Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Fast flexibility for custom tooling, easy access through cloud technology and automation are driving tool production processes

ANCA North American President Russell Riddiford recently participated in an award ceremony at ARCH Cutting Tools in Latrobe, Pennsylvania to celebrate the company’s win in the 2020 ANCA Tool of the Year competition. During this time, Russell sat down with ARCH Cutting Tools President Jeff Cederstrom to discuss the successful collaboration between both companies, as well as future trends that they see on the horizon; and how best to maximize the opportunities of these trends.

Offline and in-process solutions help to deliver speedy custom profiles and get the “first tool right”

Jeff identified the growing trend towards custom tooling. While he described ARCH as a “full-service, one-stop shop with a broad portfolio of standard tools,” he acknowledged that the company sets itself apart in the market, thanks to the breadth of their custom tooling capabilities. Many customers work with ARCH Cutting Tools, looking for custom solutions to reduce their manufacturing costs. This leads to combination tools with complex geometries. Jeff said the combination of skilled machinists, designers and technology that ANCA provides enables the process to flourish.

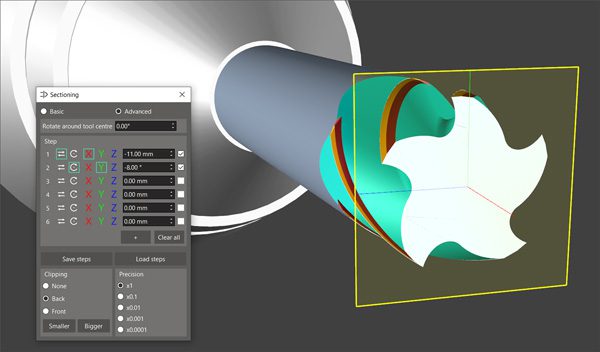

Recognizing the market need for adaptability to produce custom tools Russell highlighted the range of processes offered by ANCA that are targeted to increasing the “speed to get to the grinding point.” ANCA’s 3D simulation software generates a special profile offline, while the machine is still running and completing the previous jobs. The program is then downloaded to the machine, allowing ARCH to obtain better production of the first tool. ANCA offers ARCH the option to inspect their tool on the machine, using the LaserPlus System. The system measures the profile tool, automatically compensating the machine to correct any errors in geometry. Another option is to take the tool to a ZOLLER presetter, as ZOLLER is integrated with the ANCA machines on the floor. A full contour scan is performed using the ZOLLER »genius3« to identify any imperfections in the tool.

Russell sees the importance of having the “first tool right” as a critical point for production. After the pre-grind process through simulation to perfect the tool before it even gets to the machine, ANCA as the only company with a full linear motor product line, offers customers maximum accuracy, surface finish and stability throughout the grinding process. Another new technology is spindle temperature control, a software function that maintains consistent spindle temperature. Providing this stability again allows the first tool in production to be right.

ARCH Cutting Tool’s winning tool offers five separate functions demonstrating the kind of complexity that is in demand. Jeff commented that custom tooling is becoming more challenging and ANCA’s solutions offer significant benefits. Jeff noted: “Having the software so that it is user-friendly, and we can adapt to a request quickly and having not only the software but the machining technology to support it … is critical to us.”

Jeff’s company recently launched a program called “Hot Shop” to showcase their speed from production to delivery. If a customer needs a custom tool quickly, ARCH can produce any geometry of a solid carbide round tool and have it delivered within one week. Jeff explained: “Having equipment that is nimble and fast on the floor enables (this speed)”.

Connected machines and integrated automation

ARCH has developed a web portal called “ARCH Specials.” Customers can download drawings, a DFX file or use pulldown menus on the company website, or talk to engineers to generate a fast RFQ for application specific custom tools.

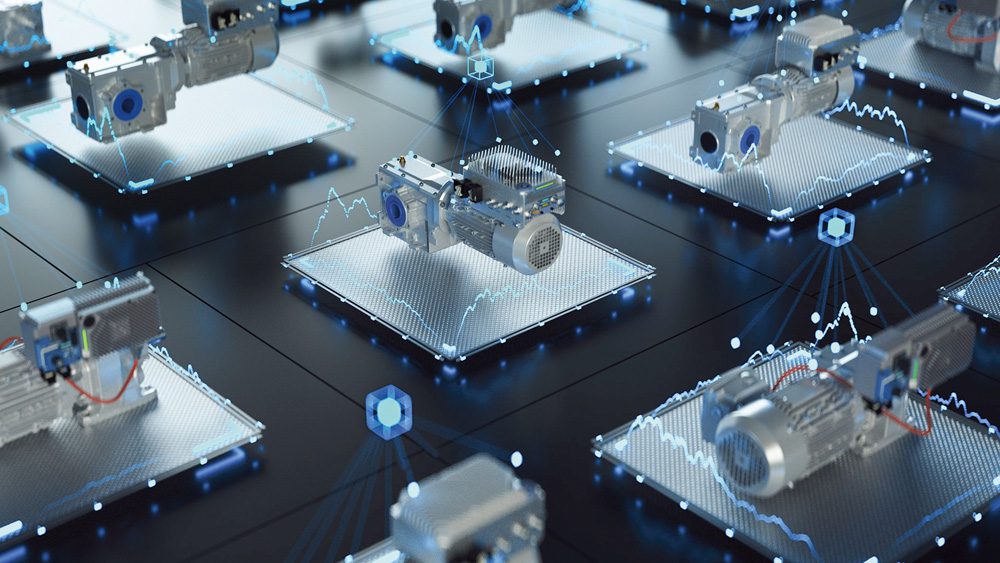

Online capabilities and cloud technology are a growing trend. ANCA can network all machines through their Management Suite software, allowing users to replicate and download files from anywhere in the country, such as across ARCH’s multiple facilities. Additionally, users can monitor real-time performance of their machines to schedule and maintain the machines, as well as predict maintenance requirements to minimize downtime.

Both Cederstrom and Riddiford identified automation as another rising trend. From customers looking for more output, better quality and more productivity, to the social distancing requirements of COVID, to the gap in skilled labor; increased automation provides a solution to these challenges. To this end ANCA has developed AIMS (ANCA Integrated Manufacturing System). Russell explains: “This is the ability to bring a stock piece of carbide at the front end and at the back end have a finished tool…without manual or operator input throughout the process. This allows end-to-end grinding.” Adding to ANCA’s product range is automated laser etching with the AutoMarkX, which fits with AIMS to complete the process. Russell added: “Some people might think of it as the future, but AIMS is here today.”

To see the discussion between Russell and Jeff, please see the video below:

For further information, please contact:

Johanna Boland

Group PR and Communications Manager, ANCA

M: +61 407799779

Johanna.Boland@anca.com

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

Continue reading

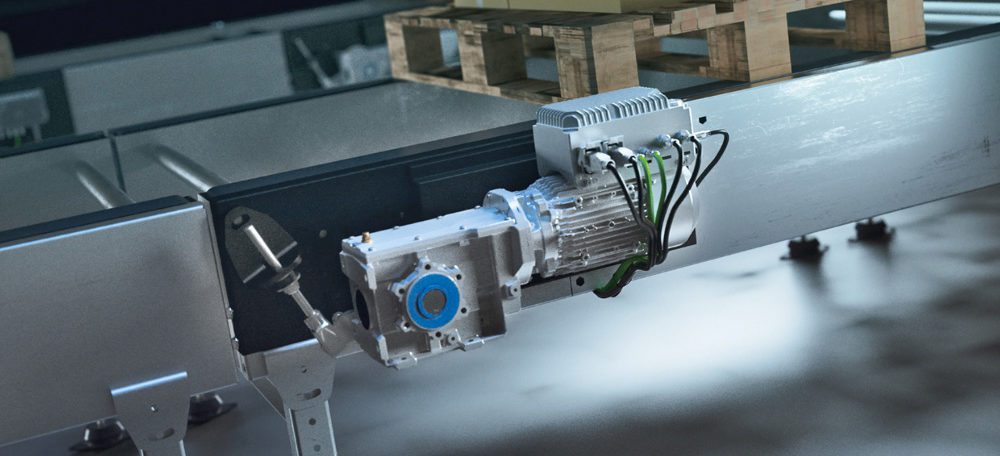

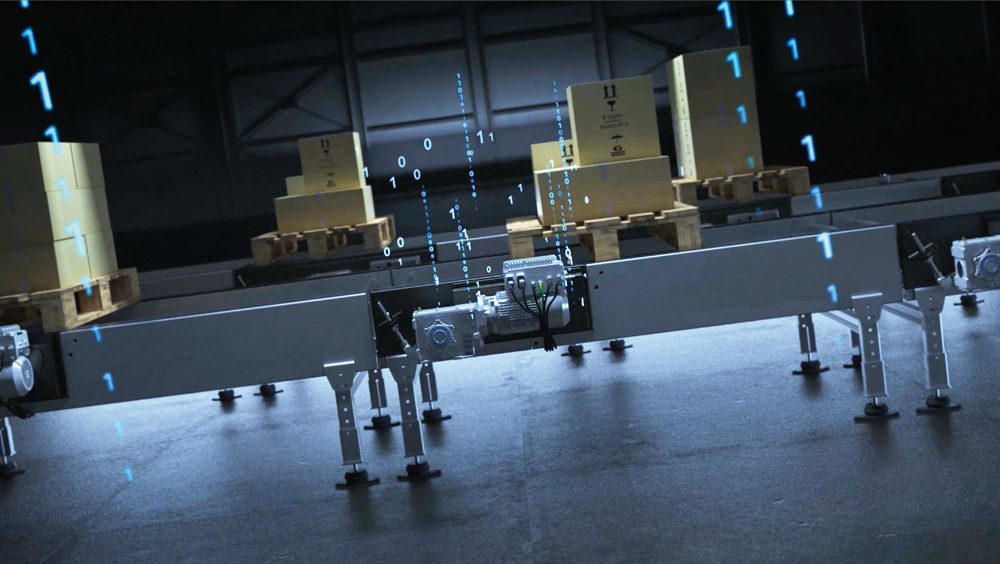

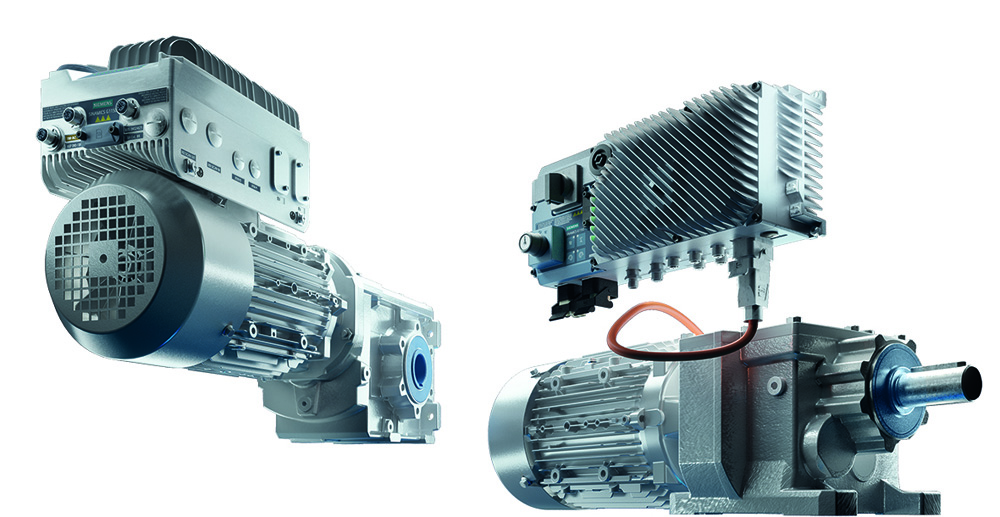

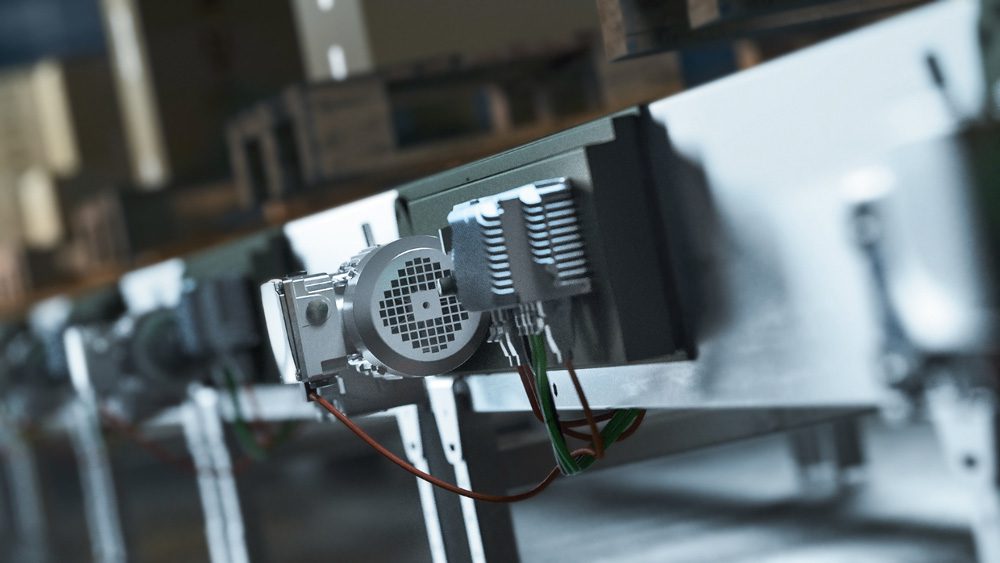

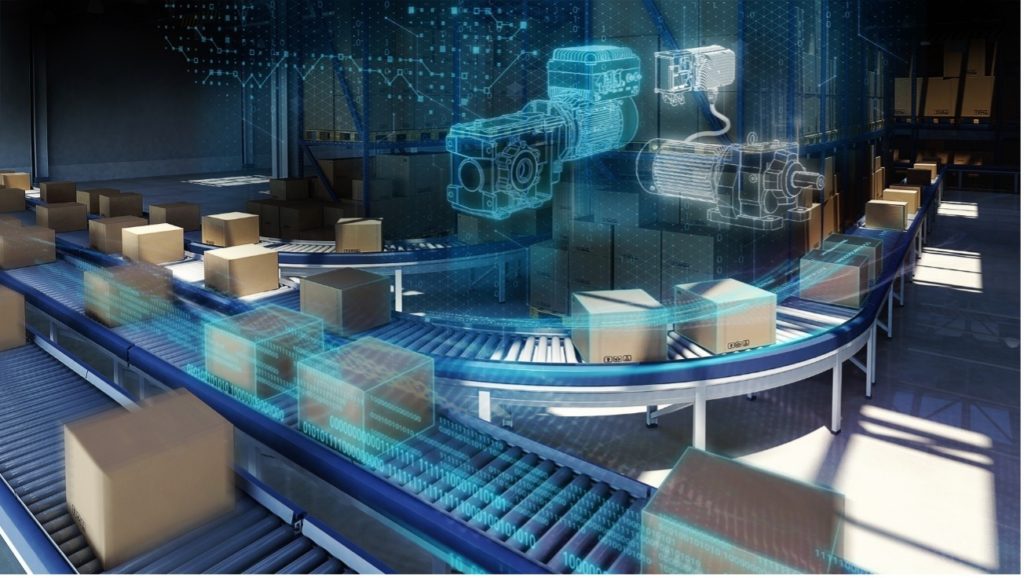

Comprised of the drive, motor and gear box, this new distributed drive system is available as a complete solution for motor-mounted and wall-mounted horizontal motion control conveyor applications.

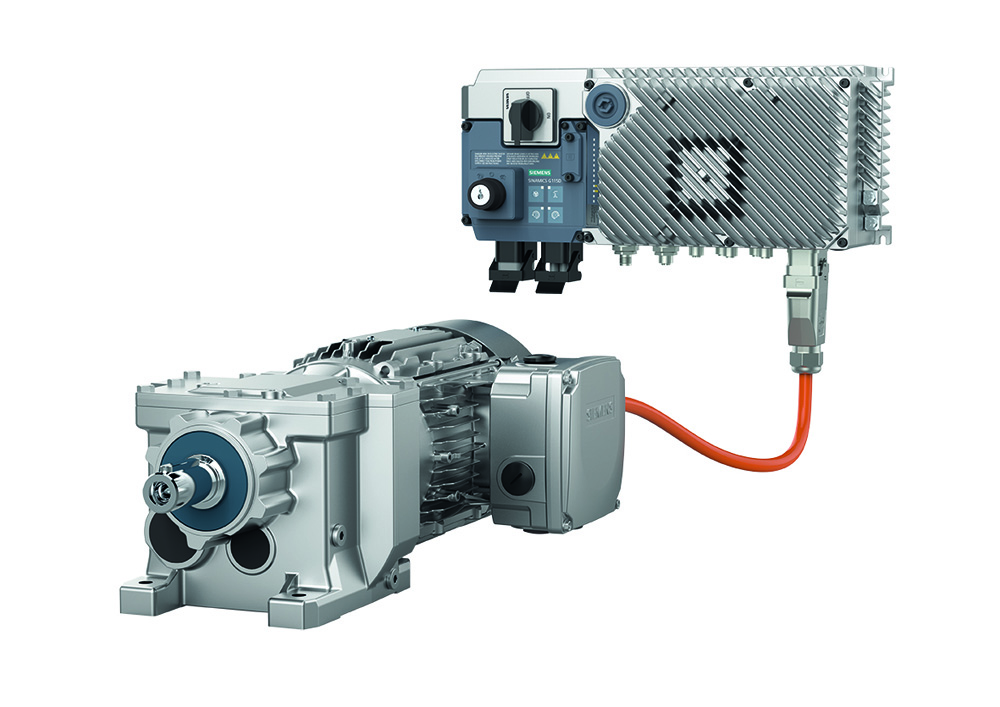

With its new Sinamics G115D, Siemens is introducing a new, compact and powerful drive system specifically designed for horizontal conveyor applications. The drive system comprises the motor, drive and gearbox in one unit and is offered in two versions — wall-mounted and motor-mounted.

The Sinamics G115D drive system is characterized by a robust design with a high IP protection class (up to IP66 / UL Type 4X) and is suitable for use in harsh environments. Thanks to its compact dimensions, the Sinamics G115D can be easily installed in confined areas. The drive system can also be operated reliably over a wide temperature range of -30 to 55 degrees Celsius (-22 to 131 degrees Fahrenheit), enabling operation in deep freezing applications.

Sinamics G115D is suitable for applications in intra-logistics and airports, as well as in the automotive and food and beverage industries. Its power ranges from 0.37 to 7.5 kilowatts

(1/2 to 10 hp) for wall-mount applications and 0.37 to 4 kilowatts (1/2 to 5 hp) for motor-mounted applications. The drive system can be put into operation quickly and easily with comprehensive integration into the Totally Integrated Automation (TIA) portal including Startdrive commissioning software or the Sinamics Smart Access Module (SAM) web-server for Wi-Fi setup and diagnostics.

To be prepared for digital transformation and to enable cloud-based analysis, Sinamics G115D is integrated into the entire MindConnect portfolio and is compatible with MindSphere applications such as Analyze MyDrives.

Thanks to Profisafe, the Sinamics G115D has Safety Integrated in the form of STO (Safe Torque Off) SIL2, which standardizes and facilitates the certification process. For flexibility in terms of installation, service and maintenance, the solution is equipped with a plug-in connector and flexible connection possibilities. The device is particularly suitable for interaction with Simatic controllers such as the Simatic S7-1200 or Simatic ET200 for motion control.

Siemens offers warranty extensions for Sinamics G115D through its Service Protect package. As part of this service package, an additional one or two-year warranty extension may be purchased for failure coverage. The package offers simplified processing under normal warranty conditions for the extended period.

For more information regarding Sinamics G115D, please visit:

usa.siemens.com/sinamics-g115d

For specific product information and inquiries, send an e-mail to: mc.us@siemens.com

Siemens Digital Industries (DI) is an innovation leader in automation and digitalization. Closely collaborating with partners and customers, DI drives the digital transformation in the process and discrete industries. With its Digital Enterprise portfolio, DI provides companies of all sizes with an end-to-end set of products, solutions and services to integrate and digitalize the entire value chain. Optimized for the specific needs of each industry, DI’s unique portfolio supports customers to achieve greater productivity and flexibility. DI is constantly adding innovations to its portfolio to integrate cutting-edge future technologies. Siemens Digital Industries has its global headquarters in Nuremberg, Germany, and has around 75,000 employees internationally.

Siemens Corporation is a U.S. subsidiary of Siemens AG, a global powerhouse focusing on the areas of power generation and distribution, intelligent infrastructure for buildings and distributed energy systems, and automation and digitalization in the process and manufacturing industries. Through the separately managed company Siemens Mobility, a leading supplier of smart mobility solutions for rail and road transport, Siemens is shaping the world market for passenger and freight services. Due to its majority stakes in the publicly listed companies Siemens Healthineers AG and Siemens Gamesa Renewable Energy, Siemens is also a world-leading supplier of medical technology and digital healthcare services as well as environmentally friendly solutions for onshore and offshore wind power generation. For more than 160 years, the company has innovated and invented technologies to support American industry spanning manufacturing, energy, healthcare and infrastructure. In fiscal 2018, Siemens USA reported revenue of $23.7 billion, including $5.0 billion in exports, and employs approximately 50,000 people throughout all 50 states and Puerto Rico.

Continue reading

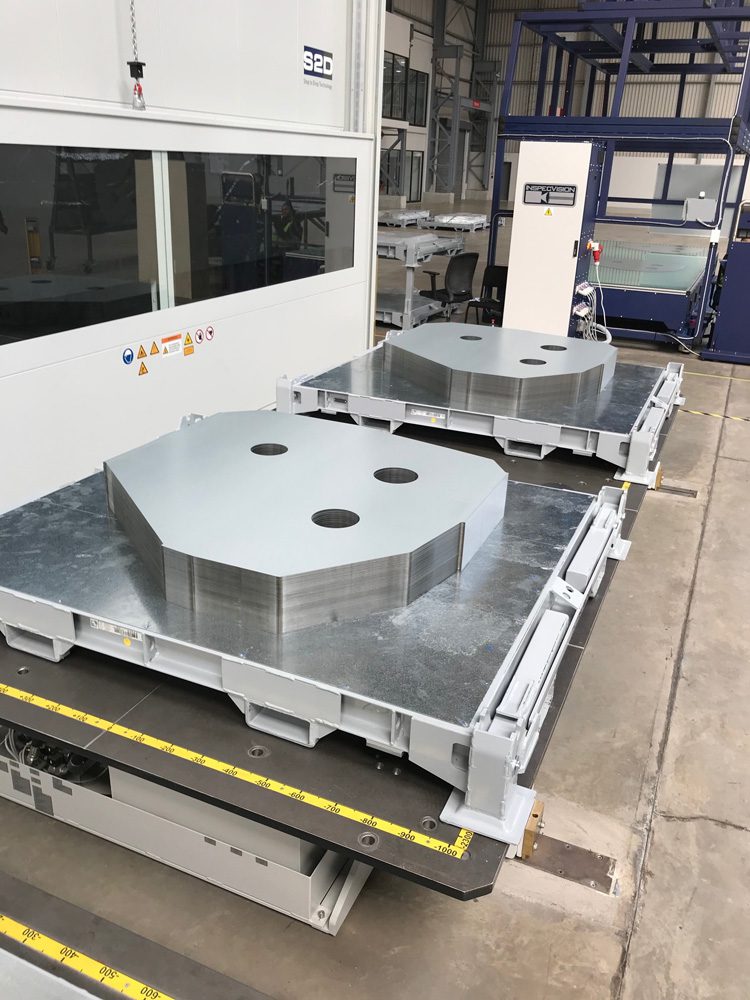

The German press manufacturer Schuler has numerous manufacturing and service locations worldwide. This ensures that customers can receive fast and efficient support from local Schuler employees. In the Americas, for example, there are sites in the USA, Mexico, and Brazil, ready to support one of the company’s latest innovations: the Laser Blanking Line.

Laser blanking makes it possible to manufacture blanks completely without dies. Instead of using presses or shears, the geometries are cut by two or three high-precision laser heads. This has several advantages: no dies, die change, die storage or die maintenance, but also no costly press foundation and no loop pit. The technological development of laser performance, combined with intelligent line automation, enables Schuler to achieve cutting speeds of up to 100 meters per minute (approx. 328 ft/min).

The design of a Laser Blanking Line is very similar to a conventional press cutting line. “Simply said, the press is only replaced by a laser cell,” explains Oswald Schoenberger, Product Manager for Laser Blanking Lines. “Operators who already have experience with conventional blanking lines can learn to handle the system very quickly, but even the ones without blanking experience the system can be operated intuitively and reliably after completing our training program,” he continues.

Programming the lasers also requires no process know-how thanks to LBL Studio. The offline program is so intelligent that cutting contours for new parts are automatically created based on CAD files. The optimal cutting distribution of the lasers is taken into account and reliable predictions about the output can be calculated in advance. Of course, changes can be made manually at any time.

With several lines around the world and production experience since 2012, Schuler is by far the leader in terms of laser blanking lines. “This is also related to our strong local service,” explains Telvi Zanin, Vice President of Service. In addition to Europe and Asia, Schuler also has long established service and manufacturing locations in North America. Schuler Inc. was founded in 1978 in Columbus, Ohio, and now has its headquarters close to Detroit in Canton, Michigan.

“With our team of 80 qualified service employees we are ready to provide high quality technical support to all our customers in North America”, says Telvi. A team from the U.S. has been sent to the product centers in Europe to join the in-house assembly where they can learn firsthand the laser blanking technology. “Our trained employees can thus react quickly and provide optimal on-site service”, says Telvi. “In addition, remote service like with Schuler Connect offers the possibility of immediate assistance from our headquarters in Canton, Michigan or from our experts in Germany if required – for established products as well as for innovations such as the Laser Blanking Line.”

www.schulergroup.com/laserblanking

About the Schuler Group – www.schulergroup.com

Schuler offers customized cutting-edge technology in all areas of forming—from the networked press to press shop planning. In addition to presses, our products include automation and software solutions, dies, process know-how and service for the entire metalworking industry. Our customers include automobile manufacturers and automotive suppliers, as well as companies in the forging, household appliance and electrical engineering industries. Presses from the Schuler Group mint coins for more than 180 countries. When it comes to the digital transformation of forming technology, we support our customers worldwide as a supplier of innovative system solutions. Founded in 1839 at our headquarters in Göppingen, Germany, Schuler AG has approx. 5,000 employees at production sites in Europe, China and the Americas, as well as service companies in more than 40 countries. The company is majority-owned by the Austrian ANDRITZ Group.

For further information on Schuler Inc., North America, please contact:

Guido Broder, Vice President of Sales & Marketing

Schuler Incorporated

7145 Commerce Blvd.

Canton, MI 48187 USA

734-207-7200

Guido.Broder@schulergroup.com

Gear ratios of 1:2, 1:3, & 1:4 with RPM max of 48,000

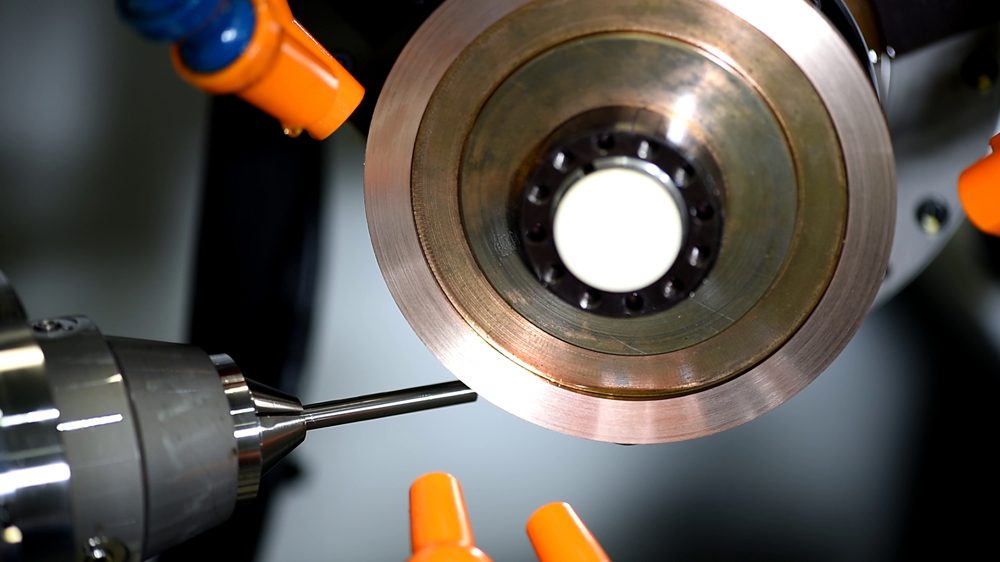

Platinum Tooling Technologies, Inc., the exclusive importer of Heimatec live tools, angle heads, and multiple spindle heads, offers immediate delivery on a variety of speeders for all popular live tool lathes. Platinum Tooling, headquartered in Prospect Heights, Illinois, serves the North American Market.

These speed multipliers are available for working the OD or Face of the workpiece, with either external or internal coolant design, and mounting configurations to suit virtually any machine tool set-up, including all VDI, BMT, and a variety of Swiss style machines.

Speed multipliers for all BMT turrets including Doosan, Haas, Miyano, and Nakamura as well as many Citizen models are now in stock in Illinois with others available from factory stock for short lead times.

According to Platinum Tooling President Preben Hansen, “As our presence in the American machine tool market continues to expand, so does our product line. These speed multipliers offer the customer a way to enhance their machine tool capabilities and increase production. These tools are available through Platinum Tooling’s extensive network of distributors and sales reps across North America.”

For further information and literature, or to arrange a demo on these products, please contact:

Preben Hansen, President

PLATINUM TOOLING TECHNOLOGIES, INC.

16 E. Piper Lane Suite 128

Prospect Heights, IL 60070

Phone: 847-749-0633

Fax: 847-749-2445

email: phansen@platinumtooling.com

Platinum Tooling Technologies, Inc. in Prospect Heights, IL, near Chicago, serves its growing North American customer base with an extensive inventory of machine tool accessories. Its experienced staff is dedicated to providing the most innovative tooling and technology. Platinum Tooling Technologies, Inc. serves the auto, aero, medical, woodworking, composites and other industries, as well as an ever-increasing number of machine tool OEMs worldwide, through its network of manufacturers’ representatives. Platinum Tooling is the exclusive importer of Heimatec, Henninger, Tecnicrafts, and AMF tooling for North America.

Continue reading

The Foundry Educational Foundation (FEF) is preparing an exciting event for its students, alumni and interested parties. The FEF Alumni/Ambassador Committee will host the first annual Virtual Fitness Challenge from April 1 to April 15. Participants can sign up as a team (maximum number of 6) representing a company, a college or just a group of friends. All FEF alumni, current students, professors, friends and friends of friends are welcome. The goal of each team is 300 miles, whether it is running, walking, rowing, biking, swimming, even walking on the foundry floor.

The cost is $34 per person and $8 for current students. All funds raised will go to the FEF student scholarship fund, ensuring ongoing support for all students. All who participate will receive a medal. First and second place prizes will be awarded to the team with the most miles. First place prizes will also go to the individual with the most miles and the team that raises the most funds.

This is a great opportunity not only to help FEF students but also to enjoy some friendly competition, engage in fitness activities and earn a participation medal.

To register please go to https://runsignup.com/Race/IL/Schaumburg/FEFFitnessChallenge

If you wish to donate but not participate, please click here https://runsignup.com/Race/Donate/IL/Schaumburg/FEFFitnessChallenge

If you would like to purchase a T-shirt, click https://www.feffitnesschallenge.com/

For more information, please contact:

Brian Lewis

Executive Director

Foundry Educational Foundation

Phone: (847) 490-9200

brian@fefinc.org

www.fefinc.org

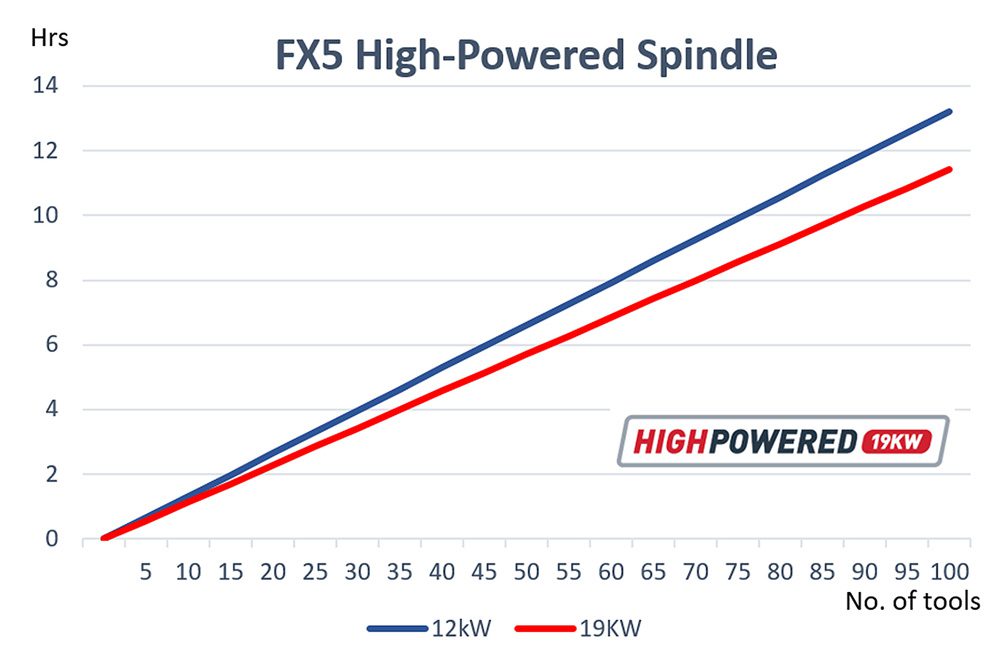

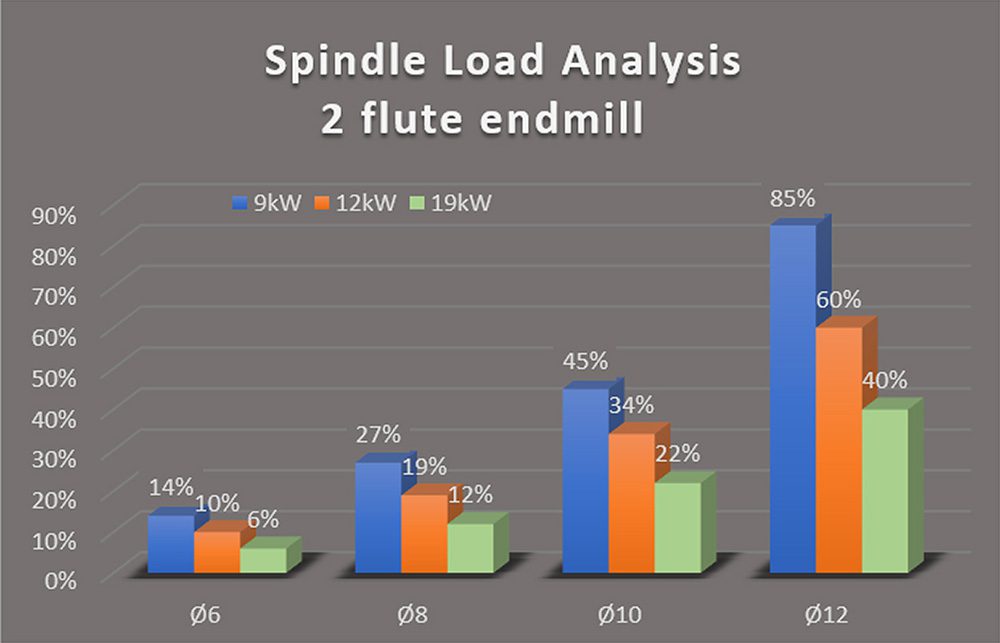

ANCA has upgraded the FX5 Linear 2-wheel pack machine with a new grinding spindle rated at 12kW peak power as well as releasing a further high-powered spindle option of 19kW.

CNC tool grinders strive to achieve the shortest possible cycle times – to keep the cost per tool produced at a minimum. Machine performance and grinding cycle time are linked to the power capabilities of the grinding spindle.

To maximize material removal rate, a commonly accepted industry practice is limiting the spindle load to between 30% and 40% for fluting operations. If the spindle load is likely to exceed 40%, tool manufacturers tend to allow for a second fluting pass as this contributes to longer wheel life and less wheel load. Auto white-sticking becomes an important option as batch sizes increase.

ANCA has conducted a spindle load analysis of fluting operations, identifying how many passes are recommended in relation to spindle load. The analysis compares two flute endmills ground with either 6, 8, 10 or 12mm diameters. The new FX5 which has now been upgraded from 9.5kW to a 12kW spindle can comfortably grind tools up to 10mm diameter in a single pass. A 12mm tool required a second grinding pass to keep the spindle load at 40%, rather than increasing to 60%.

This is where the new high-powered 19 kW spindle option makes all the difference. The 12mm endmill was ground at a 40% spindle load in one pass, with an overall time saving of one minute and four seconds – opposed to two passes at 12kW.

Match “One Pass Productivity” to tool diameter

The FX5, with the new 12kW spindle delivers increased productivity up to a diameter of 10mm. At 19kW, the new high-powered spindle option can enhance productivity further for tools up to 12mm and above. The high-powered spindle option on FX5 matches the grinding spindle fitted to the FX7 machine with 6-wheel packs, suited for a more industrial environment.

The new FX5 upgrade option features a striking high-powered decal indicating it has been fitted with the more powerful 19kW spindle.

For complex cutting tools, there can be of course further factors which influence actual grind cycles besides the tool geometry. These include the quality of the grinding wheel used and the supply of an adequate amount of cooling liquid at stable temperature, to avoid thermal damage of the workpiece. As batch sizes increase auto white-sticking helps to achieve maximum output by frequently refreshing the wheel.

Customers will benefit from the increased spindle power provided by the new 12kW standard spindle on FX5 and now have the option to purchase their new ANCA FX5 with a high-powered spindle, adding more flexibility in the tool room. Most importantly the high-powered spindle reduces the production cost and increases net output across a wider range of tools.

The use of “One Pass Productivity” for tools with 12mm diameter translates into an increased output of 15.8% – with 70 tools produced in an eight-hour shift compared to 60 tools with the new standard 12kW spindle.

The FX5 Linear continues to deliver customer satisfaction with 1000 machines sold

Contributing an impressive 1000 machines to the 1600 machines produced across the entire FX platform, the FX5 is an easy choice for customers, from light manufacturing, to regrinding and full production. Across a range of industries, the upgraded FX5 is the most versatile 2-wheel pack machine for a variety of applications.

For further information, please contact:

Johanna Boland

Group PR and Communications Manager, ANCA

M: +61 407799779

Johanna.Boland@anca.com

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

Continue readingHow the fox outsmarted the hare: using intelligence to outperform brute force.

Tom Nathan, ANCA PCD Erosion Product Manager

When ANCA decided to create the ANCA EDG (Electro Discharge Grinding) machine in 2011, the mission was clear. The company wanted to create a high-performance Rotary Electro Discharge Machining (EDM) platform that was not only able to produce best-in-class tool geometries, but also have market leading cycle times.

It was the brainchild of Pat Boland, ANCA Founder and Managing Director, who realized that to outperform the incumbents, brains was needed over brawn. “The erosion process is simple in its complexity. The basis of the process uses positive and negative electrodes with electrolyte to create sparks along a material. ANCA has a 45-year history in making the world’s best carbide and HSS tools and we wanted to use that skill set in PCD tooling,” said Pat.

The main drivers behind the ANCA EDG machines were that it needed to be simple enough for all types of brazed shear-fluted tools, but complex enough to enable the creation of the infinite variety of helical solid-tipped, veined and chevron tools. Pat adds: “We realized early on that with the complexity of tool geometries we wanted to allow our customers to create, the 5-axis interpolation while maintaining the precise erosion gap distance was going to be a challenge.”

Maintain the optimum spark erosion gap with IAC

The ANCA EDG is able to maintain the optimum spark erosion gap for both simple 2D and complex 3D path interpolations, which is fundamental to the process working with high efficacy. This is very simple for 2D paths, however, when 3D path interpolation involves 4 or 5 axes moving simultaneously; surface area, volume and path variation become a challenge. From testing, we knew that the standard was to set the machine feedrate to the lowest allowable to maintain a useable spark gap distance; however, this leads to a lot of ‘air-time’ and drastically lowers efficiency. To allow the feedrate to remain high and maintain the optimum spark erosion gap, the idea of Intelligent Adaptative Control (IAC) was born.

Intelligent Adaptive Control (IAC) is an in-time, servo-controlled feature that automatically monitors and controls the erosion gap distance, in-process. Utilizing the EtherCAT functionality of the ANCA Motion AMD5x control system, IAC synchronizes the machine moves with the generator performance. IAC adjusts and maintains the optimum spark gap which is vital while eroding 3D geometries such as PCD flutes and gashes on drills and endmills. With geometry changing in up to 5-axes at once, IAC automatically adjusts the gap distance and machine feedrate to optimize the erosion speed and surface finish. This involves not only speeding up feedrates when erosion is along linear paths but also slowing down feedrates when path changes occurs.

Twists and turns along the erosion path leads to scenarios where the electrode wheel is likely to come into close contact with the tool, or comes off the tool. This can lead to optimal, bad and missed sparks along the trajectory. IAC automatically accounts for this and maintains the fastest possible feedrate along the length of any changeable path. This results in increased feedrates, minimum thermal damage, superior surface finish, increased MRR and decreased cycle time.

An added benefit of IAC is the ease in which PCD and carbide micro-tools can be manufactured. Since IAC maintains the optimal distance, the chance of wheel collisions and hence tool breakage is very low which is critical when eroding tools under 0.5mm.

Optimize the erosion process with ASC

The current, voltage, duration, time-off and therefore intensity of sparks changes based on the material that is being eroded. That is, PCD will require certain parameters as opposed to carbide (HM) and High-Speed Steel (HSS). The challenge is that PCD wafers are generally 0.6mm PCD with a 1mm carbide backing – sintered PCD, chevron tools and solid-tipped tools are formed onto carbide backing also. When aggressively eroding along the PCD-carbide border, erosion parameters optimized for PCD can inadvertently over-erode the carbide backing. This in turn leads to over-erosion at the PCD-carbide border, named an “undercut” as it selectively erodes the carbide under the PCD. Additionally, it can lead to “cobalt leeching” which is when the PCD binder, cobalt, is preferentially eroded away.

This is akin to digging under the foundations of a paved pathway. If you dig too much material away from under the path, eventually the path will collapse. Machine testing showed that the undercut and cobalt leeching during heavy roughing lead to a brittle border along the cutting edge and premature tooling wear. To avoid this happening and to optimize the erosion process, Adaptive Spark Control (ASC) was created.

ASC uses the DSP (Digital Signal Processors) and FPGA (Field Programmable Gate Arrays) on the generator itself. The EDG erosion generator is able to monitor and process every spark, in real time. The waveform of each spark is automatically monitored and categorized based on material being eroded, erosion gap distance and other factors essential to optimal erosion process. The generator can then dynamically adapt the energy level of each-and-every spark (current, voltage, duration and time-off) to suit the material being eroded.

ASC optimizes the erosion process leading to less cobalt leaching and a reduction in undercut at the PCD-carbide border. This leads to a stronger cutting edge and a finished tool that is less prone to chipping. This helps achieve longer tool life, less tool wear and lower tooling costs. Testing on tooling suited to the machining of CFRP (Carbon Fiber Reinforced Plastic) showed a tool life increase of up to 100%.

Boost the power electronics with ANCA Motion SparX Erosion Generator

ANCA leant on the expertise from their sister company, ANCA Motion to optimize the electronics to enable even higher and more aggressive erosion all-the-while maintaining very high surface finish results. When compared to equivalent componentry, the “mega-amp per pulse” technology enables ANCA customers to broaden the power range they can access and utilize. The ANCA Motion SparX Erosion Generator exhibits superior performance over the range of Extra-Heavy Roughing to Ultra-Fine Finishing operations, utilizing Pico-pulse technology for high energy-density ablation. This enables vastly superior controllability, providing customers with optimized feedrates, superior surface quality and drastically reduced cycle times. This pulse precision allows erosion that ranges from ultra-low energy pulses for exceptional ultra-fine finishing, through to high energy pulses for fast material removal.

In the PCD erosion process, cycle time is directly related to the Material Removal Rate (MRR). The ANCA Motion SparX Erosion Generator delivers unrivalled increases in MRR utilizing the new Extra-Heavy Roughing, Super Fine Finishing and Ultra-Fine Finishing operations. What this equates to is an unsurpassed increase in MRR and a 50% decrease in cycle time compared to competitor machines – arguably the fastest cycle times in the market. Additionally, erosion surface quality also sees an improvement across all power modes. Polished surface finishes of Ra < 0.1µm and Rz < 0.5µm can be easily achieved using the newly release “Ultra-Fine Finishing” process with Pico-pulse technology. These operations enable the production of superior cutting edges necessary for the most demanding of cutting tool applications.

Combining intelligence in a domain once dominated by brute force electronics, not only gives ANCA customers an edge over the competition but enables a smarter approach to tool making. The difference between our approach and the approach of our competitors is that ANCA focuses on what our customers want to achieve with their erosion process. They strongly told us that they wanted a process optimized for helical and round PCD tooling. We worked closely with ANCA Motion to design our erosion generator to suit not only shear tooling but the infinite array of highly complex geometries, rather than re-using generator technology originally created for Wire Electro Discharge Machining (Wire-EDM). Our approach turned the industry on its head. We let the geometries dictate the process, not the process dictate the geometries available.

We used intelligence to outperform brute force, like the fox outsmarting the hare.

######

For further information, please contact:

Johanna Boland

Group PR and Communications Manager, ANCA

M: +61 407799779

Johanna.Boland@anca.com

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

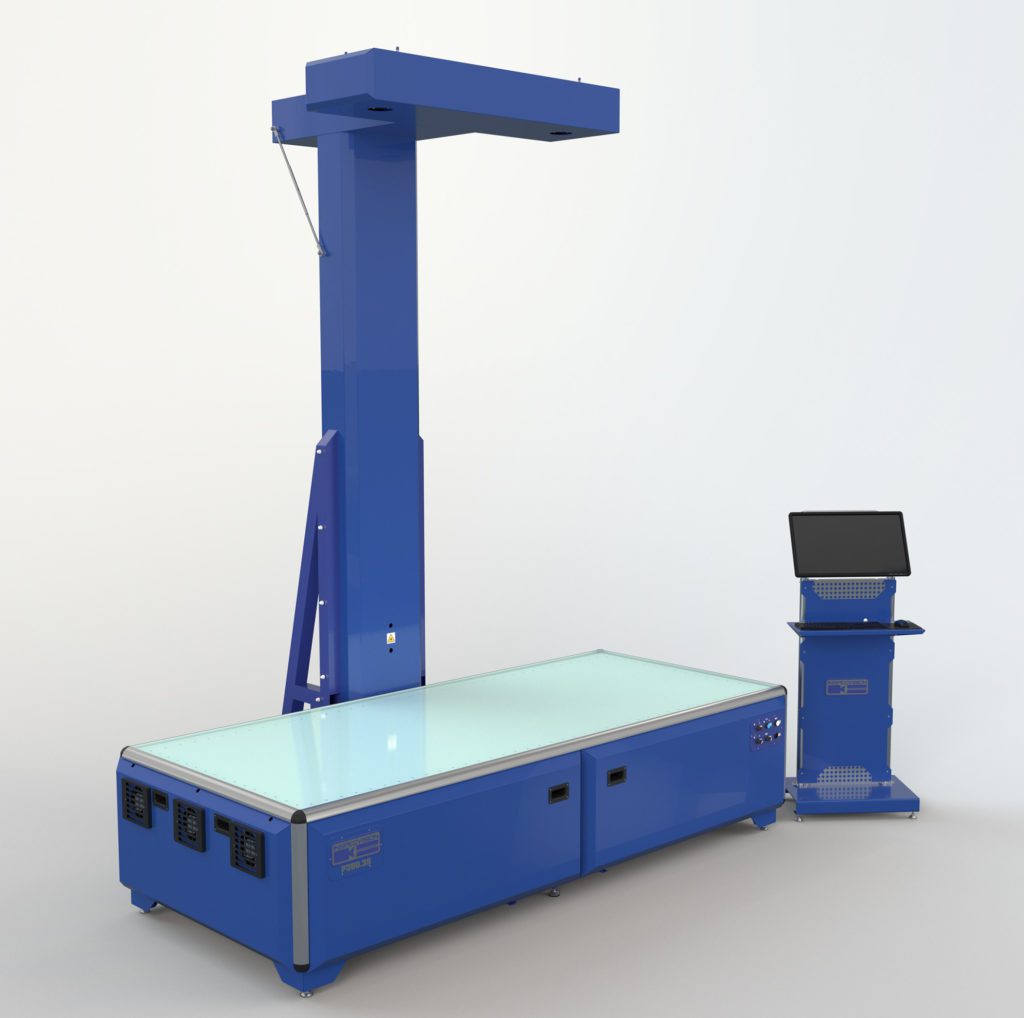

Continue readingExact Metrology, a comprehensive 3D metrology service provider and hardware sales company, represents Planar from InspecVison. This 2D inspection machine allows manufacturers to simply and quickly verify product quality by performing 2D inspection, CAD comparisons and reverse engineering in seconds.

Planar is ideal for shop floor use, requires minimal operator input and increases production throughput across a wide range of applications. These include flat and folded/formed sheet metal components, gaskets and seals, laminations, O-rings, paper acetate and electronic drawings and other opaque and semi-transparent flat materials.

A standard feature on every Planar system is 2D reverse engineering. Existing parts can be reverse engineered quickly, creating dxf or dwg CAD files. The software allows the user to edit and clean the data such as standardization of hole sizes and clean edges and eliminates the need for hand measurement and CAD programming. Physical parts or even paper, acetate or electronic image files can be reverse engineered to create CAD files. Furthermore, reverse engineering processes can also be carried out in 3D using optional 3D modules. For full 3D capability, users simply add Opti-Scan 3D, while the SurfScan module extends Planar to 2.5D.

Opti-Scan 3D is a non-contact white light scanning system that uses a high speed, high resolution camera and an LED DLP projector to scan the surfaces of an object. Patterns of light are beamed from the projector onto the part, recorded by the camera and used to create a 3D point cloud of the scanned surface. The Opti-Scan 3D outputs the ultra-high resolution points into a number of different file types which can be used in virtually any 3D inspection or reverse engineering software package.

SurfScan integrates seamlessly with the Planar 2D automatic inspection software to allow accurate inspection of both the part’s 2D shape and its 2.5D features with a single click. The SurfScan is a high resolution projector which mounts onto the existing Planar vertical column. The projector shines structured light on the part which is then imaged by the Planar’s camera to create a 3D scan of the upper surface of the part. The point clouds created by the system can then be loaded into free and readily available 3D inspection software for comparison against a 3D solid CAD model. Point clouds are also compatible with Geomagic Control, Control X, Polyworks, etc.

InspecVision Planar offers fully automated one click inspection with machine sizes ranging from 500m to 3000mm. The machine is scratch resistant, features no moving parts, has simple calibration and minimal maintenance, requires minimal training and offers rapid return on investment.

Exact Metrology is ISO, AS9100 Certified as well as FFL and ITAR Registered.

Exact Metrology, with facilities in Cincinnati, Ohio, Moline, Illinois and Milwaukee, Wisconsin, plus affiliated offices throughout the country, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

For information, please contact:

EXACT METROLOGY, INC.

Dean Solberg

20515 Industry Avenue

Brookfield, WI 53045

Local: 262-533-0800

www.exactmetrology.com

deans@exactmetrology.com

EXACT METROLOGY, INC.

Steve Young

11575 Goldcoast Drive

Cincinnati, OH 45249

Local: 513.831.6620

Toll Free: 866.722.2600

www.exactmetrology.comstevey@exactmetrology.com

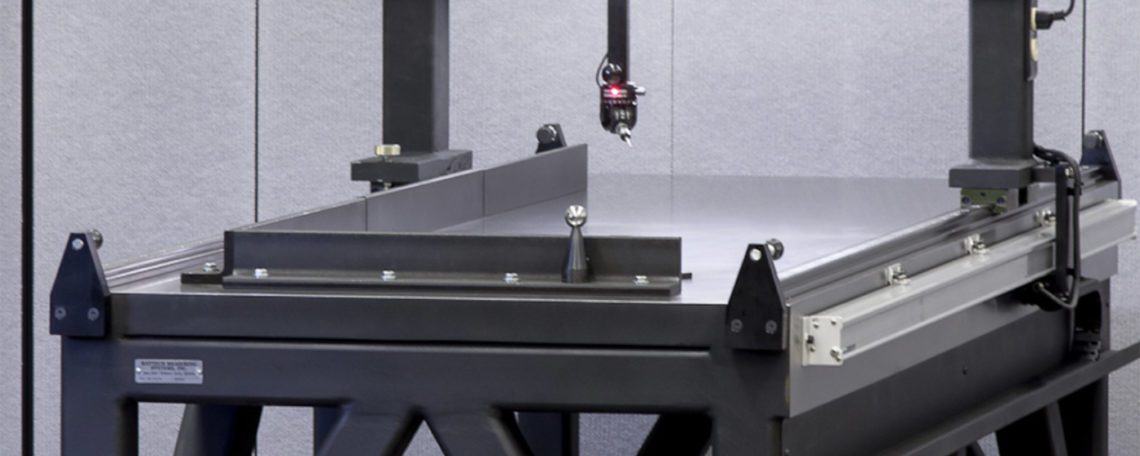

Exact Metrology, a comprehensive 3D metrology service provider and hardware sales company, sells Raytech Measuring Systems. These are shop-floor dimensional measuring machines like the single axis and the three axis table for industrial manufacturers. The company offers machines for measuring parts for cutting, bending, punching, waterjet cutting, laser cutting, drilling and tapping. Custom machines are also available.

The single axis table is ideal for checking flat sheets with straight edges and square corners. It features reduced setup time for production machines, reduced scrap rates and reduced backlog of parts for inspection. In addition, it integrates with SPC software for quality tracking and reporting, reduces operator-to-operator variation, offers long-term durability and simple operation. Squareness gage allows users to check sheets for perpendicularity of the edges or check edge camber, while diagonal blocks allow the user to check corner to corner squareness on sheets. All single axis tables come standard with interchangeable probe tips. Heidenhain readouts and scales used on the single axis tables are designed for use on machine tools and are well suited for use on shop floor gage. The edge lift gage allows users to edge waves in sheets.

When parts are more intricate or bulkier than flat sheets, then the three axis table is recommended. It is suitable for checking laser and waterjet cut parts, sheet metal parts with many features and parts that are bent and formed. The three axis table includes flexible metrology software, sealed Heidenhain encoders, low-maintenance linear bearings and a versatile Renishaw touch probe. Furthermore, it has the ability to integrate with SPC software for quality tracking and reporting and reduces operator error. As with the single axis table, it offers long-term durability and simple operation. Features include a Renishaw indexing probe for flexible probing and reduced operator-to-operator inconsistency. It also includes a standard readout system with a simple yet durable color touch screen, serial output for SPC, multiple points of error correction and multiple point feature measurements. The PC-based system allows for the full capability plus additional reporting capabilities, as well as greater program storage capacity.

Exact Metrology is ISO9001, AS9100 Certified as well as FFL and ITAR Registered.

Exact Metrology, with facilities in Cincinnati, Ohio, Moline, Illinois and Milwaukee, Wisconsin, plus affiliated offices throughout the country, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

For more information, please contact:

EXACT METROLOGY, INC.

Dean Solberg

20515 Industry Avenue

Brookfield, WI 53045

Local: 262-533-0800

www.exactmetrology.com

deans@exactmetrology.com

EXACT METROLOGY, INC.

Steve Young

11575 Goldcoast Drive

Cincinnati, OH 45249

Local: 513.831.6620

Toll Free: 866.722.2600

www.exactmetrology.com

stevey@exactmetrology.com

Exact Metrology, a comprehensive 3D metrology service provider and hardware sales company, now offers high-performance laser tracker technology in a portable and easy-to-use form factor thanks to the Leica Absolute Tracker AT960.

This is a robust, all-in-one laser tracker that fits in a single flight case. Offering high-speed dynamic measurement as standard, it is a complete solution for six degrees of freedom (6DoF) probing, scanning and automated inspection as well as reflector measurement. The AT960 laser tracker can be transported easily, unpacked quickly and powered up in minutes to deliver high-performance measurement almost anywhere. Featuring wireless communication and a battery operation option, the integrated-technology design of the AT960 reduces setup time drastically. The Leica Absolute Interferometer (AIFM) enables accurate high-speed measurement of a moving target, while the innovative PowerLock function ensures an interrupted beam is instantly re-established without user intervention, reducing operator workload and training requirements. Intuitive touch-screen controls minimize the potential for user error, thus saving time, effort and money. Check and compensation architecture means basic adjustments can be made in the field, while robust design guarantees on-specification operations with minimal calibration and servicing.

Combined with the Real-Time Feature Pack and Leica T-Mac, the AT960 becomes a laser tracker that meets the deterministic measurement data-delivery requirements of high-end automated installations. Built on industry-proven EtherCAT protocol, it enables the delivery of 6DoF measurement data with accurate timestamps at an output rate of up to 1000 Hertz. Known as 7DoF measurement data, this enables real-time machine control within even highly-dynamic robotic setups.

With a measurement volume of up to 160 meters in diameter, the AT960 is compatible with Leica T-Probe, Leica T-Mac, Leica T-Scan 5 and Leica Absolute Scanner technology. This flexibility allows AT960 to cater to a wide variety of applications — from quality lab to in-line; from the factory to the field –ensuring users have the right tool for any measurement challenge.

Exact Metrology is ISO9001, AS9100 Certified as well as FFL and ITAR Registered.

Exact Metrology, with facilities in Cincinnati, Ohio, Moline, Illinois and Milwaukee, Wisconsin, plus affiliated offices throughout the country, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

For more information, please contact:

EXACT METROLOGY, INC.

Dean Solberg

20515 Industry Avenue

Brookfield, WI 53045

Local: 262-533-0800

www.exactmetrology.com

deans@exactmetrology.com

EXACT METROLOGY, INC.

Steve Young

11575 Goldcoast Drive

Cincinnati, OH 45249

Local: 513.831.6620

Toll Free: 866.722.2600

www.exactmetrology.com

stevey@exactmetrology.com