Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

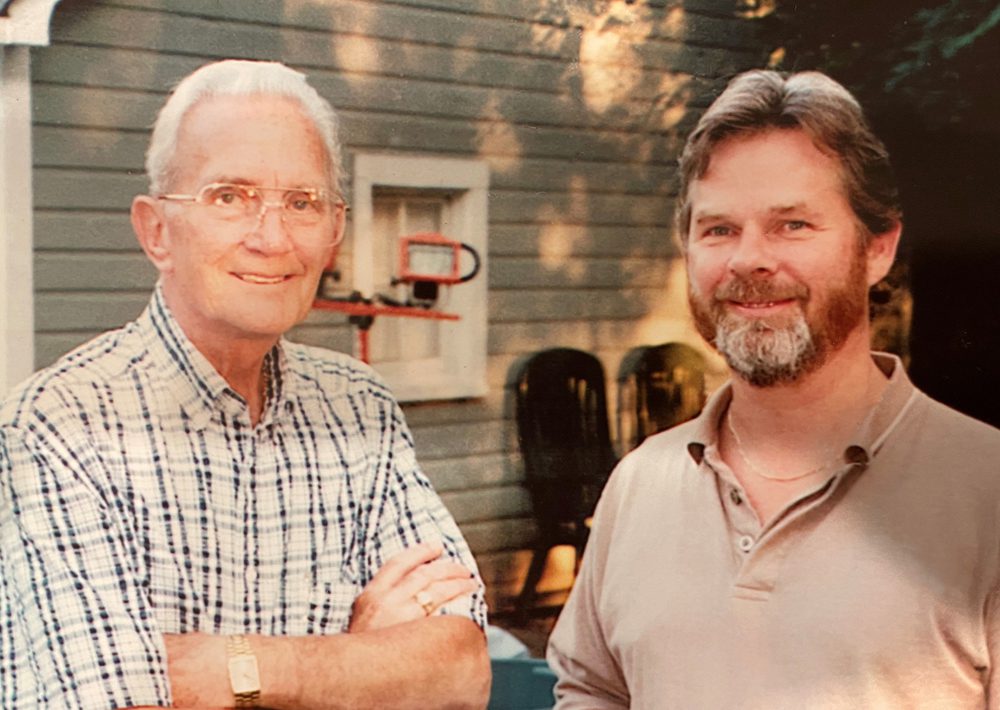

In a world where machine shops are struggling to stay open and maintain their business and in a day when “going into dad’s business” is not what it once was, Platinum Tooling is an exception to the rule. Located in Prospect Heights, Illinois, the company is set to reach an important milestone. In 2022, company President Preben Hansen and his family will celebrate 100 years working in metal cutting and four generations of Hansen men in the industry. How cool is that?

The story began with Preben’s grandfather, Louis Eckart Hansen, who learned his trade in Copenhagen, Denmark in the early 1900s. Louis worked as a machinist in the Danish Navy’s repair facility. Preben’s father, Svend Eckart Hansen, honed his skills under the guidance of Louis. In 1958, Svend emigrated with his family, including young Preben, to the U.S. Despite not knowing English, he found employment within days of arriving in Chicago, because of his skill as a tool maker. Svend began his career as a machinist and ended it in the 1990s as a master tool maker at Ramcel Precision Stamping and Manufacturing LLC in Northbrook, Illinois.

With manufacturing and tooling in his DNA, Preben worked in the machine shop of the former Fulton Machine Company in downtown Chicago, while attending the University of Illinois/ Chicago and pursuing a degree in engineering. Following college, he worked in the shop at Oakley Industries building custom machinery. After several years in the shop, Preben moved to the front office and into an inside sales position. Later, at Jemco Tool & Die, he learned programming and set-up on their CNC lathes and machining centers which was his introduction to machine tools and their accessories. His next job was at HPI, now known as Pioneer Heartech Precision Inc., a distributor of tool holders and related products, in Elk Grove Village, Illinois. Preben started as an Outside Sales representative of tool holders and rotary tables, then became the company’s Sales Manager. This was followed by work at Lyndex-Nikken, another machine tool accessory supplier in Mundelein, Illinois. Here, Preben was introduced to live tools and once again worked as Sales Manager. In 2010, Preben started a joint venture with heimatec GmbH, becoming the President of Heimatec, Inc., a company specializing in live tools, angle heads and multi-spindle drill heads. In 2018, Heimatec, Inc. was purchased by Platinum Tooling Technologies, Inc. with headquarters located in Prospect Heights, Illinois. Preben Hansen is the COO and President at Platinum Tooling.

In total, Preben has over 30 years of experience in the machine tool accessory market and over 40 years in the manufacturing industry. Given his credentials, it’s no surprise that Preben has established himself as a leading authority on these topics in the North American machine tool accessory market. He often hosts knowledge bars at trade shows to SRO crowds.

In keeping with this family tradition, Preben’s son, Luke Hansen, joined his dad’s company in 2018 as a Technical Sales Specialist for several of the product lines sold by Platinum Tooling, including Tecnicrafts collets and guide bushings for Swiss machines. After graduating from high school, Luke joined the army in search of his calling and received great training there. Upon his discharge, he decided to put into practice the motivational and goal orientation skills he had learned in the military. In his current position at Platinum Tooling, Luke continues to expand his knowledge of the machine tool accessory market as well as build valuable relationships with the North American sales and distribution network of the company.

Reflecting on 100 years as a family in the manufacturing industry, Preben Hansen says, “The machine tool industry has been and continues to be an extremely vital part of our country’s continued success. My son Luke and I are proud to be 3rd and 4th generation professionals involved in this exciting industry.”

For more information, please contact:

Preben Hansen, President

Platinum Tooling Technologies, Inc.

16 East Piper Lane, Suite 128

Prospect Heights, IL 60070

847-749-0633

www.platinumtooling.com

phansen@platinumtooling.com

Platinum Tooling Technologies, Inc. in Prospect Heights, IL, serves its growing North American customer base with an extensive inventory of machine tool accessories. Its experienced staff is dedicated to providing the most innovative tooling and technology. Platinum Tooling Technologies, Inc. serves the auto, aero, medical, woodworking, composites and other industries, as well as an ever-increasing number of machine tool OEMs worldwide, through its network of manufacturers’ representatives. Platinum Tooling is the importer of Heimatec, Henninger, Tecnicrafts and AMF Tooling for North America.

Continue reading

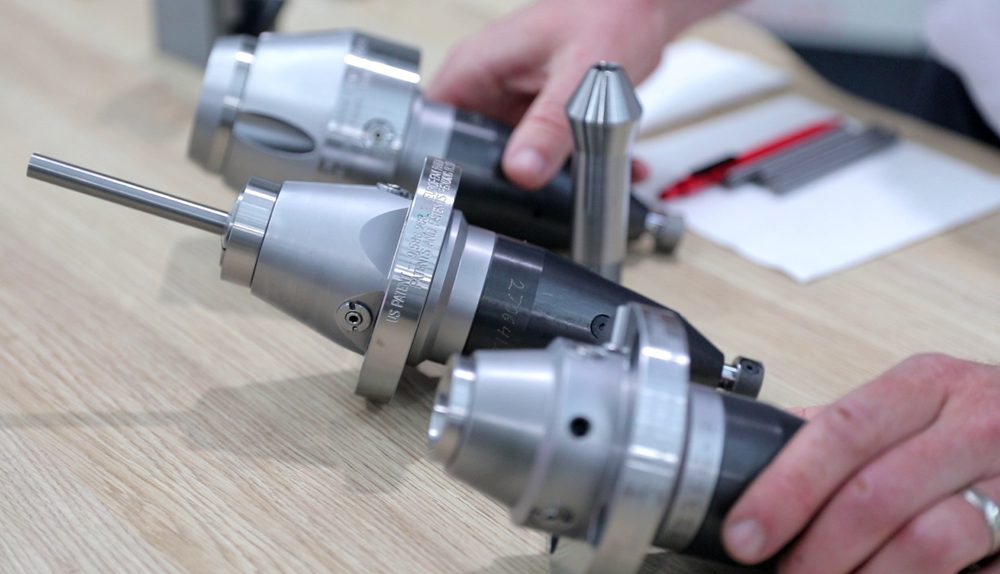

Learn how to set up a collet adaptor, a fundamental skill that all operators need to grind accurate tools and maintain stability of batch grinding

Each month, the ANCA Academy show will cover a different technical topic – from set up through to grinding. The educational videos will help ANCA machine users understand new applications and features.

Hugh Ingham, ANCA Mechanical Engineer hosts the new show and said: “I love working at ANCA because we design and apply really interesting and effective technology. It is important that we make sure we are helping our customers and those interested in getting into cutting tool grinding produce the best possible product faster, more accurately and at the lowest possible cost. The first episode will explain a PCA adaptor, how they work and how you can set your machine up for long and stable batch runs.”

“ANCA already has our Tool Tip Tuesdays, monthly newsletter, The ANCA Club, face to face training, social media and YouTube channel but we think there is so much to learn about our technology that we decided to start our own dedicated TV show. Make sure you send in any ideas or topic suggestions because this show is entirely dedicated to help our customers get even more out of their investment in ANCA. That way we both succeed.”

“The first episode covers the fundamentals of these types of collet adaptors, what makes them unique and how with some simple tricks, you can reduce your setup time and increase your productivity. After watching this episode, you will be able to confidently set up your ANCA PCA for reduced radial and axial runout and enjoy the benefits of long and stable batches.”

“If you have a brand new or an older ANCA machine and want to get right into accurate and repeatable grinding, then you definitely don’t want to miss this.”

Topics covered will include:

Sign up to our customer dedicated newsletter and don’t miss an episode: https://machines.anca.com/E-Sharp-News/Sign-up

For further information, please contact:

Johanna Boland

Group PR and Communications Manager, ANCA

M: +61 407799779

Johanna.Boland@anca.com

https://machines.anca.com/

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

Continue reading

Poly Crystalline Diamond (PCD) products are widely used in industry for their superior abrasion resistance and longevity when machining non-ferrous materials. By virtue of their uniform carbon lattice structures, diamond is the hardest material available and therefore lends itself well to manufacturing processes requiring high speeds, feed rates and extended wear behaviors. PCD is not typically used to machine ferrous materials such as iron or steel due to a chemical reaction that occurs between the diamond and the iron molecules. The Carbon atoms in the diamond react with the Iron (Ferrous) atoms of the iron or steel to produce Iron Carbide (Fe3C), causing the tool edges to collapse. However, it can tackle bimetal applications involving aluminium and cast iron.

The areas that PCD tooling excels in is the machining of non-ferrous materials, composites, electronic components, timbers and precious metals.

| Non-ferrous Metals | Polymers and Other Materials | Precious Metals |

| Aluminum | Composites | Platinum |

| Carbide | Carbon Fibers | Gold |

| Titanium | Glass Fibers | Silver |

| Nickel | Ceramics | Bronze |

| Lead | Polyether (PEEK) | |

| Copper | Timber and wood | |

| Brass | PCB |

When machining these materials, PCD tooling exhibits superior wear resistance, heat tolerance and tool longevity.

Using PCD in tooling is not new, however, the explosion of lightweight materials used in all industries as manufacturers race to create lightweight and durable products highlights how versatile PCD tooling is becoming. Aluminium and composite products continue to grow quickly with the rapid expansion of consumer electronics, light-weight transportation and more efficient power generation.

Linked to the growth in non-ferrous componentry and PCD tooling is the downward pressure being applied to machine tool builders. Lowering cycle times and increasing surface finishes enables a profitable business proposition for PCD tooling manufacturers by reducing manufacturing costs per tool and increasing quality and durability for the end user.

To enable ANCA’s customers to create high-quality, low-cost tooling the new ANCA Motion SparX Generator has been designed and built using the latest power electronics. Power Electronics allows the creation of a wide band-gap generator to achieve high current and high frequency simultaneously. This enables higher mega-amp per second Nano and Pico-pulses and far greater control of the erosion process. These combine for a much faster and controllable erosion process than conventional electronics and allow for the complete manufacture of PCD tooling using nano grade PCDs (example: Element Six CMX850 with 0.85µm diamond grains and CTX002 with 2µm grains) through to very large diamond grades (example: CTH025 with average grain size of 25µm and CTM302 a multi-modal PCD with grain sizes of 2µm to 30µm)

Additionally, by virtue of the 5-axis kinematics of the ANCA EDG machines utilizing a rotary copper electrode, almost infinite tool geometries can be created including complex end-face and fluting geometries. This linked to very aggressive pricing and performance with supreme flexibility enables tooling manufacturers to create high quality PCD tools competitively. Additionally, with the increase in performance, decrease in cycle time and increase in surface finish specification, users are able to purchase arguably the most technologically advanced erosion machine available. ANCA is the only supplier of EDG erosion machines in the market that has a synchronized, adaptable, intelligent and controllable erosion process suited perfectly to the vast array of non-ferrous materials.

To highlight these benefits, ANCA conducted testing between tools created on an ANCA EDG, tools created on a competitor laser machine and lastly on a competitor erosion machine. Testing utilized a 12mm 2D shear brazed (neutral rake face) tool due to laser ablation systems being unable to create large fluted tools. The PCD material was Element Six CTM302.

Testing showed definitively that not only did the ANCA EDG match the quality and cycle time of laser created tools, but it was vastly superior to the like-for-like erosion results.

| Laser Competitor | Erosion Competitor | ANCA EDG | |

| Settings | – | Standard Finish | Standard Finish |

| Surface Finish (µm Ra) | 0.200 | 0.400 | 0.200 |

| Cycle Time | 26m : 24s | 56m : 00s | 26m : 20s |

| Edge Corner Radius (µm) | 9.45 | 6.25 | 3.22 |

Additionally, the cutting edges were 3x keener on the ANCA created tools as opposed to the laser ablated tools. Keen cutting edges are very important in the manufacture of aluminium and composites as they reduce burring while increasing surface finishes. In composites, keen cutting edges also reduce the risk of delamination during machining.

The key take-away from this testing was that not only is the ANCA EDG with the new ANCA Motion SparX Erosion Generator well suited to all types of PCD and the varying associated industries, but that erosion processes utilizing power electronics with high current and high frequency simultaneously positions the ANCA EDG squarely in the sights of both traditional erosion and laser technologies.

For further information, please contact:

Johanna Boland

Group PR and Communications Manager, ANCA

M: +61 407799779

Johanna.Boland@anca.com

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

Continue reading

Greg Groth, the Brookfield, Wisconsin Division Manager, was part of a panel discussing additive manufacturing, its challenges and opportunities

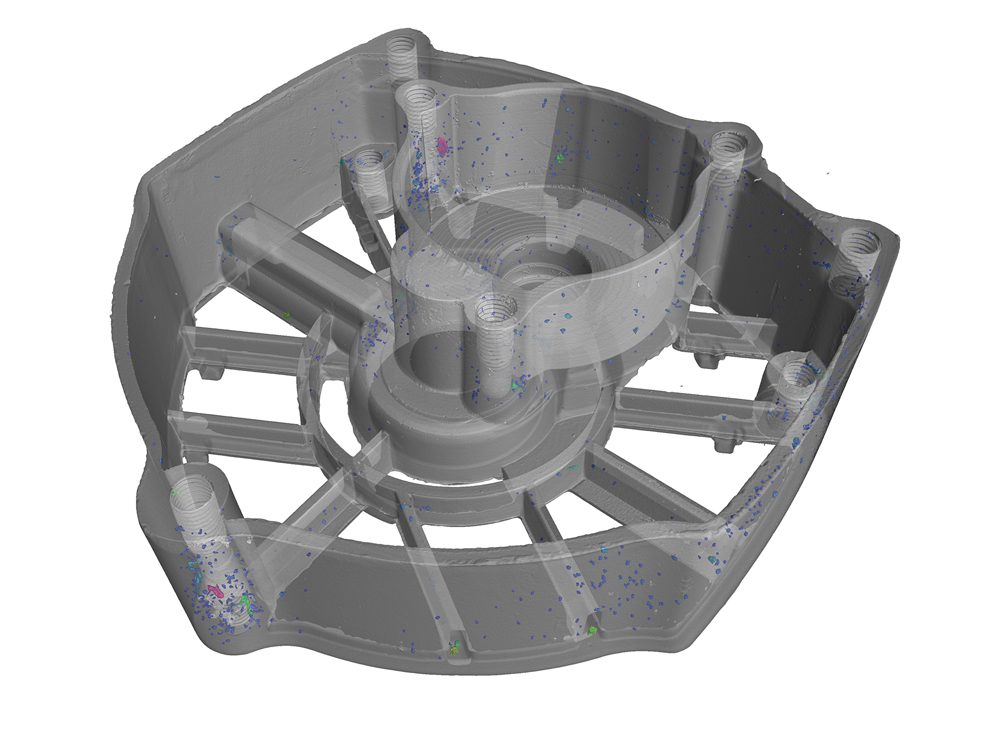

Exact Metrology: A Division of In-Place Machining Company and a comprehensive 3D metrology service provider and hardware sales company, had one of their employees give a presentation on 3D scanning and how to use it. Greg Groth, the Division Manager at the company’s Brookfield, Wisconsin location, presented at Rapid+TCT, North America’s largest additive event. Held recently at McCormick Place in Chicago, Illinois, Groth was part of a panel discussion entitled “3D Scanning: Why do it and how.”

He discussed Exact Metrology’s capabilities, with an emphasis on CT technology. Groth also cited how CT fits into the company’s business model and how it supplements additive technology. In addition, the discussion covered the challenges that arise with complex additive parts and the need to incorporate 3D scanning into the quality process that validates parts. He also shared several examples of complex projects Exact has performed over the years.

When talking about additive manufacturing today, Groth said that there is a growing need for evaluation of additive parts once they are made. “We are naïve to the thought that even though additive circumvents the traditional manufacturing restrictions (draft/shrink) when making parts, the end result part is not perfect.” He added that these parts need to be validated. Due to the fact that additive parts are so complex, inspecting them is a challenge. Thanks to CT scanning, this has become easier.

Even though CT technology has helped capture internal geometry for additive manufacturing better than other methods, there are still limitations of material penetration. Part design should think about the way the part will be inspected, whether using contact or non-contact measurement techniques.

Depending on the complexity of the part, most additive substrates can be scanned using structured light or laser scanning. However, complex powered metal substrates are feasible for CT scanning if their material properties and scale don’t impede the penetration of the X-rays on the CT scanner. The denser the material, the more power is required.

In conclusion, Greg Groth said, “I think all additive markets can find value in the scanning and validation process. With the wide variety of scanning technology available, I don’t think any market is untouchable.”

Exact Metrology: A Division of In-Place Machining Company, is ISO9001, AS9100 Certified as well as ITAR Registered.

Exact Metrology: A Division of In-Place Machining Company, with facilities in Cincinnati, Ohio, Moline, Illinois and Milwaukee, Wisconsin, plus affiliated offices throughout the country, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

In-Place Machining Company: On-Site Machining Solutions In-Place, Any Place in the World.

In-Place Machining Company, with facilities in Wisconsin, Washington, Virginia, Ohio, California, and Ontario, Canada, is the premier provider of high-precision engineered on-site machining, metrology, and large scale cutting & drilling services for a wide range of renewable energy, aerospace, industrial, and military customers throughout the world.

For more information, please contact:

Greg Groth

20515 Industry Avenue

Brookfield, WI 53045

Phone: 262-533-0793

www.exactmetrology.com

gregg@exactmetrology.com

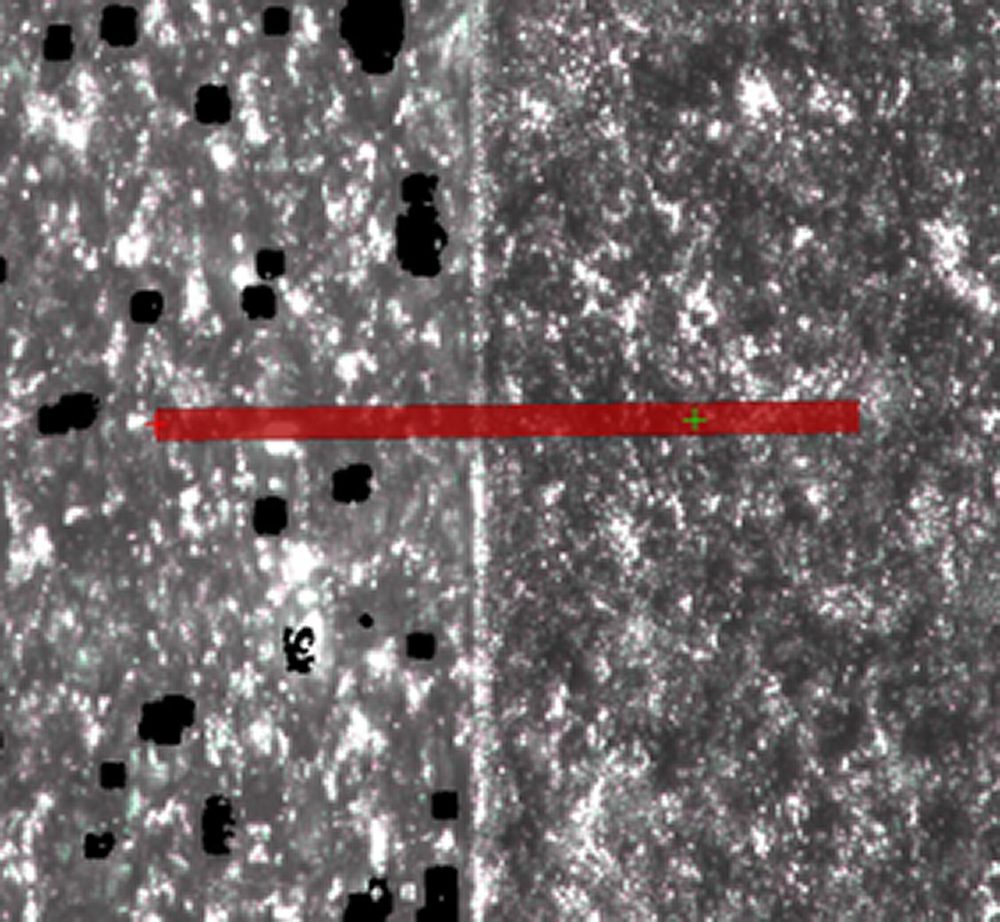

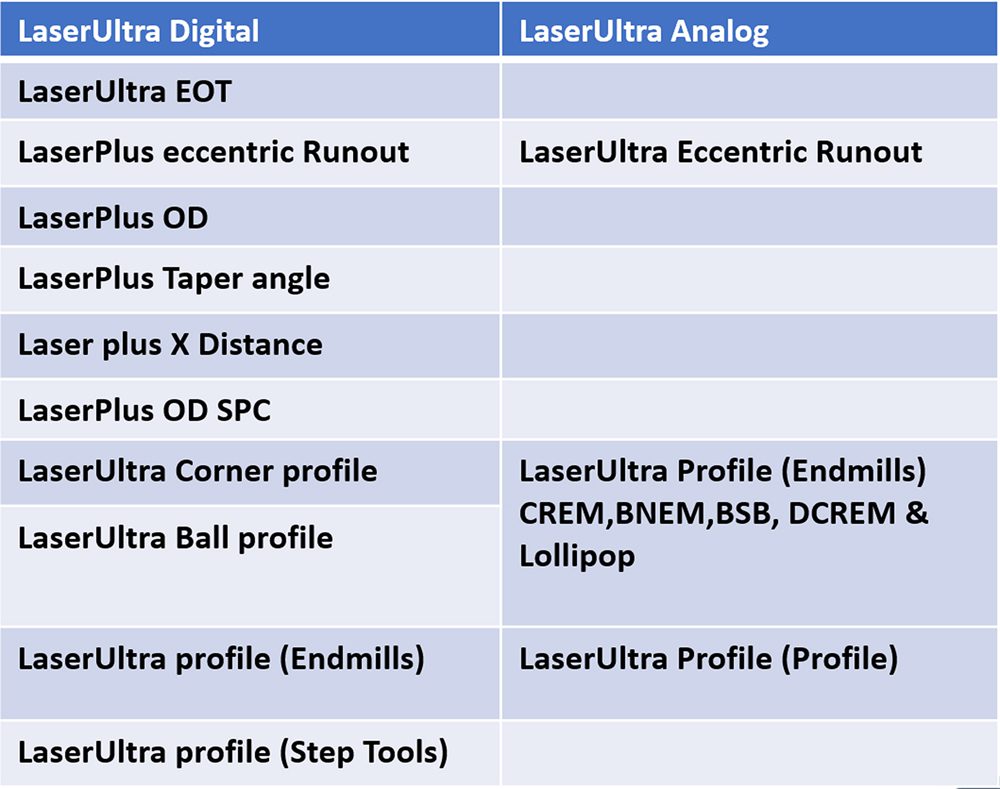

Recently launched at Eastec 2021, LaserUltra dramatically increases capacity and reduces waste through highly accurate and fast in-process measurement and compensation

ANCA leads the market in inventing, developing, and offering its customers the latest technology to realize the benefits of automation and lights out manufacturing. LaserUltra is the next generation of the highly popular LaserPlus, an in-process measurement technology only available with ANCA that gave customers the power to operate unmanned overnight with confidence they could retrieve their finished tools the next day within specification. LaserPlus was itself a game changer for the industry and already significantly faster than external tool measurement processes.

The 70% reduction in measurement time compared to Laser Plus is achieved through the new Analog measurement. The Analog measurement is a continuous edge scan instead of number of digital points along the cutting edge. This process also eliminates variations caused by machine standing idle, errors due to manual wheel corrections and the requirement of skilled operators. In its place LaserUltra has increased accuracy, productivity, and reduction of scrap.

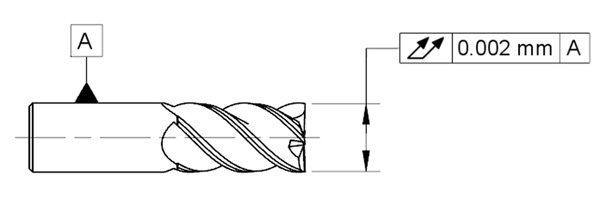

ANCA’s LaserUltra allows the measurement of tool geometries to tolerances of 0.002mm without removing the tool from the grinder, saving time in the manufacturing process, and ensuring maximum accuracy in measurement is maintained over large batch grinding.

Pat Boland, ANCA Co-Founder said: “The intersection of 5 axis milling machines, advanced CAD/CAM software and advanced profile geometry cutting tools is revolutionizing the Die and Mold and Aerospace machining industries. ANCA’s Laser Ultra tool measurement system together with RN34 software gives tool manufacturers all they need to manufacture complex profile endmills productively to outstanding accuracy.”

LaserUltra offers customers:

Thomson Mathew, ANCA Software Product Manager said: “gone are the days of manual or external measurement and compensation for critical dimensions or profile forms due to wheel wear or other grinding factors as LaserUltra can measure and compensate within a couple of microns. All this is done in process without taking the tools out of the machine with complete control of process stability and capability. These measurements are displayed at various locations to give our customers complete visibility and trust in their grinding process.”

LaserUltra is an automatic OD, profile measurement and compensating system for ANCA’s TX, MX and FX machines. It is ideal for measuring and compensating tools to maintain tight tolerances (0.002mm) in unmanned production grinding. The in-process measurement is available in both digital and analog for fast and accurate measurements to enable productivity and performance improvements.

It is permanently mounted inside the machine and will not interfere with typical grinding processes and accessories. Using the laser, the operator can perform accurate in-process measurement and compensation without removing tools from the machine.

Thomson continues: “It gives customers flexibility to service multiple markets, supporting a large range of cutting tool applications, for example, all types of endmills or step tools — including profile, compression routers and Threadmills and several more. Furthermore, different versions of LaserUltra can cover large diameter ranges and various lengths depending on user cases. And finally, LaserUltra can generate reports which can be configured depending on customers’ requirements.”

For further information, please contact:

Johanna Boland

Group Strategy and Communications Manager, ANCA

M: +61 407799779

Johanna.Boland@anca.com

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

Continue reading

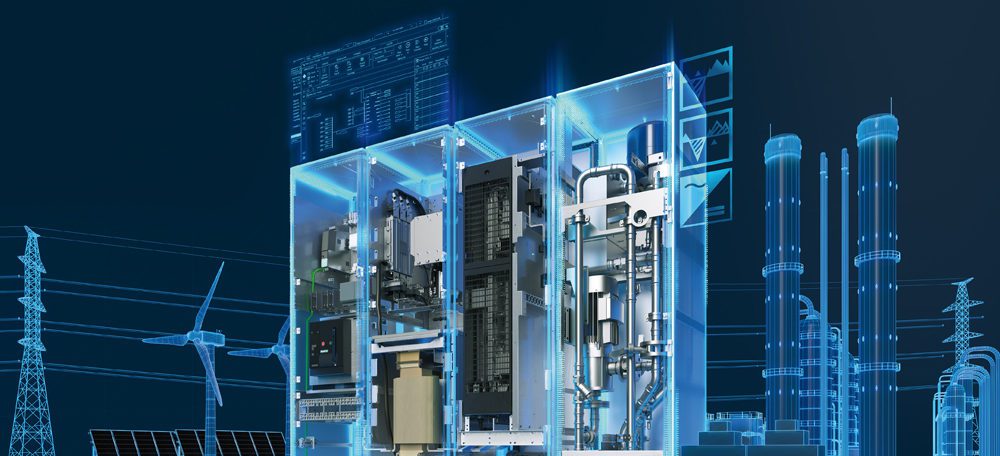

With SINAMICS PCS, Siemens presents a new power conversion system for battery storage applications. The SINAMICS PCS grid converter makes locally generated batter power usable for industrial and public power grids. SINAMICS PCS controls the charging and discharging process of the battery and helps to handle load peaks and grid disturbances via the battery storage, to store the electricity in an energy- and cost-efficient manner, and to bring the energy stored in batteries efficiently and reliably into the grid.

The grid converter is based upon the industry proven technology of the SINAMICS S120 drive platform and works very energy-efficiently thanks to liquid-cooling. The compact and robust power conversion system includes connection technology and control, line filter, drive and liquid-cooling, and can be easily integrated as a complete system in control rooms or containers.

SINAMICS PCS is certified in accordance with the “Technical Connection Rules” VDE-AR-N 4110, which is valid in Germany. This means that stationary battery storage units can be connected to the public medium-voltage grid with minimal system certification effort.

A validated Matlab/Simulink simulation model simplifies and accelerates the planning, optimization and grid integration of the power conversion system — and thanks to the SINAMICS Startdrive tool in the TIA Portal engineering framework, the grid converter

can be easily integrated into the drive world. Operating states and system parameters can be read out via the Profinet communication interface, which allows data from operation to be monitored and analyzed and makes precise statements about upcoming service work possible.

For specific product information and inquiries, send an e-mail to:

mc.us@siemens.com

Siemens presents SINAMICS PCS, a liquid-cooled, robust power conversion system for battery storage systems.

For more information about SINAMICS PCS, please visit: http://siemens.com/sinamics-pcs.

Siemens Digital Industries (DI) Siemens Digital Industries (DI) is an innovation leader in automation and digitalization. Closely collaborating with partners and customers, DI drives the digital transformation in the process and discrete industries. With its Digital Enterprise portfolio, DI provides companies of all sizes with an end-to-end set of products, solutions and services to integrate and digitalize the entire value chain. Optimized for the specific needs of each industry, DI’s unique portfolio supports customers to achieve greater productivity and flexibility. DI is constantly adding innovations to its portfolio to integrate cutting-edge future technologies. Siemens Digital Industries has its global headquarters in Nuremberg, Germany, and has around 72,000 employees internationally.

Siemens Corporation is a U.S. subsidiary of Siemens AG, a global technology powerhouse that has stood for engineering excellence, innovation, quality, reliability and internationality for more than 170 years. Active around the world, the company focuses on intelligent infrastructure for buildings and distributed energy systems and on automation and digitalization in the process and manufacturing industries. Siemens brings together the digital and physical worlds to benefit customers and society. Through Mobility, a leading supplier of intelligent mobility solutions for rail and road transport, Siemens is helping to shape the world market for passenger and freight services. Via its majority stake in the publicly listed company Siemens Healthineers, Siemens is also a world-leading supplier of medical technology and digital health services. In addition, Siemens holds a minority stake in Siemens Energy, a global leader in the transmission and generation of electrical power that has been listed on the stock exchange since September 28, 2020. In fiscal 2020, Siemens Group USA generated revenue of $17 billion and employs approximately 40,000 people serving customers in all 50 states and Puerto Rico.

Continue reading

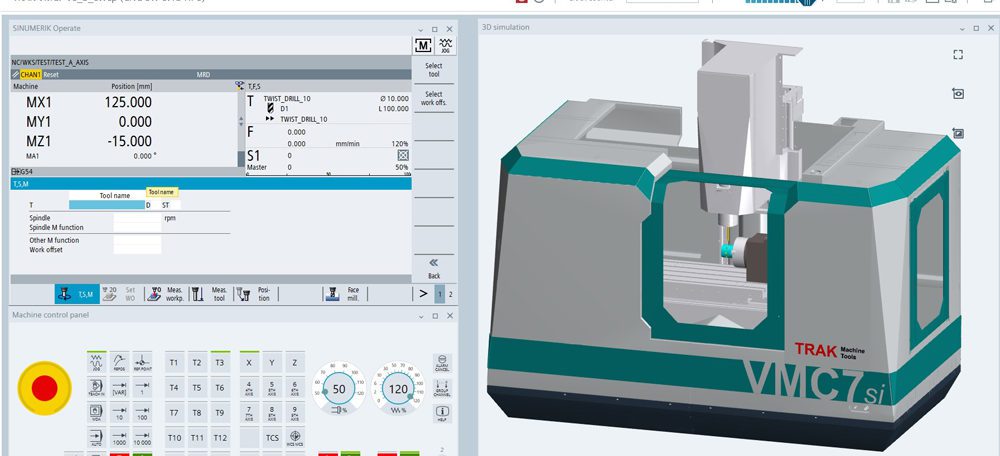

SINUMERIK ONE digital-native CNC selected as the control of choice for new line of milling and turning production machines

Siemens announced today that its SINUMERIK ONE CNC platform has been selected by TRAK Machine Tools (Southwestern Industries, Inc.) as the control of choice for their new VMC-series milling and TC-series turning machines. These new machine tools are intended to work in the high-volume, price-sensitive job shop market.

According to company president Steve Pinto, “TRAK wanted to partner with a large, well-established CNC leader with a global footprint for a new line of production machines, aiming

to reach a new level of digitalization — one that reflected that trend in every area of life today.”

Throughout the process, Siemens employed a consulting approach, selling the value of SINUMERIK CNC and the entire Siemens portfolio of product, software, communications and cloud-based data analytics. The transition to Siemens CNC was made easier, as conventional programming and HMI with SINUMERIK ONE had the same look-and-feel as the TRAK captive control. Wanting to offer automation in its portfolio, Siemens gave TRAK Machine Tools a wide range of possibilities, with the digital-native CNC.

Siemens is providing user support by ramping up its standard CNC offerings for the job shop market with SINUMERIK ONE, standard PLCs for mills and lathes, custom HMI screens and

it has worked closely TRAK Machine Tools for training. TRAK staff including application engineers, sales, service and dealers were offered SINUMERIK online web-based training,

in-person training, and time on the machines for benchmarking and test cuts. As always, Siemens is offering spare parts, 24-hour service and a quick repair turnaround to support its products and TRAK Machine Tools’ dealers.

In the future, TRAK Machine Tools also plans to develop a 5-axis and horizontal CNC offering with SINUMERIK ONE. The company is looking to brand-label a robot to automate their CNC machine with the SINUMERIK Run MyRobot application, integral to the SINUMERIK ONE CNC platform.

Brian McMinn, head of the Siemens Machine Tool Systems business, observed, “This development marks the first US-based OEM that has accepted the digital-native CNC concept of SINUMERIK ONE. At every stage of development — from concept to the Digital Twin of the machine known as Create MyVirtual Machine — to the prototype and runout, Siemens has collaborated with TRAK in a very unique way. The result is an exciting line of CNC machines that will significantly impact the job shop market, almost immediately. We are proud to partner with this forward-thinking machine tool builder.”

Steve Pinto concluded, “Having found the right technology partner in Siemens, we can now offer machine technology solutions to help TRAK customers confidently take the next step into digitally-enabled production.”

For more information about SINUMERIK ONE, please visit usa.siemens.com/sinumerik-one.

For specific product information and inquiries, send an e-mail to: cnc.marketing.us@siemens.com

Siemens Digital Industries (DI) is an innovation leader in automation and digitalization. Closely collaborating with partners and customers, DI drives the digital transformation in the process and discrete industries. With its Digital Enterprise portfolio, DI provides companies of all sizes with an end-to-end set of products, solutions and services to integrate and digitalize the entire value chain. Optimized for the specific needs of each industry, DI’s unique portfolio supports customers to achieve greater productivity and flexibility. DI is constantly adding innovations to its portfolio to integrate cutting-edge future technologies. Siemens Digital Industries has its global headquarters in Nuremberg, Germany, and has around 75,000 employees internationally.

Siemens Corporation is a U.S. subsidiary of Siemens AG, a global powerhouse focusing on the areas of power generation and distribution, intelligent infrastructure for buildings and distributed energy systems, and automation and digitalization in the process and manufacturing industries. Through the separately managed company Siemens Mobility, a leading supplier of smart mobility solutions for rail and road transport, Siemens is shaping the world market for passenger and freight services. Due to its majority stakes in the publicly listed companies Siemens Healthineers AG and Siemens Gamesa Renewable Energy, Siemens is also a world-leading supplier of medical technology and digital healthcare services as well as environmentally friendly solutions for onshore and offshore wind power generation. For more than 160 years, the company has innovated and invented technologies to support American industry spanning manufacturing, energy, healthcare and infrastructure. In fiscal 2018, Siemens USA reported revenue of $23.7 billion, including $5.0 billion in exports, and employs approximately 50,000 people throughout all 50 states and Puerto Rico.

About TRAK Machine Tools (Southwestern Industries, Inc.)

TRAK Machine Tools is well-known for its ProtoTRAK brand of CNCs and TRAK Machines. Founded in 1952 as a job shop serving the aerospace industry, it has been manufacturing ProtoTRAK CNCs since 1984 and selling them throughout North American and Europe. TRAK Machine Tools fields direct-to-customer Sales and Service Organizations throughout the United States in many of the areas that have high concentrations of manufacturing. Where it does not have its own field sales and service, TRAK Machine Tools serves customers via close relationships with independent distributors that share the core values of service to customers and community that has been the key to the enormous popularity of the ProtoTRAK and TRAK brands. The new initiative with SIEMENS will utilize the talents and reach of TRAK Machine Tools beyond the toolroom and into production and automation applications. For more information, please see www.trakmt.com.

Continue reading

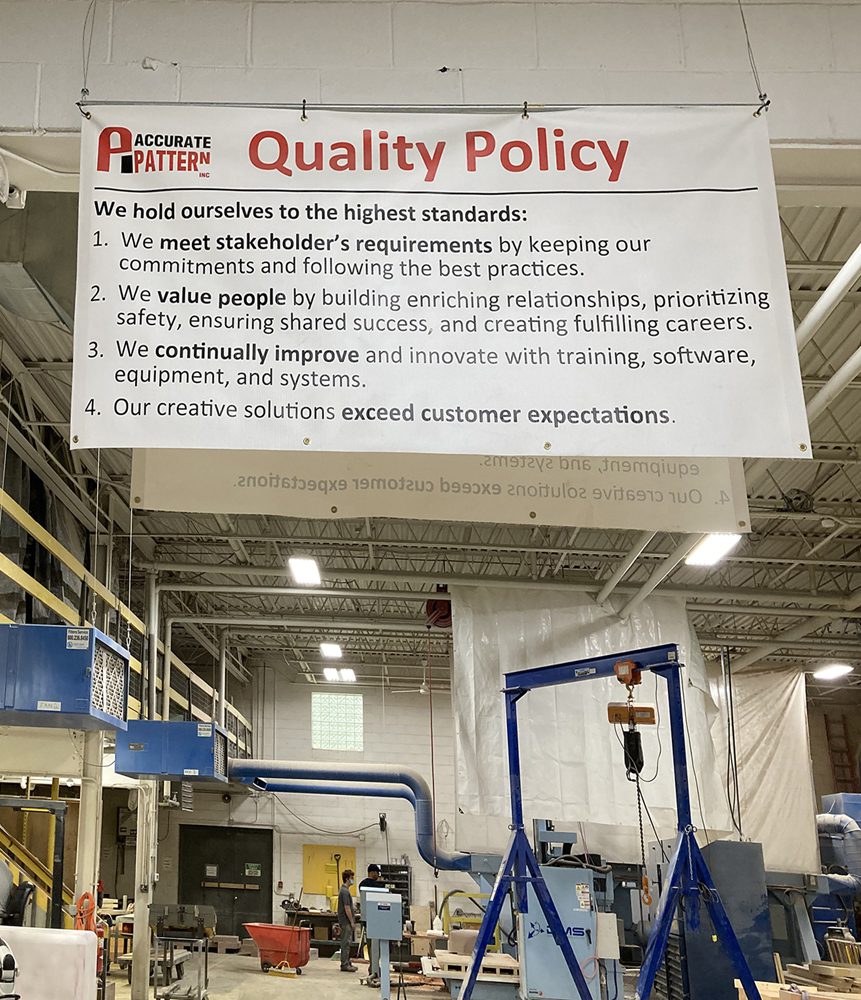

New quality standard heightens performance at company, opens new market opportunities

Accurate Pattern Inc. (Butler, Wisconsin) proudly announces it has received the Certificate of Registration for ISO 9001: 2015, effective July 29, 2021. The announcement was made by the new owners of the company, President & CEO Polly Sackett and COO Kevin Williams, who took the reins from Kevin’s father, Bruce Williams, on April 8, 2021.

As the ISO certificate states, Accurate has demonstrated that their Quality Management System complies with the requirements of ISO 9001: 2015 and, further, that the scope of this registration includes the design and manufacturing of patterns, tooling and gages for a variety of industries and provision of contract services for inspection and machining.

There are two distinct halves of this busy 25-person job shop, namely, patternmaking and fixturing. Each requires a unique set and President Polly Sackett comments, “We are so fortunate to have a dedicated group of employees who can work both sides of the operation to get the jobs done.”

Accurate performs CAD design services, manual and CNC machining up to 5-axes, CMM inspection and certification plus welding and spray coating, as it provides products to the automotive, metalcasting, marine and other markets nationwide.

In detailing the story of its ISO certification, Kevin Williams said, “The process actually began before Polly and I bought the business. Our quality manager Kris Bird has a passion for excellence and he was the key driver in this effort. But all our team really worked together, investing over 1500 hours in meetings, documentation, process and procedure development.”

Polly Sackett echoed that sentiment. “We partnered with the Waukesha County Technical College to obtain their Incumbent Worker Training Grant and it helped us train the entire team for the ISO audit, conducted by American Management Technology, Inc. (AMTEC) in Fontana, Wisconsin.” The result was a series of protocols and documentation on the entire production process at Accurate, resulting in an overnight success through the certification. As Polly notes, “We had the entire document prepped and provided it to AMTEC on a Thursday morning and we were certified by Friday night. We promptly threw a party for the employees and their families to celebrate.”

In practical terms, the benefits of achieving the ISO certification are many. The company anticipates it will explore greater opportunities in its core market of automotive, plus the ISO certification opens new market opportunities. “Those are both very exciting prospects for Accurate and we’re certain this accomplishment will lead to increased business for the company, a goal Kevin and I have set, despite these challenging times and business conditions,” she concluded.

Discussing the origin of this process at Accurate, Kevin noted, “It was a combination of customer-driven need and the passion of Kris Bird, who lobbied for the ISO certification. We quickly realized the benefits to the company and knew it would be worth the investment of time and resources to make it happen.” He further commented that the entire team at Accurate took ownership for the success of the process and the result was therefore more quickly achieved.

Polly explained the process further. “Seven or eight of us would meet weekly to discuss every stage of this endeavor and all the necessary documentation. Because we have both a metal and a model side to our company, it was a challenge to find one solution to fit both departments, but we did it,” she said, clearly proud of the achievement attained by the team at Accurate.

Kevin observed, “It was smooth sailing with very little pushback and that’s always a worthwhile experience.”

One other employee voiced his satisfaction with the accomplishment of the ISO certification. Armand “Mandi” Lulo, the company’s Director of Business Development, said, “As soon as we had the certificate in hand, I was contacting current and prospective customers to let them know. All of us at Accurate Pattern are very excited and very proud of this achievement.”

For more information, please contact:

ACCURATE PATTERN INC.

12833 W. Glendale Ave.

Butler, WI 53007

Phone: (262) 781-5558

www.AccuratePattern.com

Attention: Kevin Williams

A new option in ToolRoom cures runout woes and helps to increase tool life and productivity

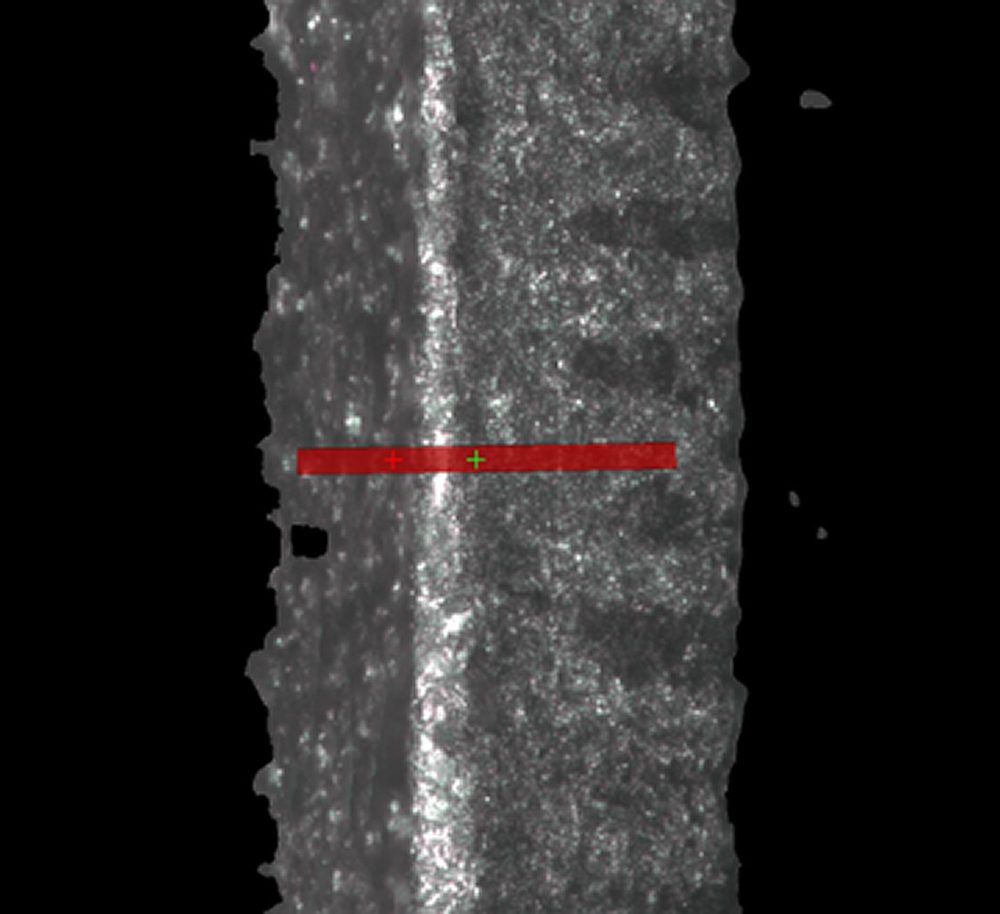

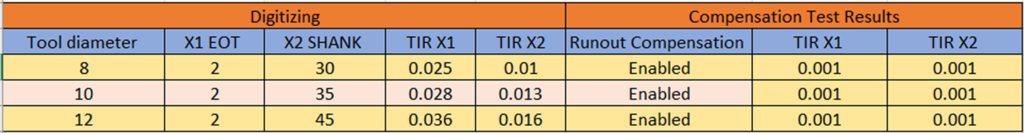

Total indicator runout (TIR) is a term often used in manufacturing, especially when dealing with rotating parts such as cutting tools, particularly endmills and drills. TIR is defined as the difference between the maximum and minimum values measured across an entire rotating surface about a reference axis.

Manufacturing high quality, high performance tools requires the Total Indicator Runout to be perfect or minimal for overall tool life and surface finish. Runout on blanks before grinding can be achieved by either spending a certain amount of time for work holding setup or alternatively, compensating the runout in software. The latest software update of ToolRoom has an option to apply complete tool runout compensation when needed.

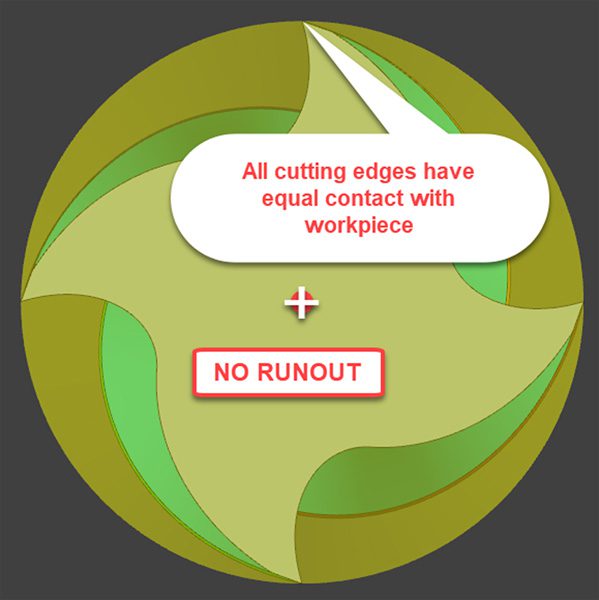

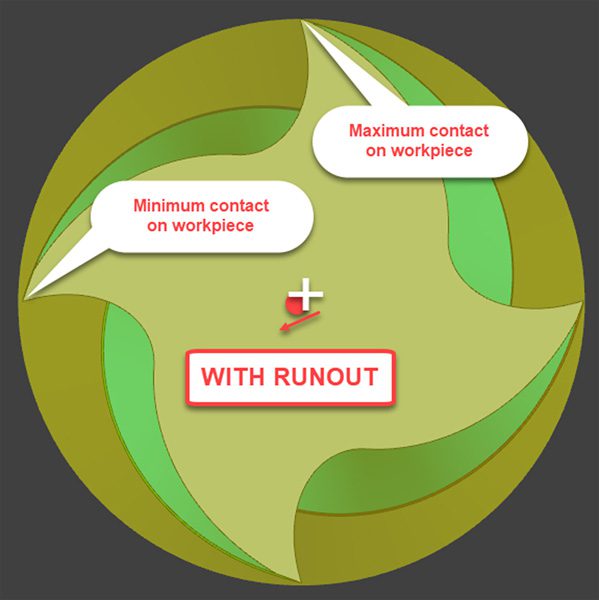

Runout creates uneven chip loads due to uneven contact on the workpiece. The result, as pictured above, is that some flutes get way too much load and wear fast while others get too little. This is not an optimal situation for endmills during machining. Not only do tools with runout have shorter tool life, they tend to be unbalanced and more prone to breaking. Additionally, they vibrate and cause chatter, increase spindle load and result in a bad surface finish on the workpiece.

On the contrary, even cutting flutes result in longer tool life, better surface finish and accurate finished parts.

Circular runout controls only a particular circular cross section of an endmill, while total runout controls the entire surface of the endmill which includes the outer diameter and endface. There are two kinds of runout: Radial and Axial. Radial runout is when the axis of rotation is off-center from the main axis, but still parallel. Axial runout is when the axis of rotation is tilted to some degree from the main axis, meaning the axis of rotation is no longer parallel to the main axis.

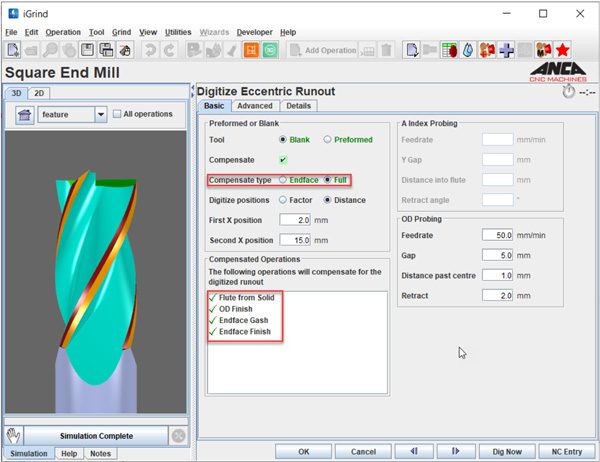

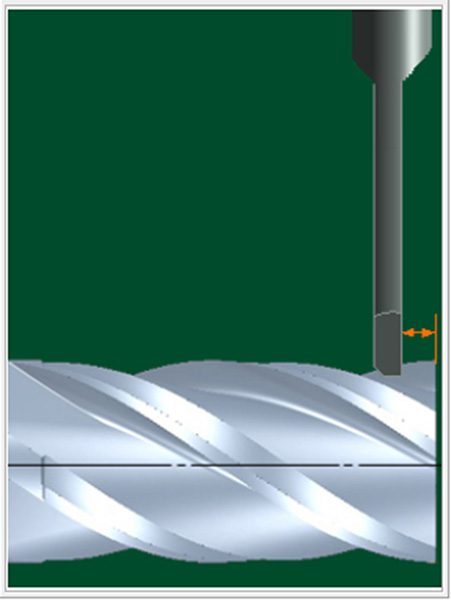

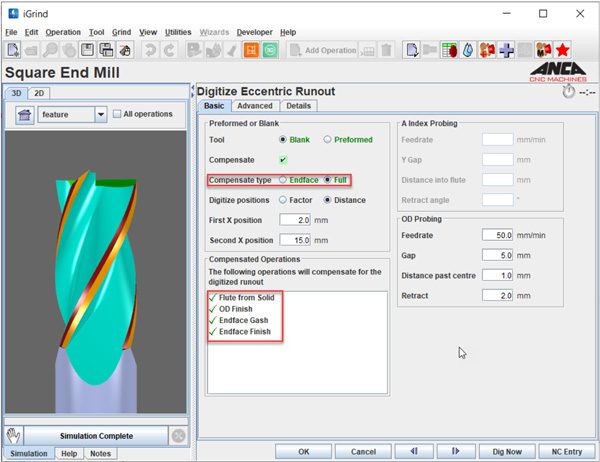

On an ANCA tool and cutter grinder, runout is measured by rotating the blank around the A-axis (headstock) and using the Renishaw touch probe. The latest update in ToolRoom RN34.1 release contains the total tool runout measurement and compensation operation in iGrind as an option. This is an addition to the existing axial runout compensation.

The runout measurement and compensation can be performed on a blank or a pre-formed blank. A pre-formed blank is a tool that has flutes ground, for example tools requiring re-sharpening. Endface compensation is used for axial runout by digitizing a single point close to the end of the tool. Only the endface operations are supported for this type of compensation.

Total runout or full compensation will measure and compensate radial and axial runout. This is mainly used while manufacturing and two points are digitized. One is near the end of the tool and the other at shank end. With the digitizing results, users are able to convert the grinding to the centerline of the blank rather than the centerline of the A-axis.

When an endmill is in rotation it is important that each tooth cuts at the exact same spot along the workpiece for longer tool life and efficient cutting. Every tool in the batch can be measured and compensated for runout to ensure the entire batch is within tolerances.

Runout in drills and reamers will result in oversized holes. This can be avoided by using the runout compensation. The chart below shows the compensation test results.

It is important to note that accuracy starts with the quality of blank. Contrary to popular belief, carbide blanks can be out of round bent or tapered. Ensure that the blanks are checked for size and accuracy, cleaned, and chamfered at insertion end. Blanks should be within 0.001mm (0.00004”) in straightness and 0.0005mm (0.00002”) in roundness to achieve the above accuracy.

Manufacturing challenges due to runout is a persistent pain point for many precision tool manufacturers. This new feature addresses this problem and will give users the assurance they need to manufacture high quality tools – ensuring that the hundredth endmill produced will be equally as good as the first.

The new complete tool runout measurement and compensation operation is now available as an option in the latest ToolRoom update for RN34.1 release. Customers will benefit from increase in productivity due to the reduced collet and collet adaptor setup time, and reduced scrap from zero rejections due to runout.

For further information, please contact:

Johanna Boland

Group PR and Communications Manager, ANCA

M: +61 407799779

Johanna.Boland@anca.com

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA as well as a comprehensive network of representatives and agents worldwide. ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

Continue reading

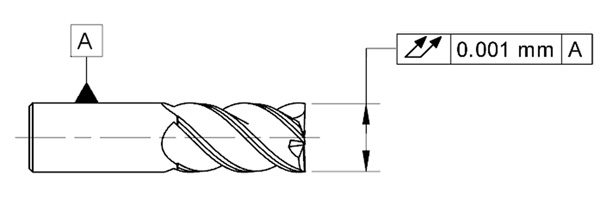

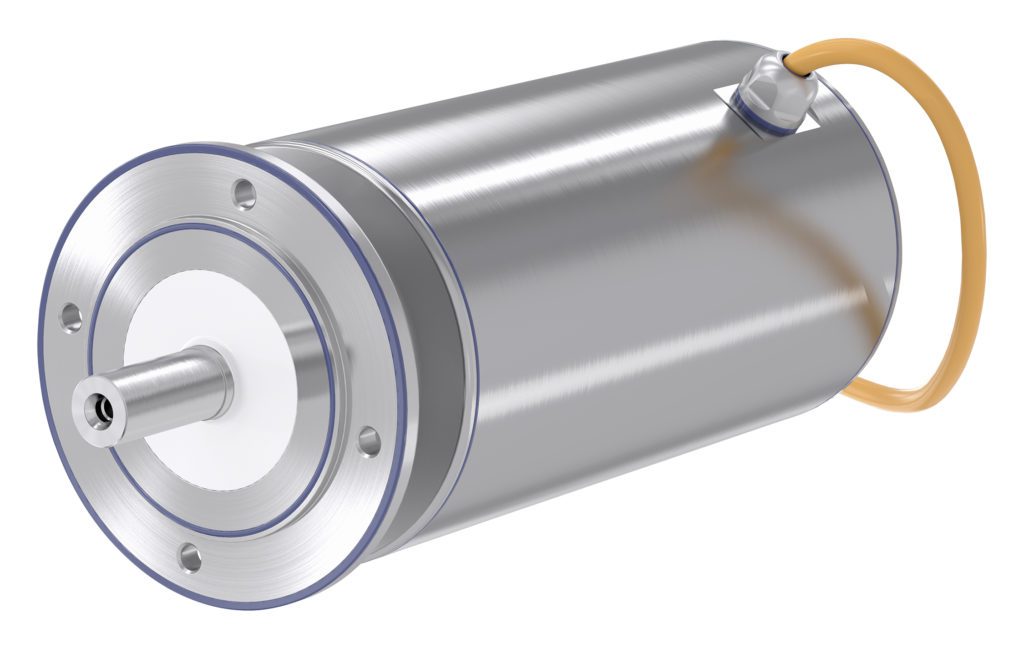

Stainless steel housings suited to high standards of hygiene and cleanliness; three sizes to 2kW (2.68 hp) power range and up to 14 Nm (10.32 ft-lbs.) torque

Siemens is introducing the new SIMOTICS S-1FS2 line of servomotors, designed for the clean condition requirements of the food, beverage, sterile packaging, pharmaceutical and other process industries. These new servomotors are offered in a variety of power ratings, from 0.45–2kW (0.60–2.68 hp) with torque from 3.1–14 Nm (2.28–10.32 ft-lbs.). Crafted with housings of 1.4404 (AISI 316/316L) stainless steel, EPDM seals and bearing grease with NSF H1 approval, these new servomotors are highly resistant to corrosion and acidic chemicals found in the process industries. This extremely high degree of protection is in accordance with IP66/67 standards on the entire motor, with IP69k (30-bar) protection provided on the motor housing.

High dynamics due to low inherent inertia plus high overload capacity for use in pick-and-place applications, plus precise movement of heavy loads, are added features. One cable connection is provided for easy installation and cleaning. The standard absolute encoder is 22-bit multi-turn.

The SIMOTICS S-1FS2 family of motors is suitable for clean-in-place (CIP) processes and for use with all commercially available cleaning agents used with washdown motors.

Quality construction further highlights this new family of motors, providing the machine builder and end-user long service life. These motors are especially designed for the 3-A (U.S.) and EHEDG (Euro) requirements of the food and beverage industries.

Options include a holding brake, stainless steel shaft with or without feather key, cable tail for direct drive connection and a MOTION CONNECT coupling. MOTION CONNECT is the Siemens fully assembled power and signal cable design for use on production machinery of many types.

SIMOTICS S-1FS2 is compatible with the SINAMICS S210 drive system.

Selection/configuration data, dimensional drawings, CAD models, data sheets and full specifications for SIMOTICS S-1FS2 servo motors are available immediately from Siemens.

Siemens introduces the new SIMOTICS S-1FS2 stainless steel servomotor for food, beverage, sterile packaging, pharmaceutical and other process applications

For more information regarding SIMOTICS S-1FS2 servo motors, please visit:

usa.siemens.com/simotics-s1fs2

Siemens Digital Industries (DI) is an innovation leader in automation and digitalization. Closely collaborating with partners and customers, DI drives the digital transformation in the process and discrete industries. With its Digital Enterprise portfolio, DI provides companies of all sizes with an end-to-end set of products, solutions and services to integrate and digitalize the entire value chain. Optimized for the specific needs of each industry, DI’s unique portfolio supports customers to achieve greater productivity and flexibility. DI is constantly adding innovations to its portfolio to integrate cutting-edge future technologies. Siemens Digital Industries has its global headquarters in Nuremberg, Germany, and has around 75,000 employees internationally.

Siemens Corporation is a U.S. subsidiary of Siemens AG, a global powerhouse focusing on the areas of power generation and distribution, intelligent infrastructure for buildings and distributed energy systems, and automation and digitalization in the process and manufacturing industries. Through the separately managed company Siemens Mobility, a leading supplier of smart mobility solutions for rail and road transport, Siemens is shaping the world market for passenger and freight services. Due to its majority stakes in the publicly listed companies Siemens Healthineers AG and Siemens Gamesa Renewable Energy, Siemens is also a world-leading supplier of medical technology and digital healthcare services as well as environmentally friendly solutions for onshore and offshore wind power generation. For more than 160 years, the company has innovated and invented technologies to support American industry spanning manufacturing, energy, healthcare and infrastructure. In fiscal 2018, Siemens USA reported revenue of $23.7 billion, including $5.0 billion in exports, and employs approximately 50,000 people throughout all 50 states and Puerto Rico.

Continue reading