Contact us today:

Author Archives: Bernard and Company

MAE Straightening and Wheel Set Presses to Be Represented By American Wera

North American sales to automotive, heavy equipment, steel, rail, OCTG and other metal fab markets to be handled by leading supplier of machine tools

MAE offers a broad line of manual, semi-automatic and automatic straightening equipment with press forces to 25,000 kN, used particularly in the automotive, heavy equipment, steel, rail and OCTG markets on round, profiled and complex shaped workpieces in lengths up to 100 feet. MAE machines possess the high accuracy and repeatability necessary for extremely tight straightening tolerances on such large workpieces.

Finally, MAE also offers special application presses in C-frame, as well as four-column styles with press forces to 10,000 kN. These special application presses are typically used in forming and calibration.

Scott Knoy, vice president of sales for American Wera, states, “We believe the MAE line will complement our existing equipment, making us a greater value adder to current customers, plus it will open new markets where our expertise can be helpful to a variety of end product manufacturers.”

Executing the agreement were American Wera President Walter Friedrich and MAE Managing Director Ruediger Goetzen.

For more information on this announcement, please contact:

GMTA (German Machine Tools of America) Formerly American Wera

4630 Freedom Drive

Ann Arbor, MI 48108

Phone: 734-973-7800

Fax: 734-973-3053

Web: www.gmtamerica.com

Email: scott@gmtamerica.com

Attention: Scott Knoy

Facebook: GMTA

Twitter: @GMTA_US

Weld lines prediction: from the Injection Molding Simulation into the Structural Simulation

With aid of the interface SIGMALINK®, the weld lines predicted with the injection molding simulation software SIGMASOFT® can now be mapped into Finite Element Analysis Software and be considered in the structural design of injection molded parts

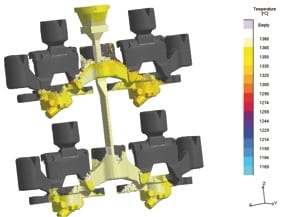

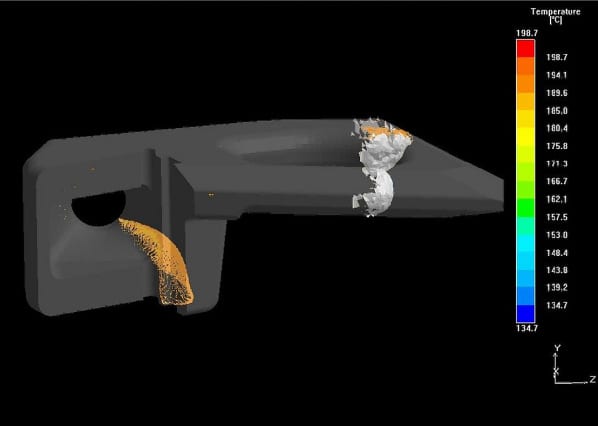

The tracer technology in SIGMASOFT® allows visualizing the fully 3D profile of weld lines over the part thickness. With SIGMALINK this information can now be mapped into structural FEA.

Schaumburg, IL – Sigma Plastic Services, presents a new functionality of its injection molding simulation software SIGMASOFT®. The simulation of the cavity filling in injection molding allows identifying regions where weld lines are formed, not only on the surface but also through the part’s thickness, with a completely 3D approach. With the interface SIGMALINK® it is now possible to transfer this 3D information into FEA (Finite Element Analysis) Software, to consider the drop in mechanical properties in these regions when performing structural design. A particular advantage of SIGMASOFT® is the fully 3D prediction of the weld lines, which reproduces the weld regions not only on the surface, but also through the part’s thickness, as it occurs in reality.

Weld lines occur as a consequence of the collision of two (or more) flow fronts in the cavity of a mold. This disruption in the homogeneity of the injection molded part causes optical defects, which compromise the surface quality, but also produces a weakening from the mechanical point of view and, under certain circumstances, weld lines can even act as stress concentrators. Therefore, there is a loss in the mechanical properties in the regions where weld lines appear.

Using the “tracer” technology, which has been available for years in SIGMASOFT®, the appearance of weld lines can be reproduced during the filling stage. The location of the weld lines can be described precisely and an indication is given regarding how critical they are. The formation of the weld lines during the filling stage and the way they flow as the packing pressure is applied are predicted accurately in a 3D approach.

The interface SIGMALINK enables exporting (mapping) physical and flow-related properties into commercial software for FEA (such as Ansys, Abaqus, Radios, etc.). Factors such as flow and thermal induced stresses and fiber orientation can be considered in the FEA. With a further expansion of SIGMALINK® it is now possible to export the information about the final position and 3D profile of the weld lines in the structural FEA. In this way, the drop in the mechanical properties produced by the apparition of weld lines can also be considered in the mechanical part design.

In Figure 1 the formation of a weld line region in SIGMASOFT® is presented. The flow front is depicted in grey. The “tracer” particles in orange show clearly that the melt fronts do not collide in a flat region, but that this weld line has a complex 3D profile at the end of the filling and packaging phases.

SIGMA (www.sigmasoft.de) is 100% owned by MAGMA (www.magmasoft.de), the market leader in casting process simulation technology based in Aachen, Germany. Our SIGMASOFT® process simulation solution optimizes the manufacturing process for injection molded plastic components. SIGMASOFT® combines the 3D geometry of the parts and runners with the complete mold assembly and temperature control system and incorporates the actual production process to develop a turnkey injection mold and optimized process.

At SIGMA and MAGMA, our goal is to help our customers achieve required part quality during the first trial. The two product lines – injection molded polymers and metal castings – share the same 3D simulation technologies focused on the simultaneous optimization of design and process. SIGMASOFT® thus includes a variety of process-specific models and 3D simulation methods developed, validated and constantly improved for over 25 years. A process-driven simulation tool, SIGMASOFT®, with its comprehensive simulation approach, provides a tremendous benefit to production facilities. Imagine your business when every mold you use produces required quality the first time, every time. That is our goal. This technology cannot be compared to any other conventional “Design” simulation approach employed in plastics injection molding.

New product success requires a different communication between designs, materials, and processes that design simulation is not meant for. SIGMASOFT® provides this communication. SIGMA support engineers, with 450 years of combined technical education and practical experience, can support your engineering goals with applications specific solutions. SIGMA offers direct sales, engineering, training, implementation, and support, by plastics engineers worldwide.

For further information on this announcement, interested parties should contact:

Christof Heisser or Matt Proske

SIGMA Plastic Services, Inc.

10 N. Martingale Road, Suite 425

Schaumburg, Illinois 60173

USA

Phone: +1 847 558 5600

Email: cheisser@3dsigma.com or mproske@3dsigma.com

Web: www.3dsigma.com

Agency contact for SIGMA:

Wendy McCormick

Bernard & Company

Palatine, Illinois (Chicago)

USA

+1 847 934 4500

Continue readingMAGMA Announces Two Certified User Achievements

Premier Aluminum and Hodge Foundry techs receive the highest level of simulation software competency designations from foundry market leader

Premier – Jason Lythjohan of Premier Aluminum in Racine, Wisconsin receives his MAGMA certification.

Schaumburg, IL – MAGMA Foundry Technologies Inc. has been a provider of proprietary casting process simulation software, MAGMASOFT®, for over 20 years. More than simply providing software, MAGMA also shares its engineering expertise through its contract service group and comprehensive training programs. This extensive training program comprises several intensive course levels, where the users gain knowledge to better utilize the software from a functional standpoint, plus insights on practical approaches to applying the technology to their metalcasting process.

Currently, the highest achievable training level is the Certified MAGMASOFT® User. There is a set of specific criteria the user must meet to be eligible to participate in the program and a list of objectives that must be met to receive the certification from Magma.

There are many benefits to completing the certification program, which aid not only the software user, but also the user’s organization and its casting customers.

Some of the key benefits include:

Hodge Foundry – Ian McNally from Hodge Foundry in Greenville, Pennsylvania receives his MAGMA certification.

- Improved efficiency and more effective utilization of the software for speed to solution

- Improved result interpretation and knowledge of root cause analysis

- Gaining a greater understanding of how simulation applies to their organization and customer base in the areas of design, process, quality and overall costs

- Enhanced communication internally and with their customers to reduce costs associated with program launches and casting quality

- Establishing a mark of excellence that sets their organization apart from the competition, including those who already have MAGMASOFT®

In 2011, two successful users achieved the MAGMA Certification, namely, Jason Lythjohan from Premier Aluminum, LLC and Ian McNally from Hodge Foundry.

Premier Aluminum has opened a technology center for its customers and potential customers to come in and use MAGMASOFT® Simulation Software for the design and engineering of their castings.

Premier Aluminum, located in Racine, Wisconsin and part of Ligon Industries LLC, is an ISO 9001-2008 certified permanent mold aluminum casting and machining shop. Premier has a reputation for partnering with its customers to find flexible and cost-effective solutions to a variety of product problems.

Hodge Foundry, founded in 1876 and located in Greenville, Pennsylvania, is an internationally-recognized specialty engineering foundry that manufactures high quality complex gray and ductile iron castings.

For more information on this release, please contact:

Christof Heisser

President

MAGMA Foundry Technologies, Inc. 10 N. Martingale Road, Suite 425 Schaumburg, IL 60173

Phone +1 847-969-1001 ext. 225 Email: cheisser@magmasoft.com Web: www.magmasoft.com

Agency contact for MAGMA:

Wendy McCormick

Bernard & Company, Palatine, Illinois (Chicago) USA +1 847 934 4500 wendy@bernardandcompany.com

Continue readingContinental communicates with its subcontractors through MAGMASOFT®

Casting process simulation to automotive industry standards

Cast components can be found throughout engine, brake system, body and interior components. For this reason, Continental, with its three automotive divisions, is one of the world’s largest consumers of castings. Continental does not produce the castings itself, but instead buys these parts in large quantities from outside vendors. In view of the great importance of these components in its products and systems, the Automotive Group devotes a great deal of attention to its cooperation with foundries. For Continental, it is vital that all suppliers reliably meet their quality standards and can guarantee secure processes. If production lines come to a standstill at Continental – or worse, at Continental’s customers – losses can quickly run into the millions.

As a direct supplier to carmakers, Continental is in a sandwich position. The company must guarantee product and process quality to its customers and pass on these requirements to its own suppliers. Consequently, continuous audits of partners are used to assure a constant, sustainable productivity and to ensure the use of the most competitive technologies. The same applies to requirements for product and service quality, which must be highly cost effective, as well as comply with project deadlines.

Casting simulation as foundry selection criterion

When it comes to the quality of purchased castings, Mustafa Ata, Senior Expert Casting Quality, is in demand in Continental’s Automotive Group. He audits the foundries which supply Continental worldwide. “The quality requirements for castings, which are for the most part installed in safety-relevant areas of cars, are extremely high. The prevailing international standards are supplemented by internal group standards, e.g. with regard to service life, material strength, metallurgical properties (microstructure), machinability of the components and optical appearance,” Mustafa Ata said when describing what he expects from foundries.

From Continental’s point of view, a reliable compliance with this performance catalog cannot be achieved without the foundries using the latest casting technology and tools. In the case of safety components, the group requires its suppliers to use software for casting process simulation, to check the casting process and analyze the results with Continental before production starts. Continental also requires that their foundries be in a position to optimize the process if necessary.

“Simulation is anchored as an important part of supplier communication. This means that in every casting project, product realization is supported from the very beginning by numerical simulation. We expect our suppliers to possess a simulation tool,” Ata noted, leaving no doubt in this regard.

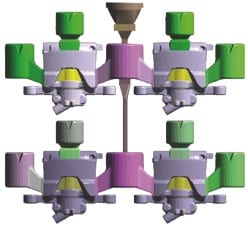

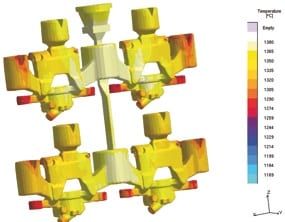

The casting development process begins at Continental. The design department designs the casting according to the automotive manufacturer’s requirements. The 3D data produced goes to selected foundries to enable the latter to simulate the casting process with suitable software. The simulation checks various factors that are critical for casting quality simultaneously.

First, the simulation can determine whether the casting was designed in a casting-appropriate manner or whether the design department, in cooperation with the suppliers (simultaneous engineering), needs to readjust the design to permit standard-compliant parts to be reliably produced in a cost-effective casting process. Second, the simulation results can reveal whether, under the specific production conditions of the foundry, a stable, economical process can be established or whether changes need to be carried out.

Simulation result: production and delivery security

As its final result, the simulation provides Ata with the certainty that the foundry can reliably produce and deliver a casting that meets the requirements at optimal costs. Without casting process simulation, such security could only be achieved with multiple casting trials and machining, at costs and project times that are no longer competitive in the automotive industry.

Simulation with MAGMASOFT® welcomed

In general terms, Continental allows its suppliers to choose which software they use for casting process simulation. But, most foundries opt for the MAGMASOFT® software from MAGMA Gießereitechnologie GmbH, which Ata welcomes for various reasons.

MAGMA is the pioneer in casting process simulation software. As a software developer, more casting engineers work at MAGMA than in many foundries. Because of this, MAGMA is regarded as the worldwide market and technology leader and sets the standard in this field.

The simulation results provided by MAGMASOFT® are extremely realistic.

Empirical checks through real trial castings regularly demonstrate that the results correspond to a large extent with the observable properties of the cast components.

“Simulation results from MAGMASOFT® are accepted as reliable by all parties involved in the production process. As a result, they form the basis on which designers, foundrymen and users can discuss component quality and process optimization, further developments and modifications,” according to Ata.

MAGMASOFT® offers solutions for all casting processes and process steps. In doing so, the software covers every possible simulation situation which arises at Continental in the cooperation with foundries. Therefore, the partners do not need to deal with different applications.

In the foundry, MAGMASOFT® users benefit from the simple operation of the software and the service of the provider, which meet the high demands of the automotive industry.

Continental considering using MAGMASOFT® itself

Until now, Continental has only required that its vendors utilize casting process simulation software. However, Continental is now considering using MAGMASOFT® itself. In this way, the design of a component could be checked for casting suitability immediately and the feedback loops shortened further. Simultaneously, communication with Continental’s development partners could be improved even more through the common “language” of simulation results.

About software for casting process simulation

Casting process simulation software considers the complete casting process including mold filling, solidification and cooling, and also provides the quantitative prediction of mechanical properties, thermally induced casting stresses and the distortion of cast components. Simulation accurately describes a cast component’s quality upfront before production starts, thus the casting layout can be designed with respect to the required component properties. This results in a reduction in pre-production sampling, but also the precise layout of the complete casting system leads to energy, material and tooling savings for the foundry.

The range of application of MAGMA solutions comprises all cast alloys, from cast iron to aluminum sand casting, permanent mold and die casting up to large steel castings. The software supports the user in component design, the determination of melting practice and casting methodology through to mold making, heat treatment and finishing. This saves costs consequently along the entire casting manufacturing line.

During the last 10 years, the use of casting process simulation has become a valuable business asset for many foundries. MAGMA5 now expands the capabilities of casting process simulation and will further accelerate the acceptance of this technology.

About MAGMA

MAGMA offers comprehensive solutions to the metal casting industry, casting buyers and casting designers worldwide. The MAGMA product and service portfolio includes the powerful modular simulation software MAGMASOFT®,with the newest release MAGMA5, as well as engineering services for casting design and optimization.

Today, MAGMASOFT® is used throughout the metal casting industry, especially for the optimization of cast components in automotive and heavy industry applications.

MAGMA Giessereitechnologie GmbH was founded in 1988 and is headquartered in Aachen, Germany. A global presence and support are guaranteed by offices and subsidiaries in the USA, Singapore, Brazil, Korea, Turkey, India and China. Additionally, more than 30 qualified partners represent MAGMA around the world.

For more information on this release, please contact:

Christof Heisser

President

MAGMA Foundry Technologies, Inc.

10 N. Martingale Road, Suite 425

Schaumburg, IL 60173

Phone 847-969-1001 ext. 225

Email cheisser@magmasoft.com

Agency contact:

Wendy McCormick

Bernard & Company

847-934-4500

Continue reading750ºF Cabinet Oven from Grieve

This Grieve cabinet oven features 6” insulated walls, subway grating shelf at the bottom of the oven workspace rated for 2500 lb. loading and four (4) pairs of shelf supports rated at 200 lbs. per shelf.

Controls on No. 997 include a digital programming temperature controller, manual reset excess temperature controller with separate contactors, recirculating blower airflow safety switch and 10” diameter circular chart recorder.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

500ºF Rotary Hearth Oven from Grieve

This Grieve rotary hearth oven features aluminized steel interior and exterior with 4” insulated walls. Two 48” diameter hearths, constructed from rolled angles and covered with perforated metal, carry the loads in process. Each hearth is designed to rotate for 15 seconds, every time the motor-operated vertical lift door is opened and closed. The hearths are driven by a 1/3 HP motor through a gear reducer with torque limiting device.

All safety equipment required by IRI, FM and National Fire Protection Association Standard 86 for gas-fired equipment are onboard No. 816, including a 325 CFM, 1/3 HP powered forced exhauster.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-9210. Web:www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank Calabrese.

Continue readingNorth American MAGMASOFT User Group Meeting 2011

Schaumburg, IL –Removing Roadblocks to Success was the theme for the 2011 MAGMASOFTNorth American User Group meeting, held September 13-15, 2011 at Eaglewood Resort & Spa in Itasca, Illinois. One of the main purposes of the annual MAGMASOFTUser Group Meeting (UGM) is for MAGMA to provide its users with ways to be more successful using MAGMASOFT, the leading simulation software in the foundry market. MAGMA has learned that their users benefit greatly by gaining knowledge from each other as well as relying on the MAGMA engineers for technical support.

MAGMA looks to its customers to help them continue to improve and grow as an organization. MAGMA sees itself as an asset to their customers’ entire organization and wants to help them to not only utilize MAGMASOFT to its fullest potential, but to go beyond the engineering department and implement MAGMASOFT in their entire organization, i.e. in sales and marketing, production, and quality departments. The more areas in the customer’s organization where MAGMASOFTis utilized, the more productive and profitable their operations become, according to company president Christof Heisser.

Christof Heisser, President of MAGMA Foundry Technologies, Inc. welcomes the MAGMASOFT users to the 2011 North American User Group Meeting.

MAGMASOFT users addressed the group with their presentations. Greg Miskinis from Thyssen Krupp Waupaca presented “How To Get Management to Write the Big Check.” Keith Pearl from Caterpillar South Milwaukee discussed “Utilizing MAGMASOFTin the Supply Chain.” Brodie Biersner and Sairam Ravi, both from the University of Northern Iowa, presented papers on mold instrumentation and simulation of veining defects using MAGMAapi, respectively. Lastly, Charlie Monroe from Caterpillar closed out the general session with his presentation entitled “Save Money Using MAGMAfrontier.”

In addition, three candidates, Ivy Courtney from Riverside Brass, Jason Lythjohan from Premier Aluminum and Ian McNally from Hodge Foundry gave their presentations for their MAGMASOFTCertification within the MAGMA User Group.

Steve Sikorski and Benji Johnson (seated at front table) both from MAGMA facilitate the non-ferrous breakout group discussion on “roadblocks”

After completing a questionnaire regarding different roadblocks during the general session, the 120 MAGMA users in attendance were split into one of four categories: HPDC, Non-ferrous, Steel or Iron. In these groups, potential roadblocks such as set-up and analysis of simulation, calculation times, hardware (memory, speed), capability (training) of users, immediate management, upper management, workload, communication issues with customers, as well as others were discussed in a peer-to-peer group setting, with attendees as well as MAGMA staffers providing possible solutions.

The advanced use of MAGMASOFTand specifically its latest version MAGMA5was a recurring topic in the traditional small group breakout sessions. In addition, guest speakers presented process and alloy specific topics, creating an environment for interaction between these technical experts, users and MAGMA staff. To close the two-day meeting, details of the anticipated version 5.2 and future developments were presented to the User Group.

For more information on this release, please contact: Christof Heisser President MAGMA Foundry Technologies, Inc. 10 N. Martingale Road, Suite 425 Schaumburg, IL 60173

Phone 847-969-1001 ext. 225 Email cheisser@magmasoft.com Web www.magmasoft.com

Agency contact: Wendy McCormick Bernard & Company 847-934-4500 wendy@bernardandcompany.com

Continue reading

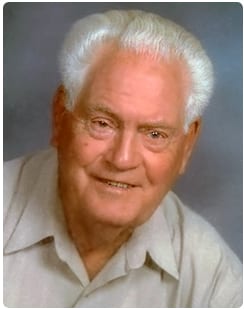

Hunter Automated Mourns The Loss Of Its Founder

Al Hunter passed peacefully on October 29, 2011 in Naples, Florida. A true giant in the world foundry market, Mr. Hunter changed the way sandcasting was done, by his invention of the matchplate molding and mold handling system in 1964, when he built his first machine, helped by his son and current president of the company, Bill, for sale to Moline Corporation of St. Charles, IL, a malleable iron foundry. He will be missed by all who knew him and appreciated his zest for life and especially his love of invention.

Born on the family farm in Wilkie, Saskatchewan on July 13, 1922, Al left home at 17, took a bus to Edmonton, Alberta and worked in a meat packing plant. In the Spring of 1940, he took a training course in airplane mechanics and then joined the Royal Canadian Air Force at 18.

Married to the late Margaret in Montreal in 1943 and released from military service in 1945, Al moved to Toronto to enter the university there, working as a floor molder at John T. Hepburn Foundry to pay for his part-time schooling.

Three children followed, Bill (current president of Hunter Automated) in 1946, Dianne in 1947 and Linda in 1949. In 1951, Al received his BSME from the University of Toronto and moved back to Montreal to accept a position with Dominion Engineering.

A daughter Heather (wife of current Hunter VP Kevin Purdy) was born in 1956. The following year, Al brought the family to America and accepted a position as chief engineer at Beardsley & Piper in Chicago, a leading builder of machinery for metalcasting and inventors of the SandSlinger technique.

At the end of 1963, Al left B&P to develop his concept for an automatic matchplate molding system. In March of 1964, he founded Hunter Automated Machinery Corporation.

Having run the company day-to-day through 1988, Al turned over the operations to his son Bill, wishing to devote more time to his design and invention activities.

During his tenure at the head of the company, Al formed partnerships and reciprocal agreements with companies worldwide, a tradition that continues today, as Hunter Automated continuously seeks to serve its myriad customer needs for sand handling, testing, molding and finishing operations. Hunter Automated is known worldwide in the foundry industry and its machines are found on every continent.

Al developed various concepts used every day in foundry operations, including multi-level mold handling systems and automatic coresetters. His pioneering, can-do spirit will be missed by all who knew him and admired his total commitment to improving the world foundry market.

He was a member of AFS since 1960, was presented with the society’s Management Service Citation in 1990 and received the foundry industry’s prestigious Grede Award in 2001. He held over 80 patents.

Al will be mourned by his children, their spouses, his 13 grandchildren, 19 great-grandchildren and 1 great-great-grandchild, as well as his family of employees at Hunter Automated, who will carry on his legacy.

The Hunter family asks that interested parties please contribute in Al’s memory to the Foundry Educational Foundation, c/o AFS, 1695 N. Penny Lane, Schaumburg, IL 60173 or at www.fefinc.com.

For more information, please contact:

HUNTER AUTOMATED MACHINERY CORPORATION

2222 Hammond Drive Schaumburg, IL 60196

Phone: (847) 397-5110

Fax: (847) 397-8254

Email: info@hunterfoundry.com

Attention: Bill Hunter, CEO

Web: www.hunterfoundry.com

Connect with Hunter Foundry online:

Complete Heat Treating Realizes Substantial Improvements with Polymer Quenchants

One job that took two weeks due to reworks now done in two days, the result of Tenaxol polymer quenchant with anti-foaming agent and greater concentration consistency

Brothers TJ (left) and Jacob Dohlun operate Complete Heat Treating, companion company to Wisconsin Steel Industries, both in the Milwaukee area. Complete operates open fire furnaces and quench tanks to process large steel castings and forgings, as well as metal fabrications and some aluminum parts.

TJ and Jacob Dohlun are not easily impressed. Despite their relatively young ages, 40 and 32 respectively, they have both worked in the family’s dual heat treating businesses in the Milwaukee area, as far back as they can remember. Their grandfather, Theodore Dohlun, started Wisconsin Steel Industries in 1939 and the family has had involvement in heat treating for three generations. Their dad Ted continued the tradition until his recent retirement and both of the “boys” have been active a long time. They began Complete Heat Treating in 2007 as a separate entity and run it with their mother, Chris Dohlun.

Both Wisconsin Steel and Complete Heat Treating run commercial heat treating operations, serving regional manufacturers in the mining, construction, wind energy, rail, government contract, medical, off-road and agricultural equipment industries. They also serve companies as far away as Brazil, however. Combined, they employ approximately 50 people at the two facilities, processing materials such as 4140 and 4340 steel in the forms of castings and forgings up to 100,000 pounds, as well as fabrications and some aluminum parts.

Never ones to rest on their laurels, however, TJ and Jake have been making significant improvements in their operations, especially on the technology side. They use a proprietary software system to operate their furnaces, they’ve incorporated a number of green initiatives into the business operation and, about a year ago, switched their polymer quenchant supplier to the originator of that chemistry, Tenaxol (Elkhorn, Wisconsin).

At Wisconsin Steel and Complete Heat Treating, they run a total of 13 open fire car bottom and feed furnaces with capacities up to 1,000,000 pounds and workspaces up to 52’ long x 20’ wide x 16’ high. Quench tanks at the facilities range up to 40,000 gallons.

Typically, hardness and mechanical specs are supplied by the customers and the metallurgists and chemists in the labs at these facilities work to determine the optimum processing conditions. Wisconsin Steel is rated to the GE Nuclear standards, while Complete Heat Treating received its ISO 9001:2008 certification just recently.

Many value-adding secondary services are supplied here, including machining, straightening, roto-blasting and saw cutting, as well as metalcoating.

The quenching operations at Complete were a particular challenge, owing to the large parts processed here, the dwell times in the quench tanks and the recurrent problems of concentration flux and, most notably, foaming and dragout. As TJ explains, “We were having a lot of problems on one part, a spun metal with thin but substantial surface area and a rimmed edge. The dragout and the excessive foaming were causing us to rework parts to hit the spec. There were shipping delays and we were struggling to hold the concentrations in the tanks for any extended period.”

Previous polymer quenchants were causing excessive foaming and were inconsistent in holding concentrations. Both problems were overcome with Tenaxol polymer quenchants, according to the brothers.

Jacob adds, “We had been talking to Tenaxol about their anti-foaming products and, despite some cost differences with our then-current supplier, we agreed to testing. Although we were not a customer, the Tenaxol team really went the extra mile to give us the best results their lab could suggest.” As a result, Tenaxol Quench 2500 Ultra polymer quenchant with a non-nitrite corrosion inhibitor, defoamer and biocide was purchased from this new supplier and the results have been outstanding, according to the Dohlun brothers. “We no longer have consistency issues, the percentages stay in line, plus we can vary the temperatures in the tanks without compromising performance. That opens more opportunities for new business and it’s been working very well.” Complete Heat Treating is currently on a record sales pace, with more customers and much faster throughput, boasting a 25% increase in sales and working capacity today. On that spun metal part, for example, TJ notes, “We went from two weeks with a lot of rework to two days on a typical batch.” Jacob adds, “The savings in staged deliveries alone run to thousands of dollars, each time.”Complete is now able to process a wider range of materials, as a result of using Tenaxol quenchants, according to the brothers, who credit Jim Harrison, CEO at Tenaxol, and his team of chemists and metallurgists with much of the significant improvement in their processing scenario.

Describing the situation when the previous quenchant vendor was used, “On that spun metal part, for example, our stacker crane would come out of the tank, full of foam. It looked like a bubble bath,” Jacob joked. TJ further noted the drain-off of the Tenaxol product allowed the parts to enter the tempering furnace much faster, avoiding excess cooling of the surface area. The Complete customer for this job, Rich Prescott of Glenn Metalcraft (Princeton, Minnesota), echoes the Dohlun’s, “The turnaround time has been super. They made great improvement in their deliveries to us over the last year and that’s helped us satisfy our customers faster.”

“This anti-foaming agent in the Tenaxol product has literally changed our shop,” TJ concludes. Jacob also cited the supplier’s customer service. “We get help from their lab on a regular basis, including water testing and support documentation, which is necessary for the PPAP requirements of several customers.” He adds, “Jim (Harrison) and his team did a lot of testing for us, before making their final recommendations and they continue to help us fine tune our operation.” He further noted Tenaxol’s involvement with MTI was important. “This supplier supports our industry and that meant a lot to us.” The supplier also provided a solution to problems Complete was experiencing in their cooling tower water by conducting lab testing, automated equipment and cost-effective chemical treatments, according to Dohlun.

As a result of this initial relationship with Tenaxol, Complete Heat Treating has expanded its purchases of products to include various greases and lubricants from this vendor, which is part of the Chemtool family of companies, a wide-ranging industry supplier of myriad lubricant, cleaning and metalcutting fluid products.

To see a video of heat quenching at Complete Heat Treat, click HERE.

For more information on this story, interested parties should contact:

COMPLETE HEAT TREATING

125 E. Greenfield Ave. Milwaukee, WI 53204-2937

Phone: 414-643-5161

Web: www.CompleteHT.com

Attn: TJ Dohlun or Jacob Dohlun

TENAXOL TECHNOLOGIES, INC.

1001 E. Centralia St. Elkhorn, WI 53121

Phone: 414-476-1400

Web: www.tenaxol.com

Attn: Jim Harrison

Large-capacity 500ºF Electric Walk-in Oven

The oven has 4” thick insulated walls, plus an aluminized steel interior and exterior. The door sill on this unit was eliminated and both oven doors are equipped with drag seals. Wear bars were also installed on the sides of the workspace for added durability.

Controls onboard No. 857 include a 975 CFM powered forced exhauster and motorized dampers on the intake and exhaust for accelerated cooling of the oven chamber.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-9210. Web:www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank Calabrese.

Continue reading