Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Guill Tool & Engineering, the global leader in extrusion tooling, attended the K Show in Dusseldorf, Germany from October 8th to the 15th. Guill’s technical sales engineer shared his thoughts on the companies they met at the show, the international extruders they’ve partnered with, intriguing applications as well as what caught his attention. Additionally, the company’s European sales manager discussed the role of Guill Tool Europe.

Known as the world’s premier plastics trade fair, K brings together global pioneers from the plastics and rubber industry. Located in Hall 1, booth C90, Guill Tool & Engineering’s team included Peter Leary, Technical Sales Engineer, Extrusion Division, Jacob Marcure, Design Engineer and Gerjan ter Wal, Sales Manager in Europe.

Commenting on the companies met at the show Leary said, “We met a wide range of companies across the extrusion and plastics industry including wire and cable manufacturers, medical tubing producers, compounding specialists and machinery OEMs. There was also a strong representation from raw material suppliers, large pipe extrusion and automation/controls providers, which gave us valuable insights into emerging technologies and potential partnerships.”

Guill interacted with extruders and processers from all over the world, including Europe, Asia and the Americas. Leary added, “A handful were existing customers stopping by to discuss current projects, but we also met a large number of new potential partners interested in Guill’s precision crosshead and tooling capabilities.” The company has contacts in China, Mexico, India, Greece, Turkey, Thailand, the UK, Australia and Algeria. Additional countries include Sweden, Japan, France, Finland, Chile, Poland, Singapore, the Netherlands, New Zealand, Egypt, Indonesia, Ireland, Brazil, Kenya and Switzerland.

Several applications stood out to Leary, notably multilayer medical tubing and advanced materials for sustainable production. He observed notable interest in tools that handle recycled or bio-based polymers while maintaining tight tolerances and flow balance.

Leary was impressed with the scale and diversity of the K Show. “One highlight was seeing the increasing integration of digital process monitoring and AI-driven control systems.”

Regarding Guill Tool Europe, ter Wal said that one of the goals expressed by visitors was to optimize their extrusion process and that the European office can help ensure smooth communication and planning for new production solutions.

For more information, please contact:

Tom Baldock, Sales Manager, Extrusion

Guill Tool & Engineering

10 Pike Street

West Warwick, RI 02893

USA

Phone: 401-465-5526

tbaldock@guill.com

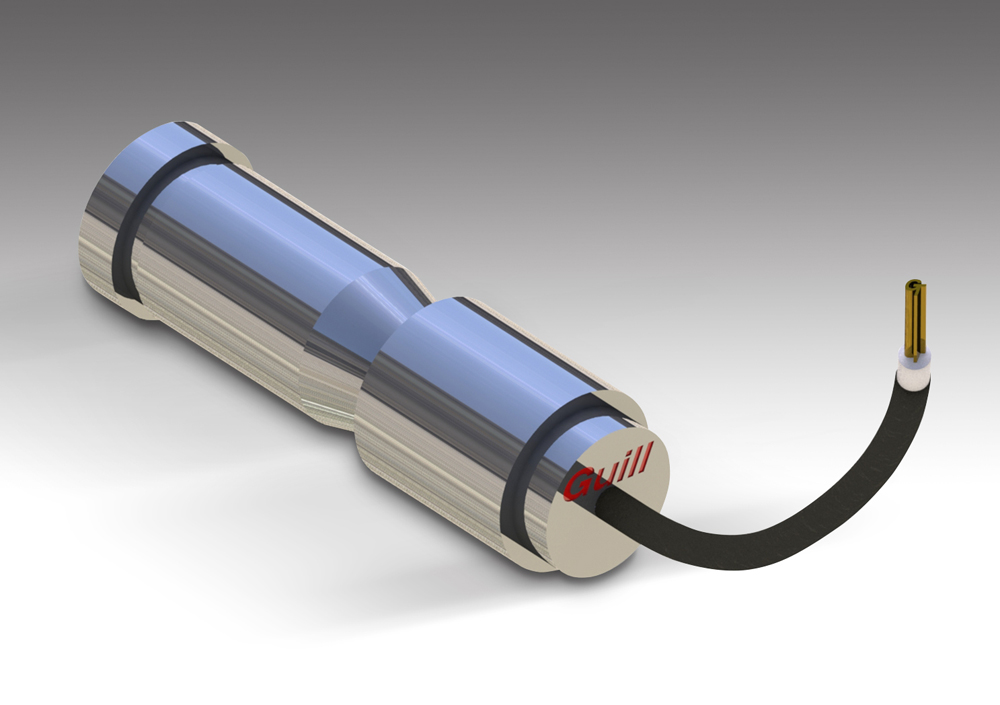

Guill Tool, the global leader in extrusion tooling, announces its 10-Day Program. This program applies to eligible tips and dies that will be shipped within 10 business days of receiving the purchase order from the customer.

Guill high-quality precision tips and dies have been manufactured in the U.S. for over 65 years. All Guill extrusion tools are produced using certified and documented quality steel material, specifically qualified for the polymer to be extruded. Furthermore, Guill designs tips and dies for any application the customer requires. These feature multi-lumen, stripe, multiple stripe, wire and cable, hose, pipe, tube, fiber optic, blown film, corrugated tube and profile. Dies include face seal, shouldered, snap-together, floating, die plate, interchangeable die plate and custom dies. Available tips include single and multi-lumen, threaded style, snap-together, fixed-center shoulder, profile, tapered style and custom.

To learn which tools are eligible for the program, check with the company or local Guill sales representative. For all other parts, company personnel will review the customer’s drawing to determine eligibility for the program.

Eligible tips and dies for this program must have a diameter less than 1.5” and a length less than 4.75.”

Guill proudly manufactures its products in the U.S. under the quality standards of ISO 9001:2015 and AS9100:2016.

For more information, please contact:

Tom Baldock, Sales Manager, Extrusion

Guill Tool & Engineering

10 Pike Street

West Warwick, RI 02893

USA

Phone: 401-465-5526

tbaldock@guill.com

Joseph Guigli, the company’s President/Owner, holds a B.S. in Mechanical Engineering from the University of Vermont. After graduation, he started working at Davis Standard in Pawcatuck, Connecticut. For the next 17 years, Guigli held various positions within the company ranging from mechanical engineer, screw designer, product manager, to regional sales manager and then Vice President of sales for the North American aftermarket.

Covering North Carolina, South Carolina, Georgia, Tennessee and Alabama, Guigli’s primary responsibility is to sell the extrusion product portfolio to existing and new customers. This includes “… providing these customers with the best buying experience possible from the time a project is kicked off until the customer is successfully using the equipment.”

When asked what he enjoys the most about working with Guill and his hopes regarding his role, Guigli said, “Guill has a strong name in the market, and they make a good product. I’m happy to be attaching my name and my company to Guill because of these reasons. I hope to bring my almost 20 years of industry experience to the customer base here in the Southeast.”

In addition to the rubber and plastics extruder market, Guigli also serves the construction, infrastructure, medical, food, industrial packaging and home care products markets.

For more information, please contact:

Tom Baldock, Sales Manager, Extrusion

Guill Tool & Engineering

10 Pike Street

West Warwick, RI 02893

USA

Phone: 401-465-5526

tbaldock@guill.com

Continue reading

Guill Tool, the global leader in extrusion tooling, has announced its 10-day program. This program applies to eligible tips and dies that will be shipped within 10 business days of receiving the purchase order from the customer.

The company’s quality precision tips and dies have been manufactured in the U.S. for 62 years. All Guill extrusion tools are produced using certified and documented quality steel material specifically qualified for the polymer to be extruded. Furthermore, Guill designs tips and dies for any application the customer needs. These feature multi-lumen, stripe, multiple stripe, wire and cable, hose, pipe, tube, fiber optic, blown film, corrugated tube and profile. Dies include face seal, shouldered, snap together, floating, die plates, interchangeable die plate and custom dies. Available tips include single and multi-lumen, threaded style, snap together, fixed center shoulder, profile, tapered style and custom.

To find out which tools are eligible for the program, check with any sales representative. For all other parts, company personnel will review the customer’s drawing to determine if it is eligible for the program.

Eligible tips and dies for this program cannot be plated and must have a diameter less than 1.5” and a length less than 4.75.”

Guill proudly manufactures its products in the U.S. under the quality standards of ISO 9001:2015 and AS9100:2016.

For more details, visit www.guill.com/tooling-cell

For more information, please contact:

Tom Baldock, Sales Manager, Extrusion

Guill Tool & Engineering

10 Pike Street

West Warwick, RI 02893

USA

Phone: 401-465-5526

tbaldock@guill.com

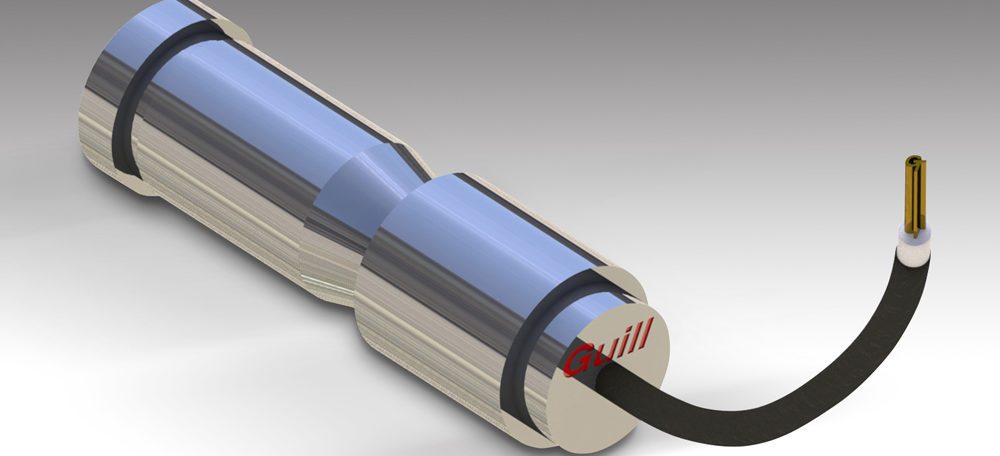

Guill Extrusion Division Enters Pultrusion Market with Advanced, Custom-Engineered Tooling Solutions

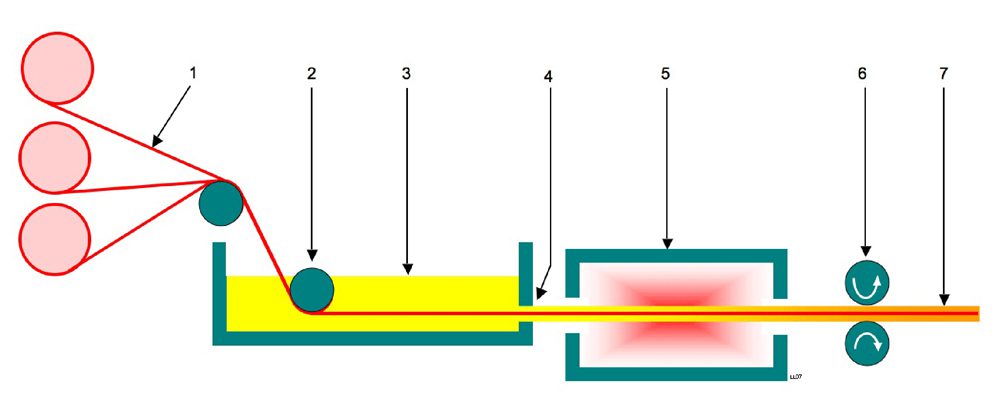

Guill, a global manufacturer and designer of extrusion dies, proudly announces the expansion of its product portfolio to include custom-engineered pultrusion dies. This strategic move marks a significant advancement in providing comprehensive, high-quality tooling solutions for industries such as automotive, aerospace, construction, energy, marine, sporting goods and telecommunications.

As the demand for pultruded composites grows due to their strength, durability and lightweight properties, Guill is well-positioned to meet this need. Leveraging its expertise in extrusion tooling, Guill is now applying its precision engineering capabilities to develop innovative pultrusion dies tailored to the specific requirements of each target industry.

“We are excited to enter the pultrusion market with our advanced tooling solutions,” said Peter Leary, Technical Sales Engineer at Guill. “Our extensive knowledge of extrusion processes and commitment to custom engineering enable us to design dies that not only meet but exceed our clients’ expectations in terms of performance, efficiency and quality.”

The Guill Tool Extrusion Division has a long history of designing and manufacturing tooling for various applications, including medical tubing, wire and cable coating, hose production and multi-layer extrusions. Its capabilities include creating multi-layer crossheads, in-line, reciprocating, rotary dies and a variety of other custom solutions supporting materials such as plastics, rubber and silicone.

New Pultrusion Tooling for Advanced Composite Applications

Guill’s new line of pultrusion dies is engineered for industries utilizing fiber-reinforced polymers (FRP), such as:

* Fiberglass Reinforced Polymers (FRP)

* Carbon Fiber Reinforced Polymers (CFRP)

* Aramid Fiber Reinforced Polymers (e.g., Kevlar)

These dies are compatible with a range of polymer matrices, ensuring versatility and high performance across different applications.

Tom Baldock, Guill sales manager, is looking forward to introducing a whole new set of customers to the company’s dies. He notes, “Pultrusion is a cost-effective process for producing parts with a constant cross section in high volumes, requiring relatively little labor. Fiber-reinforced polymer (FRP) pultruded composites are durable, corrosion-resistant and eco-friendly.”

For more information, please contact:

Tom Baldock, Sales Manager, Extrusion

Guill Tool & Engineering

10 Pike Street

West Warwick, RI 02893

USA

Phone: +1 401-828-7600

tbaldock@guill.com

About Guill

Guill is a global manufacturer specializing in custom extrusion tooling and industrial equipment. With a focus on precision engineering and computational fluid dynamics, Guill provides tailored solutions that address industry-specific challenges. The company’s mission is to deliver innovative, high-quality equipment that supports efficient, reliable production processes for customers worldwide. Based in West Warwick, Rhode Island, the company also operates Guill Tool Europe to serve its ever-expanding customer base there.

Guill Tool, the global leader in extrusion tooling, now offers a wide variety of extrusion equipment specifically for food processing.

Extrusion is increasingly becoming one of the primary methods of producing a variety of traditional and innovative food products, and the company’s extrusion tooling is designed to accommodate producing all of them. This includes breakfast cereals, sausages, snacks, pasta, baby food, confectionaries and pet food. Guill’s balanced flow designs control dimensional tolerances in order to increase product quality while reducing waste.

Custom made extrusion tooling and dies make it easy to efficiently and consistently manufacture a variety of food products. More precise tooling allows for considerably reduced wasted extrudate. Furthermore, Guill’s extrusion tooling enables precise temperature control, allowing food to be manufactured under both high and low temperatures.

The company has extensive experience in food, pharmaceutical and medical applications involving stainless steel. As a result, Guill is highly skilled in the machining, welding and assembly of stainless steel dies, the standard in the food industry. Furthermore, they comply with the all the necessary standards to produce equipment for this market.

For more information, please contact:

Tom Baldock, Sales Manager, Extrusion

Guill Tool & Engineering

10 Pike Street

West Warwick, RI 02893

USA

Phone: 401-465-5526

tbaldock@guill.com

Guill Tool, the global leader in extrusion tooling, recently announced their expansion in the European market with the creation of Guill Tool Europe. They will offer a full line of Guill products, as well as sales and engineering support throughout Europe. Padric Lunn will continue to represent Guill in the UK.

From concept design to engineering, manufacturing and supporting client processes, Guill has more than 60 years of experience in regular extrusion, multi-layered applications, jacketing, multi lumen, rubber, silicone and much more. The company maintains the highest quality standards regardless of application.

Padraic Lunn Enterprises Ltd offers a full range of extrusion machinery and consultancy for all extrusion processes with a strong emphasis on tubing, wire, pipe and profile applications. The firm represents extrusion equipment companies in the UK, Ireland and other parts of Europe.

With local sales representatives in each country, Guill looks forward to establishing a strong presence on the European continent.

For more information, please contact:

Tom Baldock, Sales Manager, Extrusion

Guill Tool & Engineering

10 Pike Street

West Warwick, RI 02893

USA

Phone: 401-465-5526

tbaldock@guill.com

For more information in Europe, except in the UK, please contact:

Gerjan ter Wal, Sales Manager, Europe

Guill Tool & Engineering Europe

Phone: +31 548 659083

Gerjan.terwal@guill.eu

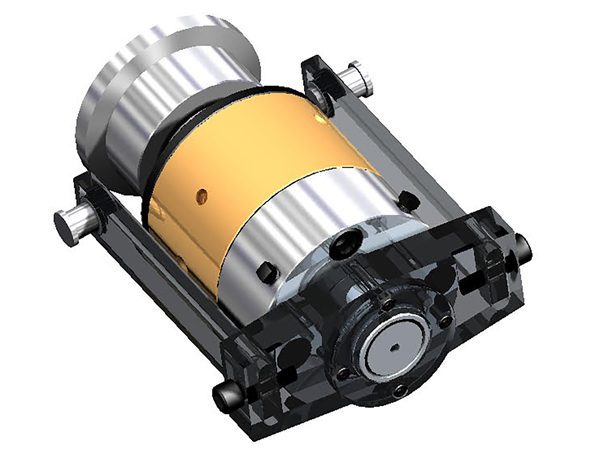

Guill Tool, the global leader in extrusion tooling, offers its Series 1000. This series of blow molding extrusion dies, features a core diameter between 8.5″ (219.5 mm) – 10″ (254.0 mm). Model 1025 uses material blends which are ideal for medical, automotive and specialty packaging.

Series 1000 is available as single layer, co-extrusion or triple extrusion. It adapts to existing extruder layout and, in most cases, accepts existing tooling. Features include fixed center or adjustable, built-in cartridge heaters, low inventory, expandable to multi-layer, heated core pin, one-piece body/flow diverter and split feed balanced flow.

Most products should be run fixed. Users need to change only one component to become fully adjustable. The cartridge heaters offer even heat for better flow and ensure there aren’t any cold spots. Low inventory produces no burning or stagnation, resulting in quick color change. Since it’s expandable to multi-layer, the crossheads run a variety of products. Benefits of the heated core pin and one-piece body/flow diverter are better temperature control and easy cleaning/quick change over, respectively. Lastly, the split feed balanced flow achieves concentric walls at all speeds.

For more information, please contact:

Tom Baldock, Sales Manager, Extrusion

Guill Tool & Engineering

10 Pike Street

West Warwick, RI 02893

USA

Phone: 401-465-5526

tbaldock@guill.com

Guill Tool, the global leader in extrusion tooling, now offers a wide variety of extrusion equipment specifically for food processing. Extrusion is increasingly becoming one of the primary methods of producing a variety of traditional and innovative food products, and the company’s extrusion tooling is designed to accommodate producing all of them. From pastas, hot dogs, and snack foods to chewing gum, licorice, and pet food, Guill’s balanced flow designs control dimensional tolerances in order to increase product quality while reducing waste.

Custom-made extrusion tooling and dies make it easy to efficiently and consistently manufacture a variety of food products. More precise tooling allows for considerably reduced wasted extrudate. Furthermore, Guill’s extrusion tooling enables precise temperature control, allowing food to be manufactured under both high and low temperatures.

Intended to increase tube wall strength, the 300 Series heads achieve concentric heads at all speeds. Additional features include low inventory/quick color change and elimination of secondary stage processing. The company’s 600 Series crosshead offers flexibility in design and extruder orientation with split balanced flow, while the 700 Series is fully adjustable and accepts existing tooling.

Guill’s 800 Series simple crosshead can be configured to be fixed center or adjustable, featuring built-in cartridge heaters and a low volume split feed balanced flow. The 900 Series Spiderless in-line head offers simplicity and fewer parts with a low volume split balanced flow. Lastly, the Bullet™ is suitable for high and low-volume applications and is accommodated with the simple, easy changing of just one component.

For more information, please contact:

Tom Baldock

Sales Manager, Extrusion

Guill Tool & Engineering

10 Pike Street

West Warwick, RI 02893

USA

Phone: 401-465-5526

Email: tbaldock@guill.com

Guill Tool, the global leader in extrusion tooling, offers their patent pending extrusion tooling, Series 400. It’s adaptable to a wide variety of corrugated equipment and molds. The Series offers a host of benefits for OEMs, as well as for automotive and medical applications.

The unique tooling includes the multi-port spiral flow design that provides a balanced compound distribution with no weld lines to the corrugator. The elimination of weld lines significantly increases the finished product’s overall strength.

Models offered include 420, 423, 432 and 434. Features of the 400 Series include Spiderless Inline, fixed center or adjustable, built in cartridge heaters, adjustable gum space, low inventory, expandable to multi-layer, heated core pin and one-piece body/flow diverter.

Since there are no spider lines, there’s room for more air and no cold legs. Most products should be run fixed. Users can change only one component and become fully adjustable. The cartridge heaters offer even heat for better flow and ensure there aren’t any cold spots. More control of product size is achieved with adjustable gum space. Low inventory results in no burning or stagnation-quick color change. Due to the fact that it’s expandable to multi-layer, the crossheads run a variety of products. Lastly, benefits of the heated core pin and one-piece body/flow diverter are better temperature control and easy cleaning-quick changer, respectively.

For more information, please contact:

Tom Baldock, Sales Manager, Extrusion

Guill Tool & Engineering

10 Pike Street

West Warwick, RI 02893, USA

Phone: 401-465-5526

tbaldock@guill.com