Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

QUICK® knurling and marking tools used in various industries including medical, aerospace, automotive and fitness

Platinum Tooling, the importer and master distributor of live tools, angle heads, marking tools, Swiss tools and multi-spindle tools manufactured by various global suppliers, is now the North American importer of the QUICK® knurling and marking tools from Hommel & Keller. The announcement was made by Platinum Tooling president, Preben Hansen, at headquarters in Prospect Heights, Illinois, near Chicago.

A longtime global leader in high-end knurling and marking tools, Hommel & Keller manufactures the QUICK® line with a combination of function and innovation. Quality, precision and stability are the key principals used to make QUICK® tools successful. Furthermore, the company prides itself on a rich history of providing customized solutions for its customers.

The QUICK® product spectrum offers innovative solutions for diverse knurling technology applications. For both form knurling and cut knurling, QUICK® fulfills the most stringent quality standards and masters difficult tasks. Knurling tools are available for use on a wide range of workpiece diameters, including small tools for Swiss type lathes from Ø 1.5 mm.

QUICK® marking tools make it possible to mark workpieces in seconds on a variety of surfaces and part geometries. Through single marking segments, the marking text can be individually customized. Tools are available in two diameters for interchangeable lettering, as well as custom logos.

These tools are used whenever absolute precision and first-rate surface quality are needed. Examples include medical and dental instruments, watches, fishing gear, windshield wiper shafts, barbells, screwdriver bits, fittings, connectors plus welding and cutting equipment.

To download the full catalog, click: https://platinumtooling.com/catalog/quick-catalog/

For further information, please contact:

Preben Hansen, President

PLATINUM TOOLING TECHNOLOGIES, INC.

16 E. Piper Lane

Suite 128

Prospect Heights, IL 60070

Phone: 847-749-0633

Fax: 847-749-2445

Email: phansen@platinumtooling.com

Platinum Tooling Technologies, Inc. in Prospect Heights, IL, near Chicago, serves its growing North American customer base with an extensive inventory of machine tool accessories. Its experienced staff is dedicated to providing the most innovative tooling and technology. Platinum Tooling Technologies, Inc. serves the auto, aero, medical, woodworking, composites and other industries, as well as an ever-increasing number of machine tool OEMs, through its network of manufacturers’ representatives. Platinum Tooling is the master importer of Heimatec, Henninger, Tecnicrafts, AMF Tooling and Hommel + Keller QUICK® for North America.

Continue reading

As part of the digitalization group at Siemens and currently working with the machine tool systems business in Elk Grove Village, Illinois, near Chicago, Chunrong “Shelly” Shan is a digitalization software pre-sales engineer, primarily focused on the company’s advanced Industrial Edge technology. Edge brings machine tool users the ability to capture operational data from a machine or production line, feed it up to the cloud and analyze it in real time, in relation to a preset battery of monitored conditions. This technology, on a very practical level, enables the small job shop with a few CNC machines or a large production department with hundreds on the factory floor to maintain the highest levels of output coupled with consistent and constantly evolving manufacturing control, largely running through the algorithms in the machine’s control.

Shelly finds such work very stimulating. “In my current role at Siemens as pre-sales engineer, my primary task is to help our customers develop customized programs based upon our Edge technology platform to improve their manufacturing productivity.” She cites a recent example of her work, where she developed a software application for a top U.S. automotive manufacturer to capture the high-frequency data from the CNC on their many machine tools, then send that data to what Shelly calls the “data lake” for production optimization. Through the use of Edge devices on the various machines, such data are extracted from the machine controllers and fed to that data lake. Shelly notes it was a very big challenge, since the end user’s data lake uses a very specialized, proprietary protocol not supported by the standard Siemens solution. “That’s where it got interesting,” she muses.

Through a series of customized adaptations in the software, Shan was able to create a smooth interface between the data gathering and the host protocol, resulting in an optimal solution for the customer. One of the most significant challenges in Edge technology is something of a “too much of a good thing” scenario, as the power of Edge allows massive data sets to be gathered. The software needs to separate the data, prioritize it, compare it to preset levels or limits, then take the appropriate corrective action, all within milliseconds.

Shelly Shan brings an impressive skill set to the task, as she holds a Master’s degree in computer science from Penn State, as well as a Master’s degree in Mechanical Engineering from Beihang University in her home country of China. She first worked for Siemens in China for 11 years and now four years at the company’s U.S. machine tool headquarters in Chicago.

Shelly’s skills range from software development to AI, big data and cloud computing. She came to the U.S. when her family migrated.

In reflecting on her reasons for entering the engineering field, Shelly states, “I think it involves a combination of my personality and my technical interests. I feel most comfortable and engaged when I’m solving problems for a customer. That gives me a lot of strength and confidence, as well as joy in helping others.”

She makes mention of her mentor in China. “I had one colleague there who was simply good at everything! He could master technologies, problem-solve very quickly, and he was capable of numerous achievements simultaneously. His top skills were controller commissioning and debugging, as well as digitalization coding. I would say he definitely gave me a lot of help and guidance, as I worked to find the right directions in my career.”

Shelly enjoys her variety of tasks in customizing Edge application development and she seeks to do further software development for Siemens.

As a woman engineer, she notes there are both advantages and challenges. “Everyone tends to be very friendly to the often-lone woman in the room, which is nice,” Shan notes, also noting that it is sometimes difficult to talk to anybody about makeup or clothing styles. On the business side, she believes females tend to be more careful about details and can often communicate more easily with customers. The issue of work-life balance can also be a challenge. “Women often feel the need to take care of family as well as work, plus travel can be difficult, but I handle it. The company is also very supportive and flexible in helping me achieve my goals.”

From her performance and track record in the industry with a major corporation such as Siemens, Shan seems to handle it all quite well.

Asked where she sees herself in the coming years, Shelly observes, “I am sure I’ll still be working as an engineer and I’d like to make more contributions to the technology. I think the future for women in engineering is very bright and promising, as it will continue to drive the development of many technologies and improvements in our world.”

Continue reading

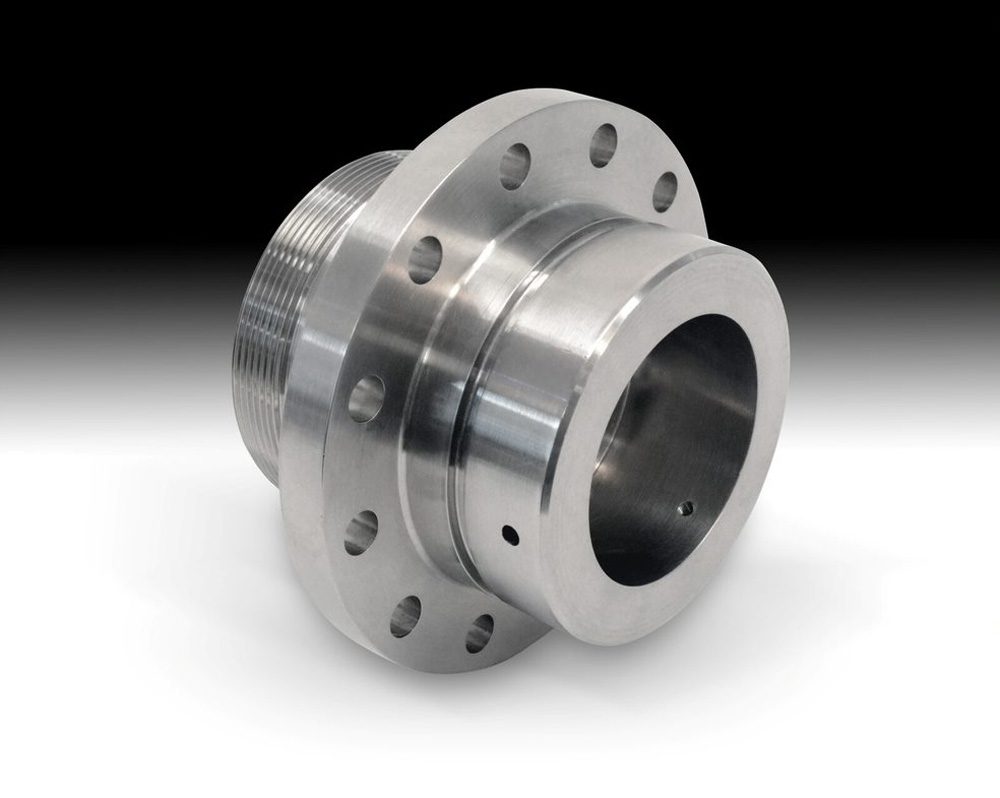

Guill Tool, a growing supplier of components to the global aerospace industry, today announced the production of a new Conduit Conductor. The conductor is made of Monel 400.

Dimensions on this product are 5.25” outer diameter x 3.625” overall length, or (133.35mm outer diameter x 92.075mm overall length). This Guill conduit conductor is turned on a CNC lathe and holes are drilled on a milling machine.

Guill now offers its substantial machine shop capabilities as an independent service to customers in aerospace manufacturing. Products are made to customer specification.

For over 55 years, Guill Tool has offered high-quality, precision machined components for the defense and commercial industries. The company manufactures flanges, valves, fittings and various critical components for aircraft, weapons and nuclear submarines.

Guill offers its full capability of CAD/CAM design, plus EDM and 5-axis machining centers to the aerospace industry. Owing to its many years in the government and defense sectors, Guill also provides industry-standard cybersecurity and NDA confidentiality to its customers.

Guill has the following registrations and certifications: AS9100:2016 – Aerospace Manufacturing, ISO9001:2015 registered, JCP Certified – Government Contracting, ITAR Registered and NIST SP800-171Compliant Cyber-Security.

For more information, please contact:

Tom Baldock

Guill Tool & Engineering – Aerospace Division

10 Pike Street

West Warwick, RI 02893

USA

Office: 401-828-7600

www.guill.com/aerospace

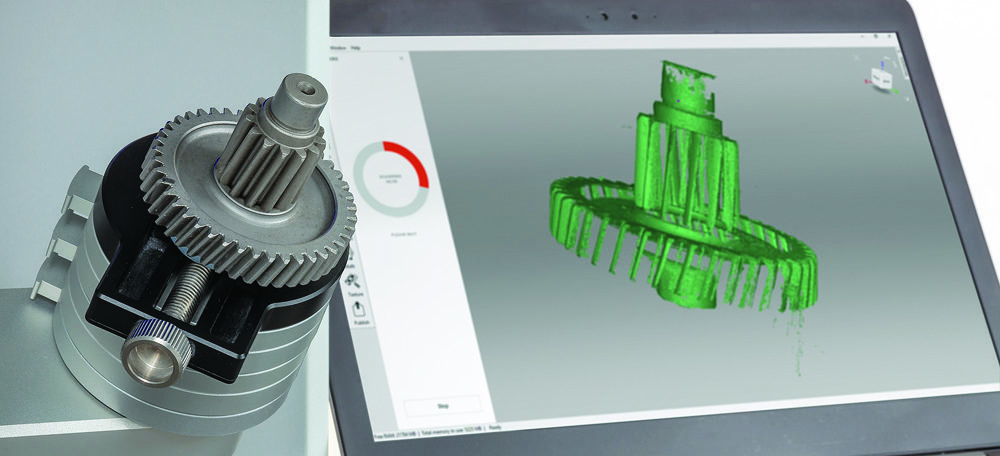

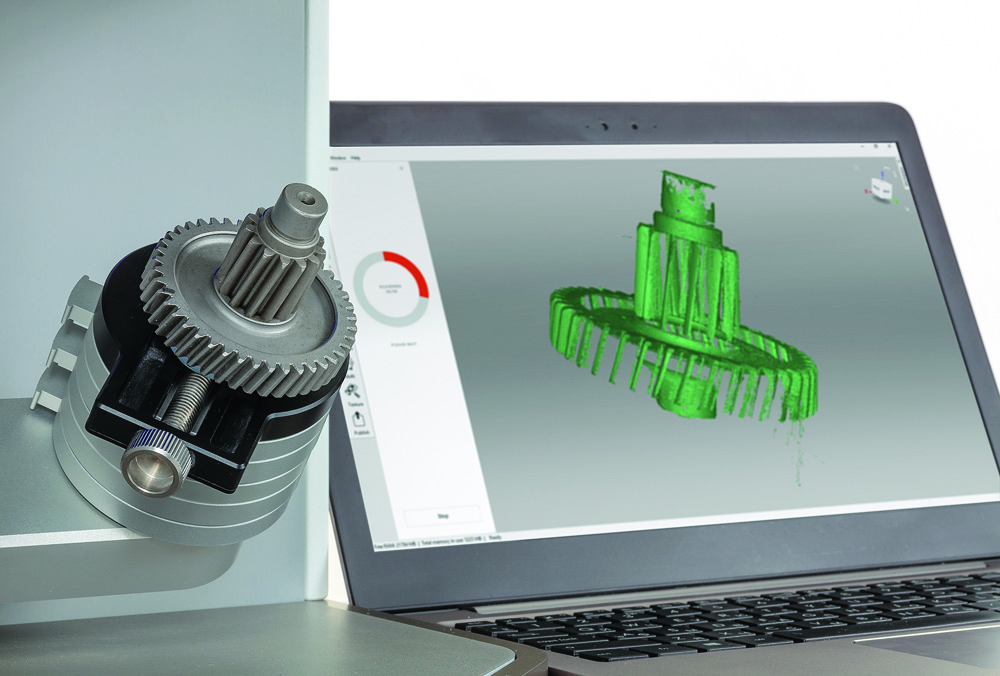

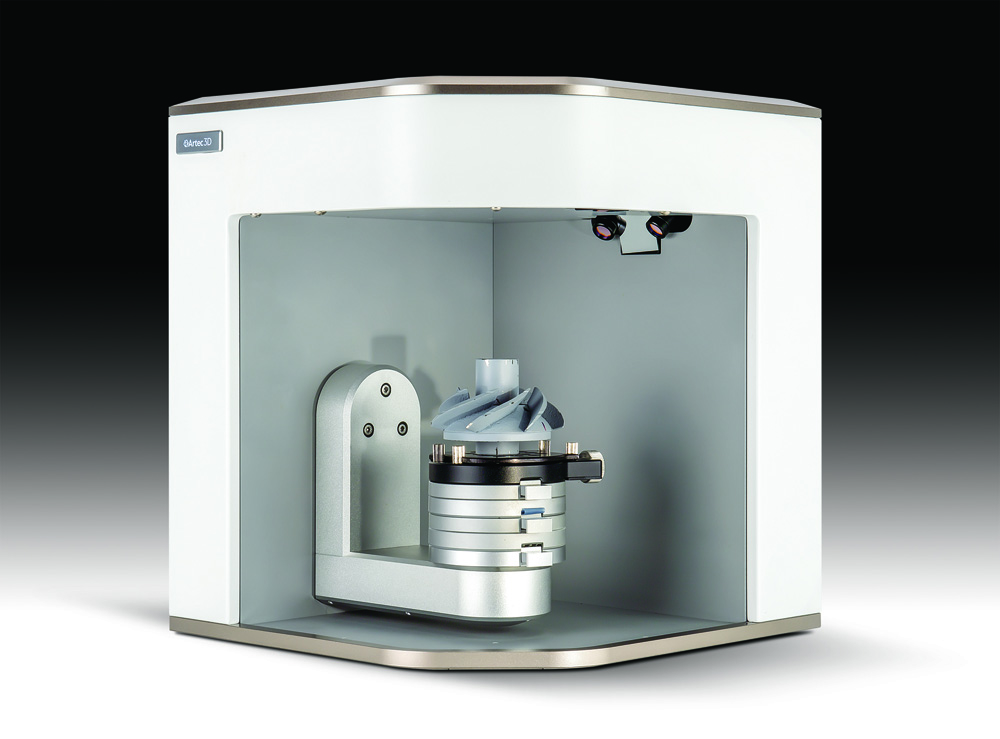

Exact Metrology: A Division of In-Place Machining Company and a comprehensive 3D metrology service provider and hardware sales company, now offers the newest version of its Artec Micro scanner. This new model distinguishes itself through its professional ultra-high precision industrial desktop 3D scanner, designed to deliver industrial-quality scans in just one click.

With a 2-year warranty, features of the Artec Micro include up to 10 microns accuracy and is perfect for quality testing and reverse engineering. It produces metrology-grade scans suitable for quality control, while removing the need for targets on the scanned object.

Artec Micro’s advanced twin color cameras and blue LED lights are synchronized with the scanner’s dual-axis rotation system to create a digital copy of your object with a minimum of frames captured. In addition, the Smart Scanning mode captures every surface of the object in the least amount of time, using an ideal number of frames. A minimum amount of training is required with Micro, as the scanner is user-friendly and ready to set up quickly. The scanner integrates with Artec Studio for real-time digital capture.

Delivering highly accurate scans, not only can Micro “see” well below the human visibility threshold of 40 microns, but its 3D measurements are among the best in today’s cutting edge scanners, making it a perfect choice for inspection and much more. Reverse engineering is completed with Artec Micro’s precise 3D measurement to digitally fit together legacy parts with those customers create, capturing even the smallest details that most scanners miss.

In minutes, Artec Micro transforms intricate items into CAD/CAM data for design, modification, 3D printing and casting. As a result, this saves hours of time in the design and production of complex pieces. The scanner also creates highly-detailed 3D models.

In-Place Machining Company: On-Site Machining Solutions In-Place, Any Place in the World.

In-Place Machining Company, with facilities in Wisconsin, Washington, Virginia, Ohio, and Ontario, Canada, is the premier provider of high-precision engineered on-site machining, metrology, and large scale cutting & drilling services for a wide range of renewable energy, aerospace, industrial, and military customers throughout the world.

Exact Metrology: A Division of In-Place Machining Company, is ISO9001, AS9100 Certified as well as ITAR Registered.

Exact Metrology: A Division of In-Place Machining Company, with facilities in Cincinnati, Ohio, Moline, Illinois and Milwaukee, Wisconsin, plus affiliated offices throughout the country, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

About Artec 3D

Artec 3D is an international company, headquartered in Luxembourg, with offices in the United States (Santa Clara, California), China (Shanghai) and Russia (Moscow). Artec 3D develops and produces innovative 3D solutions and products. Artec has a team of professional experts in the collection and processing of 3D surfaces as well as biometric facial recognition. Artec 3D’s products and services can be used in many industries, such as in engineering, medicine, media and design, entertainment, fashion, historic preservation, security technology and many more.

To see the unboxing of the Artec Micro, click

For more information, please contact:

Exact Metrology: A Division of In-Place Machining Company

Kelly Baldasare

11575 Goldcoast Drive

Cincinnati, OH 45249

Local: 513-831-6620

Toll Free: 866-722-2600

www.exactmetrology.com

kellyb@exactmetrology.com

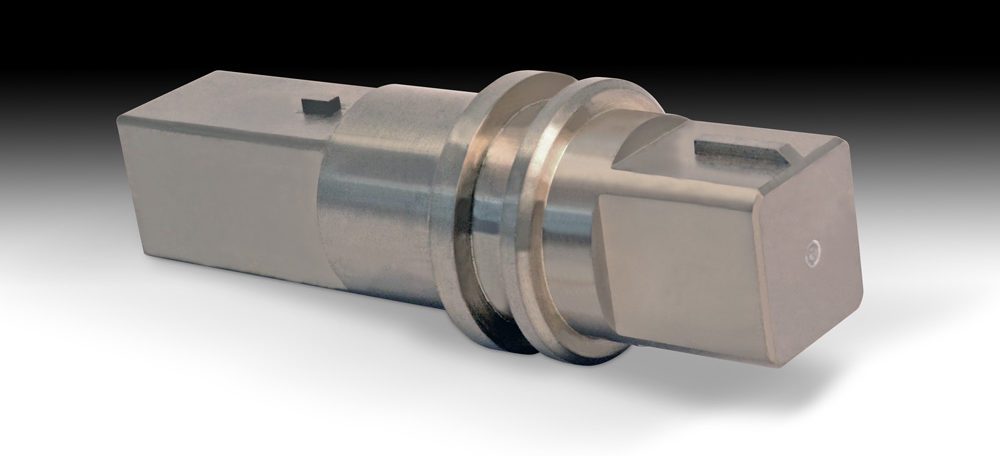

Guill Tool, a growing supplier of components to the global aerospace industry, today announced the production of a new Brass Fitting. The Brass Fitting is made of C706 copper nickel alloy.

Dimensions on this product are 1.875” outer diameter x 1.25” square each end X 5.40” overall length, or (47.625mm outer diameter x 31.75 square each end x 137.16 overall length). This Guill Brass Fitting is turned on a CNC lathe and milled on a 5-axis milling machine.

Guill now offers its substantial machine shop capabilities as an independent service to customers in aerospace manufacturing. Products are made to customer specification.

For over 55 years, Guill Tool has offered high-quality, precision machined components for the defense and commercial industries. The company manufactures flanges, valves, fittings and various critical components for aircraft, weapons and nuclear submarines.

Guill offers its full capability of CAD/CAM design, plus EDM and 5-axis machining centers to the aerospace industry. Owing to its many years in the government and defense sectors, Guill also provides industry-standard cybersecurity and NDA confidentiality to its customers.

Guill has the following registrations and certifications: AS9100:2016 – Aerospace Manufacturing, ISO9001:2015 registered, JCP Certified – Government Contracting, ITAR Registered and NIST SP800-171Compliant Cyber-Security.

For more information, please contact:

Tom Baldock

Guill Tool & Engineering – Aerospace Division

10 Pike Street

West Warwick, RI 0289

USA

Office: 401-828-7600

www.guill.com/aerospace

The global dental drills and burrs market is expected to display annual growth rate of approximately 6.5%. While the market is fragmented experts say that oral disease is increasing and is affecting half of the world’s population. A growing number of dental schools and dentists in developed countries is a key driver for accelerating growth in this segment.

A dental drill is popularly known as a dentist’s drill. While a source of anxiety for many, dental drills are used routinely to perform common dental procedures, like removing decay and are usually fitted to a hand-held mechanical instrument. The hand-held device works at high speeds using dental drills or burrs.

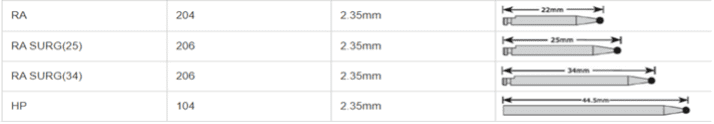

International Standards are defined for all dental rotary instruments, and each instrument is assigned a distinct ISO number code. Most common are HP Shank (ISO104) and RA Shank (ISO204 & 209) with a shank size of Ø 2.35mm.

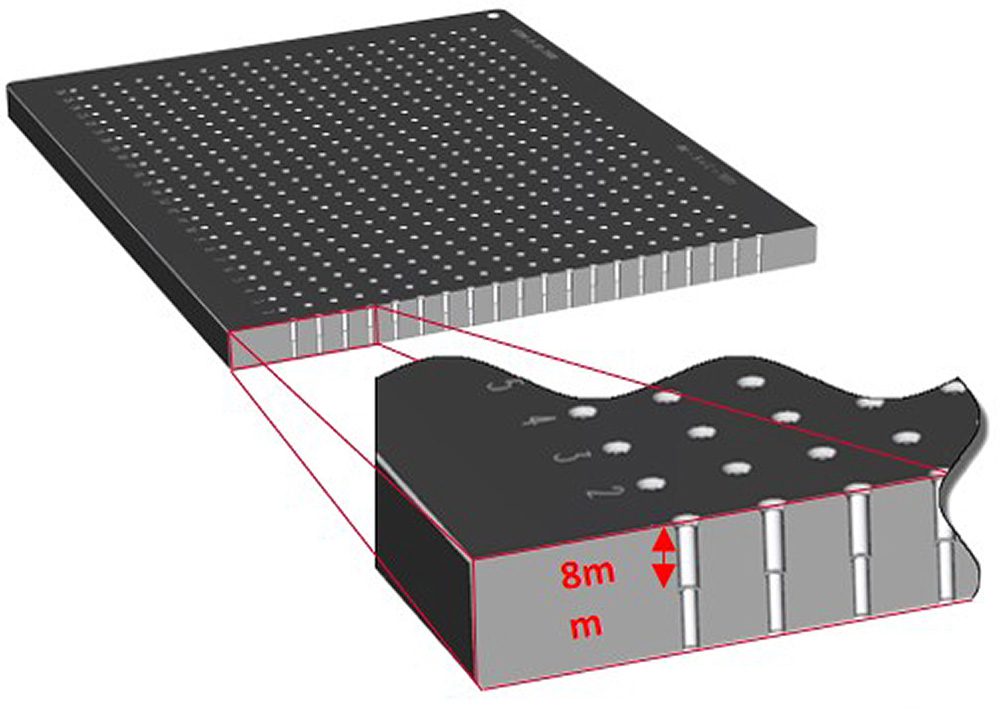

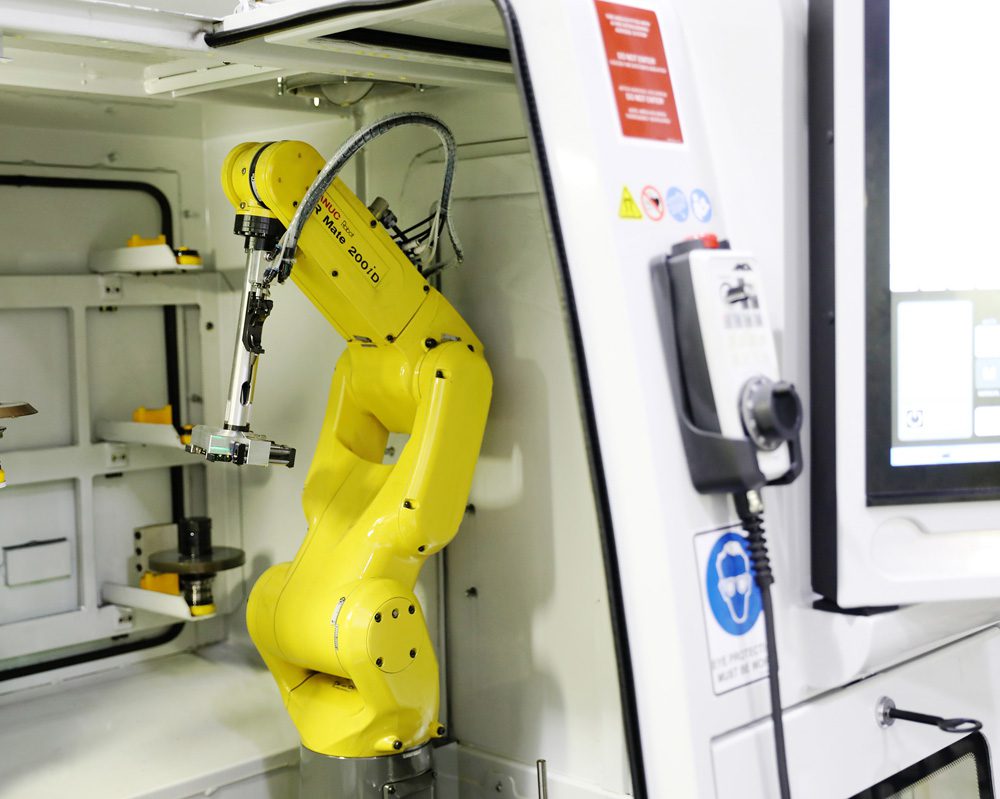

Due to an increasing demand to grind Ø2.35mm shank medical drills, ANCA has created a special tool loading solution for FX Linear machines to address this need. Many medical drills have a short shank length with a head larger than 2.35mm.

ANCA has designed a special dental drill loading kit including tailored RoboMate pallets for FX machines using a Fanuc 200iD robot loader. The pallet top allows a reduction of the insertion depth of the shank with an 8mm pocket depth, so that drills with only 10mm of available shank length can be loaded. The robot grippers have also been modified for the reduced thickness of medical tools. The medical gripper can accommodate Ø2-10mm x 100mm with a maximum head diameter of 14mm.

Medical instruments are typically manufactured from stainless medical grade alloy, so handling can be sensitive. The small medical drill kit also includes adjustable pressure setting from 1.5bar to 5bar for tool clamping to prevent damage from tool loading, with the pressure adjustable via the RoboMate program.

The medical drill package for FX Linear machines is growing in popularity with orders steadily increasing since 2018.

ANCA CNC tool grinders are well suited to grind a vast array of medical instruments. ToolRoom software includes tool design applications for a diverse range of round tools and burrs. Available technologies like white-sticking, in-machine wheel balancing and micro adjustable tool steadies, add to ANCA’s solutions for supporting diverse applications.

For further information, please contact:

Johanna Boland

Group PR and Communications Manager, ANCA

M: +61 407799779

Johanna.Boland@anca.com

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

Continue reading

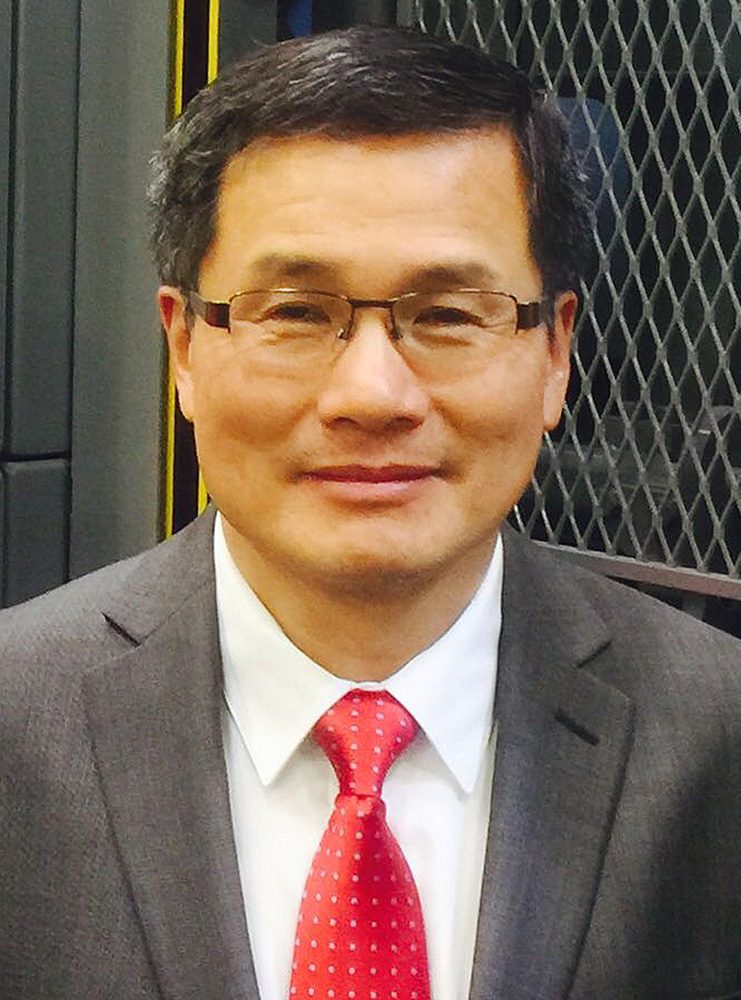

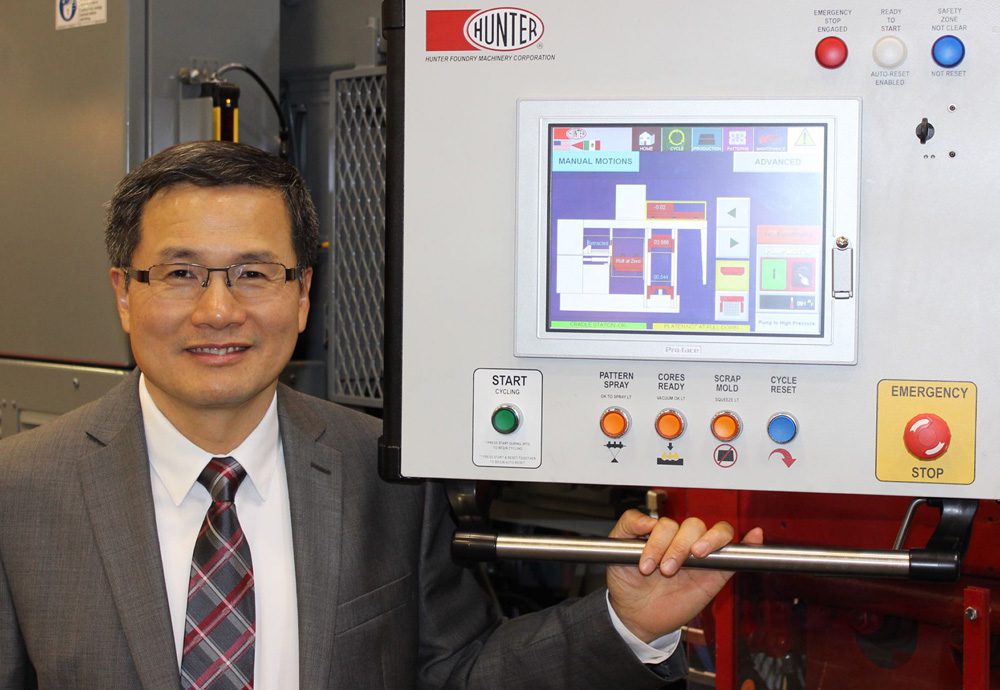

Recently Peter J. Li became the third President in the history of Hunter Foundry Machinery Corporation, a world leader in matchplate molding and sand casting technology. The announcement was made by Chairman of Board Bill Hunter at the company headquarters in Schaumburg, Illinois, near Chicago.

Peter joined Hunter in May, 1996 as a sales engineer. He was promoted to Regional Sales Manager Asia Pacific in 1998. In the year 2000, he became General Manager of Hunter Shanghai; in 2016 he was promoted to Managing Director, International. This history totals 25 years at Hunter, mainly in executive level positions.

Peter graduated from Shanghai Jiaotong University with a B.S. in Foundry Engineering. He then obtained an M.S. in Mechanical Engineering at Oklahoma State University; spent three years in the PhD Metallurgical Program at the University of Alabama, where, by coincidence, the very first Hunter molding machine was donated for that institution’s foundry education programs.

Before joining Hunter, Peter worked for Presto Castings as a metallurgist in Phoenix, Arizona.

Peter comments, “When I first encountered a Hunter machine, I quickly realized it had a unique and very practical labor-saving aspect and this fact was a big reason for its success in the global foundry market.” Li knew the reputation of the company’s founder, Al Hunter, as well as Bill Hunter, the two men who preceded him as President of the company.

Li further observes, “Our challenge for the future is to keep an open mind and remove restrictions on our thinking about the foundry business. The most successful companies in our industry have automated and that bodes well for Hunter matchplate molding machinery, automated mold handling equipment and the advanced software we bring to our customers worldwide.” He also commented that his combination of sales, technical experience and corporate management at Hunter, both in America and at the Shanghai plant the company operates, have given him a perspective on the company and the market that will serve him well in his new role as President of Hunter. “I do consider myself a people person and I believe that remains an important element in our relationship with the foundry business, Li added.”

Hunter is a global force in the foundry business, with an installed base in nearly every industrialized country in the world. In addition to the manufacturing locations in Chicago and Shanghai, Hunter has a worldwide network of sales agents.

The company was founded in 1964 by Al Hunter, who pioneered the automated matchplate molding machine concept and held dozens of patents in the industry. His son Bill, the current Chairman of Board, likewise developed numerous innovations in sand molding machine and mold handling equipment for the global foundry market.

In naming Peter Li the new President of Hunter, Bill commented, “Peter is exceptionally qualified for this position and we know he will lead Hunter into a bright and prosperous future. We have a great team of people at Hunter and, under Peter’s leadership, I am certain the company will move forward in a positive direction.”

For further information on this announcement, interested parties may contact:

HUNTER FOUNDRY MACHINERY CORPORATION

2222 Hammond Drive

Schaumburg, Illinois 60196-1094

USA

Phone: +1 847 397 5110

Email: info@hunterfoundry.com

Web: www.hunterfoundry.com

Attention: Bill Hunter

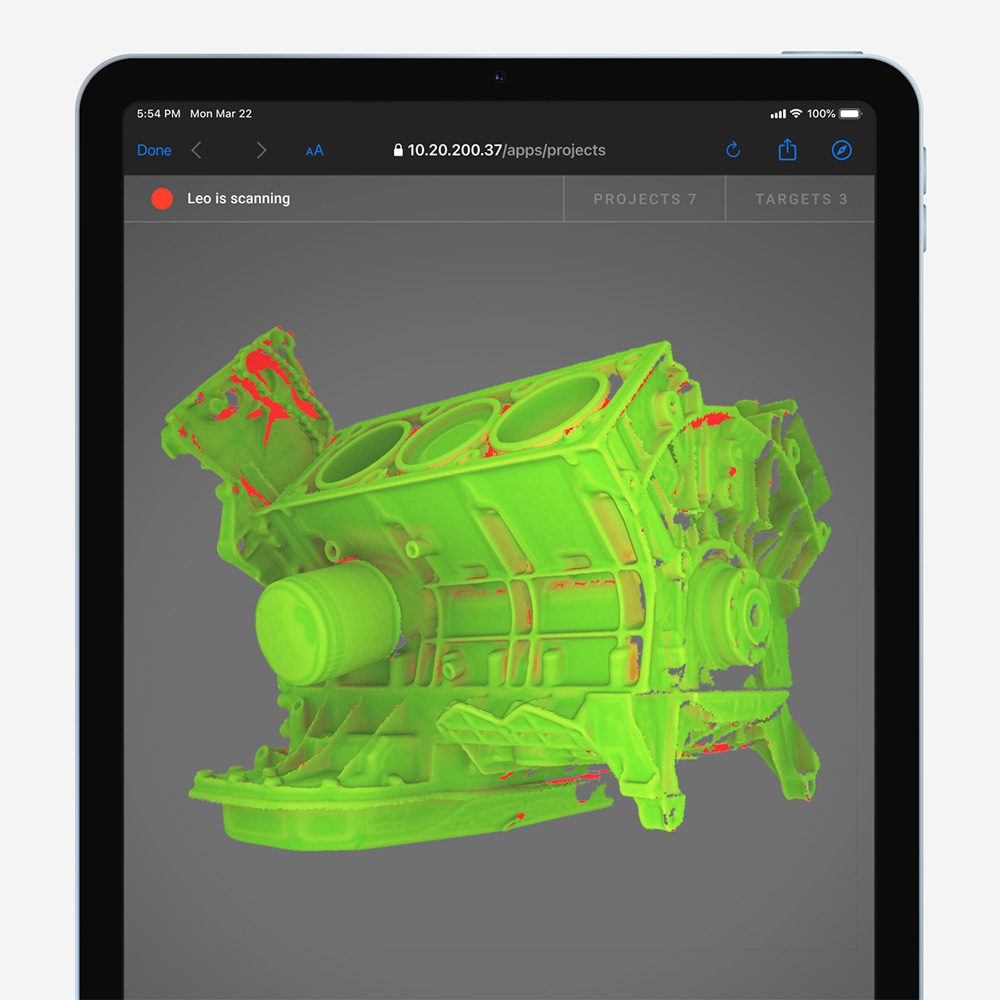

Exact Metrology: A Division of In-Place Machining Company and a comprehensive 3D metrology service provider and hardware sales company, now offers the 2022 Artec Leo from Artec 3D. With the new modifications, customers can experience guaranteed accuracy, more power, improved vibrant color capture and multi-language interface.

The new NVIDIA Jetson TX2 processor in this new version runs at more than twice the power of its predecessor, while consuming less than 7.5 watts. Additionally, it’s equipped with multi-core processing with the NIVIDIA Denver 2. This adds two cores and even more horsepower to what’s now a Heterogeneous Multi-Processor Architecture, with 2GHz on each of the six cores. The 2022 Leo also features a new 3D scanning experience with a fresh new user interface and a screen that’s easier to use.

Accuracy is guaranteed with a new calibration certificate. To test the accuracy, every scanner is calibrated with highly precise reference objects in different positions within the scanner’s working volume, using different parts of the scanner’s sensor and at different distances. A calibration kit has also been introduced so users can independently check the scanner accuracy and adjust the parameters. The new Auto Temperature Control enables the scanner to regulate its operation and keep its components at optimum operating temperature for capturing data at maximum accuracy.

Building on the scanner’s advanced color-capture capabilities, the 2022 Leo has algorithms to automatically adjust the brightness level when scanning, providing true-to-life evenly lit color 3D models without the need for manual correction. The new texture optimization algorithm has reduced the size of the texture by 2x, making it faster to process and load data for creating 3D color models.

Lastly, the scanner’s interface is now available in six different languages including English, Chinese, Japanese, Spanish, French and German.

In-Place Machining Company: On-Site Machining Solutions In-Place, Any Place in the World.

In-Place Machining Company, with facilities in Wisconsin, Washington, Virginia, Ohio, and Ontario, Canada, is the premier provider of high-precision engineered on-site machining, metrology, and large scale cutting & drilling services for a wide range of renewable energy, aerospace, industrial, and military customers throughout the world.

Exact Metrology: A Division of In-Place Machining Company, is ISO9001, AS9100 Certified as well as ITAR Registered.

Exact Metrology: A Division of In-Place Machining Company, with facilities in Cincinnati, Ohio, Moline, Illinois and Milwaukee, Wisconsin, plus affiliated offices throughout the country, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

About Artec 3D

Artec 3D is an international company, headquartered in Luxembourg, with offices in the United States (Santa Clara, California), China (Shanghai) and Russia (Moscow). Artec 3D develops and produces innovative 3D solutions and products. Artec has a team of professional experts in the collection and processing of 3D surfaces as well as biometric facial recognition. Artec 3D’s products and services can be used in many industries, such as in engineering, medicine, media and design, entertainment, fashion, historic preservation, security technology and many more.

For more information, please contact:

Exact Metrology: A Division of In-Place Machining Company

Kelly Baldasare

11575 Goldcoast Drive

Cincinnati, OH 45249

Local: 513-831-6620

Toll Free: 866-722-2600

www.exactmetrology.com

kellyb@exactmetrology.com

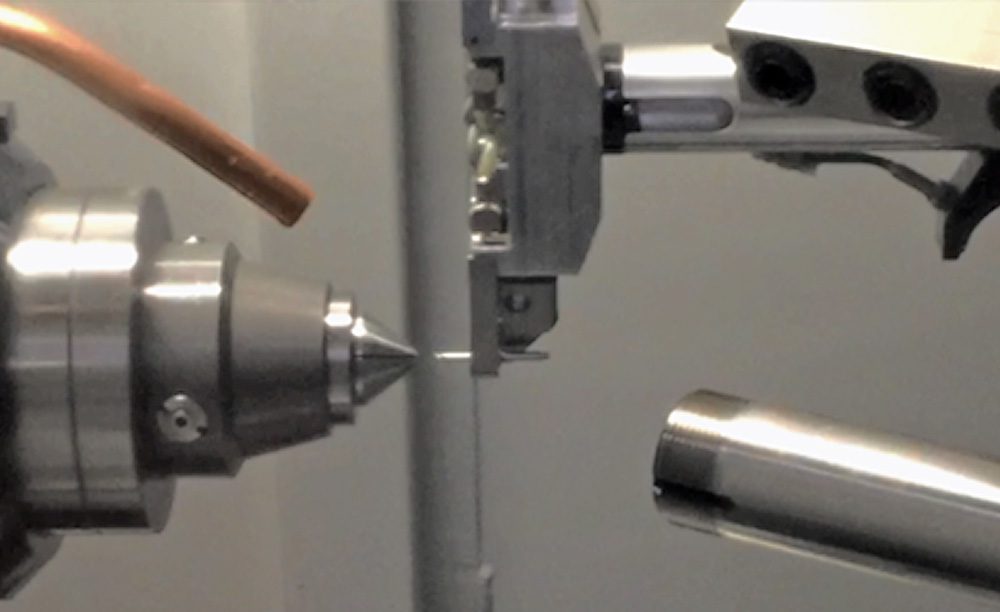

Guill Tool, a growing supplier of components to the global aerospace industry, today announced the production of a new Acme shaft. The Acme shaft is a square head shaft made of K-Monel.

Dimensions on this product are 2.125” outer diameter X 1.125” over flats X 4.125” overall length, or (53.975mm outer diameter x 28.575mm over flats x 104.775mm overall length). This Guill Acme shaft is machined complete on a Mazak/Mill turn machine.

Guill now offers its substantial machine shop capabilities as an independent service to customers in aerospace manufacturing. Products are made to customer specification.

For over 55 years, Guill Tool has offered high-quality, precision machined components for the defense and commercial industries. The company manufactures flanges, valves, fittings and various critical components for aircraft, weapons and nuclear submarines.

Guill offers its full capability of CAD/CAM design, plus EDM and 5-axis machining centers to the aerospace industry. Owing to its many years in the government and defense sectors, Guill also provides industry-standard cybersecurity and NDA confidentiality to its customers.

Guill has the following registrations and certifications: AS9100:2016 – Aerospace Manufacturing, ISO9001:2015 registered, JCP Certified – Government Contracting, ITAR Registered and NIST SP800-171Compliant Cyber-Security.

For more information, please contact:

Tom Baldock

Guill Tool & Engineering

10 Pike Street

West Warwick, RI 02893

USA

Office: 401-828-7600

www.guill.com/aerospace

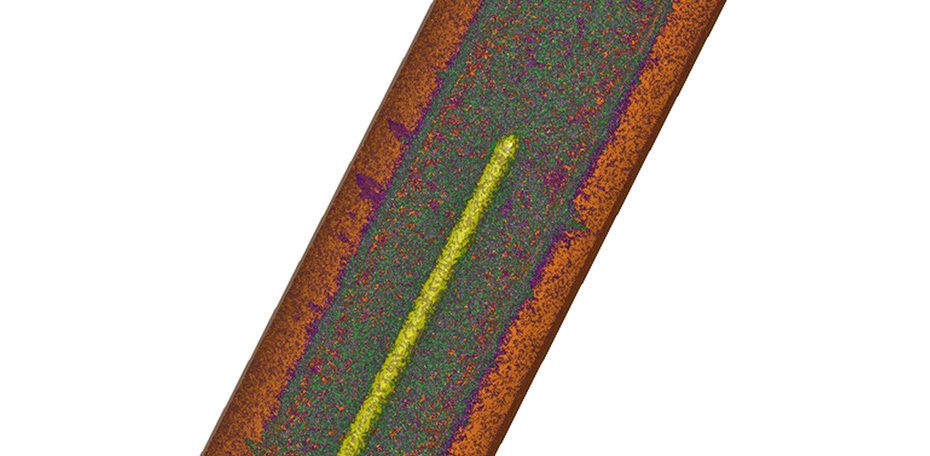

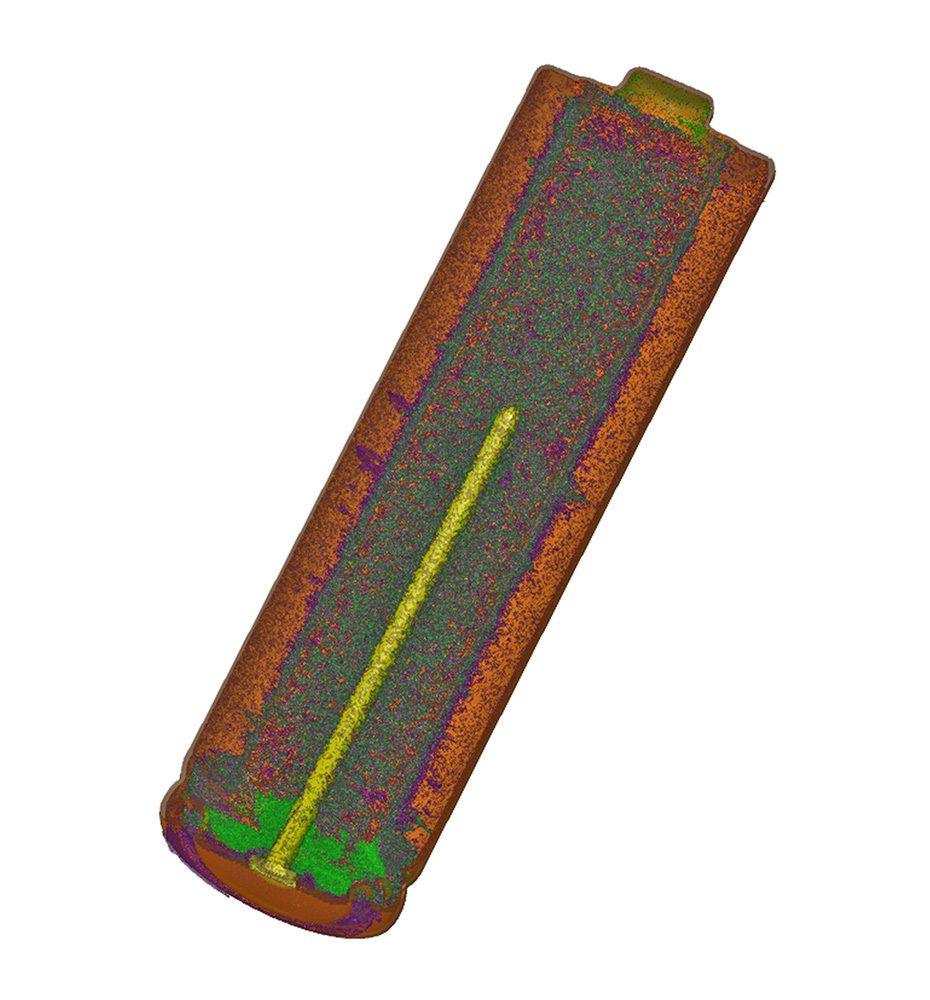

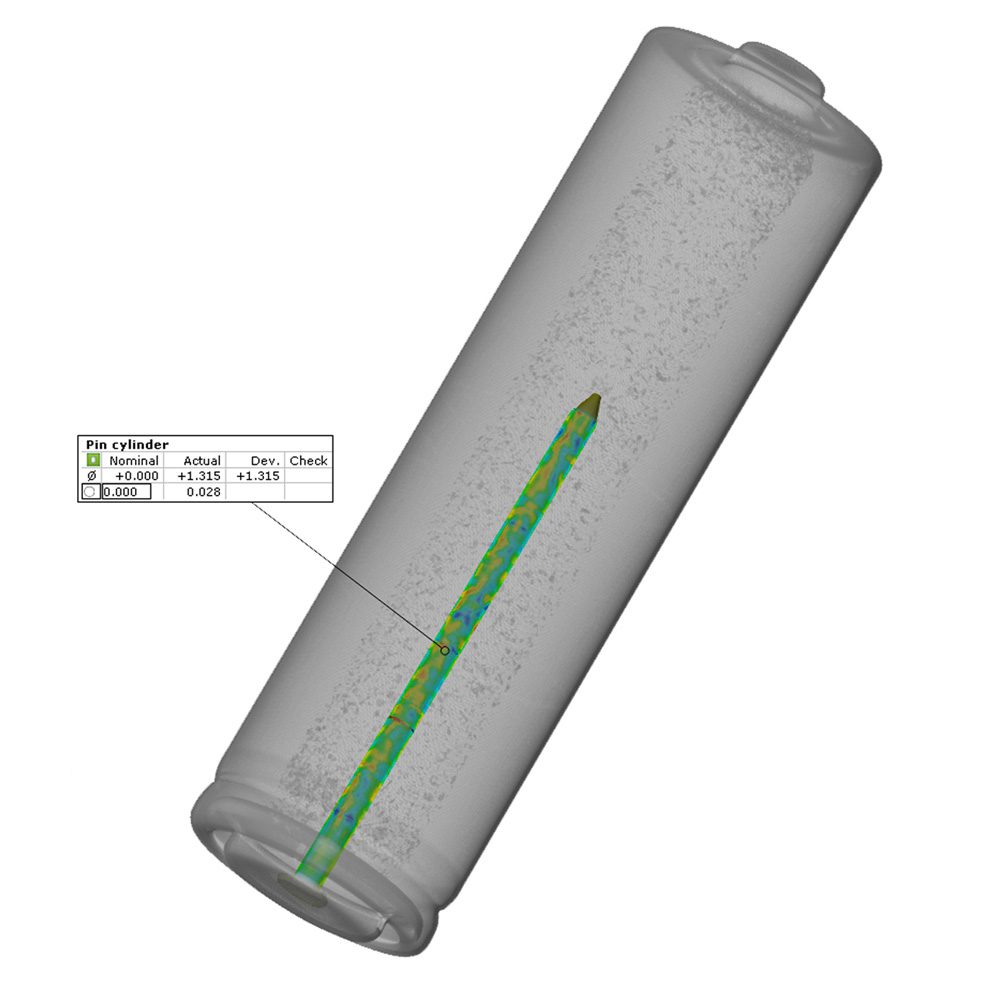

Exact Metrology: A Division of In-Place Machining Company and a comprehensive 3D metrology service provider and hardware sales company, recently used CT technology for an interesting project. The goal was to obtain an inside look at an AA battery.

The ZEISS METROTOM 6 scout, formally known as a GOM CT, was used. Considered the powerhouse of resolution for CT and inspection and metrology, the METROTOM 6 scout digitizes complex parts including the internal geometries at the finest level of detail. Users obtain a complete 3D image for GD&T analysis or nominal-actual comparisons. The metrology CT excels in digitizing small plastic parts. Furthermore, the combination of a 3k detector and 225 kV X-ray enables ZEISS METROTOM 6 scout to provide high contrast, high-resolution measurement results and exceptional sharpness of detail.

Using CT technology, Hayden Lee, Exact Metrology Applications Engineer, separated the battery into several 3D elements. Thus, he was able to obtain several different types of measurements in different portions of the battery and also extract several battery elements such as: pin, separator wall and case. A color map using GOM Inspect was also created of the pin cylinder inside the battery. The software analyzes 3D measuring data from fringe projections or laser scanners, CMMs and other measuring systems. The GOM software is used in product development, quality control and production. Obviously, it’s very dangerous to cut apart a battery or destroy it. According to Hayden, “CT scanning allows you to internally inspect something, even an alkaline battery, without having to destroy it.” This of course allows for better safety and precision. Additional benefits of CT include very little time to capture data and troubleshoot parts and multiple uses with one scan. In contrast to conventional tactile coordinate measurement techniques, a CT acquires all surface points simultaneously —on even the most complex objects.

In-Place Machining Company: On-Site Machining Solutions In-Place, Any Place in the World.

In-Place Machining Company, with facilities in Wisconsin, Washington, Virginia, Ohio, and Ontario, Canada, is the premier provider of high-precision engineered on-site machining, metrology, and large scale cutting & drilling services for a wide range of renewable energy, aerospace, industrial, and military customers throughout the world.

Exact Metrology: A Division of In-Place Machining Company, is ISO9001, AS9100 Certified as well as ITAR Registered.

Exact Metrology: A Division of In-Place Machining Company, with facilities in Cincinnati, Ohio, Moline, Illinois and Milwaukee, Wisconsin, plus affiliated offices throughout the country, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

For more information, please contact:

Exact Metrology: A Division of In-Place Machining Company

Kelly Baldasare

11575 Goldcoast Drive

Cincinnati, OH 45249

Local: 513-831-6620

Toll Free: 866-722-2600

www.exactmetrology.com

kellyb@exactmetrology.com