactured and CFD tested at the Guill factory in West Warwick, Rhode Island.

The Guill Spiderless Pipe Die incorporates unique design features to produce pipe more efficiently, according to company CEO Rich Guillemette.

For more information, please contact:

Tom Baldock

GUILL TOOL & ENGINEERING

West Warwick, Rhode Island

www.guill.com

+1 401 828 7600

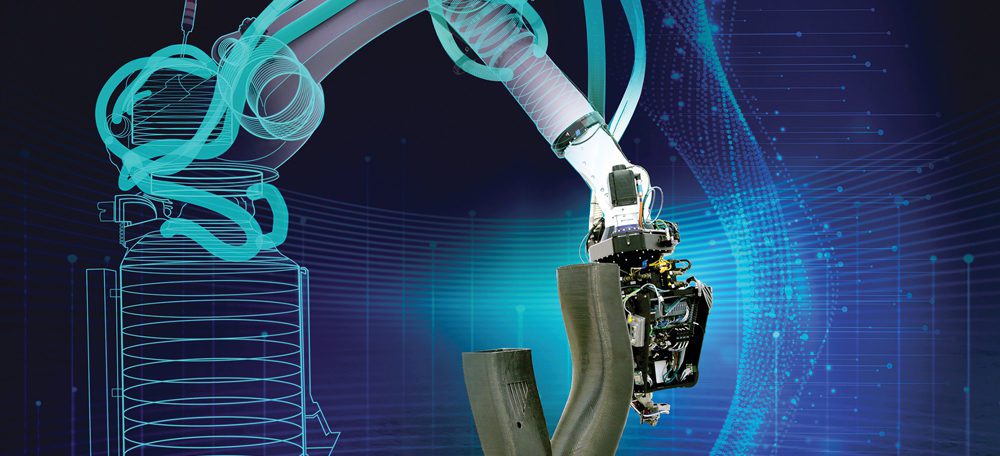

This industrial, true 6-axis continuous fiber-reinforced 3D printer enables tool-less rapid fabrication of aerospace-grade integrated composite structures.

Aerospace and defense design engineers and the complex components they develop require true manufacturing agility. Shepherding ideas from seeming impossibilities to sparks of inspiration to groundbreaking products that enable innovation can be both exhilarating and maddening. To iterate quickly and enable true collaboration, the fastest teams in engineering employ the Electroimpact SCRAM system powered by the Siemens SINUMERIK ONE CNC.

Helping to make the impossible possible, Electroimpact has integrated an in-situ out-of-autoclave thermoplastic Automated Fiber Placement (AFP) process, an advanced Fused Filament Fabrication (FFF) 3D printing process, a Fused Granulate Fabrication (FGF) 3D printing process, and subtractive machining into a unified Scalable Composite Robotic Additive Manufacturing (SCRAM) system. SCRAM is an industrial, true 6-axis continuous fiber-reinforced 3D printer that enables the tool-less rapid fabrication of aerospace-grade integrated composite structures.

High-performance thermoplastics combined with a high percentage of continuous fiber reinforcement are used to produce parts with exceptional material properties previously unheard of in the world of additive manufacturing. The enhanced performance of the 6-axis system offers unmatched dexterity and flexibility, enabling shapes, accuracies and intricacies not possible otherwise.

This technology has no equal in the industry and is a unique offering available only from Electroimpact. The capabilities and processing speed of the SINUMERIK ONE control empower Electroimpact engineers to achieve these breakthroughs in additive manufacturing.

Most 3D printing processes are more accurately described as 2.5D printing. The material is deposited successively in

flat slices, which when stacked together form a 3D object. In contrast, the SCRAM process renders true 3D printing.

Layers of continuous fiber-reinforced thermoplastic capably take the shape of complex contours, including aerodynamic surfaces and ducts for fluid flow. As a 6-axis process, fiber orientation within each layer can be tailored to the specific application, providing optimal strength and appropriate stiffness distribution throughout the part, much like a conventional AFP system.

In addition to the continuous fiber-reinforced thermoplastic printing process and the FGF support tool printing process, SCRAM cells are also fitted with two FFF nozzles optimized for deposition of thermoplastic material reinforced with short or “chopped” fiber.

A proprietary laser heating system is incorporated, producing exceptionally strong bonds between layers. This process is ideal for situations in which layering continuous fiber is geometrically impossible or otherwise does not make sense. “It allows us to deposit the material exactly where it needs to be and only where it needs to be, achieving the highest possible strength and lowest weight,” says Ryan Bischoff, senior composite engineer at Electroimpact.

This is a true 3D printing process where the layers are not simply a stack of planes. Complex geometries such as variable density core and other internal structures can be printed directly onto continuous fiber-reinforced layers with widely varying curvature. If desired, additional continuous fiber-reinforced layers can then be deposited on top of the chopped fiber-reinforced core structure, forming an upper skin.

The system is an integration of several additive and subtractive processes, combined with Electroimpact’s patented accurate robot, a rotating build platform and a climate-controlled build chamber.

Electroimpact then supercharges everything with the SINUMERIK ONE control from Siemens. “SINUMERIK ONE allows us to run more complicated code much faster,” says Kylie Martineau, Electroimpact controls engineer.

“Electroimpact expanded from doing mostly drilling and fastening to additive manufacturing about 15 years ago,” Bischoff says. “That move and the advancements over the years led to the development of a system that we call a ‘factory in a cell.’ Instead of needing a whole assembly line, with each dedicated machine only performing a single function, it is one system, which can be printing ducts for jet engines one day and a wing component the next. It can be quickly changed and adapted according to needs.”

The SCRAM enables the tool-less rapid fabrication of aerospace-grade integrated composite structures. This factory in a cell gives builders the option to produce low-run parts that make all the difference in their designs.

This might be a carbon fiber element for Formula One racing or a part made from a revolutionary alloy that is destined for space. For short runs or small runs, nothing can compete with this technology. “Here is where the factory in a cell helps teams develop parts much more quickly than a traditional facility. You complete the whole process within the SCRAM system. It makes sense because these are not the kind of parts that are produced in the thousands,” Bischoff says.

“Our customers are doing extraordinary work, and we are right there alongside them,” he adds. “Your Electroimpact engineer is with you though the lifespan of the system for all questions and requests. We are here to help builders push boundaries. We service our equipment till the day it dies. Support is one of the things that Electroimpact does better than anyone else in the industry.”

With the SCRAM system, 3D printing replaces the need for the traditional complex tooling development typically used for automated carbon-fiber layup. This eliminates the inflated cost and time investments needed in traditional tooling and development; therefore, the SCRAM system allows for faster corrections and modifications.

Once the complex tooling is printed, the SINUMERIK ONE control facilitates rapid changes throughout the process. First, the SCRAM system changes to a multi-axis milling head that finishes the form to exacting specifications. Then the SCRAM system changes once again to the 6-axis carbon-fiber placement head and applies the intricate pattern of carbon fiber tape to the support material.

Bischoff explains that the tape is deposited quickly, establishing the form. Next, the support material additive is then completely dissolved away, leaving behind a component in the exact shape the manufacturer needs.

“The knowledge that we’re able to dissolve the tooling without creating graywater brings us great peace of mind,” Bischoff says.

The SCRAM system, with the power of SINUMERIK ONE, also enables iteration. “We are working to make an open system that will support the material choices and make the parts each customer needs. We are driven by customer demand,” Bischoff explains.

Electroimpact engineers appreciate the advanced features of this next-generation control platform.

“The faster processor times for both motion control and PLC, combined with new functionalities of the SINUMERIK ONE, further enable the incredible work Electroimpact is doing with the SCRAM system,” says Steve Czajkowski, engineering manager at Siemens.

Brian Cubie, account manager for Siemens, agrees. “Our system is the foundation on which they are building, and it is just incredible to experience,” he says. “I have been in robotics for many years, and to see what the engineers at Electroimpact are doing in terms of digitalizing the factory floor is exciting. They are always at the forefront. Electroimpact does a phenomenal job of taking our new SINUMERIK ONE control and adding encoders for feedback and run it though their own kinematics.”

SINUMERIK ONE is built for high-speed processing that enables the accuracy needed for specialized parts. It is ideally suited to the SCRAM’s groundbreaking ability to shift from 3D printing to finishing and continuous carbon-fiber placement, all from one control.

SINUMERIK ONE makes product development faster, more flexible, and more efficient.

Looking towards the future, the SINUMERIK ONE control platform will take the SCRAM into advanced digital twin technology. This will help teams engineer a fully functioning machine even before a real-life prototype exists and for teams to transfer tasks from the real world to the virtual environment. It will keep projects moving consistently to the work preparation phase. Having SINUMERIK ONE as a built-in tool will help reduce overhead costs for projects and support.

“There‘s a huge industry push to having a digital twin,” Martineau says. “I am extremely excited about supporting SCRAM in our customers’ endeavors moving forward. Each customer is pushing what is possible. They are reaching for ideas that are slightly out of the ordinary. With this true digital twin, instead of needing to travel for an on-site visit or asking for photos or video footage of their challenges, the PLC will allow simulation right inside the control.”

Just as customers can run the digital twin from their computer, Martineau will be able to operate the digital control of a customer’s SCRAM right from hers.

“We hear from customers when they’re striving for the next level, pushing the system to the max. Being able to jump in and see what’s happening is so valuable,” she says. “The digital twin capabilities of SINUMERIK ONE will enable us to work extremely close to our customers in the future, supporting their desires to push the envelope of product development. With digital twin technology this accurate, customers will benefit from knowing we can jump in anytime to seamlessly help troubleshoot.”

Siemens and Electroimpact have been partners for more than 10 years. The SCRAM previously included the SINUMERIK 840D sl, a precision CNC control highly favored by the aerospace industry. SINUMERIK ONE is faster and excels at more complex code. With the advancements of the SINUMERIK ONE control, the possibilities are endless.

“Electroimpact is always pushing the envelope,” says Brian McMinn, head of the Siemens Machine Tool Systems business. “Their approach is to always be at the very leading edge of manufacturing technology. We are glad to be a part of their team as SINUMERIK ONE has the power and speed to make it all possible.”

Expect to see further advancements from Electroimpact in the next few years that raise the bar even higher for complex aerospace design and development.

The SINUMERIK ONE control will continue to evolve and support the next wave of design and development in machine building.

For more information and to watch the video, visit: usa.siemens.com/ei-scram

Recognized for significant contributions to the science of inspection and the advancement of the inspection profession.

East Coast Metrology (ECM): A Division of In-Place Machining Company is pleased to announce that Gary Confalone is the recipient of the 2023 ASQ Hromi Medal. Each year the American Society for Quality (ASQ) Hromi Medal committee recognizes individuals who have made noteworthy contributions to the science of inspection and/or the advancement of the inspection profession. Recipients of the award have contributed to the profession throughout their career by delivering products and processes to advance the state of inspection through test, calibration, cost reduction, and professional development.

Mr. Confalone’s contributions to the science of inspection began more than 30 years ago when he started his career as a Systems Integration Engineer at Sikorsky Aircraft. It was during his time at Sikorksy that his passion to improve the industry with more efficient technology was ignited. After joining the American Helicopter Society, he delved into the research for the production of the Army’s RAH-66 Comanche Helicopter and later received the Inventor’s Recognition Award from Sikorsky Aircraft for the development of a laser boresight system. A publication titled Laser Based Alignment, Advanced Manufacturing Techniques, detailing the advantages of this system can be obtained on the VTOL website.

After a decade of working to develop and improve laser-based metrology, he moved on to further advance the inspection sector of the developing laser tracker system through his work with Spatial Metrix Corporation. With a bachelor’s degree in electrical engineering and a master of science in mechanical engineering, Mr. Confalone founded East Coast Metrology (ECM) in Topsfield, Massachusetts, an engineering firm offering a variety of metrology solutions to a wide range of industries. ECM has since experienced exponential growth spanning the globe over the last 20 plus years.

In 2009, Mr. Confalone joined the newly formed Certification Committee of the Coordinate Metrology Society (CMS). This committee is comprised of industry volunteers who would work to later develop the industry’s first standardized metrology certification exam for both portable and stationary coordinate measuring machines. In 2021 he assumed the volunteer position of Chairperson of the Certification Committee devoting his spare time to assessing the industry requirements needed for achieving better standardized metrology processes.

In 2010, Mr. Confalone was elected to the CMS by his industry peers where he served on the Executive Committee assisting with the annual Coordinate Metrology Society Conference. The CMSC combines technical presentations from industry experts, hands-on workshops, and unprecedented training opportunities on the highest quality hardware and software in the field of metrology. In 2017, Mr. Confalone was elected Chairperson of the Executive Committee. This was a three-year voluntary commitment which involved Gary heading up the committee to oversee the society and the annual conference.

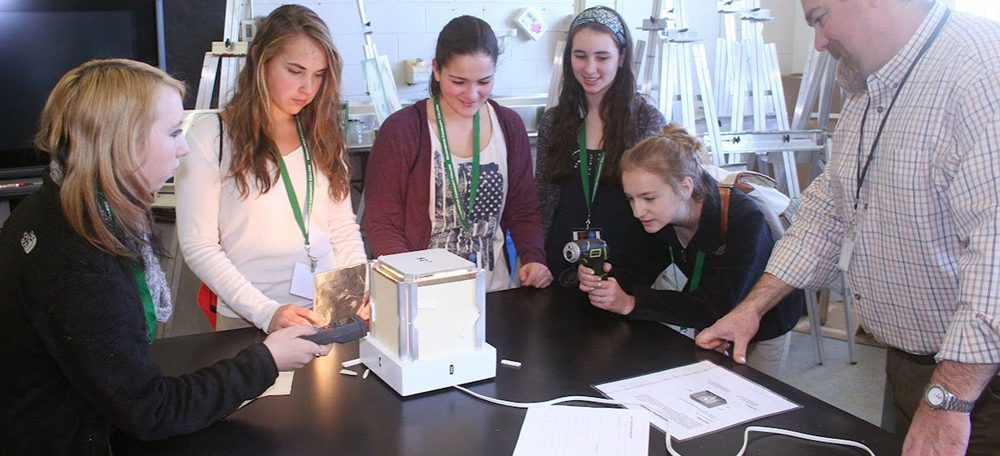

Mr. Confalone’s track record of contributions to the science of inspection is vast, however his passion for the advancement of the inspection profession lies in educating younger generations coming into the industry. He regularly brings ECM engineers to local high schools and colleges to speak with students about the opportunities in the field of engineering and metrology, including hands-on demonstrations of equipment in hopes of garnering student’s interest in this discipline.

Most recently, Mr. Confalone has co-authored and published 3D Scanning for Advanced Manufacturing, Design, and Construction. This highly educational book

provides a comprehensive introduction to 3D scanning and its applications in both the manufacturing and AEC industries. After establishing the history and basic principles of 3D scanning, it includes discussions of data collection and analysis and the many real-world applications of this technology. The book is currently available for purchase from Wiley Publishing.

In 2022, East Coast Metrology was strategically acquired by In-Place Machining Company (IPM) and is now part of their Measurement and Alignment Services Division, offering industry professionals one source for industrial metrology solutions. Mr. Confalone currently serves as Vice President of ECM and continues his initiative to advance the inspection industry by combining forces with OASIS Alignment Services and Exact Metrology, creating a powerhouse of metrology solutions from one source and is set to become the #1 metrology service provider in the world.

Mr. Confalone was awarded the Hromi Medal on Sunday, May 7th during ASQ’s Award Ceremony immediately prior to the start of ASQ World Conference on Quality and Improvement in Philadelphia, PA.

For more information on this development, please contact:

Mr. Alan Brown

Senior VP & GM – Field Machining

In-Place Machining Company

3811 North Holton Street

Milwaukee, WI 53212

Phone: 414-562-2000

abrown@inplace.com

www.inplace.com

In-Place Machining Company: On-Site Machining Solutions In-Place, Any Place in the World.

In-Place Machining Company is the premier provider of high-precision machining, large scale cutting and drilling, dimensional metrology, instrument calibration, and machine alignment services for a wide range of renewable energy, aerospace, industrial, and military customers throughout the world. Now with seventeen service locations across the U.S. and Canada, IPM has a breadth of service offerings that is unmatched in the industry.

Exact Metrology: A Division of In-Place Machining Company, is ISO9001, AS9100 Certified as well as ITAR Registered.

Exact Metrology is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 3d modeling. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

OASIS Alignment Services: A Division of In-Place Machining Company, a Leader in Precision Measurement, Machine Alignment and Mechanical Services

With a unique combination of tooling and services and a team of knowledgeable and dedicated engineers and field technicians, OASIS partners with customers to develop solutions specific to their precision measurement and machine alignments needs. Using a fleet of precision metrology instruments and mechanical tools, OASIS can provide full turnkey service from a North American network of service centers.

Company increases focus on additive manufacturing research and development to help accelerate transformation of American manufacturing

Siemens, a global leader in technology for additive manufacturing (AM) is expanding focus on AM initiatives in the United States to help accelerate the transformation of the US AM industry through serial additive manufacturing.

“We are on the threshold of a new frontier in American industry, where the implementation of additive manufacturing will bring fundamental changes to the landscape, end-to-end, from product to machine to manufacturing. Siemens is very excited to be at the forefront of this process,” said Steve Vosmik, Head of Siemens Additive Manufacturing in the United States.

Siemens is focused on supporting the domestic AM machine builder community, so is bringing its world-class motion control, automation hardware, digitalization software and technology capabilities to assist machine builders. From its Charlotte Advanced Technology Collaboration Hub (CATCH), located in Charlotte, North Carolina, Siemens will act as an ecosystem platform for machine builders, machine users and additive design engineers alike.

“More than 100 machine builders from around the world are implementing Siemens automation solutions to industrialize their machines,” says Rajas Sukthankar, Vice-President, Motion Control, Siemens Industry, Inc. He continues, “Now it’s time to support even more customers and accelerate their transformation from single machines to series additive manufacturing factories. North America is heading in this direction.”

Siemens can assist AM job shops as well as Tier One production facilities with end-to-end solutions, including product design software, digital twin machine simulation and virtual execution of manufacturing methods, with full data feedback into the design protocol for necessary adjustments, prior to any machine building. “This comprehensive suite of software and motion control hardware offerings makes Siemens a viable partner at every step of the AM process”, according to Vosmik.

Siemens is adding technology to CATCH to incorporate metal binder jet technology through the purchase and installation of an ExOne/Desktop Metal Production System and Meltio Robotic System with the Siemens SINUMERIK RunMyRobot application onboard. SINUMEIK RunMyRobot controls the kinematic path of an industrial robot as it integrates with the CNC machine.

Siemens is also establishing an Additive Manufacturing Advisory Board of renowned industry leaders in AM, drawn from various industries and technical disciplines, to provide the company guidance, as it seeks to support the fast-growing needs of the AM market. “We are looking forward to engaging and collaborating with this talented group of industry experts as we move ahead together into this exciting new world of manufacturing in America,” concludes Vosmik.

Visit the Siemens Additive Manufacturing website to learn how Siemens is accelerating transformation in the manufacturing industry.

Siemens Digital Industries (DI) is an innovation leader in automation and digitalization. Closely collaborating with partners and customers, DI drives the digital transformation in the process and discrete industries. With its Digital Enterprise portfolio, DI provides companies of all sizes with an end-to-end set of products, solutions and services to integrate and digitalize the entire value chain. Optimized for the specific needs of each industry, DI’s unique portfolio supports customers to achieve greater productivity and flexibility. DI is constantly adding innovations to its portfolio to integrate cutting-edge future technologies. Siemens Digital Industries has its global headquarters in Nuremberg, Germany, and has around 75,000 employees internationally.

Siemens Corporation is a U.S. subsidiary of Siemens AG, a technology company focused on industry, infrastructure, transport, and healthcare. From more resource-efficient factories, resilient supply chains, and smarter buildings and grids, to cleaner and more comfortable transportation as well as advanced healthcare, the company creates technology with purpose adding real value for customers. By combining the real and the digital worlds, Siemens empowers its customers to transform their industries and markets, helping them to transform the everyday for billions of people. Siemens also owns a majority stake in the publicly listed company Siemens Healthineers, a globally leading medical technology provider shaping the future of healthcare. In addition, Siemens holds a minority stake in Siemens Energy, a global leader in the transmission and generation of electrical power. In fiscal 2022, which ended on September 30, 2022, Siemens Group USA generated revenue of $18.6 billion and employs approximately 45,000 people serving customers in all 50 states and Puerto Rico.

Continue reading

After 32 years as president of GMTA (German Machine Tools of America), formerly American Wera, Walter Friedrich is stepping down, having appointed Michael Rose to be his successor as the new president and CEO at GMTA.

Mr. Friedrich was one of the first three employees when GMTA—American Wera at the time—was formed in 1991. He started his career at Pittler Maschinenfabrik where he advanced from toolmaker to NC programmer, eventually transferring to Chester, Connecticut in 1984 to support the North American operations of the company. He later joined Liebherr in 1986, where he was project manager within the automation group.

On January 30 of this year, he spoke with the company’s board of directors and decided to step down. The change was effective April 1st.

Mr. Rose brings twenty-plus years of machine tool experience to the new post, having been most recently employed as the Director of Sales for a leading German machine tool builder. Mr. Friedrich is confident that Mr. Rose is fully prepared to handle all his new responsibilities. “Michael’s experience within the Automotive sector as a Key Account Manager and most recently as Director of Sales, has prepared him well for his future responsibilities within GMTA. I’m sure he will continue the company’s expansion.”

Mr. Rose is grateful for this opportunity, adding, “My objective is to continue the tradition of excellence established by Mr. Friedrich, while at the same time creating additional growth opportunities for the organization.”

For more information:

German Machine Tools of America

4630 Freedom Drive

Ann Arbor, MI 48108

www.gmtamerica.com

ANCA’s dynamic new FX-RFID automated regrinding solution runs mixed tool batches lights out

Automated regrinding solutions have gained popularity among tool service providers due to their efficiency and cost-effectiveness in saving time, manual labor, and resources.

With the ANCA RFID (Radio Frequency Identification) regrinding solution, tools of various types and diameters and from different orders can be dynamically loaded, rather than having to sort them by diameter or customer as was previously necessary in mixed batches.

ANCA recently introduced its new FX-RFID solution, extending the popular RFID workflow to the FX Linear platform, unveiling it at IMTS 2022.

Andreas Sommer, ANCA Product Manager explains: “ANCA provides a range of automated regrinding solutions for mixed batches, including collet loading with Nikken collets. This entry-level solution is available on the FX5 with the AR300 robot and allows for the tool and collet to be changed together. The Loadermate software sets up a mixed batch of tools for unattended operation.”

Regrinding solutions to fit your needs

ANCA also provides the option of collet changing with RFID technology, which was previously only available on the MX platform. This feature has now been extended to the FX5 and FX7 models, allowing customers to select the regrinding solution that best fits their business needs in terms of both capacity demands and budget.

While some resharpening services aim to run their machines unattended for a brief period with only a small mixed batch of tools, many medium-sized companies seek to enhance their tool loading capacities and flexibility. ANCA’s RFID solution is designed to meet the needs of medium-sized tool service providers, enabling them to run their machines unattended for several hours, or even overnight.

How the RFID automation solution works

The FX-RFID solution uses two pallets and a pallet top with a maximum capacity of 88 tools. According to Andreas, “Regrinding an endmill or a similar cutting tool takes an average of five to six minutes. With a rate of 10 tools per hour, it’s easy to estimate the potential for unattended lights-out regrinding to increase machine utilization and productivity.”

ANCA’s Dynamic Tool Group Manager programming station enables preparation of any combination of tools from different customers for regrinding. With the RFID workflow, tools can be loaded into the machine without the need for pre-programming individual pallet pockets. The RFID and tool carrier can be placed anywhere on the RFID pallet top, and the tool holder’s RFID code is used to locate the assigned program.

Every tool will be assessed at the workstation, where skilled operators select and modify the required grinding program. The individual program reference is then encoded onto an RFID tool holder, which is placed in a pallet along with the tool for the grinding machine. Customer names and job numbers can be added to each tool holder, making it easier to identify the original customer order after grinding.

During the running schedule, tools can be added, removed, or rearranged within the pallet. The job will terminate when an empty pocket is detected, indicating the end of the pallet.

The RFID tool holder is then parked at an interchange station, and the tool is loaded for regrinding. Meanwhile, the robot picks up the next tool and scans the RFID code, all while the previous tool is being automatically reground.

Every FX machine with an RFID package comes with an extension to the machine canopy and is fitted with a Fanuc 200iD robot. The following components enable the dynamic loading:

Other highlights will include:

For further information, please contact:

Amanda Bakun

Marketing & Communications Manager – Americas

248-497-1168

amanda.bakun@anca.com

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

Guill Tool, the global leader in extrusion tooling, recently announced the availability of its Spiderless Pipe Die. This new offering utilizes precision tooling to provide increased material savings compared to conventional basket dies for pipe extrusions.

In the coming years, the global market for pipes used in irrigation/sewage systems and industrial applications is expected to grow. This increased demand for pipes is driven by the increasing need for water and wastewater infrastructure, as well as the growth of industrialization and urbanization. These factors are expected to drive demand for pipes in emerging economies such as China, India and Brazil, as well as in developed markets including the U.S. and Europe.

Used by tube and pipe producers for larger diameter capabilities, this new pipe die is capable of providing a finished extrusion with OD from 2”-15”. It’s offered in 4140 steel or stainless with heat treating.

The company’s Spiderless Pipe Die design differentiates itself from a basket die with its focus on precision tooling gained from decades of experience in medical tubing, flow analysis and Guill’s ISO 9001 and AS9100 (Aerospace) quality systems. The significance of the Guill Spiderless Pipe Die becomes evident when considering material savings.

In general, the cost of the polymer material can range from 50% to 70% of the total cost of producing polymer pipes. The cost of other materials such as additives, fillers and reinforcements, as well as the cost of energy, labor, equipment and overhead also contribute to the total production cost.

In some cases, the cost of energy, particularly electricity and natural gas, can be a significant part of the total cost of production, especially for large-scale production facilities. In other cases, labor costs in regions with high labor costs, can significantly impact the cost of production.

Also a factor is that the cost of the raw polymer can be affected by market fluctuations in the price of oil, impacting the cost of petrochemicals used in the production of polymers. Additionally, the cost can also be influenced by supply and demand factors and global trade dynamics.

Guill’s Spiderless Pipe Die is now available to meet the needs of its customers as they consider all the factors needed to remain competitive in pipe production. This product was entirely conceived, designed, engineered, manufactured and tested at the Guill factory in West Warwick, Rhode Island.

For additional information, please visit:

https://www.guill.com/series/900-series/

For more information, please contact:

Tom Baldock, Sales Manager, Extrusion

Guill Tool & Engineering

10 Pike Street

West Warwick, RI 02893

USA

Phone: 401-465-5526

tbaldock@guill.com

John Legleu, Exact Metrology Product Manager, provides insights into the advancements and benefits of CT technology, especially as it relates to the future of the aerospace industry

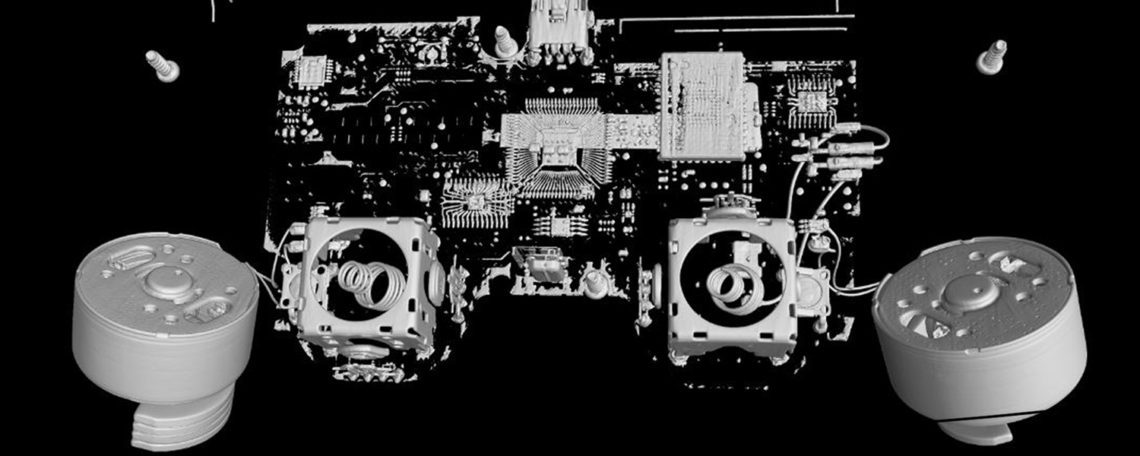

Computed tomography (CT), also known as industrial x-ray and industrial imaging, is used to obtain 3-dimensional (3D) results by placing an object on a rotational stage between an x-ray tube and x-ray detector, rotating the object 360 degrees and capturing images at specific intervals—such as every degree or half degree. For its services to clients, Exact Metrology uses CT technology in almost every industry, including aerospace, automotive, medical, injection molding, plastics, additive manufacturing and electronics.

Its most often used scanners are the ZEISS METROTOM 6 scout and GE V TOME XM 300Kv. The METROTOM 6 scout digitizes complex parts including the internal geometries at the finest level of detail. Users obtain a complete 3D image for GD&T analysis or nominal-actual comparisons. The metrology CT excels in digitizing very small plastic parts. The GE V TOME scanner is a versatile X-ray microfocus CT system for 3D metrology and analysis with up to 300 kV / 500 W.

According to Legleu, the technology offers numerous benefits, such as higher accuracy/resolution, non-destructive ways to obtain true dimensional data and scanning multiple parts in a single scan. In addition, CT scanning requires very little time to capture data and troubleshoot parts and also offers multiple uses with one scan (void analysis, inspection, volume, porosity, reverse engineering etc.). In contrast to conventional tactile coordinate measurement techniques, a CT acquires all surface points simultaneously —on even the most complex objects.

The technology does bring challenges with it, namely due to high-density materials that are difficult to scan. In addition, parts that have more than one material are challenging to surface. The size and weight of parts are also limited.

Legleu points out how CT has already evolved in the rapidly emerging additive manufacturing industry, making scanning faster, with higher resolution and better accuracy. Although used primarily in additive manufacturing to find porosity or unformed materials within printed parts, CT scanning can also be used to analyze the raw material for 3D printing, such as powdered metals or filaments.

He concludes by stating, “I predict that aerospace will begin to use CT exclusively to inspect all additive manufactured parts. Presently, CT is considered an “emerging technology” in aerospace but that is likely to change within the next few years. All predictions show a growth rate of 7.5% between 2021 and 2028, increasing from $460 million to $765.8 million.”

Exact Metrology: A Division of In-Place Machining Company, is ISO9001, AS9100 Certified as well as ITAR Registered.

Exact Metrology: A Division of In-Place Machining Company, with facilities in Cincinnati, Ohio, Moline, Illinois and Milwaukee, Wisconsin, plus affiliated offices throughout the country, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

In-Place Machining Company: On-Site Machining Solutions In-Place, Any Place in the World.

In-Place Machining Company, with seventeen locations across North America, is the premier provider of high-precision engineered on-site machining, in-shop industrial machining, metrology solutions, machine alignment, and large scale cutting & drilling services for a wide range of renewable energy, aerospace, industrial manufacturing, marine, and military customers throughout the world.

For more information, please contact:

John Legleu

11575 Goldcoast Drive

Cincinnati, OH 45249

Phone: 513-813-4207

Mobile: 513-504-8092

www.exactmetrology.com

johnl@exactmetrology.com