Contact us today:

Author Archives: Bernard and Company

L-MAX – A New and Unique Way To Machine Multiple Layer & Composite Materials

For best results in the machining of multiple material layers, cutting parameters must be applied for each different material. The new L-MAX, a portable drilling unit from SOMEX (a member of the SUHNER group of companies) can perform all of these functions in automatic mode.

Multiple material layers, also referred as Stacks, can be composed of completely different materials, stacked up in layers of, for ex ample: Titanium, Carbon or Aluminum. In order to achieve optimal machining results, each material layer must be programmed with its own cutting parameters- ideally for each layer automatically. The spindle speed and feed rate must be adapted for each material transition to the next.

In the past, aluminum was the primary choice of materials used in the aircraft industry and portable, handheld pneumatic-driven drilling units were used as a common tool in this industry.

The application of these conventional pneumatic drilling units in today’s modern and innovative aircraft industry necessitates extreme compromises. In addition to large air consumption combined with high noise emissions, pneumatic-driven drilling units cannot perform feed and speed variations as required for different stack materials.

Consequently, only a portable, handheld NC-programmable drill unit is capable to deliver optimal results and high efficiency, since the aircraft industry imposes rigid quality standards including:

– Concentricity / position between holes ≤ 40 μm

– Surface quality between Ra 1.6 und Ra 3.2

– Circularity / Hole quality for rivets ≤ H8

– Other requirements such as avoidance of delamination.

Working principle for a portable, handheld

NC-programmable L-MAX drilling unit

An L-MAX concept integrates 2 servo motors: The larger motor drives the spindle and the smaller servo regulates the feed. The feed rate is determined by the speed difference between ball screw and ball screw nut or, in other words:

– If the speed (rpm) of the feed servo motor is higher than the spindle motor speed (rpm), then the L-MAX spindle will advance.

– If the speed (rpm) of the feed servo motor is lower than the spindle motor speed (rpm), then the L-MAX spindle will retract.

Both servo motors are controlled by the control system IDM. It allows the user to regulate spindle speed and feed at any position of the total travel.

Furthermore, an adaptive drilling mode can be selected to help improve and optimize a drilling cycle. In this mode, the drill unit recognizes the transition from one layer to the next, automatically. Irregular material thickness of layers at any position are detected and matched with the correct cutting parameters. This way, cycle times can be minimized and machining quality and results optimized.

The control system includes a Minimum Quantity Lubrication (MQL) system, which is directly mounted to the mobile platform.

– Programmable spindle speed and spindle feed

– Work cycles such as chip brake cycle and peck feed cycle Spindle speed range from 3,000 rpm up to 5,000 rpm

– Drilling capacity from 4.76 mm (3/16”) up to 11.11 mm (7/16”)

– Integrated Minimum Quantity Lubrication (MQL)

– Light weight, depending on drilling capacity, from 5.5 kg (12lbs)

– Quiet operation up to 65 dBA

– Option: Adaptive drilling mode

SUHNER INDUSTRIAL PRODUCTS, CORP.

Hwy 411 S./Suhner Drive

P.O. Box 1234

Rome, GA 30162

Phone: 706-235-8046

Fax: 706-235-8045

Attention: Lee Coleman, Automation Division

www.suhner.com

automation.usa@suhner.com

Text and pictures files can be found and down loaded at:

www.suhner-press.com

GMTA News Of Note (Issue 2015-2)

Ann Arbor, Michigan – GMTA (German Machine Tools of America) represents various top-quality German metalworking machine builders, including Wera Profilator, K + G, Pittler, Praewema and WMZ, as well as Arnold lasers. These machines are sold to the North American market exclusively by GMTA, primarily for gear and spline production, as well as other power transmission and various metalworking applications. The company’s target markets include automotive, off-highway, energy and other heavy equipment manufacturing. Machines are provided for gear honing, gear grinding, the patented Scudding® process for gearmaking, polygon milling, turning, gear tooth pointing and multi-task machining operations, as well as various laser operations or laser line integration and parts washing. This newsletter is provided to our friends in the media to keep you and your readers updated on News of Note at GMTA.

In the news…

-GMTA participated in the annual Auto Show Charity Preview in Detroit and a good time was had by all.

-GMTA is running at “light speed” with their new Arnold laser work cells. Available as single or double work cells, the Arnold systems are offered as CO2 or fiber lasers, with full integration into a machining line, either by means of robotic part articulation or other automated transfer mechanisms, most of which are being supplied to customers by GMTA engineering. Leads from IMTS and the company’s aggressive ad program are already being developed into serious opportunities for the company, often in tandem with other machine tool lines and the Rosink parts washers now offered by GMTA.

-Recently, a Diskus vertical double-disc grinder was sold to Hoergiger Fine Stamping in Canada. The DDS 600 machine feature two vertically arranged motor spindles, each equipped with 600mm grinding wheels used for simultaneous two-sided grinding of shims. The machine has a rotary through-feed system and an integral post-process measuring system, all developed by Diskus engineering and provided to the customer by the GMTA teams from Ann Arbor.

-The Mexico office of GMTA is reporting brisk activity, owing to the substantial procurement authority in-country now. According to VP Scott Knoy, “This contrasts with bygone days, when the decision-making and purchasing were largely centered in America and specifically in Detroit. It’s a whole new ballgame with the Mexican market today and we believe our new location (Queretaro) there is well positioned to serve this dynamic manufacturing environment.” GMTA already has a substantial installed base of machines in Mexico from all their partner companies.

-GMTA management will be attending EMO in Milan with its partners, then exhibiting at Gear Expo, being held this year in Detroit, October 20-22.

-The alliance with Star, through which GMTA is sourcing tooling locally, continues to prosper and mutually benefit both companies.

-GMTA was featured prominently in a recent article in Manufacturing Engineering magazine, covering the subject of gear making for the energy sector.

-Now available from GMTA, the Präwema SynchroFine 205 HS gear honing machine features direct-driven, digitally controlled spindles for the tool and the workpiece, enabling precise, rigid synchronization. The Präwema Honing gear finishing process produces quality comparable to grinding results for spur and helical gears, as well as shafts. The machine’s software checks the stock allowance and workpiece runout and then optimizes the X-axis approach distance. Measuring the workpiece does not affect the cycle time and the process can reduce overall cycle times by 3 to 5 sec.

For more information on this announcement, please contact:

GMTA (German Machine Tools of America)

4630 Freedom Drive

Ann Arbor, MI 48108

Phone: 734-973-7800

Fax: 734-973-3053

Web: www.gmtamerica.com

Email: scott@gmtamerica.com

Attention: Scott Knoy, VP

Connect with GMTA online:

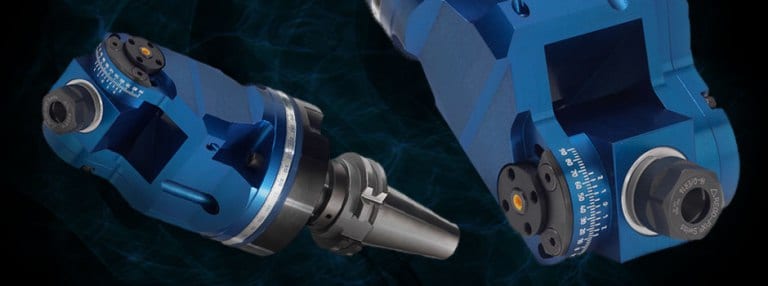

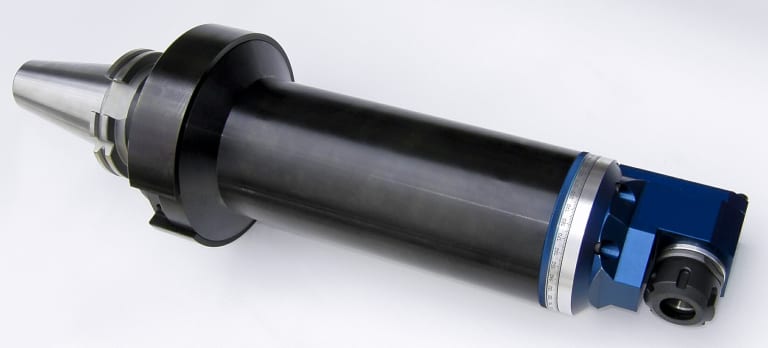

Coolant-Thru Tooling From heimatec

Straight and angle head styles available for all popular machine tools; now offered on all tools in company’s current line

Heimatec, a world leader in live tools, angle and multi-spindle drill heads, today announces immediate availability of its newest development, a coolant-thru feature on all the company’s current line items.

Coolant-thru technology is often the answer for faster, cleaner cutting on larger and deeper parts, where the chips and excess heat build-up are significant challenges. Heimatec now offers high-pressure coolant-thru designs up to 1000 psi on straight and 2000 psi on angle head tools.

Company president Preben Hansen comments, “Production drilling should almost always be done with internal coolant tools and this development means we’ll be able to satisfy more customer needs in that area.”

A full range of styles and pressures is available immediately, according to the company.

Heimatec literature is offered, fully detailing all products available, both with and without this coolant-thru feature.

For further information and literature, or to arrange a demo on this new line, please contact:

Preben Hansen, President

HEIMATEC INC.

16 E. Piper Lane Suite 129

Prospect Heights, IL 60070

Phone: 847-749-0633

Fax: 847-749-2445

Email: info@heimatecinc.com

Website: www.heimatecinc.com

Ultratech Forms Productive Partnership With Press Supplier

Fond du Lac, Wisconsin tooling supplier and metal stamper uses press and diework relationship with Heim to further develop its business, enter new markets and prosper

Ultratech Tool & Design Inc. (Fond du Lac, Wisconsin) began as a tool shop in 1990 (happy 25th anniversary!), serving the small engine manufacturing sector, Over the course of the past seven to ten years, the company has been supplying stampings from its 32-ton to 600-ton presses, with products ranging from simple washers to complex automotive and aerospace components. As President Bill Melang notes, “We took the tooling expertise we had from the start and built the business around it. This approach gave us the ability to see our customers’ challenges from the inside and help them find better solutions for their own production.” Major manufacturers in industries such as automotive, consumer goods, electrical products and aerospace populate the ranks of Ultratech’s North American customer base.

All jobs begin here with the tool design. Ultratech uses Solidworks and Logopress software to produce its designs, then interacts with its customers in that fluid exchange of ideas, engineering suggestions and production fine tuning that creates the finished product. That product is made entirely in-house at Ultratech on the latest CNC machines and CMM test equipment. Melang comments, “We try our best to stay ahead of the competition with our machine tools and design protocols, using the best technology available in the market.” Sensor selection on the dies, for example, is performed in the shop’s sensor lab, where simulation of the die-in-press scenario translates to a tool that is less likely to crash, plus Ultratech produces dies with complex in-die tapping and nut/stud insertion capabilities, as well as lamination dies.

Out on the production floor, another key reason for the shop’s success stands at the center of the operation. Back in 2002, according to Melang, the company formed a working relationship with The Heim Group (Chicago, Illinois), buying their first Heim press. Today, there is an 80-ton Heim OBS with 5000 lb. feed line, plus a 500-ton Heim Maxi-Stamper with 10,000 lb. feed and a 600-ton Heim Maxi-Stamper with 20,000 lb. feed. Complementing this equipment is a full resistance welding, heat treating and assembly cell operation. Ultratech also supplies its customers a range of finishing and part coating options to facilitate ready-to-assemble requirements.

Describing the partnership his company enjoys with Heim, Bill Melang observes, “Back in 2002, we bought our first Heim press. It was an older machine and Heim helped us with a rebuild. Since that time, we’ve developed a value-adding relationship with Heim, as they’ve provided us considerable assistance with press utilization and maintenance advice, while I think we’ve also been helpful to them with die design ideas.”

Heim President Katie Heim further comments, “Our relationship with Ultratech has benefited both our companies, over the years. As our industry knows, the die dictates the press and we’ve worked closely with Bill and his team, as this particular customer’s knowledge of die design and performance characteristics in the press has created a real synergy with our engineers, who bring decades of press design and die handling mechanics to the task. The fact that Ultratech also has some of the nicest people in the industry, starting with Bill, is the icing on the cake, so to speak,” Katie remarks.

This American-made press builder, Katie notes, is quite often asked for a turnkey system of press, die and coil handling equipment, including complex die and part handling mechanisms, in a single package. She observes, “The knowledge we’ve shared with and acquired from Ultratech has made us both stronger players in the market today.” She added that the decline in the workforce numbers and equipment manufacturers based in America has created the need for companies such as Heim to be more pro-active in the turnkey area, as customers today seek this assistance on a much more frequent basis than previously occurred.

Katie Heim is third generation owner of the business, which has built presses in Chicago for nearly 70 years and today boasts over 55,000 machines in the global stamping market.

Heim produces presses to 1000 tons and also supplies coil handling, part transfer mechanisms and complete die systems in turnkey packages for customers worldwide.

Ultratech is an ISO 9001:2008 certified supplier and is currently advancing to the TS automotive specification that will enhance the company’s involvement as a supplier to that industry. The shop employs 25 people, including the next generation, as Bill Melang’s son is in the business and has recently completed a plant expansion of 30,000 square feet.

Lastly, Bill Melang mentioned the assistance he’s received from Jack Best and Tony Mase at Heim. “There isn’t a single question we’ve thrown their way that went unanswered. They do what they say they’ll do and that gives us great confidence in their abilities to handle our very fast-paced variety of needs for presses and support engineering.”

For more information on this story, please contact:

Bill Melang, President

ULTRATECH TOOL & DESIGN INC.

1210 Scott Street

Fond du Lac, WI 54936-0548

Phone: 920-922-0257

www.ultratechtooldesign.com

bmelang@ultratechtooldesign.com

OR

Katie Heim, President

THE HEIM GROUP

6360 W. 73rd St.

Chicago, IL 60638

Phone: 08-496-7400

www.theheimgroup.com

katie@theheimgroup.com

Voith Hydro Achieving Improved Production of Power Generation Equipment Through Standardization of Machine Tool Controls

Large parts and one-off runs present particular challenges; common CNC platform offers many benefits to busy York, PA shop

Despite the large, heavy workpieces and frequent one-off production, Voith Hydro maintains a steady flow of work for its machining, typically holding +/- 0.002” tolerances on various carbon and stainless steels. Workpieces here often exceed 25’ in diameter.

Voith Hydro in York, Pennsylvania is a major manufacturer of hydroelectric power generation equipment, especially the intricate turbines used in such operations, supplying hydroelectric generating companies and municipalities throughout North America. Over 12,000 units have been commissioned in the field with more than 65,000 MW of installed capacity, plus Voith Hydro has also upgraded over 600 existing power generation units. As a turnkey supplier to the industry, the company manages all phases of power plant projects, from analysis and planning, design and implementation, to commissioning and operation. Voith Hydro is ISO 9001 and ISO 14001 Certified.

Milling, line boring and turning operations are performed on large multi-axis machine tools, most equipped with Siemens SINUMERIK 840D CNC onboard to control all axes of motion.

At the York facility, very large multi-axis machining centers produce carbon and stainless steel work pieces, most often in a one-off mode and at sizes frequently exceeding 35’ in diameter. Adam Ward, the manager of maintenance & facilities at Voith Hydro, says the machining done typically holds +/- 0.002” tolerances here, nonetheless. “We do turning, line boring and milling on extremely large and heavy work pieces that often challenge us to design the optimum machining cycle. Our long cycles can frequently result in heat distortion on material surfaces and so we take great care in looking for problems before they occur.”

Voith Hydro maintains an impressive array of machine tools and multi-axis machining centers here. Despite a variety of builder brands, the majority of the machines have one common component, namely, the Siemens SINUMERIK 840D CNC onboard.

Remote condition monitoring is performed between Voith Hydro and many of its machine tool builders to troubleshoot and resolve issues in real time, using the CNC on the machine.

As Ward notes, “Our operators are quite comfortable with the CNC from Siemens and they use it for all motion control, plus the operator interface has the ability to afford us great troubleshooting capability and something else we value greatly, the commonality of the HMI on the control. That fact allows us to do a great deal of cross-training and that’s very important to us. We need to be highly flexible, given the one-off nature of our work here.” Most of the operators at Voith Hydro are capable of running multiple machines, while the maintenance personnel on his team can more easily service the machining equipment in the facility, adds Ward. He credits his machine builders and the Siemens team led by Howard Weinstein and Robert Stiefel for this ongoing flexibility.

Part designs are run through the company’s CAM system and simulated offline to preserve machine uptime.

Voith typically takes a customer design, runs it through their CAM system and simulates the cycle offline, in order to preserve valuable machine uptime. Since the work here involves highly complex geometries on the turbine sections, the simulation must be equally complex and account for all machine motions and collision avoidance. Once the program is finally determined for a part, it is fed over the Voith Hydro network to the appropriate machine tool or machining center for scheduling and production startup.

During production, a system of real-time remote condition monitoring is available through the CNC for troubleshooting by both the Voith Hydro maintenance personnel and, when required, machine builder personnel, working offsite.

Large Ingersoll milling machine was retrofit recently, with all new Siemens CNC, motors, drives and other hardware.

Ward cites one example where an Ingersoll milling machine was completely retrofitted both mechanically and electrically by a Siemens Solution Partner, with a new CNC, motors, drives, encoders, other hardware and software. “Working with the builder and Siemens support personnel, we were able to resolve issues and implement changes to the programming, right on the CNC of the machine…and all done remotely, in a very short time period.”

Voith Hydro in York, PA produces a wide variety of power generation components for various machine builders and municipalities across America.

Voith Hydro boasts machining capabilities on workpieces over 42’ diameter and 350 tons at the York facility. Surface finishes are typically 250 and 125 Ra, though occasionally 64 or 32 Ra is required. The finishes are achieved through both machining and secondary finishing operations, according to company sources.

Adam Ward further notes that, on most new machines required at Voith Hydro, “The cross-training capability of the CNC, the standardization of the HMI on various types of machines, the support provided and the previous successes our operators and maintenance personnel have realized, all combine to make specifying Siemens as our control of choice an easy decision.”

Howard Weinstein, business development manager for the power industry manufacturing sector at Siemens, comments on the relationship with Voith, “We’re a proud partner to Voith Hydro in York, Pennsylvania. Their facility is a great showcase for our flagship CNC, the SINUMERIK 840D, as used on an array of multi-axis machining centers to produce large, complex geometry parts for the hydroelectric power industry.”

For more information on this story, please contact:

SIEMENS INDUSTRY, INC.

DRIVE TECHNOLOGIES – MOTION CONTROL (MACHINE TOOL BUSINESS)

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/cnc

Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communication

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

Others involved in this story may also be contacted:

Voith Hydro

760 East Berlin Road

York, PA 17408-8701

Phone: 717-792-7512

Web: www.voith.com

Email: adam.ward@voith.com

Adam Ward, Manager of Maintenance & Facilities

Chemcoaters Service Center Workshop & Plant Tour

Take a few hours to gather some great information and ideas to make your 2015 a great year!

Come on over to Chemcoaters for networking, lunch and to see new and exciting things to amaze your customers!

When: Thursday February 26, 2015

Where: Chemcoaters, Gary, IN (more details below)

Time: 11:00am – 1:00pm

What:

- Information about the products and processes that can help your customer

- Learn all about Intercoat© ChemGuard and the customers it can help

- Dry Film Lubricants, Thin Film Acrylics, Reclamation

- Markets and the products that can help you succeed in them

- Technical Experts to address all questions and concerns

- Tour of the coating line and facility

- Lunch will be served

- Networking

- Gift for participating

“If you’ve been to a workshop before, this will give you more insight and get you even more familiar with everything we do and how you can use it to develop more business.”

“If this is your first chance to learn about Intercoat© ChemGuard, you’ll be amazed at how this can help some of your current customers, and just may unlock the door that has been locked up this point! Invest in yourself!”

Call Mike Tieri to reserve your spot for a fun, interesting and informative session!

Mike Tieri

Director of Sales Marketing

Chemcoaters, Inc.

700 Chase Street

Gary, IN 46404

Phone: 877-411-2905

Email: miket@chemcoaters.com

Website: www.chemcoaters.com

Connect with Chemcoaters online:

1000°F Electric High Temperature Universal Oven for Cleaning and Heat Treating

Workspace dimensions inside this unit measure 24” wide x 36” deep x 24” high. 24kW power is installed in Incoloy sheathed tubular heating elements. A 1000 CFM, 3/4 HP recirculating blower provides a front-to-back horizontal “universal” airflow to completely surround the workload.

This Grieve oven features 8” thick insulated walls, an aluminized steel interior and exterior, plus inner and outer door gaskets. The inner gasket seals directly against the door plug, while the other gasket seals directly against the front face of the oven for optimum seal integrity. The unit accommodates up to seven shelves on 3” centers.

Standard equipment includes a digital indicating temperature controller, manual reset excess temperature controller with separate heating element control contactors, a recirculating blower airflow safety switch and a UL Listed control panel, top-mounted to minimize floor space requirements.

All standard universal ovens by Grieve meet the requirements of National Fire Protection Association Standard 86, Industrial Risk Insurers, Factory Mutual and OSHA Standards.

This unit was entirely designed, engineered, built and full tested by Grieve.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

Guill Tool Offers Wide Variety of Extrusion Tooling at NPE 2015, Booth 5549

Guill Tool, a West Warwick, RI designer and builder of extrusion tooling, offers an assortment of literature for machine builders and extruders at its website, www.guill.com.

Individual brochures are offered, depicting the wide array of tooling possibilities…straight inline heads, rotary heads and crosshead dies…available to suit any extrusion machine built anywhere in the world, running all types of compounds.

Guill provides tooling for plastic, rubber, TPE and other material extrusions, with end products ranging from extremely thin-walled, multi-lumen medical tubing and catheter balloon tubings up to multi-layer wire & cable jacketing and 20” diameter pipe for industrial applications and agricultural drip lines. Guill also provides tooling for film, sheet and profile extrusions.

The company designs, engineers, machines, assembles, tests and delivers all tooling to its worldwide customer base in all the consuming industries for extrusions. The company also offers tooling carts and disassembly/cleaning stations for easier line integration.

According to company sources, the utilization of properly designed and engineered tooling can result in substantial material savings for extruders of all types.

NOTE: Guill will attend MD&M West in February, NPE in March and Interwire in April, 2015.

Please visit www.guill.com to request a quotation or obtain company literature.

For further information, please contact:

GUILL TOOL & ENGINEERING CO., INC.

10 Pike Street

West Warwick, RI 02893

Phone: 401-828-7600

Web: www.guill.com

Email: sales@guill.com

Attention: Bill Conley

Connect with Guill Tool online:

NIIGATA To Feature Two New All-Electric Injection Presses at NPE Booth W-1363

Longtime market leader in all-electric injection presses NIIGATA will introduce two new machines to the market at the upcoming NPE in Orlando, March 23-27.

Visit NIIGATA at NPE Orlando, Booth W-1363, March 23rd-27th with a free guest pass.

NEW: NIIGATA all-electric MDVR110S7000 (Vertical IMM with 2-station rotary table)

NIIGATA introduced the world’s first all-electric vertical IMM in 1996 and its latest model, the S7000, capitalizes on NIIGATA’s long history and 100% focus on making all-electric machines.

Highlights of the new MDVR110S7000 include:

~While many vertical machines have high table heights, forcing the customer to build a work platform around the machine, the NIIGATA patented vertical toggle system allows lowering the table height on this 110-ton model to just 3.4 feet from the ground, including leveling pads.

~The machine has a wider table than standard verticals, allowing larger molds to be placed on the platen. The MDVR110S7000 boasts a mold size capacity of 500mm x 500mm (33.64” x 33.64”).

~Fast table rotation of under 1 second.

~Ultra low-speed injection can be beneficial in molding thicker walled insert jobs. NIIGATA boasts an ultra low-speed capability of just .01 mm/sec injection speed.

~With a 2-station machine running separate “A” and “B” mold halves, a molder can often encounter problems with differences in mold halves causing part variations. With the NIIGATA Vertical, two completely independent injection profiles can be set for the “A” and “B” halves, allowing the molder to finish the job without making expensive and time consuming mold repairs or adjustments.

NEW: NIIGATA MD110S7000 horizontal all-electric IMM

Having introduced our first fully-electric machine at the Japan Plastics Fair in 1984, NIIGATA has devoted 100% of its R&D resources toward improving all-electric molding machine technology. Using the Japanese Kaizen system, we are now introducing our 7th generation of the all-electric machine, built entirely in Japan to tough quality standards.

A few NEW features of the MD110S7000 all-electric IMM include:

~Elimination of moving platen’s lower side tie bar bushings to improve the cleanliness of the part drop area.

~Addition of an FDA-approved grease supply system that allows medical cleanroom and food grade applications with fewer worries about part contamination.

~NIIGATA’s standard high nozzle touch force, similar to that of the hydraulic machines, can now be dialed down when the application allows, to promote longer sprue bushing life.

~Fully automatic and adjustable mold clamping force is continuously monitored by tie bar sensors.

~NIIGATA’s horizontal machines boast the industry’s shortest footprint, but heaviest overall weight to provide superior machine durability.

Also in the Niigata booth…

NIIGATA MD385W6000 all-electric IMM:

NIIGATA’s “workhorse machine”, the MD385 is being exhibited running a drink cup mold provided by a customer, together with an impressive IN-MOLD LABELING SYSTEM manufactured by Campetella of Italy. See and learn more about the MD385 HERE and at the show!

Also running during the show…

NIIGATA MD55S6000 all-electric IMM:

NIIGATA’s small size all-electric press will be exhibited at the booth of LUBE Corp. USA ( #W-2389). This machine will have clear covers, highlighting the automatic lube system of the machine. ( http://lube-global.com/english/)

Don’t forget! NPE, Booth W-1363

For more information on all these developments, please contact:

Peter Gardner

Vice President Sales and General Manager

NIIGATA Operations North America

DJA Global Group

939 AEC Drive

Wood Dale, IL 60191

Phone: 630.875.0202

Fax: 630.361.6060

E-mail: peter.gardner@niigata-us.com

Website: niigata-us.com

Connect with NIIGATA online:

Honing Machine Optimizes Gear Finishing

Available from German Machine Tools of America, the Präwema SynchroFine 205 HS gear honing machine features direct-driven, digitally controlled spindles for the tool and the workpiece, enabling precise, rigid synchronization

Ann Arbor, Michigan – Now available from German Machine Tools of America (GMTA), the Präwema SynchroFine 205 HS gear honing machine features direct-driven, digitally controlled spindles for the tool and the workpiece, enabling precise, rigid synchronization. The Präwema Honing gear finishing process produces quality comparable to grinding results for spur and helical gears, as well as shafts. The machine’s software checks the stock allowance and workpiece runout and then optimizes the X-axis approach distance. Measuring the workpiece does not affect the cycle time and the process can reduce cycle times by 3 to 5 sec.

The machine features a pick-up design to enable automation. The workpieces and dressing tools are loaded and unloaded by the workpiece spindle. The large X-axis travel enables placement of additional stations adjacent to the loading/unloading station inside the machine, such as a two-flank roll-checking device. External robots and conveyor systems can also be integrated by GMTA engineering.

The honing machine is constructed on a natural granite bed to promote stability and control thermal fluctuations. The X and Z axes are equipped with linear motor drives. The cutting tool is clamped with a hydraulically operated system and the tool spindle can be swiveled into a vertical position, enabling easy access. Additional options are available for machining over-sized drive shafts as long as 850 mm and the Präwema SynchroFine 205 HS-D model, equipped with two spindles, is offered for further reduction of cycle times.

For more information on this announcement, please contact:

GMTA (German Machine Tools of America)

4630 Freedom Drive

Ann Arbor, MI 48108

Phone: 734-973-7800

Fax: 734-973-3053

Web: www.gmtamerica.com

Email: scott@gmtamerica.com

Attention: Scott Knoy, VP

Connect with GMTA online: