Contact us today:

Author Archives: Bernard & Company

Schuler and Porsche Form Joint Venture for Car Body Parts

Joint venture for “press shop of the future”

Canton, Michigan, September 5, 2018 – Porsche and Schuler announce plans to build an innovative press shop together for the car factory of the future. Representatives of both companies signed the contract on Tuesday, September 4, 2018 for the foundation of a corresponding joint venture. The European Commission has already green-lighted the joint undertaking. Approval from further anti-trust authorities is still pending. The objective of this Schuler and Porsche joint venture is to create what is termed the “Smart Press Shop” as part of a networked Industry 4.0 approach. The new press shop’s pioneering technologies will enable the highly flexible production of complex car body parts, where the focus will be on aluminum body panels and small batch production.

“Porsche wants to use the joint venture to lay the foundations for the future of sports car manufacturing,” says Albrecht Reimold, Member of the Executive Board for Production and Logistics at Porsche AG. “We plan to exploit future technologies and innovations in order to make our processes even more efficient. By dovetailing design, development, car body planning, toolmaking and production within the Porsche Group, we can significantly influence the quality of our sports cars.”

Schuler CEO Domenico Iacovelli stated, “Porsche and Schuler will be using a press shop that sets new standards in two respects – in terms of manufacturing performance, as well as the digital networking and readability of data streams along the entire production process. Not only Porsche will benefit from this major step forward, but ultimately other manufacturers as well.”

The systematic further development of process know-how in the field of metalforming will be achieved in part by the end-to-end networking of production data and the use of machine learning. Porsche and Schuler aim to set new standards in the field of predictive maintenance and intelligent production control.

The joint venture will utilize Schuler’s new Servo 20 Technology. It raises maximum output from 18 to 20 strokes per minute while reducing energy consumption per stroke and per part. A newly developed die-changing concept makes it possible to produce small batch sizes with a high degree of economic efficiency. Further features of the new line include an optimized servo drive in the downstream presses plus a reduced footprint.

The joint venture will operate as an independent company (GmbH & Co. KG) held in equal proportions by Schuler AG and Porsche. Each of the two companies will invest a double-digit million Euro amount in the joint venture. Over 100 highly skilled jobs are to be created. The location of the new company has not been finally decided yet. However, its location is expected to minimize logistics distances for car body parts – thus significantly reducing CO2 emissions.

For further information on Schuler Inc., North America, please contact:

Jeferson Valerio, Director of Sales

Schuler Incorporated

7145 Commerce Blvd.

Canton, MI 48187 USA

734-207-7200

info@schulerinc.com

www.schulergroup.com

About the Schuler Group – www.schulergroup.com

Schuler is the world market leader in metal forming technology. The company supplies presses, automation solutions, dies, process know-how, and services for the entire metalworking industry and lightweight automotive design. Customers include automobile manufacturers and suppliers as well as companies from the forging, household appliances, packaging, energy, and electronics industries. Schuler is the leading supplier of minting presses and supplies system solutions for aerospace, rail transport, and large pipe manufacturing. In 2017, Schuler posted sales of € 1,233 million. Following the acquisition of toolmaker AWEBA and a majority stake in Chinese press manufacturing company Yadon, Schuler employs around 6,600 members of staff in 40 countries. The Austrian ANDRITZ Group holds a majority share in Schuler.

Continue readingParrot-Beak® Drum Truck for Handling all Rimmed Drums

Buffalo Grove, IL Liftomatic Material Handling, Inc., an industry leading material handling equipment manufacturer, recently introduced a new 4-wheel hand truck, the Liftomatic 10HT-4W.

The drum truck has two 10″ main wheels with full roller bearings, and two 4″ swivel casters to support the drum while moving through plants and warehouses, in addition to Liftomatic’s exclusive “Parrot-Beak®” clamping mechanism. Other features include a clamping mechanism that can be adjusted to handle all drum sizes from 10 to 85 gallons.

Liftomatic Material Handling, Inc. is an acknowledged leader in the design and manufacture of drum handling equipment. Headquartered in Buffalo Grove, Illinois, Liftomatic maintains manufacturing, engineering and sales facilities around the globe. Liftomatic currently sells products in over 40 countries and sells to more than 400 of the Fortune 500 companies.

For more information, please contact:

Liftomatic Material Handling, Inc.,

700 Dartmouth Lane, Buffalo Grove, IL 60089,

Sales Dept. 847-325-2930

Web: www.liftomatic.com

Email: info@liftomatic.com

For more product information, please contact:

George Gambini

Liftomatic Material Handling

700 Dartmouth Lane

Buffalo Grove, IL 60089

sales@liftomatic.com

847-325-2930 ext. 1226

www.liftomatic.com

250°F Special Electrically Heated Oven from Grieve

This Grieve oven holds one stainless steel tray 6″ wide x 18″ long x 6″ deep with perforated bottom. The tray sets on drip trap/air diffuser which is removable for cleaning. Features include 2” insulated walls and Type 304, 2B finish stainless steel interior.

Controls on the No. 861 include a digital indicating temperature controller, manual reset excess temperature controller with separate contactors and a recirculating blower airflow safety switch.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, Illinois 60073-2835

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese

SencorpWhite and Minerva Associates Announce a Strategic Merger

Acquisition designed to deliver advanced logistics software offerings for manufacturing and distribution

ISSUED UNDER EMBARGO until Sept 1, 2018 – SencorpWhite (Hyannis, Massachusetts) announces the acquisition of Minerva Associates, a strategic merger designed to expand SencorpWhite’s complete warehouse logistics system solutions for the global market.

Minerva Associates, based in San Diego, CA, has provided warehouse management, warehouse control, and asset management system software since 1987. Serving a base of regional distributors to Fortune 500 customers, Minerva’s WMS, WCS, and AMS products are field-proven in distribution, manufacturing and 3PL billing & order management.

This merger complements SencorpWhite’s inventory storage and retrieval products and extensive field-service options. It strengthens SencorpWhite’s expanding software resources and allows the SencorpWhite family to offer comprehensive, turn-key hardware and software solutions; solutions that improve accuracy and efficiency, and satisfy unique customer needs with increased configuration choices. This acquisition further strengthens the company’s overall value proposition in the market, in tandem with the 2017 acquisition of Intek warehouse software and the partnership with ICAM for vertical lift modules.

“We are excited to be a part of this strategic merger,” said Lisa Minerd who will remain Minerva’s President. “SencorpWhite shares our dedication to provide customers with the highest level of service, and comprehensive system solutions that improve the customer’s bottom line.”

“Our strategy is to be a great solutions company, and Minerva reinforces our position as a world-class provider of complete solutions for warehouse and storage automation,” said Frank Doyle, CEO of Connell Limited Partnership and chairman of its subsidiary SencorpWhite. “Minerva has a 31-year track record of providing great solutions to some of the world’s most recognizable companies, including large manufacturers and tech companies. This acquisition adds to our recently acquired Intek software bench strength multiple times over, and together we offer customers the strongest and most experienced WMS people in the business,” said Stan McLean, Intek’s VP System Sales & Implementation.

About SencorpWhite

SencorpWhite, a Connell Limited Partnership portfolio company, is a leading provider of unique end-to-end solutions for the packaging and management of high-value inventory. The company’s products and services – which range from innovative thermoformers and other packaging technologies to automated storage and retrieval systems and inventory management software – cover the entire supply chain spectrum, from the point-of-manufacture through distribution and to the point-of-use. For more information, call (508) 771-9400 or visit hwww. sencorpwhite.com and www.intek.com.

About Minerva Associates

Minerva Associates was founded in 1987 and is the sole owner, designer, developer, and provider of the Advanced Warehouse Logistics software platform, AWL. AWL provides measurable accuracy and efficiency improvements for distribution, manufacturing and 3PL billing & order management, from small regional distributors to Fortune 500 manufacturing enterprises. AWL installations can be found in North America, Western Europe, and the Pacific Rim. Minerva’s product offering and passionate talent are what make them stand out from other WMS software companies. For more information, call (858)-792-8626 or visit http://minerva-associates.com/.

SencorpWhite

400 Kidds Hill Rd | Hyannis, MA 02601 USA

508.771.9400 | info@sencorpwhite.com

www.sencorpwhite.com

Attention: Brian Urban

Minerva Associates

5910 Pacific Center Blvd. #330 | San Diego, CA 92121

858.792.8626 | info@minerva-associates.com

www.minerva-associates.com

Attention: Lisa Minerd

Siemens Introduces Updated Converting Toolbox

Software solution combines maximum performance with minimal implementation time

The toolbox enables machine builders to achieve considerably faster time to market by reducing the time required for engineering, programming, commissioning and documentation as much as 80%.

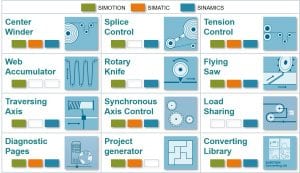

The Siemens Converting Toolbox has separate modules for each of the Siemens product categories typically found on converting machines, including SIMOTION motion controllers, SINAMICS drives and SIMATIC PLCs. SIMOTION is designed for high-performance motion control applications with centralized control in conjunction with the SINAMICS S120 drive system. SINAMICS is ideal for drive-based applications with process-related control implementation in the SINAMICS S120 drive system with graphical drag-and-drop programming. Lastly, the SIMATIC platform applies to centralized converting applications implemented in the PLC control to work in tandem with the SINAMICS S120 drive system.

Additional features of the Converting Toolbox include converting base applications such as: center winder, unwind flying splice control, sectional drive with tension/draw control, accumulator, rotary knife with print mark correction, flying saw, traversing control, synchronized multi axis drive control, load sharing, diagnostics Web pages, project generation tools and converting library process and logistic functions. These function blocks can literally be cut and pasted into a new design, with minimal programming time.

Other specialized application blocks are available upon request.

For more information, please contact:

William Gilbert, Converting Market Manager

Siemens Industry Inc.

5300 Triangle Parkway

Norcross, GA 30092-2538, USA

Tel: +1678 314-4222

William.gilbert@siemens.com

www.usa.siemens.com/converting

Siemens Digital Factory (DF) offers a comprehensive portfolio of seamlessly integrated hardware, software and technology-based services in order to support manufacturing companies worldwide in enhancing the flexibility and efficiency of their manufacturing processes and reducing the time to market of their products.

Siemens Corporation is a U.S. subsidiary of Siemens AG, a global powerhouse focusing on the areas of electrification, automation and digitalization. One of the world’s largest producers of energy-efficient, resource-saving technologies, Siemens is a leading supplier of systems for power generation and transmission as well as medical diagnosis. With approximately 351,000 employees in 190 countries, Siemens reported worldwide revenue of $88.1 billion in fiscal 2016. Siemens in the USA reported revenue of $23.7 billion, including $5.4 billion in exports, and employs approximately 50,000 people throughout all 50 states and Puerto Rico.

Continue readingPaR Systems Uses Siemens Digital Tools to Make Crane Operations More Productive and Safe

The Solution

Fortunately, recent advancements in digital technologies have fueled innovation in the field of crane control, and new solutions have been developed that are safer and smarter. One unique solution for modernizing cranes was designed to help operators by reducing load sway by a stunning 95%. This innovative solution, EXPERTOPERATOR™, was developed by PaR Systems (PaR) of Shoreview, Minnesota (www.par.com). PaR is a global manufacturer of advanced automation, robotic, and specialty material handling solutions. PaR supports global customers in automotive, aerospace, nuclear, life science, marine and other core industries.

EXPERTOPERATOR is currently installed on over 150 cranes worldwide – many of which are located in automotive, primary metal, and heavy equipment industry facilities. Users have indicated that EXPERTOPERATOR has allowed operators to control their crane loads with 95% less sway and 90% fewer “close calls” or collisions. Optional modules to the EXPERTOPERATOR platform provide robust zone control, sideload/snag prevention, and automatic load positioning.

How material handling customers are benefitting from EXPERTOPERATOR

Across 150 installations, EXPERTOPERATOR has improved personnel safety, reduced damages to equipment, increased efficiency, and reduced maintenance costs.

- Heightened safety of people and product – EXPERTOPERATOR minimizes payload motion by intercepting an operator’s commands and adjusting the output to emulate those of an experienced operator. This technology is proven to reduce cable sway by 85-95%. Thus, operator concentration can be focused both on the load and on the immediate environment surrounding the adjacent plant floor, instead of controlling load sway. As a result, both the load and the surrounding equipment are less likely to suffer damage.

- Increased efficiency and productivity – Many of PaR’s customers run 24×7 operations and have reported significant improvements in productivity. For example, one customer in a high-throughput locomotive manufacturing process reported that the critical path load positioning time was reduced from approximately 4 minutes to less than 2 minutes. This result is not atypical. End users who implement EXPERTOPERATOR generally report between 10 and 50% reduction in load positioning time.

- Easier-to-use crane operations – Increased productivity is due – in part – to the reduction of load swing, which makes the crane easier to operate efficiently. The intense manual manipulation ordinarily required by an operator to mitigate load swing is replaced by a simpler manipulation task: positioning a stabilized and swing-free load.

The evidence that EXPERTOPERATOR makes cranes easier to operate is further demonstrated by data captured through operator studies that measured the frequency of button pushes. While using the technology, operators pressed pendant buttons 60- 80% less than while conducting the same manipulation task without EXPERTOPERATOR. This metric demonstrates that fewer commands are needed to manipulate a swing-free load.

- Rapid Operator Training – Because EXPERTOPERATOR makes cranes easier to use, novice operators can quickly become proficient. In fact, new operators who utilize the technology generally perform as well or better than their more experienced counterparts who use conventional cranes. This technology effectively accelerates the rate at which operators learn to drive safely and efficiently.

- Reduced maintenance costs – Each time a crane operator pushes a button, electric current rushes through the power section of the drives. The current also flows into the motors, and this causes torque to be propagated in the mechanical drive train through to the gears, wheels, and finally the rails of the crane’s infrastructure. When the number of starts, stops and surges in current are reduced by 60-80% with EXPERTOPERATOR, the life of that critical equipment is prolonged. As a result, the mean time between failure (MTBF) statistic is improved by a factor of 2-3 times and maintenance costs are drastically reduced.

PaR Systems knew their success would depend on their ability to work with a partner who could provide critical hardware that is robust for industrial environments, quick to deploy, and highly configurable.

In material handling crane operations, wireless capability is a key operational factor. The Siemens Scalance W wireless solution offered PaR Systems a wireless component that was reliable and predictable. PaR had experience with non-Siemens wireless solutions in the past that were problematic, both functionally, and from a manufacturer support perspective. The Scalance W wireless solution can be configured to operate in a less congested frequency range (5 GHz), allowing for a more robust wireless signal. Since installing Siemens Scalance W wireless modules as part of their solutions, customers have experienced 100% uptime of their wireless communications. In addition to reliability, the Scalance Wireless Modules offered PaR exceptional customer and OEM technical support.

EXPERTOPERATOR is an advanced crane motion control system that is implemented entirely within the Siemens platform. The system uses equipment such as Simatic S7 PLCs, Simatic HMI Panels, and Scalance W Industrial Wireless Modules.

Time to market is also important to PaR Systems when delivering customer solutions. The Siemens Totally Integrated Automation (TIA) portal provided a platform to shorten engineering time through its simulation tools, programmer productivity tools, and additional diagnostics. PaR Systems benefitted from unique capabilities when programming the Simatic S7 PLCs and Simatic HMI Panel. They were able to dynamically change the cycle time of the main control loop during runtime, which is critical for optimizing the performance of their unique motion control. Debugging capabilities were enhanced because the tool monitors values and updates programs in real time for instantaneous feedback. Such tasks that are tedious and time consuming within other platforms happen automatically and dynamically when using the Siemens TIA solutions.

Material handling requires a fine balance between precision, efficiency, productivity, and most importantly, safety. As a result of the collaboration between PaR Systems and Siemens, new and experienced crane operators around the world can now confidently perform their tasks and contribute to enhanced plant safety and operational efficiency, while reducing equipment maintenance.

To learn more about how Siemens and PaR Systems can help digitalize operations, improve safety, and boost operational efficiency, visit https://www.siemens.com/global/en/home/products/automation.html or https://www.par.com/technologies/crane-controls/

Siemens Industry, Inc.

5300 Triangle Parkway

Norcross, GA 30092

For more information, please contact our Customer Support Center.

Phone: 1-800-241-4453

E-mail: info.us@siemens.com

usa.siemens.com

For specific information on this application, please contact:

Adam Shively

OEM Account Manager

Siemens Digital Factory

Phone: 952-221-3791

E-mail: adam.shively@siemens.com

Support: (800) 333-7421

The technical data presented in this document is based on an actual case or on as-designed parameters, and therefore should not be relied upon for any specific application and does not constitute a performance guarantee for any projects. Actual results are dependent on variable conditions. Accordingly, Siemens does not make representations, warranties, or assurances as to the accuracy, currency or completeness of the content contained herein. If requested, we will provide specific technical data or specifications with respect to any customer‘s particular applications. Our company is constantly involved in engineering and development. For that reason, we reserve the right to modify, at any time, the technology and product specifications contained herein.

About Siemens USA

Siemens Corporation is a U.S. subsidiary of Siemens AG, a global powerhouse focusing on the areas of electrification, automation and digitalization. One of the world’s largest producers of energy-efficient, resource-saving technologies, Siemens is a leading supplier of systems for power generation and transmission as well as medical diagnosis. With approximately 348,000 employees in more than 190 countries, Siemens reported worldwide revenue of $86.2 billion in fiscal 2015. Siemens in the USA reported revenue of $22.4 billion, including $5.5 billion in exports, and employs approximately 50,000 people throughout all 50 states and Puerto Rico.

Continue readingLongtime Rep Corporation President Tim Graham Assuming New Role at Company

Graham to become Director of Special Projects, Jim Wirtz to succeed as President

Tim Graham has been a force in the North American rubber industry for many years. After attending Hope College and the University of Michigan, where he achieved his degree in engineering. Tim began his career in technical sales with REP in 1979, when REP Corporation was less than a decade old. REP Corporation is the North American subsidiary of REP International, based in Lyon, France, a world leader in rubber molding and related machinery.

Working with former presidents Jim Jennett and Ron Dagar, Tim Graham helped to steadily build the REP install base of machines in the North American market, which today totals over 3000. He comments, “I’ve seen REP develop an amazing line of machines, over the years, starting with the G3. I was with the company when we made a major breakout on G6 injection presses, the first in the industry with microprocessor closed loop control, a huge jump in technology for the rubber industry.” Tim also watched the development of the company’s pioneering of valve-gated cold runner molding, which made a huge impact on the material consumption of the machinery on the market.

Graham become VP at REP in 2005 and, shortly afterwards, assumed the role of president, the position he’s held until today. He notes, “I’ve been at REP through some great periods of growth and also through some intense downtimes, but we’ve had a terrific team of sales and service people here at the company, over the years. They’re responsible for helping the company achieve the position we hold in the market today, in combination with what I believe to be the most advanced rubber molding technology in the world.”

Along the way, Tim Graham has met some incredible people in the rubber business. “I’ve always been impressed by the quality of the people in this industry, which I think derives from their technical skills combined with the people skills that drive any successful business. Even as the industry has transitioned to a very high technical level and gone online for so much of the communications over the years, it’s still very people-centric and the relationships I’ve had with some of the stellar members of the rubber business have been extremely rewarding, on a personal level.”

Tim Graham has taken an active role in the industry, participating for many years in local rubber group functions and as a founding member of the Association for Rubber Products Manufacturers. Tim’s legendary talents on the golf course are often the subject of discussion, he jokes, but he’s been proud to join his colleagues over the years in both business and social activities. He’s also attended every rubber trade show since 1979.

As only the third president of REP Corporation since its inception in 1970, Tim is very proud of the continuity of management and commitment to the industry at REP. “I’m certainly a very different person from my predecessors, but we all still talk and share stories about the industry and our company’s leading role in it.”

On the business side, Graham cites one project in particular as a shining star moment. “REP was challenged by a leading pharmaceutical product manufacturer to devise a highly automated work cell arrangement. We brought a variety of our engineering and machine building skills to the task at REP and fulfilled, even exceeded, our customer’s expectations. We all worked very hard to meet the challenge and were very pleased with the outcome, as was our customer. I think that, no matter how long you’re on the job, those moments are still very satisfying.”

He cites the many changes in the industry over the years. “Service has never been more important. From the early days of just-in-time in the auto industry until today, where the market has gone global and the high degree of automation means downtime must be minimized, we are now called upon more than ever to provide immediate assistance to our customers, whether it’s application engineering, commissioning and start-up validation, after-sales parts or machine service. Yes, we sell quality machines, but there’s so much more to the customer relationship today, especially as the older rubber guys leave and a whole new generation assumes the workload.”

Tim Graham gets philosophical, at times. “If I had to give advice to somebody in any business, it would be, don’t rest on your laurels. Always reach out for the next challenge and keep innovating the ways you build machines as well as the way you do business. A lot has changed over my years in the rubber industry, but that attitude has served REP well, since we began.” He notes that following college, he worked for his dad, also in the rubber industry, who’d given him some of that same advice.

Jim Wirtz, the new president at REP, muses, “We’re very glad Tim is sticking around for a time. His knowledge and especially his personal relationships with our customers are invaluable assets to REP. I look forward to working with him in the new role.”

Tim Graham is a Detroit native and grew up in Bloomfield Hills. Today, he resides in St. Charles, Illinois with wife Mary Anne.

For more information on this announcement, please contact:

REP Corporation

8N740 Tameling Court

Bartlett, IL 60103-8146

Phone: 847-697-7210

www.repinjection.com

Attention: Tim Graham or Jim Wirtz

AMF Marking and Cleaning Tools Now Available from Heimatec USA

Andreas Maier products now offered by live tooling importer

Marking tools from AMF (foreground) and cleaning tool (background), now represented in North America by Heimatec Inc.

Heimatec Inc., the North American importer of precision live tools, angle heads and multi-spindle drill heads, announces immediate availability of marking and cleaning tools from its European partner Andreas Maier, under the AMF brand. The announcement was made by the president of Heimatec Inc., Preben Hansen. “This development brings additional products to our current customers and responds to the market needs for quality marking and cleaning tools for workpieces in CNC machining,” he observed.

AMF marking tools are used for the permanent marking of workpieces made from all types of metal and thermoplastic substrates. They are typically mounted in Toolholders for use in the spindle of a CNC machine tool. Marking surfaces is achieved by a combination process of pressure and material displacement. These tools can function with or without rotation and usually without height adjustment on the spindle, resulting in a high-speed, highly efficient marking process and no degradation of the substrate. Very thin material as well as cylindrical workpieces can be easily marked, using AMF tools. Cost savings are said to be substantial, compared to conventional marking or labeling. Key design feature of the AMF marking tool is its needle, which achieves the surface marking with clarity and at high speed.

AMF cleaning tools are used for the cleaning of workpieces, tooling and the interior of CNC machines. They are typically clamped in Toolholders and mounted directly onto the machine spindle. Using through spindle coolant or compressed air, the cleaning tool removes swarf and other debris from workpieces, clamping tools, rotary tables and other fixtures before the next workpiece blank is loaded. The machine spindle can remain stationary or in slow rotation mode during the cleaning process. Models are available in horizontal or vertical styles to suit the machine spindle configuration and feature adjustable jet nozzles for precise cleaning and coolant or compressed air conservation. Kits can be furnished complete with tools, gauge and all fastening hardware or sold separately.

These new products from Heimatec Inc. are available immediately and are described in the literature available on request or at the company website.

For further information and literature on this new product line, please contact:

Preben Hansen, President

Heimatec Inc.

16 East Piper Lane, Suite 129,

Prospects Heights, IL 60070

USA

Tel: 847-749-0633

www.heimatecinc.com

Email: phansen@heimatecinc.com

Heimatec Inc. in Prospect Heights, IL, near Chicago, serves its growing North American customer base with an extensive inventory of machine tool accessories. Its experienced staff is dedicated to providing the most innovative tooling and technology. Heimatec serves the auto, aero, medical, woodworking, composites and other industries, as well as an ever-increasing number of machine tool OEMs worldwide, through its network of manufacturers’ representatives.

Continue readingAnother IMTS, but with BIG DIFFERENCES

As Industry 4.0 continues to make its mark on every industry in which we work for our industrial client base, no show better represents the sea change brought to the market better than IMTS, upcoming in a month.

The “digital factory” and “big data” and “industrial internet of things” and other buzzwords are perceived quite differently by each market we serve, which is why marketers must be cognizant of the landscape in their particular industry, when addressing this issue. Those concepts hit the ears of automotive, aerospace, medical, EOEM, forge and foundry people in radically different ways. Learn where your market is today on the subject. For a quick summary, call me!

I can remember the 1970s, when our injection molding machine client’s president instructed me not to use the world “electronic” in an ad, as he feared it would scare off his customers and prospects, as that industry was largely curing parts with glorified egg timers. Today, that client’s machines are leading the charge in the generation, capture and cloud-based management of all production values and machine kinematics. And we’ve been privileged to journey that path with them.

(more…)

Retargeted Advertising: The Way of the Future…and Now!

Most web users (which is most people), should be well aware of retargeted ads. Even if you don’t realize why or how they work, you’ve probably noticed suspiciously interesting ads following you from site to site. You may be asking, “how do they know what I was just searching, or what I’m interested in? How are they able to follow me?” The question you should be asking is this: “how do I reach my customer base this same way?”

We live in a time that allows us to advertise specifically to customers who have shown a direct interest in your product, whether they had visited your website, made a search inquiry relating to one of your products or searched websites of a similar topic. This technology is here for the taking, so what’s holding you back?

- Cost is oftentimes a fear when first beginning a retargeting program, but this shouldn’t be the case. Retargeting is one of the most affordable ways to reach your customer, usually costing just a couple bucks for a click on your ad. If you’ve really done a good job of controlling and organizing where and how your ads show, clicks can be under a dollar!

- Another concern is the initial setup required and time necessary to monitor and adjust the account. While it can be daunting, the process is well worth the time. We’re here to help with this as well, setting up, monitoring, adjusting and providing feedback on how the campaign is working, tweaking things along the way to keep your cost-per-click as low as possible and overall quality of clicks as high as possible.

- Finally, you’ll always hear the concern that retargeting is just “too creepy and invasive.” New technology will always be looked at this way – you can bet that the invention of the telephone elicited a similar response – but people adjust and become comfortable with everything over time. In fact, users stay interested in retargeted ads twice as long as a regular online ad, and for good reason – they’re ads that the user has already shown interest in ahead of time! Retargeting isn’t going anywhere and will only increase in popularity over time. Now is the time to take advantage of your competitors who are not using this service!