Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Take a few hours to gather some great information and ideas to make your 2015 a great year!

Come on over to Chemcoaters for networking, lunch and to see new and exciting things to amaze your customers!

When: Thursday February 26, 2015

Where: Chemcoaters, Gary, IN (more details below)

Time: 11:00am – 1:00pm

What:

“If you’ve been to a workshop before, this will give you more insight and get you even more familiar with everything we do and how you can use it to develop more business.”

“If this is your first chance to learn about Intercoat© ChemGuard, you’ll be amazed at how this can help some of your current customers, and just may unlock the door that has been locked up this point! Invest in yourself!”

Call Mike Tieri to reserve your spot for a fun, interesting and informative session!

Mike Tieri

Director of Sales Marketing

Chemcoaters, Inc.

700 Chase Street

Gary, IN 46404

Phone: 877-411-2905

Email: miket@chemcoaters.com

Website: www.chemcoaters.com

Connect with Chemcoaters online:

Longtime market leader in all-electric injection presses NIIGATA will introduce two new machines to the market at the upcoming NPE in Orlando, March 23-27.

Visit NIIGATA at NPE Orlando, Booth W-1363, March 23rd-27th with a free guest pass.

NEW: NIIGATA all-electric MDVR110S7000 (Vertical IMM with 2-station rotary table)

NIIGATA introduced the world’s first all-electric vertical IMM in 1996 and its latest model, the S7000, capitalizes on NIIGATA’s long history and 100% focus on making all-electric machines.

Highlights of the new MDVR110S7000 include:

~While many vertical machines have high table heights, forcing the customer to build a work platform around the machine, the NIIGATA patented vertical toggle system allows lowering the table height on this 110-ton model to just 3.4 feet from the ground, including leveling pads.

~The machine has a wider table than standard verticals, allowing larger molds to be placed on the platen. The MDVR110S7000 boasts a mold size capacity of 500mm x 500mm (33.64” x 33.64”).

~Fast table rotation of under 1 second.

~Ultra low-speed injection can be beneficial in molding thicker walled insert jobs. NIIGATA boasts an ultra low-speed capability of just .01 mm/sec injection speed.

~With a 2-station machine running separate “A” and “B” mold halves, a molder can often encounter problems with differences in mold halves causing part variations. With the NIIGATA Vertical, two completely independent injection profiles can be set for the “A” and “B” halves, allowing the molder to finish the job without making expensive and time consuming mold repairs or adjustments.

NEW: NIIGATA MD110S7000 horizontal all-electric IMM

Having introduced our first fully-electric machine at the Japan Plastics Fair in 1984, NIIGATA has devoted 100% of its R&D resources toward improving all-electric molding machine technology. Using the Japanese Kaizen system, we are now introducing our 7th generation of the all-electric machine, built entirely in Japan to tough quality standards.

A few NEW features of the MD110S7000 all-electric IMM include:

~Elimination of moving platen’s lower side tie bar bushings to improve the cleanliness of the part drop area.

~Addition of an FDA-approved grease supply system that allows medical cleanroom and food grade applications with fewer worries about part contamination.

~NIIGATA’s standard high nozzle touch force, similar to that of the hydraulic machines, can now be dialed down when the application allows, to promote longer sprue bushing life.

~Fully automatic and adjustable mold clamping force is continuously monitored by tie bar sensors.

~NIIGATA’s horizontal machines boast the industry’s shortest footprint, but heaviest overall weight to provide superior machine durability.

Also in the Niigata booth…

NIIGATA MD385W6000 all-electric IMM:

NIIGATA’s “workhorse machine”, the MD385 is being exhibited running a drink cup mold provided by a customer, together with an impressive IN-MOLD LABELING SYSTEM manufactured by Campetella of Italy. See and learn more about the MD385 HERE and at the show!

Also running during the show…

NIIGATA MD55S6000 all-electric IMM:

NIIGATA’s small size all-electric press will be exhibited at the booth of LUBE Corp. USA ( #W-2389). This machine will have clear covers, highlighting the automatic lube system of the machine. ( http://lube-global.com/english/)

Don’t forget! NPE, Booth W-1363

For more information on all these developments, please contact:

Peter Gardner

Vice President Sales and General Manager

NIIGATA Operations North America

DJA Global Group

939 AEC Drive

Wood Dale, IL 60191

Phone: 630.875.0202

Fax: 630.361.6060

E-mail: peter.gardner@niigata-us.com

Website: niigata-us.com

Connect with NIIGATA online:

5-axis cnc grinder with extended x-y axis paths plus two aux slides for workpiece clamping

Equipped with unique SIGSpro software system to allow full 3D simulation on the HMI or offline for more accurate quotes, complete cycle validation

New Schütte 325linear cylindrical grinding system features extended x-y paths plus two auxiliary slides

Schütte (Jackson, Michigan) today announces the introduction of its new 325linear machine, a 5-axis CNC grinder with extended x- and y-axis movement plus two auxiliary slides for workpiece clamping and improved grinding wheel guidance over the entire machining envelope. Micro tools, gun drills, hob cutters and complex geometries can be accommodated on this new machine, which operates in the range of 2500-4000 rpm, typically. The additional second auxiliary slide enables the 325linear to utilize tool guidance, part support, tailstock or workpiece pallets in operation. This new Schütte machine further expands the user’s automation possibilities, as it also offers significant advancements in wheel change and robotic workpiece handling.

Specifically, on the a-axis, a user can install collet chucks, hydraulic expansion chucks or multi-range chucks. With the automated collet changer on the machine, workpieces with different diameters can be clamped with high concentricity in the unmanned loader station. The Schütte a-axis configuration on this machine also permits position-oriented clamping of non-rotationally symmetrical workpieces. In this way, sequential workpieces with various roughing and finishing requirements can be preset on the machine for continuous processing.

SIGSpro (Schütte Integrated Grinding Software) enables full 3D simulation of the entire cycle, either on the HMI or offline, for improved estimating and safety concerns

Likewise, this new Schütte grinding system offers scalable automation, with a 140-position tool changer, 5-24 grinding wheel magazine and a flexible robotic tool gripper for changing the smallest micro tools as available options. The same base machine can be utilized for continuous production of a single part in a work cell setup or used for sequential one-off work, as needed.

The 325linear features a universal rotation a-axis with a high level of concentricity (<0.0001º resolution) and pitch accuracy, while the xyz-axis resolution is maintained at

The machine is offered with the proprietary SIGSpro (Schütte Integrated Grinding Software) as the programming interface, allowing users to assign clamping options for each grinding operation being performed. When the support and tool guidance system are used, preset distances from the grinding wheel to the workpiece can be defined and held constant. In the 3D mode, all cycle steps can be simulated, controlled and optimized for exact estimating, collision avoidance and even external workstation integration with the other workpieces.

Optional robotic handling, wheel changing and tool magazines allow the same machine scalable automation in use

All motion control on this new grinder is maintained on a Siemens 840D sl CNC with compatible drive technology.

This new Schütte 325linear grinding machine is available for viewing at the company’s North American headquarters in Jackson, Michigan, as well as a number of the upcoming trade shows in 2015.

For further information, please contact:

SCHUTTE MSA, LLC

4055 Morrill Road

Jackson, MI 49201

Phone: 517-782-3600

www.schutteusa.com

rfq@schutteusa.com

Sinumerik CNC ensures high-quality guitar craftsmanship

Fryer Machine Systems supplies an American guitar builder with milling machines for the production of high-quality guitars. Right-angle head compensation is essential to the accurate, repeatable milling of guitar necks — an easy task for the Sinumerik 840D CNC on board Fryer machines.

The challenge of repeatable product performance is not new to C.F. Martin & Company. Six generations ago, company founder C. F. Martin Sr. was confronted with managing a guitar-making enterprise that was producing totally handcrafted guitars, one by one, with little means for standardization. Since those days, guitar legends such as Gene Autry, Eric Clapton, John Mayer and new-comers Ed Sheeran and Hunter Hayes have relied on the consistently distinctive tone, treble and bass specific to Martin acoustic guitars. When Martin learned that its previous machine tool builder had exited the market, the company turned to Fryer Machine Systems for new machines to cover a production increase and seized the opportunity to upgrade the control technology with Sinumerik CNCs.

Larry Fryer (left) and Mark Bickert from Martin Guitar are satisfied with Siemens CNC technology, service and part quality.

Hands-on support in customizing the CNC

“We use right-angle head aggregates in our CNCs,” explains Mark Bickert, engineering project manager at Martin. “We needed to find a machine builder that could give us right-angle head aggregate capability in conjunction with right-angle head compensation and a high-rpm spindle.” Fryer Machine Systems has earned a reputation for building reliable production machines that come with unexpectedly advanced features and functionality. The company happens to be the largest purchaser of Siemens controls in the United States, and the customizable aspects of a Fryer machine can often be attributed to the versatility of the Siemens controls on board. This time, however, Martin needed to be certain that the new Fryer machines would perform as expected.

“Anyone can sell you a machine with a controller on it and say, ‘Here you go,’” Bickert says. “But that’s not what happened this time. We were buying a machine through a Fryer dealership, and the machine had a Siemens control. Siemens invested their time in us during our transition and set-up. They really excelled.”

Bickert says a potential constraint to the transition was that all-new milling programs might need to be written for the Fryer machines, including the right-angle head cutter compensation programs, which were essential. “Siemens not only gave us the right-angle head cutter compensation we wanted and the ability to do it properly, they also helped write the programs,” Bickert says. “They took the programs that we already had for cutting parts on our existing machines and reconfigured them to work in the Fryer machine with the Siemens controller.”

Guitar body castings now also machined in-house

Having made a smooth transition to the company’s new Fryer-built machines last year, Martin has not skipped a beat in its ability to perform right-angle compensation milling. Martin now has eight Fryer/Siemens machines, utilizing one for the guitar maker’s tooling and machinery operations and seven for various other guitar production operations. It is here, behind the scenes, that the company’s machinists reside and modern CNC technology and Old World craftsmanship come together to create the fixtures, tools and wherewithal that contribute to the mastery of Martin guitar making. It is also here that Martin found a way to bring previously outsourced operations in-house, a step that has improved repeatable production quality while reducing production costs. “The machining of our castings had been another hurdle for us,” says Terry Kline, Martin’s manager of tooling and machinery. Until the company invested in the Fryer machines with the Siemens controls, Martin had outsourced the machining of its guitar body castings, with inconsistent results. “Now we’re holding close tolerances on our guitar body castings,” Kline says. “The quality of the castings is consistently accurate.”

CNC technology meets craftsmanship

On a daily basis at Martin, Kline sees what is possible when CNC technology and craftsmanship work together. “Without CNC technology, we’d be still carving out all our necks by hand, and that’s just not efficient enough to compete in today’s world,” he says. The intersection of technology and craftsmanship has come naturally for this 180-year-old guitar company, without one side compromising the other. “I think every manufacturing company needs to embrace technology,” says Kline. “Technology and craftsmanship go hand-in-hand. People are amazed by how much handwork still goes into our guitars. We’ll build a neck and a body and then assemble the two elements together, which makes that guitar come to life.”

Right-angle head compensation is essential to the accurate milling of guitar neck components. The function requires the sophisticated Sinumerik 840D sl CNC and ShopMill software from Siemens. Guitar image courtesy of C.F. Martin & Company.

For more information on this story, please contact:

SIEMENS INDUSTRY, INC.

DRIVE TECHNOLOGIES – MOTION CONTROL (MACHINE TOOL BUSINESS)

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/cnc

Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communication

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

–

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Here it is – heimatec’s 2015 Show Schedule!

Check out all the places you’ll be able to learn about the heimatec advantage this year (Click the show name to see more about heimatec at the respective show):

February 24-26 | HOUSTEX Booth 209 | Houston, TX

March 17-20 | HAAS-Tec | Oxnard, CA

April 1-2 | Northwest Machine Tool Expo Booth TBA | Portland, OR

April 21-23 | PMTS Booth 936 | Columbus, OH

May 12-14 | EASTEC Booth 5137 (with Tom Paine Group) | West Springfield, MA

June 15-17 | WMTS Booth 129 (with Expertech Distribution & Technology) | Edmonton, AB

September 28-October 1 | CMTS Booth TBA | Toronto, ON

For further information, please contact:

Preben Hansen, President

HEIMATEC INC.

16 E. Piper Lane Suite 129

Prospect Heights, IL 60070

Phone: 847-749-0633

Fax: 847-749-2445

Email: info@heimatecinc.com

Website: www.heimatecinc.com

Energy production specialist MCE uses a simultaneous five-axis mill-turn center with Sinumerik 840D sl for producing model running wheels in one setting and thereby reducing throughput time.

MCE Maschinen- und Apparatebau GmbH CEO Gottfried Langthaler (right) and Buz Bozner, head of the Alzmetall Technology Center, agree: The efficiency of the Sinumerik 840D sl makes an important contribution to enabling simultaneous milling and turning in every position with the GS 1000/5-FTD.

MCE Maschinen- und Apparatebau GmbH in Linz, Austria, produces various components for large gas, steam, and water turbines, as well as for wind power stations and other segments of energy production. But before the company receives any orders for these products, realistic models must prove their efficiency, underlines MCE CEO Gottfried Langthaler: “It is therefore very important for us to be able to manufacture the turbine models in high quality and, at the same time, productively with a short throughput time.”

In mid-2010, the running wheels were still being milled individually on a five-axis machining center and then bolted or welded together. The average throughput time was six weeks. Thanks to a few technical tricks and the Sinumerik-controlled GS 1000/5-FTD from Alzmetall, which has been used in model production since the end of 2010, the machining expert Langthaler was able to reduce throughput time by up to one-third — to about four weeks, depending on the product. As a qualified master of mechanical engineering and design, he already knew before purchasing the Alzmetall machine that it would be ideal for his model production if a Francis turbine could be produced from solid brass: “I was merely skeptical that a machining center could do that. After all, we have to achieve a high roughing cut and smooth with maximum precision and surface quality.” Initial tests with the GS 1000/5-FTD revealed that the technical conditions were right. Langthaler adds: “Alzmetall also flexibly adapted the machining center to our needs so that we can meet all the requirements regarding accuracy and surface quality — in one setting if necessary.”

User-friendly CNC for milling and turning jobs

Because this machine must also perform turning tasks, in addition to milling tasks, at MCE, this requirement is also in the specification and is met by the GS 1000/5-FTD. Buz Bozner, head of the Technology Center at Alzmetall, explains the technical basis: “We integrated torque motors in all round axes. We therefore achieve speeds of 300 rpm in the c-axis.” The mill-turn center offers an enormous machining space that not even standard lathes achieve. Parts with a diameter of up to 1,000 mm can therefore be machined. A highlight of the GS 1000/5-FTD is that it can be turned to any round axis position and level.

The energy professionals in model construction have been relying on Sinumerik controllers since the mid-1990s because, according to the mechanical engineering boss Langthaler, these were always convincing, especially in complex five-axis machining: “The handling of Sinumerik 840D is also clear and simple on the ShopMill and ShopTurn graphical user interfaces.” The operator can work particularly easily and clearly when a GS 1000/5-FTD with the new Sinumerik Operate user interface is used. Operation and programming always have the same structure, regardless of whether milling or turning processes are to be programmed and set-up. The operator is also supported by graphical displays and animations. Many intelligent functions are available, which are helpful, among other things, for tool and workpiece measurement. The operation and programming of 3+2 axis machining is also supported by the integrated Cycle800 functions. Animated Elements simplify the explanation of functions such as selection of the direction and free running, as well as swiveling.

Another highlight of the new GS 1000/5-FTD is the Sinumerik MDynamics technology package, which is especially important for complex five-axis machining. Maximum surface quality and exact contour accuracy can be achieved even more rapidly. The key is in the new Advanced Surface intelligent path control, which contains an optimized look-ahead function and an optimized online CNC data compressor, among other things. The integrated intelligent jolt limiter relieves stress on the machine mechanics because it enables gentle acceleration and deceleration despite extreme dynamic response.

Customers reap the benefits

As a specialist in single-part and small-series production for small to large workpieces, MCE is equipped to meet even extraordinary demands on-time and with top quality. By equipping its machines with state-of-the-art Siemens technology, the company is able to achieve high throughput times in model production and pass these advantages on to its -customers.

For more information on this story, please contact:

SIEMENS INDUSTRY, INC.

DRIVE TECHNOLOGIES – MOTION CONTROL (MACHINE TOOL BUSINESS)

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/cnc

Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communication

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

–

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue readingMetal service centers and other key customers of Gary, Indiana coil coater hear company updates, enjoy great cigars and camaraderie

As Chemcoaters Director of Sales & Marketing Mike Tieri puts it, “We might not be politically correct, but we have a great time and it’s a very productive session, as the interaction is just what we wanted.” He’s referring to the ongoing Cigar Fest sessions, being hosted by Mike and Chemcoaters President Bill Capizzano, on a recurrent basis at a local area establishment in Countryside, Illinois, namely the Casa de Montecristo (www.casademontecristo-chicago.com)

Held every other month, Mike Tieri gathers 10-20 customers, mostly from the company’s metal service center base, to enjoy a meal, hear a presentation on the Chemcoaters service package of coil coatings, plus engage in a lively exchange of topics relevant to the business world of the service center, the market conditions and the future outlook for business development between service centers, their suppliers and their customers. The sessions conclude with an assortment of cigars and lively conversation. Tieri notes, “We have intentionally planned these events, so there’s a good mix of small and large firms, plus the service centers often bring their customers, so we gain that extra perspective on the market and we learn a lot about how to serve it better. Every session so far has yielded some great ideas for our customers and our company alike.”

Based in Gary, Indiana, Chemcoaters is a leading supplier of green coil coatings, as well as traditional prepaint and protective coil coatings, dry film lubes and RoHS-compliant coatings. Virtually no VOCs or HAPs are present in the process.

The company’s patented InterCoat ChemGuard® is formulated with trivalent vs. hexavalent chrome, making it environmentally friendly for all building, architectural and mechanical appliance applications. Superior corrosion resistance and documented cost reductions are provided, as well. Chemcoaters offers a presentation that evidences these facts to all interested parties.

Any companies interested in attending an upcoming Cigar Fest can contact Mike Tieri (details below).

For more information, please contact:

Mike Tieri

Director of Sales Marketing

Chemcoaters, Inc.

700 Chase Street

Gary, IN 46404

Phone: 877-411-2905

Email: miket@chemcoaters.com

Website: www.chemcoaters.com

Connect with Chemcoaters online:

Smiths Machine answered the recession with a formula for major change

So what’s the secret to their success?

To begin with, the omission of the apostrophe from the company’s name was deliberate. Being different is in the DNA of Smiths Machine. This is a second-generation, family-owned business that found a way to grow its workforce by 70 people during the last five years That’s a 300% employment surge that mostly happened during the recession, a time when many machine shops (and for that matter, many businesses), were struggling just to hang on.

Ahead of the recession, Smiths Machine did what many machine shops were doing at the time. They were riding the wave of automotive parts production and doing seemingly fine, until the massive downturn came. The bankruptcies of the tier one automotive companies suddenly left many machine shops vulnerable to volume-based supply from overseas competition; and a once well-oiled machine tool business model now seemed unstable and uncertain. Equally uncertain was the idea of moving the business in an entirely different direction.

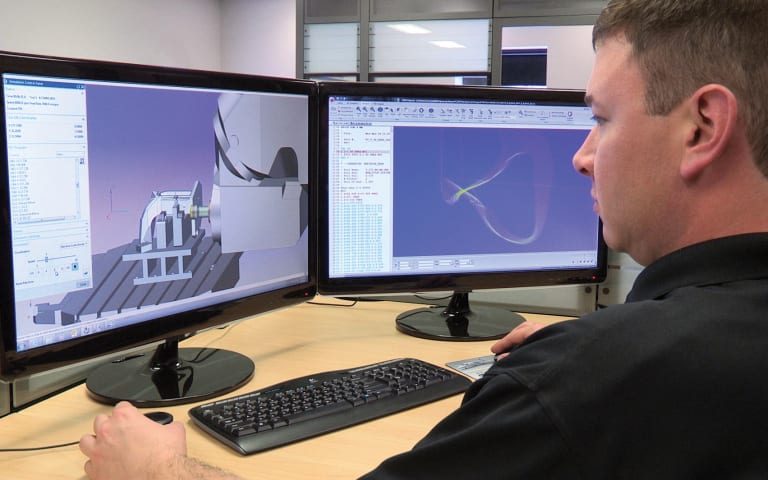

Manufacturing complex parts for the aerospace and defense industry, demands consistency, high-quality and precision — achieved only with Siemens CNC.

To be or not to be — different

Defense and aerospace part manufacturing require a different business approach altogether, says Tim Smith, vice president of Smiths Machine.

“It is specialized work that requires special approvals, log-down processes and complicated procedures,” Smith says. “The complexity is challenging. And it all starts with a different way of thinking, more of an engineering approach than a production approach.”

Smith says his company needed to build a new business model and the operations to support it. The defense and aerospace machining market is characterized by small lot counts, generally lower margins, and a very low tolerance for errors. Scrap rates thought to be nominal in the past would now be out of the question.

“You can’t make a $6,000 part and have a 30% scrap rate or even a 10% scrap rate,” explains Smith. “The emphasis is not on throughput, but on the high quality, highly precise manufacturing of very complex parts.”

Based on these three inseparable machining requirements — quality, precision and complexity — Smiths Machine set out to reach its greater potential in the machine tool market, not as a production machine shop, but as company focused on complex part manufacturing. Having achieved some early success in this new direction, the way forward for the company soon could be summed up more simply:

“The more complex the part, the more competitive we are,” says Smith.

To protect and grow this competitive advantage, the company’s leadership knew that their internal processes and technology needed to match up with the unique requirements of the defense and aerospace industries. Major investments in large, complex, five-axis machines would need to be enhanced by equally complex control capabilities. Smith recounts how a decision made previously by the company would now come into play in a profound way.

A backbone for change

Traditionally a milling and turning company, Smiths Machine first teamed up with DMG and Siemens in the year 2000 to establish their singular machine tool platform. This brought about a synergistic approach to complex milling and turning; an advantage that took on greater significance when the company decided to focus on the defense and aerospace markets later in the decade.

“Siemens controls were available on DMG milling and turning machines, and that was a natural fit for us,” Smith recalls. The DMG / Siemens platform has enabled Smiths Machine to establish and maintain a high level of operational proficiency. The central advantage here, Smith says, has been the ability to invest, train and keep his people moving forward based on a stable technology platform.

“The technology and the people using it are the backbone of our organization,” Smith asserts. “Even with 25 machines, we can share knowledge between the milling and the turning machines. The common control is a Siemens Sinumerik 840D sl. Our technology purchases are based on where we want to be in ten years, not on a workforce that is fractionally trained and a platform that can rapidly deteriorate due to a change in market condition or a change in employment condition.”

Smith says an example of this singular platform advantage is the control’s similarity across milling and turning operations. “All controls are customized to a certain extent,” Smith acknowledges. “But unlike Siemens, many other control series are individually customized so that the keyboard layout will be different from machine to machine. The Sinumerik 840D sl CNC is consistent. So when you train your operators, you can say, here’s the jog button, here’s the axes button, here’s your alarm button and your offset button. And this level of consistency extends to a graphical interface that really complements how we teach and learn.”

Teaching and learning are closely held values within an organization that uses a breadth of visual techniques to foster education, efficient information sharing, and quality control.

“We are a very visual company,” Smith says. “We use a lot of colors and we buy a lot of printer toner. Our parts inventory uses color-coded tags and the same is true across our production. We use yellows and blues and reds for consistent instruction. And the Siemens 840D sl control uses the same approach. You are guided visually for such things as axis direction, approach point, final depth and other variables inside a cycle. And this is true from control to control, for milling and turning.”

Smith says visually guided information flow is characteristic of today’s complex range of next-generation electronic communications, because this speeds understanding and information sharing. Whether for a smart phone or a CNC, graphically guided interfaces enable rapid learning and proficiency, a fact that has been well leveraged by the 840D control interface design.

Smiths Machine’s plan for stable growth started with its investment in a stable CNC platform: The steady progression of a stable machine / control platform has enabled the company’s similarly growing workforce to build on existing knowledge, rather than learn new and different versions every few years.

New angles on programming

Gerhard Hetzler, engineering manager at Smiths Machine, has experienced firsthand how the company’s singular platform approach has brought continuity to such manufacturing functions as post, machine simulation, NC code, and control functionality.

While the Siemens 840D sl control has evolved in significant ways over the years, Hetzler says these changes have served only to accelerate the performance of the programmers and operators, rather than impede them with new and different procedures. The control platform has also given Smiths Machine the freedom to create custom cycles that can be copied and shared from control-to-control, and so machine-to-machine.

“I’ll give you an example,” says Hetzler. “To catch occasional entry errors on the tool management side, we created a cycle that checks the length of the tool and within a specific tolerance. So within in a matter of milliseconds, the control compares that value to what was entered in the tool management side, and if the tolerance is exceeded by 2mm, the control immediately stops the machine.”

Hetzler says another advantage resulting out of the DMG and Siemens relationship is the continued simplification of complex cutting operations, especially in the area of angular milling heads.

“Siemens has come a very long way to improve the cycles and support related to milling heads,” Hetzler says. “Aerospace requires a lot more use of angular milling. Even a five-axis approach can’t do it. You need an angular milling head. I would put this on the top of my list of the advantages DMG and Siemens have developed. And this relates to another important development, Siemens NX.”

NX as in next

Siemens NX software integrates CAD, CAE and CAM for faster part manufacturing, encompassing all areas of tooling, machining and quality inspection. NX has become integral to Smiths Machine’s CNC platform, because it supports part planning through manufacturing, with the prevention of errors and related costs.

“Our ability to develop all of our own post-processors in house is supported by Siemens NX,” Hetzler explains. “We setup our angular milling heads in NX, so we can post the G-code before we even send it out to the machine.”

An early introduction to the power of NX came when the company found that it needed to write code to produce an especially challenging aerospace landing gear. The code took six-weeks to manually program. This was before the company learned that it could do the same task in nine days using NX.

“Siemens knows five-axis machining and NX is a Siemens product that leverages five-axis,” Hetzler says. “As an example, we can do three-plus-two axes work in NX. There is a cycle for that called Cycle 800. So when NX outputs the NC code, the machine then also understands it. Other control brands will have a cycle that can be made to work, but they are a lot more problematic. We are talking about managing the change of plane, a concept that has been around for a long time and was always problematic to do. Now Cycle 800 in NX does it all for you.”

Hetzler says Cycle 800 makes programming the change of plane easier, faster, and with higher accuracy than traditionally calculated methods. “We would normally round off after the third or fourth decimal,” he recalls. “Now the control calculates to nine decimals. When you start talking microns, especially in the aerospace industry, it makes a huge difference. And this difference has been fully implemented by DMG. They have invested a lot of time and money to make sure from their side that Siemens NX and Cycle 800 work 100% of the time.”

The Cycle 800 function within Siemens NX supports the programming of 2-1/2 axis and 3D milling throughout the rotation of all X-Y-Z planes, while maintaining a zero offset. Functions include automatic shifting of zero offset, tool length and radius compensation in rotated planes, compensation of machine geometry, and all machining cycles can be used.

Please forward all inquiries to:

SIEMENS INDUSTRY, INC.

DRIVE TECHNOLOGIES

MOTION CONTROL

MACHINE TOOL BUSINESS

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/cnc4you

Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communication

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

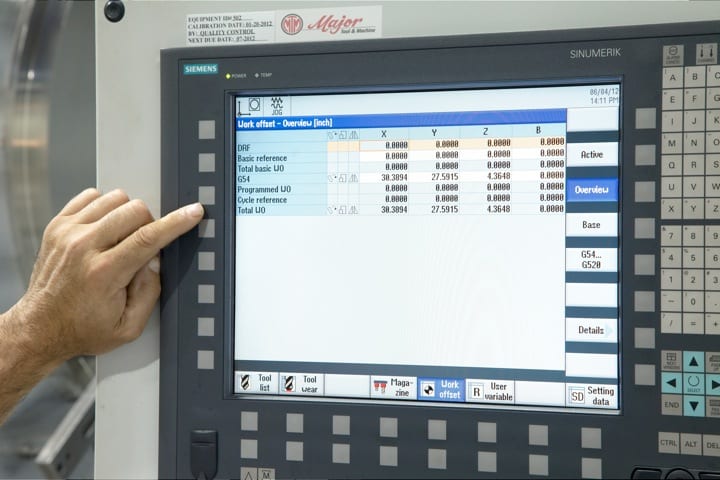

Continue readingMajor Tool & Machine, Inc. retrofitted two of their machining centers in 2010 changing to a CNC technology platform that was completely new to the company. Ten more such large-scale retrofits have followed, bringing increased enthusiasm, momentum and productivity.

Major Tool & Machine has been on track to retrofit over a dozen of its giant milling and turning machines within just two years, all supported by a new Siemens CNC platform. MTM’s management says the process has been an empowering experience for the company.

CNC upgrade enhances performance and precision

Major Tool & Machine (MTM) is a large job shop, producing precision milled and turned hardware throughout the company’s 500,000 square foot Indiana facility. Performance is essential, because MTM contracts with aerospace, energy, nuclear and defense companies on many mission-critical, one-off projects. Owner and CEO Steve Weyreter will tell you openly, MTM is more competitive by way of a significant CNC technology change, starting with an aggressive retrofit strategy.

Günther Zimmermann, CNC Controls Engineer at MTM, says the company’s retrofit program and the decision to change to the Siemens SINUMERIK CNC platform have brought a new enthusiasm and momentum to the company. Over the last two years the change has also brought significant time and cost reductions, especially in the areas of programming, maintenance engineering, and machine operations.

“The initial goal in early 2010 was to retrofit two Cincinnati U5 Gantry machines,” Zimmermann recounts. “We evaluated two CNC technology platforms and after considerable analysis our CEO Steve Weyreter announced that Siemens would best support the company’s future.”

The decision to reduce costs by moving to a single CNC platform was the least difficult decision for the company to make, Zimmermann explains. The larger challenge for MTM was the integration of a new CNC technology platform that was new to the company.

Bill Henderson, MTM’s manager of large machining and maintenance, agrees that the decision to change to a Siemens CNC platform integrated with advanced part and tool probing was critical, because the shop manages constant changeovers from one complex job to the next, making setup times a critical time/cost constraint for the company. Another big advantage is the increased flexibility by only having to train machinists and maintenance personnel on one type of control.

Henderson went on to say “the decision to change to a new control has signaled higher expectations for the company, along with new challenges for those who program, operate and maintain the company’s big machines.

Naturally, there’s a resistance to change,” Henderson says. “People are comfortable with what they normally run, but after our discussions with the people on the plant floor, they understood the overall objective. Our retrofit program is not finished, yet it’s already showing tremendous benefits.”

An advantage MTM gained by its retrofit strategy has been the ability to interchange heads and rotary tables from machine to machine. Easy-to- use head storage and tool management programming provided by the Siemens CNC platform support the new interchange capability.

Retrofitter Doug Huber says having Siemens as a new CNC technology partner has made a difference for Major Tool & Machine, but it’s also been an evolutionary uplift for his own retrofitting company, Indiana Automation.

“Indiana Automation has increasingly retrofit using Siemens controls in recent years, Huber explains. “On a retrofit, we always try to exceed what the original machine could do, and that’s just kind of inherent when you put on a Siemens 840D. Major Tool’s first retrofits were the Cincinnati U5 machines, a bridge model and two gantry models. These are five-axis machines and five-axis is the 840D’s forte. The processing power of the control is so much better, that it just whips through the blocks faster. So right off, cycle time is a major performance enhancement.”

Huber says something else happened this time. As his firm finished retrofitting the first three giant machines with Siemens five-axis controls, drives and motors, the reaction within the company was not just that the machines were now predictably more efficient, but that they performed as very different machines. A new advantage is the ability to interchange machining heads from machine-to-machine, and all driven by the Siemens CNC platform.

Central to MTM’s retrofit program has been the Siemens SINUMERIK 840D sl control, which features the SINUMERIK Operate interface. The highly intuitive interface enables both programmers and operators to easily capitalize on the broad capabilities of the control.

“On many of the U5 machines, the axes come off with the heads,” Huber explains, “and we rebuilt these machines to accept any one of three different heads. That’s one of Major Tool’s key strategies. They insist on having flexible machine capabilities, so that they can run all kinds of different parts. They have straight heads for serious metal cutting, contour heads for five-axis work and finesse work. They have 90-degree heads for more flexibility than a straight head, but it’s also not as fragile as the contour head. And they wanted to interchange all of these heads to automatically go pick up a head out of the shuttle and, on the fly, reconfigure the axes and the zero positions. To do this, the compensation tables all had to be updated. Everything needed to be done with the macro program so that each head came on ready to run.”

The interchangeable head strategy was a challenge, Huber says, because the machines were not originally capable of sharing heads. But with support from Siemens, the strategy has worked, including the ability to interchange rotary tables as well as heads. “Each head or rotary table has a configuration file that has all the settings and compensations and travels with it from machine to machine. So now when you mount that head the control just runs the configuration file that goes with it and its all set up for you. We also incorporated Siemens Tool Management for each machine’s 60-pocket tool chain. We used the feature on these machines to manage all the different tooling MTM uses, both in the automatic tool changer as well as the ones manually loaded.”

Huber says, “MTM’s ability to smoothly transition to more advanced CNC is largely due to the HMI’s ease of use. The Operate interface is a huge help to us and to Major Tool. The HMI helps make better parts. And it didn’t take very long for the operators to fall in love with it.”

Programming as easy as 1-2-3: Using the SINUMERIK Operate interface, a machinist can turn on coolant flow by 1) pressing Cycle Stop to stop the machine, 2) Coolant On, and 3) Restart.

“I had never used a Siemens control before,” admits MTM machinist Mike Burthay. “I have extensive knowledge of G-code and CNC controls and I would say the Siemens 840D sl with the Operate interface is the easiest one I’ve ever run. It’s user friendly, that’s exactly the words for it.”

Burthay reports several ways in which the Siemens SINUMERIK Operate interface has made his life easier. “There’s not as much G-code,” he says. “The control does it all for you as long as you put in the parameters as to size, length, width. Then once you’re in Job Mode, there’s a screen where you can tool change or jog the machine around to certain positions, or turn the spindle on, turn the coolant on, anything that traditionally required G-code. So now you can push a cycle stop button to pause the machine, enter a change such as turning coolant on, then restart the program.

“Another function I love is Block Search, which allows me to start or restart right in the middle of a program. Say you’re finishing a pocket and you have to run the tool two or three times to get a tight tolerance, I can enter in a line number and hit Block Search, the control picks up every line before that, restarts the spindle and everything for you.”

Burthay says the Siemens control also enables him to program parts right on the machine whenever necessary, using a simple yet robust program called ShopMill. “I can go into ShopMill, type in some parameters and it will kick out that G-code program for me automatically. Say I want to drill a hole two inches deep. I open ShopMill, pick my tool, tell it the depth and these steps are all interactive on the screen. It even shows me 3D motion images of the tool path, confirms the drill going down as expected into the part. So I hit go and it puts a drill cycle into the program for me.”

Programmed for collaborative growth

Lead Programmer, Tim Hayden, has from the beginning conducted all processor setups for the newly retrofitted machines. Hayden says integrating the Siemens CNC platform has been an empowering experience he had not expected, given the fact that he had never before set up a post processor to run a Siemens control, nor had he ever before operated a Siemens control.

“Now, when I look at the Siemens control, I think man, it would have been so much better to have had it all along,” Hayden says, “because the other control I’ve been using is just a lot more cryptic. The Siemens control with the SINUMERIK Operate interface is more powerful for writing macros and the language seems modern, whereas the other control seems like it is still based on an old FORTRAN type language.”

Work offsets for compound angles can be scaled and rotated using the Frames function of the Siemens SINUMERIK Operate interface. Many advanced machining operations can be managed simply, without the use of time-intensive manual G-code programming.

Hayden points to the Frames coordinate and offset programming function of the Siemens interface as an example of improved programming convenience.

“We do a lot of work on compound angles,” Hayden explains, “and with the Siemens Frames function, you can scale and rotate your coordinate system on the control, just plug it in with your work offsets. Whereas, on the other control you will see a G54 request, you’ve got to enter G-code. You can’t just plug it into your work offsets like you can with the Siemens control.”

Hayden says the SINUMERIK Operate interface brings greater programming flexibility. The HMI enables him to enter G-code using a comparatively more advanced manual data entry (MDI) function; however the HMI has all but eliminated the need for G-code entry by way of its intuitive design and evolved capabilities.

Another example of such HMI evolution is in the area of data management.

“When we post a program, we no longer have to use a G-code based MDI,” Hayden explains. “We no longer need to type in T= and enter a nine digit number and then enter M6 to make a tool change. With the Operate HMI, you pick your tool off a screen and hit cycle start. It’s just as easy to program going to a position. Instead of doing things the old way by typing G0X0Y0Z0 into the MDI, you open the Operate interface, click position, then click how you want to wrap it and then you just type the numbers into those fields. So it’s a lot more user friendly.”

Hayden says the Siemens CNC platform has supported greater collaboration at MTM between him and the machinists, and this is helping the company find ways to increase performance and efficiency. He agrees with his coworkers’ assessments that shorter setup times and greater operator freedom are making a significant difference.

“One of our production bottlenecks has been programming,” Hayden says. “The machinists that run our machines are professionals, they’re not button pushers, and with the SINUMERIK Operate interface, we can now rely on them to control and program certain parts right on their machines, while we programmers work on the more complex projects.”

“Siemens was the best fit for all of us,” Hayden concludes. “Siemens CNC is set up as an open control, and with that kind of flexibility, it seems anything is possible.”

For more information on Siemens SINUMERIK CNC, visit www.usa.siemens.com/cnc.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

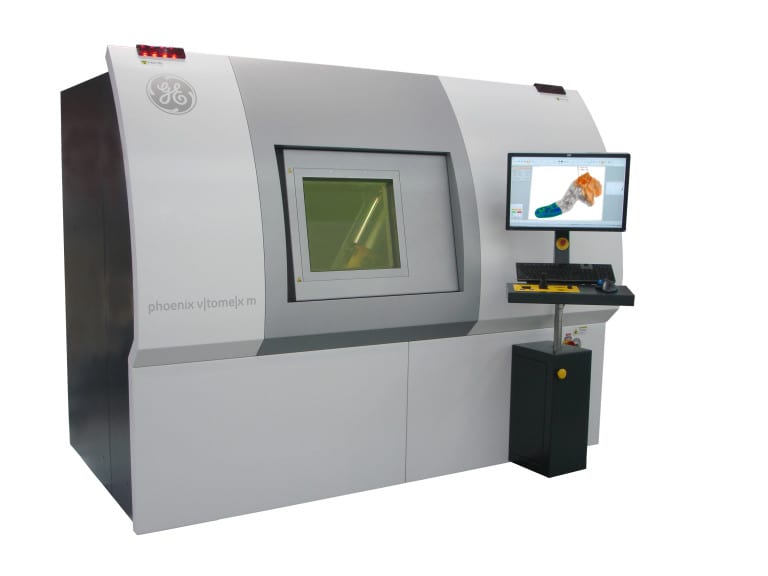

Will enable measurement to 2 microns, even on denser parts

Exact President Steve Young notes, “We bought the new system because it has significantly greater accuracy, better detail and great reliability. Exact is currently seeking users for this new system.” The system has already received operational approval from the state of Ohio and is installed at the company’s main facility in Cincinnati.

The Phoenix v|tome|x m system features a unique temperature stabilized detector array (up to 30fps) for extremely fast CT data acquisition on workpieces up to 500 mm diameter and 600 mm in height, weighing up to 50 kg (110 lbs). Typical functions performed on this system might include 3D analysis of a scanned turbine blade, automatic pour porosity volume analysis on an aluminum casting and 3D measurements with nominal-actual CAD comparisons on a machined aluminum cylinder head.

With full CT automation, click & measure capability and the dual tube technology, this new system can perform analyses on an extremely wide range of samples, from high-resolution nano CT of low-absorbing samples to the high-power micro CT applications such as engine turbine blades.

Other applications for possible utilization of this new system at the Exact Metrology facility include light metal castings, electronic assemblies, thermoplastic molded and composite parts, plus all types of machined metals.

Compared to conventional tactile or optical CMMs, this new scanner system can generate a first article inspection report including internal dimensions in less than one hour, with high accuracy and repeatability.

Utilizing the GE Phoenix Datos|X CT and Volume Graphics software platform further enables full automation of the system at Exact Metrology, thereby reducing the time to perform the testing procedures.

Exact Metrology is an ISO 9001:2008 Certified Company.

To see videos on this new scanner’s capabilities, please visit:

VG GE casting analysis with CT hi-res at Exact Metrology

v | tome | x m CT scanner at Exact Metrology

For more information on this new system or to arrange a demonstration, please contact:

EXACT METROLOGY, INC.

11575 Goldcoast Drive

Cincinnati, Ohio 45249

Phone: 513-831-6620

Toll Free: 866-722-2600

www.exactmetrology.com

stevey@exactmetrology.com

Steve Young, President

—

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.