Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Increasing demands made on precision and the push for the decrease of price of modern components is pushing traditional manufacturing processes. EMAG offers three production technologies that complement or replace traditional processes such as turning, milling and grinding.

PECM for nickel- and titanium-based alloys

The ECM process is used to deburr components only at the points where material needs to be removed, and without it having any mechanical or thermal impact on the workpiece.

With its PECM technology (Precision Electro-Chemical Machining) EMAG presents a production process that opens up completely new fields of application. PECM is a process for the machining of high-alloyed materials, such as nickel- and titanium-based alloys. The disadvantages of traditional metal cutting – tool wear, mechanical stresses, micro-fissuring caused by heat, oxidization layering and the need for subsequent deburring operations – are eliminated, because this process is a non-contact one without heat input. All electro-chemical machining processes are characterized by stress-free material removal, smooth transition points and surfaces without ridge formations.

The ECM process is used to deburr components only at the points where material needs to be removed, and without it having any mechanical or thermal impact on the workpiece.

The advantages that the PECM process provides for different branches of industry are best shown with the example of a turbocharger for the automotive industry. The electro-chemical process is one that can be used to effectively in the machining of many high-alloy components, especially those in the high-temperature sector of the turbocharger – it also offers a much shorter and very efficient process chain. The typical clean-up operations necessary when traditional machining processes are used – such as deburring after milling – are no longer necessary. PECM machining operations are burr-free. And there is hardly any tool wear. The result: downtimes are minimal, when compared to milling (which requires regular tool changes). The process as a whole is sturdier and less prone to errors. And another important factor that our example of the turbocharger shows: the superb surface finish of the PECM process, where Rz-values of 0.3 micron can be achieved.

Will camshafts ever again be made of a single piece?

Another highlight is EMAG’s heat-shrink assembly technology, a process that scores particularly well in camshaft production. The high degree of precision achieved with the joining process drastically reduces the number of cam profile grinding operations or – with the use of precision cams – avoids them altogether. Another benefit of the process is the ability to combine different materials in the construction of the shaft, such as forged cams (e.g. in 100Cr6) and sintered cams, which do not require regrinding. Accessory components, such as plugs and end pieces, can – like the shaft itself – also be made of better materials. This allows for the camshaft to be adapted to the requirements of the engine and to be optimized in load bearing capacity and manufacturing costs.

Operating costs reduced by 50 %

Production laser welding is already a highly productive process in the manufacturing of gearwheels. The use of diode-pumped solid-state lasers – such as disc or fiber lasers –reduces operating costs by up to 50%. EMAG has been involved with the use of solid-state lasers in the welding of powertrain components from an early stage and is considered a pioneer in the technology. EMAG again has fulfilled a promise to their users offering them the lowest possible cost-per-piece, by coming up with an innovative technology that brings true cost benefits.

For many applications, solid-state lasers allow welding without shielding gas. This not only reduces operating costs, it also avoids having to follow the annoying logistics imposed by the use of shielding and laser operating gasses. In many cases, the welding process can also be sped up considerably. This increases productivity and – through a reduction in energy input per unit length – reduces welding distortion, resulting in better component quality.

For more information:

Kristal Kilgore

EMAG LLC

38800 Grand River Avenue

Farmington Hills, MI 48335

Tel: (248) 875-0313

Fax: (248) 477-7784

E-mail: kkilgore@emag.com

Web: www.emag.com

CNC upgrade enhances performance and precision

Major Tool & Machine (MTM) is a large job shop, producing precision milled and turned hardware throughout the company’s 500,000 square foot Indiana facility. Performance is essential, because MTM contracts with aerospace, energy, nuclear and defense companies on many mission-critical, one-off projects. Owner and CEO Steve Weyreter will tell you openly, MTM is more competitive by way of a significant CNC technology change, starting with an aggressive retrofit strategy.

Günther Zimmermann, CNC Controls Engineer at MTM, says the company’s retrofit program and the decision to change to the Siemens SINUMERIK CNC platform have brought a new enthusiasm and momentum to the company. Over the last two years the change has also brought significant time and cost reductions, especially in the areas of programming, maintenance engineering, and machine operations.

“The initial goal in early 2010 was to retrofit two Cincinnati U5 Gantry machines,” Zimmermann recounts. “We evaluated two CNC technology platforms and after considerable analysis our CEO Steve Weyreter announced that Siemens would best support the company’s future.”

The decision to reduce costs by moving to a single CNC platform was the least difficult decision for the company to make, Zimmermann explains. The larger challenge for MTM was the integration of a new CNC technology platform that was new to the company.

Bill Henderson, MTM’s manager of large machining and maintenance, agrees that the decision to change to a Siemens CNC platform integrated with advanced part and tool probing was critical, because the shop manages constant changeovers from one complex job to the next, making setup times a critical time/cost constraint for the company. Another big advantage is the increased flexibility by only having to train machinists and maintenance personnel on one type of control.

Naturally, there’s a resistance to change,” Henderson says. “People are comfortable with what they normally run, but after our discussions with the people on the plant floor, they understood the overall objective. Our retrofit program is not finished, yet it’s already showing tremendous benefits.”

Heads-up interchangeability

An advantage MTM gained by its retrofit strategy has been the ability to interchange heads and rotary tables from machine to machine. Easy-to-use head storage and tool management programming provided by the Siemens CNC platform support the new interchange capability.

Retrofitter Doug Huber says having Siemens as a new CNC technology partner has made a difference for Major Tool & Machine, but it’s also been an evolutionary uplift for his own retrofitting company, Indiana Automation.

“Indiana Automation has increasingly retrofit using Siemens controls in recent years, Huber explains. “On a retrofit, we always try to exceed what the original machine could do, and that’s just kind of inherent when you put on a Siemens 840D. Major Tool’s first retrofits were the Cincinnati U5 machines, a bridge model and two gantry models. These are five-axis machines and five-axis is the 840D’s forte. The processing power of the control is so much better, that it just whips through the blocks faster. So right off, cycle time is a major performance enhancement.”

Huber says something else happened this time. As his firm finished retrofitting the first three giant machines with Siemens five-axis controls, drives and motors, the reaction within the company was not just that the machines were now predictably more efficient, but that they performed as very different machines. A new advantage is the ability to interchange machining heads from machine-to-machine, and all driven by the Siemens CNC platform.

“On many of the U5 machines, the axes come off with the heads,” Huber explains, “and we rebuilt these machines to accept any one of three different heads. That’s one of Major Tool’s key strategies. They insist on having flexible machine capabilities, so that they can run all kinds of different parts. They have straight heads for serious metal cutting, contour heads for five-axis work and finesse work. They have 90-degree heads for more flexibility than a straight head, but it’s also not as fragile as the contour head. And they wanted to interchange all of these heads to automatically go pick up a head out of the shuttle and, on the fly, reconfigure the axes and the zero positions. To do this, the compensation tables all had to be updated. Everything needed to be done with the macro program so that each head came on ready to run.”

The interchangeable head strategy was a challenge, Huber says, because the machines were not originally capable of sharing heads. But with support from Siemens, the strategy has worked, including the ability to interchange rotary tables as well as heads. “Each head or rotary table has a configuration file that has all the settings and compensations and travels with it from machine to machine. So now when you mount that head the control just runs the configuration file that goes with it and its all set up for you. We also incorporated Siemens Tool Management for each machine’s 60-pocket tool chain. We used the feature on these machines to manage all the different tooling MTM uses, both in the automatic tool changer as well as the ones manually loaded.”

Huber says, “MTM’s ability to smoothly transition to more advanced CNC is largely due to the HMI’s ease of use. The Operate interface is a huge help to us and to Major Tool. The HMI helps make better parts. And it didn’t take very long for the operators to fall in love with it.”

Leveraging the machinist’s skills

Central to MTM’s retrofit program has been the Siemens SINUMERIK 840D sl control, which features the SINUMERIK Operate interface. The highly intuitive interface enables both programmers and operators to easily capitalize on the broad capabilities of the control.

“I had never used a Siemens control before,” admits MTM machinist Mike Burthay. “I have extensive knowledge of G-code and CNC controls and I would say the Siemens 840D sl with the Operate interface is the easiest one I’ve ever run. It’s user friendly, that’s exactly the words for it.”

Burthay reports several ways in which the Siemens SINUMERIK Operate interface has made his life easier. “There’s not as much G-code,” he says. “The control does it all for you as long as you put in the parameters as to size, length, width. Then once you’re in Job Mode, there’s a screen where you can tool change or jog the machine around to certain positions, or turn the spindle on, turn the coolant on, anything that traditionally required G-code. So now you can push a cycle stop button to pause the machine, enter a change such as turning coolant on, then restart the program.

Programming as easy as 1-2-3: Using the SINUMERIK Operate interface, a machinist can turn on coolant flow by 1) pressing Cycle Stop to stop the machine, 2) Coolant On, and 3) Restart.

“Another function I love is Block Search, which allows me to start or restart right in the middle of a program. Say you’re finishing a pocket and you have to run the tool two or three times to get a tight tolerance, I can enter in a line number and hit Block Search, the control picks up every line before that, restarts the spindle and everything for you.”

Burthay says the Siemens control also enables him to program parts right on the machine whenever necessary, using a simple yet robust program called ShopMill. “I can go into ShopMill, type in some parameters and it will kick out that G-code program for me automatically. Say I want to drill a hole two inches deep. I open ShopMill, pick my tool, tell it the depth and these steps are all interactive on the screen. It even shows me 3D motion images of the tool path, confirms the drill going down as expected into the part. So I hit go and it puts a drill cycle into the program for me.”

Programmed for collaborative growth

Lead Programmer, Tim Hayden, has from the beginning conducted all processor setups for the newly retrofitted machines. Hayden says integrating the Siemens CNC platform has been an empowering experience he had not expected, given the fact that he had never before set up a post processor to run a Siemens control, nor had he ever before operated a Siemens control.

“Now, when I look at the Siemens control, I think man, it would have been so much better to have had it all along,” Hayden says, “because the other control I’ve been using is just a lot more cryptic. The Siemens control with the SINUMERIK Operate interface is more powerful for writing macros and the language seems modern, whereas the other control seems like it is still based on an old FORTRAN type language.”

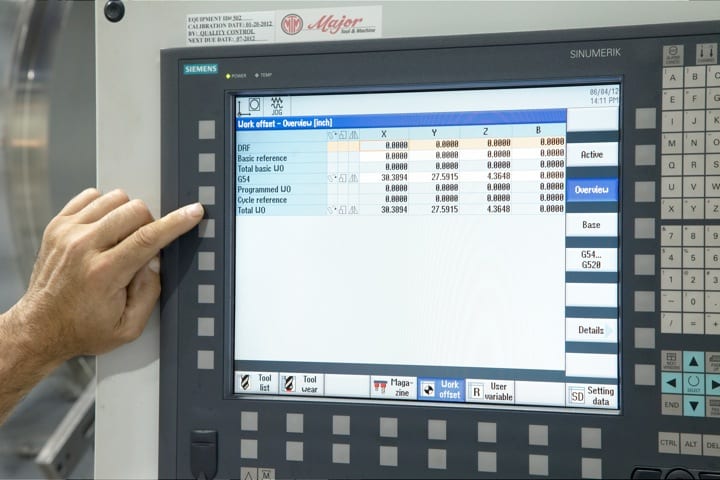

Work offsets for compound angles can be scaled and rotated using the Frames function of the Siemens SINUMERIK Operate interface. Many advanced machining operations can be managed simply, without the use of time-intensive manual G-code programming.

Hayden points to the Frames coordinate and offset programming function of the Siemens interface as an example of improved programming convenience.

“We do a lot of work on compound angles,” Hayden explains, “and with the Siemens Frames function, you can scale and rotate your coordinate system on the control, just plug it in with your work offsets. Whereas, on the other control you will see a G54 request, you’ve got to enter G-code. You can’t just plug it into your work offsets like you can with the Siemens control.”

Hayden says the SINUMERIK Operate interface brings greater programming flexibility. The HMI enables him to enter G-code using a comparatively more advanced manual data entry (MDI) function; however the HMI has all but eliminated the need for G-code entry by way of its intuitive design and evolved capabilities.

Another example of such HMI evolution is in the area of data management.

“When we post a program, we no longer have to use a G-code based MDI,” Hayden explains. “We no longer need to type in T= and enter a nine digit number and then enter M6 to make a tool change. With the Operate HMI, you pick your tool off a screen and hit cycle start. It’s just as easy to program going to a position. Instead of doing things the old way by typing G0X0Y0Z0 into the MDI, you open the Operate interface, click position, then click how you want to wrap it and then you just type the numbers into those fields. So it’s a lot more user friendly.”

Hayden says the Siemens CNC platform has supported greater collaboration at MTM between him and the machinists, and this is helping the company find ways to increase performance and efficiency. He agrees with his coworkers’ assessments that shorter setup times and greater operator freedom are making a significant difference.

“One of our production bottlenecks has been programming,” Hayden says. “The machinists that run our machines are professionals, they’re not button pushers, and with the SINUMERIK Operate interface, we can now rely on them to control and program certain parts right on their machines, while we programmers work on the more complex projects.”

“Siemens was the best fit for all of us,” Hayden concludes. “Siemens CNC is set up as an open control, and with that kind of flexibility, it seems anything is possible.”

See Siemens CNC at Major Tool & Machine in action HERE!

For more information, contact:

SIEMENS INDUSTRY, INC.

MOTION CONTROL

MACHINE TOOL BUSINESS

John Meyer

Manager, Marketing Communications

Siemens Industry, Inc.

(800) 879-8079 ext. Marketing Communications

www.usa.siemens.com/cnc

SiemensMTBUMarCom.industry@siemens.com

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue readingATLANTA, Oct. 18, 2012 — Siemens Industry, Inc. today announced its plans to open an assembly and manufacturing plant as part of the company’s Drives Technologies Division, Mechanical Drives Business Unit. The 45,600 square-foot facility will be located in the city of Mauldin in Greenville County. Siemens anticipates opening the facility later this year.

“The new South Carolina geared motor facility will place the company and its products manufactured in South Carolina closer to machine builders and manufacturers in the Southeastern United States,” according to Doug Keith, President of Siemens Drive Technologies Division in the U.S.. “The announcement of this plant adds to Siemens ability to be a single-source provider of integrated drive train solutions for industry. Our portfolio of gears, motors, drives and automation is helping to lead a global transformation of the industrial and manufacturing sector, by increasing productivity and energy efficiency to the highest possible levels.”

The facility will assemble Siemens new Simogear family of geared motors, featuring helical, parallel shaft, and helical bevel gear units primarily used in modern conveyor systems often found in warehousing, logistics and distribution, airport baggage handling, automotive manufacturing and food and beverage processing.

Keith added that the site combined all of the necessary elements Siemens was seeking in a location, including proximity to transportation infrastructure, including interstates and ports, a highly skilled workforce with reputable educational institutions nearby, a green-minded community and a dedicated group of business partners.

“It’s a great day in South Carolina when a world-class company like Siemens chooses to locate new operations in our state. We celebrate the company’s decision to invest in South Carolina and create new jobs. Announcements like this show we are doing the right things to attract businesses from around the globe to our state,” said Gov. Nikki Haley.

Throughout the site selection process, Siemens officials worked closely with several entities that were instrumental in the decision to locate in Mauldin, including the State of South Carolina, Greenville County, the City of Mauldin and Laurens Electric Cooperative.

“It’s exciting to see a company like Siemens bring a new manufacturing operation to the Palmetto State. Every one of these jobs will have impact locally. Announcements like this are made possible by a strong team effort from state and local officials,” said Secretary of Commerce Bobby Hitt.

Local Siemens officials are currently working with readySC and Greenville Technical College on workforce development and training needs. Siemens plans to begin hiring in October and individuals interested in learning more may visit the Siemens career web site at www.usa.siemens.com/careers.

Siemens Mechanical Drives Business Unit manufactures mechanical and electrical drive equipment typically used in mechanical designs, including processing, transport and conveying systems, power generation and many off-shore applications. This portfolio particularly concentrates on gear technology, ranging from geared motors to industrial gear units and couplings as well as large gears for power stations and wind turbines. This portfolio of products and solutions are the mechanical foundation to Siemens’ Totally Integrated Automation (TIA) platform.

For more information visit: http://www.usa.siemens.com/answers/en/#683050?stc=usidt100004&sp_source=usidt100004.

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue reading

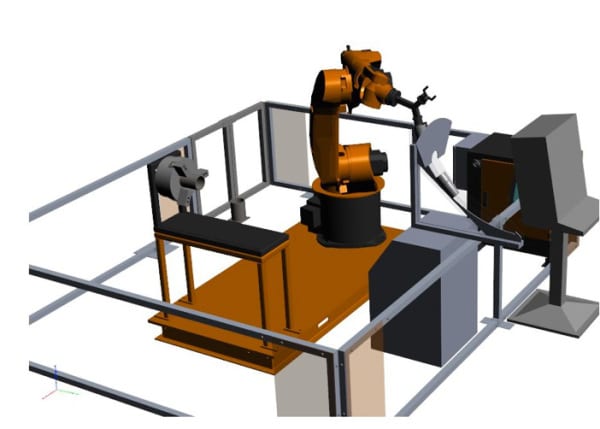

CHICAGO — At this year’s International Manufacturing Technology Show (IMTS) in Chicago, Siemens will demonstrate its recent collaboration with KUKA Robotics. In the Siemens booth E-5010, a KUKA robot will be articulating parts, simulating the operation on a CNC machine tool. Key to this development is the machine builder’s ability to integrate mxAutomation from KUKA directly through the Siemens Sinumerik CNC platform, thereby allowing the operator of the machine to run both the machine tool and robot from the single control panel.

The motion sequence of the robot is entirely engineered within the Sinumerik 840D sl CNC, then transferred by the 840D sl’s PLC function to the mxAutomation interpreter on the KR C4. All program changes to a six-axis robot can easily be input on a second channel of the CNC and fully operated. This scenario provides the ability to not only run a machine tool’s automation sequence more efficiently, but also make more changes on-the-fly to minimize machine downtime, with no special knowledge of robot programming language.

During the operation of the machine tool, all changes made can be visualized directly on the CNC screen, further minimizing operator actions. Siemens is the first CNC supplier to show this capability for single-screen operation of the machine tool and robotic materials handling on the CNC.

In operation, the KRC4 integrator and mxAutomation convert the robot language into the same commands used for multi-axis machine tool functions. A single Profinet cable runs between the robot and the CNC. According to KUKA’s Andreas Schuhbauer, key technology manager for machine tool automation (Augsburg, Germany), “mxAutomation allows the machine tool builder a single I/O language for integrating robotics on the CNC, while the end user operator can run both the machine tool and the robot from a single screen on the control.” mxAutomation for Sinumerik CNC was a joint development between KUKA and Siemens. KUKA created plug-in function modules for the Siemens Step 7 PLC engineering software and provided its robot knowledge to Siemens for creation of the second channel logic on the CNC, Andreas Schuhbauer further noted. All safety functions and test functions for load / unload, brake test, gripper, robot communication and safe operation of the robot are provided through the Siemens Profinet and Profisafe platforms.

Future developments for mxAutomation are planned, including a wider application range for robots in the CNC machine tool environment.

Join the user community by following us on Facebook: www.facebook.com/SiemensCNC and talking to us on Twitter: www.twitter.com/siemens_cnc_us. Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability.

For more information on this story, please contact

SIEMENS INDUSTRY, INC. DRIVE TECHNOLOGIES MOTION CONTROL MACHINE TOOL BUSINESS

390 Kent Avenue Elk Grove Village, IL 60007

Phone: 847-640-1595 Fax: 847-437-0784

Web: www.usa.siemens.com/cnc

Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communication

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability.

Continue reading

Bill Hunter raises company-supported endowment to Foundry Educational Foundation; $25,000 in memory of Al Hunter will provide scholarships to students involved in metalcasting

Bill Hunter, left, president of Hunter Automated Machinery, presented a check to Bill Sorensen, executive director of the Foundry Educational Foundation, on August 9, 2012 at Hunter headquarters in Schaumburg, Illinois, near Chicago. The check raised the amount of money in the FEF Scholarship Fund to $25,000, in honor of Al Hunter, founder of the company.

Schaumburg, Illinois (USA)-Hunter Automated Machinery today announced a donation to the Foundry Educational Foundation (FEF), raising the current endowment to $25,000, in memory of Al Hunter, founder of the company and father of current owner Bill Hunter. Bill made this donation on August 9, presenting a check to the FEF Executive Director, Bill Sorensen.

Hunter Automated has been a contributor to the FEF for many years. Upon the death of Al Hunter in 2011, the family asked that donations be made to the foundation in honor of him. Once the contributions were collected, the Hunter family asked that FEF establish an endowment to honor Al’s memory, with scholarships provided at selected schools. The first school chosen was the University of Alabama. It provides a deserving student a scholarship in Al Hunter’s name.

FEF is a non-profit organization and the foundry industry’s first link to the college campus. The foundation uses funds contributed from the foundry industry to encourage the pursuit of metalcasting as an academic endeavor at schools across the country. Hunter has pledged to donate $500 every year to FEF, going forward.

As Sorensen explained, “Students will benefit not only from the scholarship monies, but also from getting to know the contributions Al Hunter made to the industry and the substantial legacy he left behind.” Al Hunter held over 80 patents in his lifetime and was chiefly responsible for the development and implementation of automatic matchplate molding machine technology in the North American and ultimately the global foundry market.

Bill Hunter presented the check to Bill Sorensen at Hunter headquarters in Schaumburg, Illinois (Chicago) on August 9, 2012. “It is our privilege to help fund this scholarship program that both encourages young people to enter the foundry industry and continues to honor the technological contributions made by Al Hunter,” Bill remarked.

Sorensen further noted that approximately 90% of the students who have received FEF scholarships continue to pursue their careers in metalcasting.

For further information on this announcement, interested parties may contact:

HUNTER AUTOMATED MACHINERY CORPORATION

2222 Hammond Drive Schaumburg, IL 60196

Phone: (847) 397-5110

Fax: (847) 397-8254

Email: info@hunterfoundry.com

Attention: Bill Hunter, CEO

Web: www.hunterfoundry.com

Connect with Hunter Foundry online:

Bill Hunter assumes 100% ownership of pioneering company in automatic matchplate molding machinery for sand casting

Schaumburg, Illinois (USA)-Hunter Automated Machinery today announced the completion of an asset buyout of the company and all its foreign subsidiaries by current President Bill Hunter. In his words, “We have successfully crossed the bridge of generational transition with this arrangement.” Mr. Hunter bought the assets of the company held by his three sisters, Dianne, Linda and Heather. All were the children of Al Hunter, the late founder of the company that began building the automatic matchplate molding machine Al invented, in 1964. Today, Hunter machines and mold handling lines are operating in foundries worldwide. Hunter operates plants in the USA, Brazil and China. The company has European headquarters in Italy and regional offices in India.

Karen Hunter, corporate secretary, Bill Hunter, president and John Purtill, corporate attorney at signing

Bill Hunter noted, “I am very thankful to my sisters, who worked closely with me on this agreement, allowing us to keep the company in the family. Likewise, I will always honor the memory of my father, who taught me much about this business and left a legacy of innovation and achievement in the global foundry market. We fully intend to continue and build on the company’s long-standing traditions of technology, quality and service to the industry.”

The agreement was finalized on June 27, 2012.

For further information on this announcement, interested parties may contact:

HUNTER AUTOMATED MACHINERY CORPORATION

2222 Hammond Drive Schaumburg, IL 60196

Phone: (847) 397-5110

Fax: (847) 397-8254

Email: info@hunterfoundry.com

Attention: Bill Hunter, CEO

Web: www.hunterfoundry.com

Connect with Hunter Foundry online:

Texas foundry buys new equipment, including Hunter XL matchplate molding machine, to respond to customer needs with fast pattern changes, shorter runs and on-the-fly flexibility in job scheduling, deliveries

Schaumburg, Illinois (USA)-In the heart of Limestone County sits Coolidge, Texas, halfway between Dallas and Houston. This classic American small town is home to another classic, Frazier & Frazier Industries, a ductile and gray iron foundry, established in 1972 by C.W. Frazier as a traditional cope-and-drag sandcasting operation with two squeezers and run today as a formidable shop by Plant Manager Will Frazier. An ISO 9002 Certified process operation, F&F combines the best of the old ways with the newest casting technologies and equipment in the market. As Will Frazier points out, “This is one of the biggest reasons we’ve continued to prosper, while so many other foundries have disappeared. We recognize what works and what doesn’t, to best suit our current business and market conditions.”

Once a heavy production shop, F&F today continues to support their large batch customers, but has reshaped the business model in many ways, according to Frazier. “We have traditionally worked in pieces from a few ounces up to 150 pounds or more. The large runs were more typical in days past, while we saw a new business environment emerging, several years ago, when the market began to decline overall.” He continued to explain how many of the company’s traditional customers began to reduce their inventories and thus placed shorter run orders with much tighter lead times. In something of a “perfect storm” scenario, this combination of increased job numbers and more urgent shipping requirements literally changed the pace of business at F&F. Frazier notes, “It’s not unusual for us to come in on a Sunday to finish a job for a customer who really needs it…and we rarely charge a premium, because we know how tough things are, for most of our accounts.”

While the oil & gas market applications are prominent here, as they are with most foundries in the region, F&F currently sells to end product manufacturers for the automotive, agricultural, wind energy, municipal water works and other market segments, a strategy that has helped to maintain a better balance in this shop’s workload. With its own sales force plus several manufacturers’ rep organizations in the field, Frazier & Frazier boasts customers in a wide variety of markets and as far away as Indiana, a relatively rare achievement in the foundry business, especially when larger, heavier workpieces are involved.

With over 8000 patterns in-house, F&F today experiences as many as 15 pattern changes per day per machine on the floor. This further complicated the job scheduling and work flow. Will Frazier and his team of Bob Pranger, general manager and Harlon Easton, vice president of sales, quickly saw the need for more automation in the machinery lineup.

F&F still does hand-rammed oil and air set cores, but over the years they’ve acquired automatic coresetting equipment, as well as automated molding machines, including the most recent purchase, a Hunter XL2024 automatic matchplate molding machine, which is used with the already in-place Hunter mold handling turntable system at F&F, as are other molding machines here. Three melting units feed the certified chemically correct iron to the molding stations. Currently, this shop does approximately 70% of its work in ASTM Class 60-100 ductile and 30% in Class 15-50 gray iron.

The XL2024 is a fully automated matchplate molding system, using gravity-fill technology pioneered by Hunter. It produces sand molds up to 20” x 24” with shallow 6-1/2” cope and 5-1/2” drag (165mm/140mm) at 180 cycles per hour, using 400 lbs. (181kg) of sand. Variable squeeze surface pressures to 142 psi (10kg/cm2) can be achieved in production.

This latest Hunter machine continued the tradition of leading-edge sandcasting technology used at Frazier & Frazier. Although several generations of Hunter and other brands of machines have been used here, when a new machine was planned, Will Frazier notes there were some key criteria to be met. “We’d been having critical problems with another machine builder, getting parts and service. We always knew the Hunter folks were excellent in those areas based on past experience, plus they were willing to provide considerable application engineering assistance and set-up help with the new machine. Coupling that with their stability as a company and great reputation in the world foundry market, we looked at all our options and settled on the XL2024.” Frazier further cites his long relationship with Hunter’s Mike Hughes as a factor. “Mike came down here several times to help us and, since the machine has been up and running, he’s stayed in close touch with us, even though we’ve had no performance issues with the machine.”

Will Frazier also points out that, currently, over 20% of the orders at F&F are rush and the quick changeover time of the Hunter machine makes it a highly productive piece of equipment and a definable competitive advantage in the market for his shop.

Frazier & Frazier provides its customers with metal castings as well as CNC machining, heat treating and galvanizing services, when needed. The shop has a fully equipped quality inspection department, highlighted by CMM and other state-of-the-art lab apparatus.

For further information on this story, interested parties may contact:

FRAZIER & FRAZIER INDUSTRIES, INC.

817 South First Street P.O. Box 279

Coolidge, Texas 76635 USA

Phone: 254-786-2293

Fax: 254-786-2284

Web: www.ffcastings.com

Email: willfrazier@ffcastings.com

Attention: Will Frazier, Plant Manager

Or

HUNTER AUTOMATED MACHINERY CORPORATION

2222 Hammond Drive Schaumburg, IL 60196

Phone: (847) 397-5110

Fax: (847) 397-8254

Email: info@hunterfoundry.com

Attention: Bill Hunter, CEO

Web: www.hunterfoundry.com

Connect with Hunter Foundry online:

Wisconsin foundry adding value to parts produced

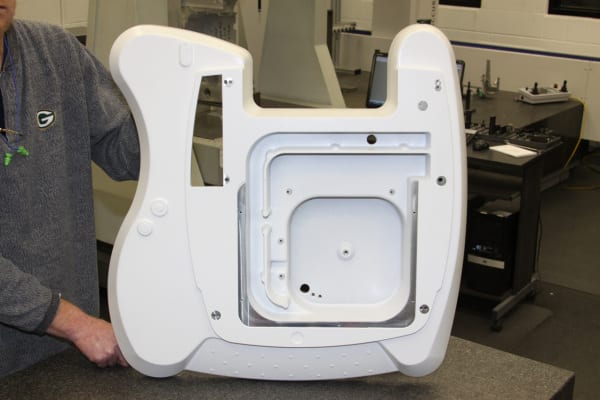

Watry Industries LLC, a large permanent mold aluminum foundry located in Sheboygan, Wisconsin, takes pride in working closely with its customers to co-develop and optimize casting design. In addition to offering casting design assistance and permanent mold casting production in its 172,000 square foot facility, Watry also performs heat treating, precision machining, powder coating and assembly operations in-house.

Watry Industries LLC, a large permanent mold aluminum foundry located in Sheboygan, Wisconsin, takes pride in working closely with its customers to co-develop and optimize casting design. In addition to offering casting design assistance and permanent mold casting production in its 172,000 square foot facility, Watry also performs heat treating, precision machining, powder coating and assembly operations in-house. Watry worked closely with its customer to assist in the design process for this part, as well as two other castings used on the same program, from concept through tooling and into production. Several other production processes were considered for making this part, including injection molded plastic, structural foam, plastic cowling over steel fabrication and several casting processes including sand cast, permanent mold and high pressure die cast. After investigation, mechanical strength concerns eliminated some of the plastic construction methods and a thorough cost analysis eliminated the fabrication options as being too expensive. Aluminum castings had a proven track record in similar applications, and a cost analysis was done to compare the various cast processes. Based on the combination of part cost and tooling cost (total cost of ownership) the result of all these studies was that permanent mold was selected as the best process for the application.

Watry worked closely with its customer to assist in the design process for this part, as well as two other castings used on the same program, from concept through tooling and into production. Several other production processes were considered for making this part, including injection molded plastic, structural foam, plastic cowling over steel fabrication and several casting processes including sand cast, permanent mold and high pressure die cast. After investigation, mechanical strength concerns eliminated some of the plastic construction methods and a thorough cost analysis eliminated the fabrication options as being too expensive. Aluminum castings had a proven track record in similar applications, and a cost analysis was done to compare the various cast processes. Based on the combination of part cost and tooling cost (total cost of ownership) the result of all these studies was that permanent mold was selected as the best process for the application.

Dale Christel

Sales Manager

Watry Industries LLC

3312 Lakeshore Drive

Sheboygan, WI 53081

Office: 1-920-457-4886

www.watry.com

dchristel@watry.com

Connect with Watry Industries online:

Experts at the nuances of powder coating parts produced in all metalcasting processes, as well as powder application on stampings, extrusions, weldments and assemblies, Watry is able to provide their services on castings made by other processes as well as steel, iron and various alloys.

Watry is capable of masking features before painting as well as blowing off un-cured powder in areas where masking is not practical. The Nordson Cyclo-Kinetic reclaim booth, utilizing both manual and automatic guns, is capable of applying the most demanding and high temperature powders, reaching the most difficult areas on any workpiece. In addition, reclaiming the powder that does not adhere to the part during the application process helps control overall costs.

Watry’s roof mounted cure oven, encompassing over 250 feet of conveyor track and operating at temperatures up to 500º F, can cure powder on the largest and heaviest parts at very high line speeds, providing another cost-controlling feature.

Strict quality control systems and procedures include film thickness checks, adhesion testing, color verification and paint hardness testing to ensure compliance to customers’ most demanding requirements.

To watch a video on the Watry powder coating operation, please visit http://www.watry.com/video_library.html

For more information on this release, please contact:

Dale Christel

Sales Manager

Watry Industries LLC

3312 Lakeshore Drive

Sheboygan, WI 53081

Office: 1-920-457-4886

www.watry.com

dchristel@watry.com

Connect with Watry Industries online:

Increasing demands made on precision and the push for the decrease of price of modern components is pushing traditional manufacturing processes to their limits. From September 10th-15th, 2012 at IMTS in Chicago, IL, EMAG will present three production technologies that complement or replace traditional processes such as turning, milling and grinding.

The ECM process is used to deburr components only at the points where material needs to be removed, and without it having any mechanical or thermal impact on the workpiece.

PECM for nickel- and titanium-based alloys

With its PECM technology (Precision Electro-Chemical Machining) EMAG presents a production process that opens up completely new fields of application. PECM is a process for the machining of high-alloyed materials, such as nickel- and titanium-based alloys. The disadvantages of traditional metal cutting – tool wear, mechanical stresses, micro-fissuring caused by heat, oxidization layering and the need for subsequent deburring operations – are eliminated, because this process is a non-contact one without heat input. All electro-chemical machining processes are characterized by stress-free material removal, smooth transition points and surfaces without ridge formations.

Six in one – the EMAG ECM deburring process can be adjusted to suit individual production requirements.

The advantages that the PECM process provides for different branches of industry are best shown with the example of a turbocharger for the automotive industry. The electro-chemical process is one that can be used to effectively in the machining of many high-alloy components, especially those in the high-temperature sector of the turbocharger – it also offers a much shorter and very efficient process chain. The typical clean-up operations necessary when traditional machining processes are used – such as deburring after milling – are no longer necessary. PECM machining operations are burr-free. And there is hardly any tool wear. The result: downtimes are minimal, when compared to milling (which requires regular tool changes). The process as a whole is sturdier and less prone to errors. And another important factor that our example of the turbocharger shows: the superb surface finish of the PECM process, where Rz-values of 0.3 micron can be achieved.

Will camshafts ever again be made of a single piece?

Another highlight is EMAG‘s heat-shrink assembly technology, a process that scores particularly well in camshaft production. The high degree of precision achieved with the joining process drastically reduces the number of cam profile grinding operations or – with the use of precision cams – avoids them altogether. Another benefit of the process is the ability to combine different materials in the construction of the shaft, such as forged cams (e.g. in 100Cr6) and sintered cams, which do not require regrinding. Accessory components, such as plugs and end pieces, can – like the shaft itself – also be made of better materials. This allows for the camshaft to be adapted to the requirements of the engine and to be optimized in load bearing capacity and manufacturing costs.

Operating costs reduced by 50 %

Production laser welding is already a highly productive process in the manufacturing of gearwheels. The use of diode-pumped solid-state lasers – such as disc or fiber lasers –reduces operating costs by up to 50%. EMAG has been involved with the use of solid-state lasers in the welding of powertrain components from an early stage and is considered a pioneer in the technology. EMAG again has fulfilled a promise to their users offering them the lowest possible cost-per-piece, by coming up with an innovative technology that brings true cost benefits.

For many applications, solid-state lasers allow welding without shielding gas. This not only reduces operating costs, it also avoids having to follow the annoying logistics imposed by the use of shielding and laser operating gasses. In many cases, the welding process can also be sped up considerably. This increases productivity and – through a reduction in energy input per unit length – reduces welding distortion, resulting in better component quality.

For more information:

EMAG LLC

38800 Grand River Avenue

Farmington Hills, MI 48335

Tel: (248) 875-0313

Fax: (248) 477-7784

E-mail: info@usa.emag.com

Web: www.emag.com

Attention: Peter Loetzner

Continue reading