Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

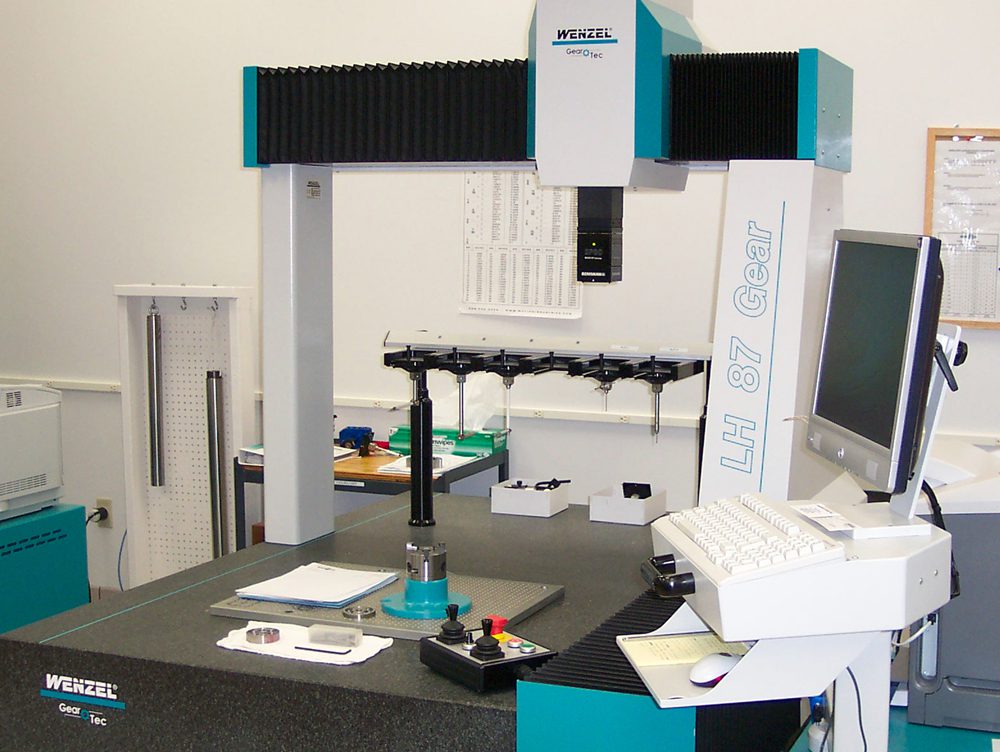

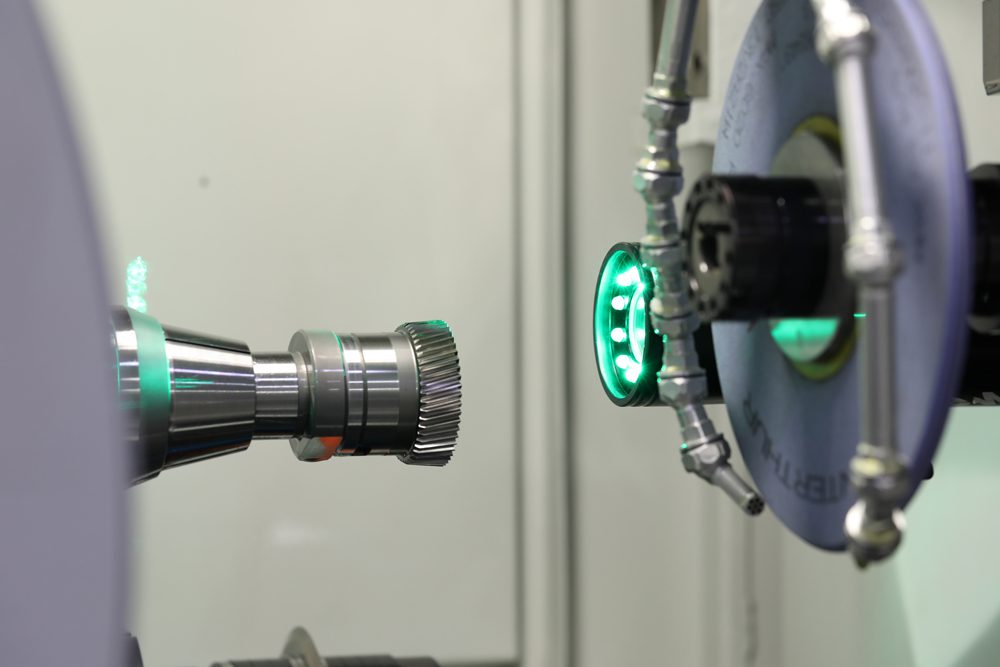

Closed loop between WENZEL gear inspection system and Nidec gear grinder

♦ Utilizing VDI/VDE Gear Data Exchange format

♦ Automatic process corrections

Wixom, MI – IMTS 2022 will host a variety of gear technologies that will set the tone for manufacturing innovation in the years to come. At the forefront is the integration of data for process control, providing outstanding solutions to manufacturers. WENZEL America and Nidec’s collaboration started with the mutual drive for serving their customer with excellence through data management.

“Showing how easily WENZEL’s metrology systems integrate into any production process is what we would like to display at this year’s show. We are excited to have Nidec as a partner to demonstrate how we apply this to the gear industry,” said Drew Shemenski, President of WENZEL America. “Collaborations like this are a way we bring innovation to our customers.”

The successes achieved in the field of measurement technology solutions based on closed-loop processes are pushing the boundaries on throughput and delivery. Because of this, launching the technical collaboration between Nidec and WENZEL at IMTS 2022 was an easy decision.

According to Scott Knoy, VP Sales at Nidec Machine Tool America, “Both Nidec and WENZEL are able to utilize the international VDI/VDE gear data exchange format. Our joint effort with WENZEL offers gear manufacturers the ability to automatically make corrections to the process based on inspection data. This will be shown at IMTS connected to Nidec’s internal gear generating grinder, the ZI20A-G.”

Speaking on integrated metrology at IMTS, WENZEL’s Chief Digital Officer, Prof. Dr. Heiko Wenzel will emphasize the solutions that WENZEL develops and works towards productivity success for their customers through integration.

Interested parties can contact:

Scott Knoy, VP Sales

248-756-5017

Scott.Knoy@nidec.com

NIDEC MACHINE TOOL AMERICA LLC

46992 Liberty Drive

Wixom, MI 49393

www.nidec-machinetoolamerica.com

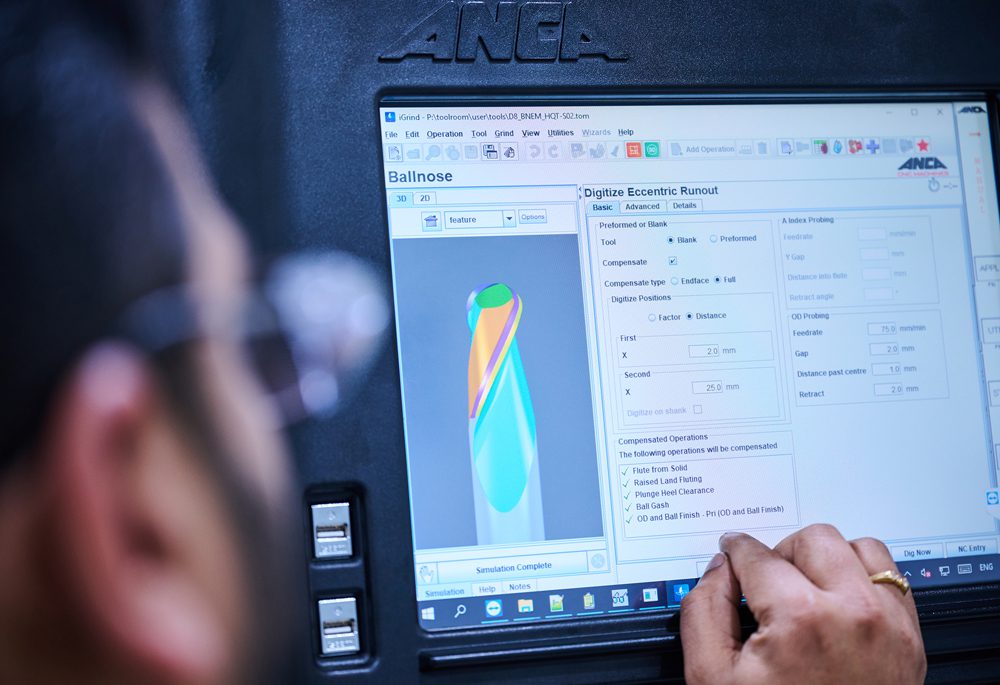

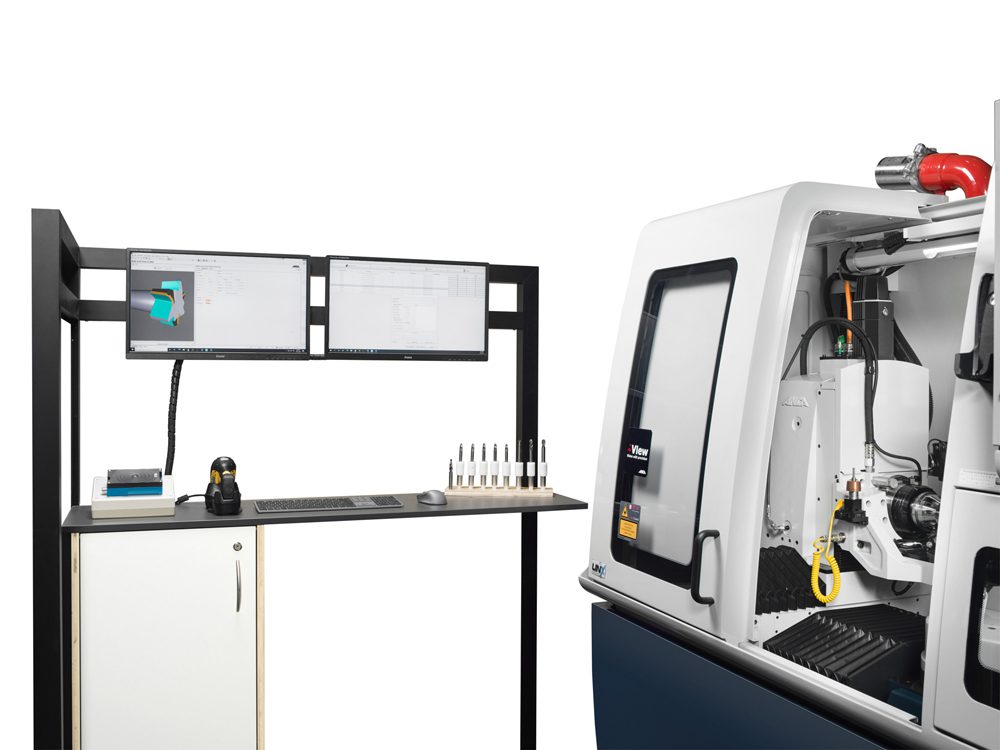

Introducing one nanometer axis resolution, the new MX7 ULTRA machine’s performance can maintain less than +/- 0.002mm line form accuracy of any profile which includes ballnose and corner radius endmills. See the ultra-performance machine at IMTS – Booth #237406.

The new MX7 ULTRA can manufacture large volumes of endmills and other cutting tools of the highest accuracy and quality. The minute size of a micron is beyond the human eye, but in becoming even more precise and moving from micrometers to nanometers, ANCA will offer the highest accuracy and quality in a cutting tool in the market. New software, hardware and design features are combined to make significant advances in surface finish, accuracy, and controlled runout, to deliver batch consistency from the first ground tool to the thousandth.

The MX7 ULTRA includes:

Pat Boland, ANCA co-founder says: “The MX7 ULTRA is a significant development in precision machine design and will change the industry expectations for accuracy and tool life. Achieving these outstanding results has only been possible because of our extensive experience working with customers to manufacture the highest quality cutting tools over many years. At ANCA we are always designing and innovating to find better customer solutions and I am very proud of the ANCA team that has developed the MX7 ULTRA.”

“The ULTRA machine is truly market changing. It is the culmination of ANCA’s elite technology, deep industry knowledge, and customer experience in grinding,” says Thomson Mathew, ANCA product manager for the MX series and software products.

Unlike its competitors, ANCA is vertically integrated. This provides a significant advantage as it means ANCA teams can develop and manufacture their own machines from base to canopy – including controls and drive systems, design and simulation software and even machine monitoring software. Owning all the technology means engineers and designers can consider the entire machine as a single system when developing new solutions.

“We wanted to create technology that could produce premium cutting tools that are above the current market standard in both accuracy and tool life. We introduced nanometer resolution into our axis, which is new to the cutting tool market. The result is a perfect example of ANCA’s vertical integration capabilities as we have the in-house ability to fine tune or develop the new algorithms for our drives to make this happen.”

“Cutting tools like ballnose, corner radius, barrel shape ballnose and double corner radius endmills are used widely across industries including diemold, aerospace, and power generation. The surface finish quality, accuracy and runout are critical for the performance and cutting life in all applications – so our customers want a guarantee that their first tool will be exactly the same as the hundredth, or thousandth. The MX7 ULTRA can produce high quality cutting tools to suit all customer needs to satisfy all industry types.”

“With almost 50 years of expertise, we are experts in the field of cutting tools and we want to impart our knowledge through best grinding practices. As part of the ULTRA experience, skilled application engineers will be available to train and educate our customers to ensure the machine will produce high quality tools from the first day of production.”

“It has taken years of research and development, and engineering excellence for us to develop this premium solution to grind high quality tools. In my 25 years in the industry, I believe this is one of the most outstanding innovations we have accomplished that will really change the cutting tool market. We are confident that our customers will be very satisfied with the life and performance of cutting tools produced on this premium machine,” Thomson concluded.

The MX7 ULTRA superior performance highlights

Greater control for the velocity and acceleration or deceleration along with machine jerk limits: To increase the stiffness of the C-axis, the MX7 ULTRA combines developments to the nanometer or micro degree resolution in the linear and rotary axis, tuning parameters, several system enhancements, and major mechanical changes.

ULTRA-fast response to internal or external disturbances: ANCA’s newly designed servo control algorithm allows silky smooth motion of an axis with the use of a unique algorithm and nanometer measurement in the control system. This will create finer cutting edges and eliminating micro-chips making it more efficient while used in actual machining of materials.

Better cycle time and higher productivity of high-quality cutting tools: The unique algorithm is key to the performance of the machine and ensures outstanding tracking performance. It also allows ULTRA-performance of the servo system without using a complex, complicated, or expensive mechanical system.

Reduces setup times and scrap: Cutting-edge software has been developed by ANCA to ensure batch consistency in large volumes. LaserUltra is part of the MX7 ULTRA package to maintain consistency and accuracy of the grinding process which includes in-process measurement and compensation to accommodate wheel wear and other external variations during large batch grinding. Its analog capability can maintain less than +/- 0.002mm line form accuracy of any profile which includes ballnose and corner radius tools.

Increased wheel life and better-quality tools: Tool and wheel performance can be further optimized by the iBalance software, which guides a user to the optimal grinding position and RPM for vibration monitoring and balancing the wheelpack inside the machine. Correctly balanced wheelpacks result in superior surface finish and reduced wheel wear due to the elimination of wheel vibration.

Consistency in finished tool quality: A major inclusion in the MX7 ULTRA package is the total tool runout measurement and compensation operation in iGrind. When an endmill is in rotation it is important that each tooth hits at the exact same spot along the workpiece for longer tool life and efficient cutting. Every tool in the batch can be measured and compensated for runout to make sure the entire batch is within a tolerance of 0.002mm. It is another piece of assurance that the first endmill will be as good as the last.

Consistent spindle thermal stability: Motor Temperature Control (MTC) is a patented (US PAT. 11,394,331) innovation built into the motor spindle drive firmware. Smart control algorithm actively manages and maintains the temperature of motorized spindles in the MX7 ULTRA. Dramatically reduced machine warmup time means production can start sooner, once the machine has reached thermal stability. This improves productivity and machine use. Consistent thermal stability of the spindle over time regardless of changes in load or speed, or coolant temperature, greatly improves the dimensional stability of grinding results.

Post grinding processes: The smoother, finer cutting edge and surface finish as a result of the combination of all the above including the nanometer control will assist in all post grinding applications like edge preparation and coating. A finer edge that has been properly prepared has greater stability, which reduces the likelihood of it chipping, while also decreasing surface roughness which can cause increased friction between the tool and the workpiece.

For further information, please contact:

Johanna Boland

Group Corporate Communications Manager

M: +61 407799779

Johanna.Boland@anca.com

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

Continue reading

Global EDM supplier also moves to new location to enhance production and service capabilities

Batavia, Ohio- Beaumont Machine is a world-class builder of Electrical Discharge Machines (EDM) for the aerospace, power gen and electronics production industries. Founded by Ed and Tanya Beaumont over 30 years ago, the company was recently repurchased, after the owners had sold the business in early 2013. As Ed Beaumont explains, “We had a great relationship with the new owner but we believed the company needed a revitalization to benefit our customers, employees and the evolving EDM industry. In addition to repurchasing Beaumont Machine, we have reassumed the day-to-day operation of the company. In addition, we have moved the operation into a larger location to increase production and expand our service capabilities.” That new location is 2010 Glenn Parkway in Batavia, Ohio, just outside Cincinnati.

Beaumont Machine’s contributions to the aerospace and power generation industries are many and, with this buyback, the company is ready to meet the needs of the changing EDM industry. “We pride ourselves on not only understanding the applications in the various industries we serve but also on building the best machines for the applications we encounter, from small hole to large workpieces,” adds Tanya Beaumont.

From the standard mill style EDM to machining cells with complete robotic operation for large aircraft engine and launch vehicle sections, Beaumont has built machines with an 8’ part rotation, a robotic arm with 10’ reach, and machines as small as 36” in width. A new 7-axis EDM drill has just been developed. All Beaumont machines feature the most advanced CNC technology and user interface.

With customers worldwide, as Ed Beaumont observes, “We are committed to innovation and customer partnerships in various industries, in countries around the globe. It’s a testimony to the fact that the world is still hungry for American technology and ingenuity. We’re very proud of that.”

Ed and Tanya Beaumont founded the company, Beaumont Machine, 30 years ago. Beaumont Machine focuses on building a line of standard EDM’s as well as custom machines plus repairing and retrofitting machine tools of all types. The company started building Fast Hole EDM in 1997 and has been specializing in EDM technology since that time. In 2013, they turned over the ownership of the company to a new owner. With this reacquisition of the company, Ed and Tanya Beaumont are again actively involved in day-to-day operations.

Among its recent successes is a custom robotic EDM work cell for SpaceX, as shown in the below photo.

For more information on these developments, please contact:

Ed Beaumont, President

BEAUMONT MACHINE

2010 Glenn Parkway

Batavia, OH 45103

Phone: 513-701-0421

Exact Metrology: A Division of In-Place Machining Company and a comprehensive 3D metrology service provider and hardware sales company, recently announced they have become the North American distributor of HandsOnMetrology. The new digital platform HandsOnMetrology.com was set up to share the benefits of 3D metrology with a global community. As a representative of this new 3D scanning network, Exact Metrology will be an official contact for companies in the US who want to optimize their quality control processes with new, state of the art 3D scanning and automation solutions.

Available at both the Brookfield (Milwaukee), Wisconsin and the Cincinnati, Ohio location, the #HandsOnMetrology portfolio offers measuring systems including GOM Scan 1, ATOS Q, T-SCAN 10/20 and the hand-held T SCAN hawk. Exact Metrology also offers the GOM ScanCobot automation solution.

GOM Scan 1 delivers the foundation for detailed and accurate 3D meshes with industrial standards such as GOM fringe projection technology and Blue Light Technology. The sensor is built to deliver 3D data with high precision. Easy to operate, the scanner is ideal for simple and fast measurements of small to medium-sized parts, even in confined spaces. With pre-installed GOM Inspect software, users can generate precise meshes and obtain 3D data easily and quickly.

ATOS Q is a flexible 3D scanner for complex measurement and inspection tasks in different industries. The scanner delivers fully traceable measurement results, especially in harsh conditions. Optical and electronic systems of the robust, optical 3D sensor are dustproof and splashproof. ATOS Q captures quality information quickly and with a high degree of detail, providing a reliable basis to easily interpret the information. Its Triple Scan Principle offers advantages for measuring reflective surfaces and objects with indentations. The Blue Light Equalizer enables high-speed fringe projection and is so powerful that, on dimensionally challenging surfaces, short measuring times can be achieved.

The compact hand-held 3D scanner T-SCAN hawk is designed to capture data whenever needed. It includes technical features such as: photogrammetry of large objects, multiple laser sources and three scanning models. This makes it the perfect solution for fine detail. Thanks to the GOM Inspect onboard, the T-SCAN hawk offers a complete solution to simplify your entire workflow from scanning to evaluation and reporting.

The GOM ScanCobot, a mobile automated 3D scanning system, easily integrates with ATOS Q. With the high-precision quality of ATOS combined with an automated robotic arm, the GOM ScanCobot is cost-effective and easy to use. It improves efficiency in quality control of small to medium-sized parts, including plastics, fabricated metals and castings. The combination of the GOM ScanCobot and the proven ATOS performance results in fast fringe projection, data processing, high throughput and a design ideal for industrial use.

In-Place Machining Company: On-Site Machining Solutions In-Place, Any Place in the World.

In-Place Machining Company, with facilities in Wisconsin, Washington, Virginia, Ohio, and Ontario, Canada, is the premier provider of high-precision engineered on-site machining, metrology, and large scale cutting & drilling services for a wide range of renewable energy, aerospace, industrial, and military customers throughout the world.

Exact Metrology: A Division of In-Place Machining Company, is ISO9001, AS9100 Certified as well as ITAR Registered.

Exact Metrology: A Division of In-Place Machining Company, with facilities in Cincinnati, Ohio, Moline, Illinois and Milwaukee, Wisconsin, plus affiliated offices throughout the country, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

#HandsOnMetrology

#HandsOnMetrology is a new global 3D scanning network and provides a digital go-to for everything you always wanted to know about 3D scanning on the platform HandsOnMetrology.com. The platform is operated by GOM Metrology that sets new standards in optical 3D metrology. From step-by-step setup instructions to more advanced tutorials and expert hacks: the platform is made for learning and for getting inspired. It gives users all the information they need to deliver 3D scanning excellence. HandsOnMetrology.com supports the community of designers, technicians, engineers, scientists and specialists with valuable knowledge to increase product quality, optimize processes and expand possibilities.

For more information, please contact:

Exact Metrology: A Division of In-Place Machining Company

Dean Solberg

20515 Industry Avenue

Brookfield, WI 53045

Local: 262-533-0800

www.exactmetrology.com

deans@exactmetrology.com

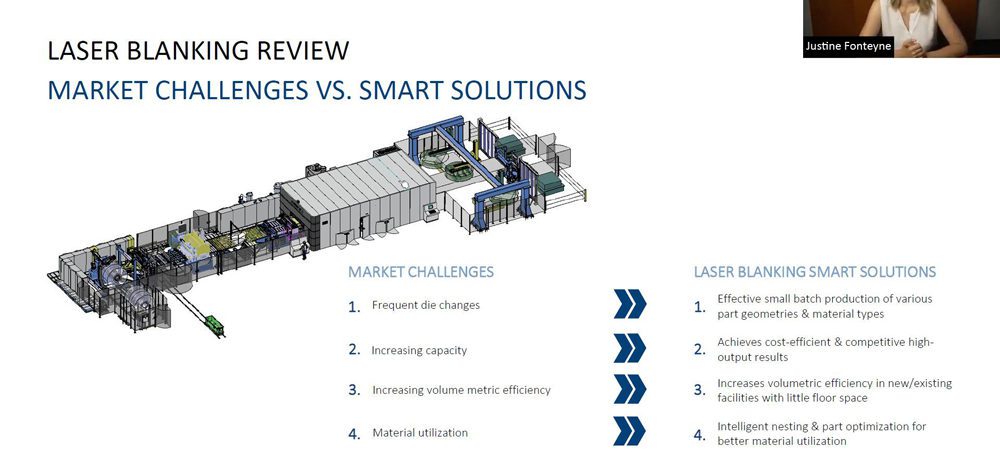

The technology offers maximum flexibility, efficiency and part quality, as well as material savings of up to one million USD per year

Canton, Michigan, July 27, 2022 – A blanking line is usually made up of a coil line, an uncoiler, a threading unit, leveler, roll feed, the cutting area and the stacking unit. This holds true with laser blanking lines, but the material is cut by a laser cell instead of a shear or press. Justine Fonteyne, Schuler’s Area Sales Manager of the Americas, has recently explained the technology’s multiple advantages in an online seminar.

There has been a rising interest for laser blanking lines, given the die-free blanking capabilities. Schuler has sold 15 worldwide, including five in North America. With the frequent changeover of new car models, vehicle manufactures are happy to avoid investing in expensive dies – especially new players within the EV market, for which ramp-up production may be slower. “And die change time costs production time,” Fonteyne underlined. Additionally, no dies equate to no die storage or maintenance, and less initial infrastructure investment as no heavy press foundation or loop pit is required. Apart from that, no noise or vibration is emitted.

Overall equipment efficiency of up to 80 percent

Because of Schuler’s Dynamic Flow Technology (DFT), Schuler’s laser blanking lines are also much faster than conventional stop and go laser cutting systems like flatbed lasers. The material runs continuously without the need to stop-and-start before cutting. The output can reach 45 parts per minute, depending on the geometry of the blank. Due to no die changes, the overall equipment efficiency (OEE) is up to 80 percent.

“Depending on the part mix, Laser Blanking can be the cheapest way of blanking,” Fonteyne stated. “Due to digital nesting solutions, the technology has much greater material utilization.” In contrast to conventional lines, the parts can be designed independently from die restrictions. Also separation strips can be avoided with edge-to-edge nesting. Improvements in material utilization of an outer body part mix of approximately 1 percent quickly add up to material savings of up to one million USD per year.

No wear of dies and presses

Schuler’s laser blanking lines produce homogenous cutting edges with hardly any burr. “This is relevant for aluminum because the flitter in the die is reduced to almost zero,” Fonteyne explained. The rising number of high-strength steel pose further challenges to conventional lines regarding the wear of dies and presses, but the lasers are not affected by this at all. Schuler offers workshops for part simulation and optimization as well as business calculation.

Fonteyne provided insight into Schuler’s Track & Trace solution that has already been implemented at the Smart Press Shop in Germany, a joint venture between Schuler and Porsche. “Being the first station for the material in the press shop, we start the tracking of the production data here,” said Fonteyne. “The production data is connected to every part and can be tracked easily and continuously. For example, data pertaining to the thickness of a blank or the amount of oil distributed can be transmitted to the press line in order to achieve a perfect forming process.

Watch the complete video of the online seminar here: https://youtu.be/oC59OzaCW0c

Listen to Carla Bailo, President & CEO of the Center for Automotive Research (CAR), and Justine Fonteyne discuss laser blanking via CAR’s podcast: https://anchor.fm/the-car-podcast/episodes/Laser-blanking—featuring-Justine-Fonteyne-of-Schuler-Group-GmbH-e1krdmp/a-a8799jm

Internet

laserblanking.schulergroup.com

About the Schuler Group – www.schulergroup.com

Schuler offers customized cutting-edge technology in all areas of forming—from the networked press to press shop planning. In addition to presses, our products include automation, dies, process know-how and service for the entire metalworking industry. Schuler’s Digital Suite brings together solutions for networking forming technology and is continuously being developed to further improve line productivity and availability. Our customers include automotive manufacturers and suppliers, as well as companies in the forging, household appliance and electrical industries. Presses from the Schuler Group mint coins for more than 180 countries. Founded in 1839 at our headquarters in Göppingen, Germany, Schuler has approx. 5 000 employees at production sites in Europe, China and the Americas, as well as service companies in more than 40 countries. The company is part of the international technology group ANDRITZ.

For further information on Schuler Inc., North America, please contact:

Jaime Bartholomai, Marketing & Communications Manager

Schuler Incorporated

7145 Commerce Blvd.

Canton, MI 48187 USA

Jaime.Bartholomai@schulergroup.com

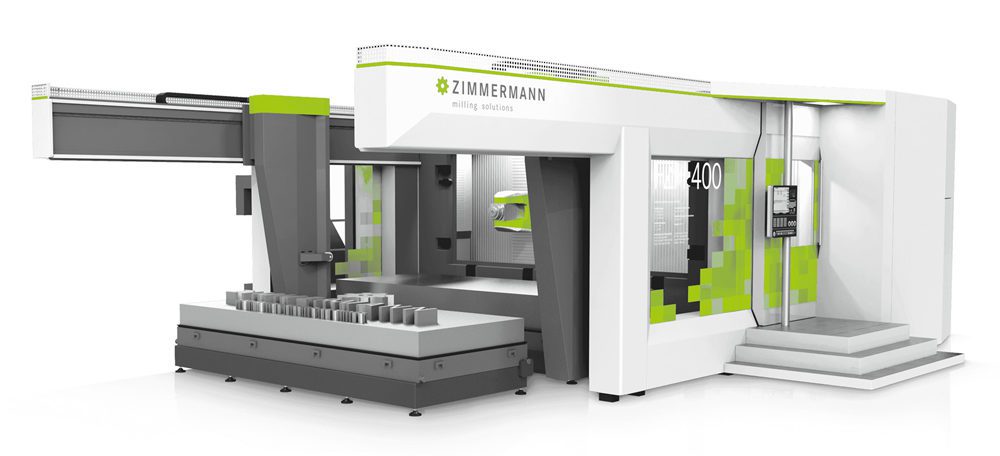

Zimmermann Milling Solutions, a leading global high-tech supplier of portal milling machines, will virtually show three new gantry machines at their booth. IMTS will be held September 12-17, 2022, in Chicago.

When discussing rigidity, nothing beats mass. Our biggest double bridged gantry sets new standards for dynamic roughing while maintaining high precision. The FZ42 CNC gantry milling machine represents power at its best, combining work areas of different sizes, travels, milling heads and CNC controls. Regardless of weight and size, the milling process is exact. Furthermore, the gantry design is particularly suitable for the entire range of component machining. The structurally rigid center-guiding gantry, cross and Z-Ram, and dynamic milling head enable a consistent, efficient milling process. This combination of high thermal stability and rigidity meets industry-specific requirements in tool and die making, aerospace and automotive industries.

Just as strength and agility make an athlete perform at his/her best, the same is true for the newest high-performance gantry FZ37. Due to its modular system concept, the FZ37 is available in various sizes, custom configuration and CNC controls. The newly designed gantry with center guided Z-Ram in combination with Zimmermann’s dynamic milling heads ensure an efficient and consistent milling process. The high thermal stability and rigidity meet industry-specific requirements in model, tool and die making as well as in the aerospace and automotive industries.

The FZ32 is the high-performance athlete for dynamic machining of aluminum, fiber composites, plastics and tooling board. Its thermosymmetrical design results in high surface quality and accuracy. The rigid center-guiding gantry allows the company to meet the increasing demands in model and mold making as well as aerospace. Additionally, the flexible design of the FZP machine line offers various sizes and configurations through its modular system as well as extensive equipment options and a fully enclosed work area, including effective dust extraction systems and more.

Visit Zimmermann at IMTS 2022 in the South building, Level 3, booth 339336.

For more information, please contact:

ZIMMERMANN INC.

30587 Century Drive

Wixom, MI 48393

Phone: 248-956-8511

www.zimmermann-inc.com

Mr. Cornelius Kiesel, President

cornelius@zimmermann-inc.com

On a brand-new stand ANCA will showcase the next generation of technology enabling customers to grow capacity, improve profit margins and gain efficiencies.

Cutting tools continue to be an essential component across many industries, as these industries expand their own product range and complexity, manufacturers increasingly demand high-quality cutting tools that meet unique requirements. For cutting tool manufactures, deciding what technology to invest in should be driven by business goals and at IMTS, ANCA will present the grinding tech to tackle now — demonstrating the advantages of investing in a technologically advanced future.

Pat Boland, ANCA Co-Founder and Joint Managing Director, said: “Designing the best technology requires a multi-pronged approach. We immerse ourselves in the market; are continually inventing; keep a keen eye on new developments and bring them into our applications. We seek out intelligent, talented people, and interact with customers daily to understand their specific needs. This is how we design and manufacture our market-leading solutions.”

ANCA Inc General Manager Russell Riddiford is head of the Wixom, Michigan ANCA office and said: “With a long four-year wait since the last IMTS, I am excited to show our visitors the latest technological advancements from ANCA. We have not been idle between shows – once again ANCA has industry-first innovations launching in Chicago this year, and we will be presenting technology that helps solve the challenges faced by many manufacturers in the market.”

“We are also pretty excited to announce the winners of the fifth ANCA Tool of the Year competition on our stand at IMTS. The ‘Oscars’ of the cutting tool industry, the contest celebrates the deep experience and creativity of tool manufacturers across a highly skilled grinding industry,” Russell concluded.

TRULY INTEGRATED MANUFACTURING WITH AIMS

The ANCA Integrated Manufacturing System (AIMS) optimizes cutting tool production through streamlined manufacturing, automation, and connectivity. With ANCA and AIMS, customers can achieve continuous, unattended production that dramatically reduces non-productive machine time, with smart automation that connects sequential tool production processes and offers connectivity across the whole factory.

This is Industry 4.0 — factory-wide integration. The technology considers a factory as a single machine, rather than separating it into many different process elements. This is a powerful concept that brings together one ecosystem and builds it to be as efficient as possible. AIMS, being a modular solution, can be deployed in stages, allowing for easy, gradual, and smooth transition from traditional to automated and integrated manufacturing.

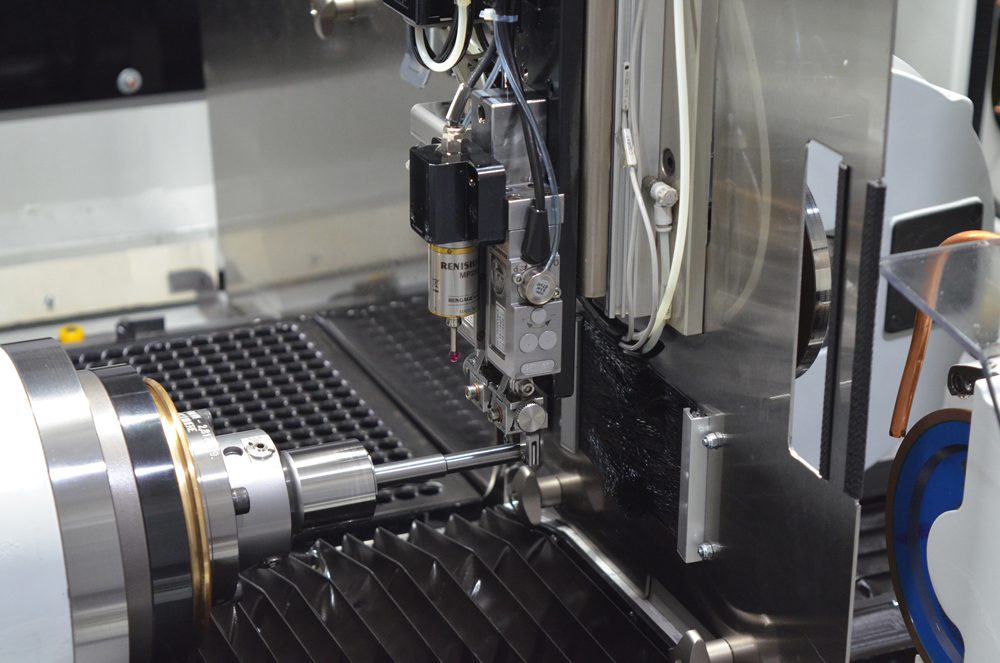

A fully operational manufacturing cell will be displayed at IMTS, demonstrating a fully automatic process of tool manufacturing, from blanks to ground tools. Included will be ANCA’s latest premium machine MX7 ULTRA capable of manufacturing high quality cutting tools, along with an AutoSet job preparation station, AutoLine for pallet and tool transfer as well as AutoFetch – a robot responsible for material transfer between processes – pallet and individual tools between job preparation, grinding and tool measurement on ZOLLER measuring machine.

Jan Irzyk, AIMS Product Manager said: “AIMS can be configured in many ways but at IMTS visitors can see an unattended manufacturing workflow of two varieties of endmills on one MX7 machine. An important part of this workflow is closed loop measurement and compensation process using ZOLLER Genius as a measurement station. Depending on an individual customer’s requirements, our system can automatically transfer a tool from the ground batch, clean it, measure required geometries and transfer the results to the respective grinder where grinding parameters compensation is taking place to achieve required dimensional tolerance of the batch.”

ANCA TOOL OF THE YEAR 2022 WINNERS ANNOUNCED AT IMTS

The fifth #ANCATooloftheYear2022 competition winners will be announced live at IMTS. The ‘Oscars’ of the cutting tool industry, the contest celebrates the deep experience and creativity of tool manufacturers across a highly skilled grinding industry.

Pat Boland, ANCA Co-Founder said: “Reviewing Tool of the Year entries I am always in awe of the passion and talent of customers that push our machines to their limits and create tooling masterpieces.”

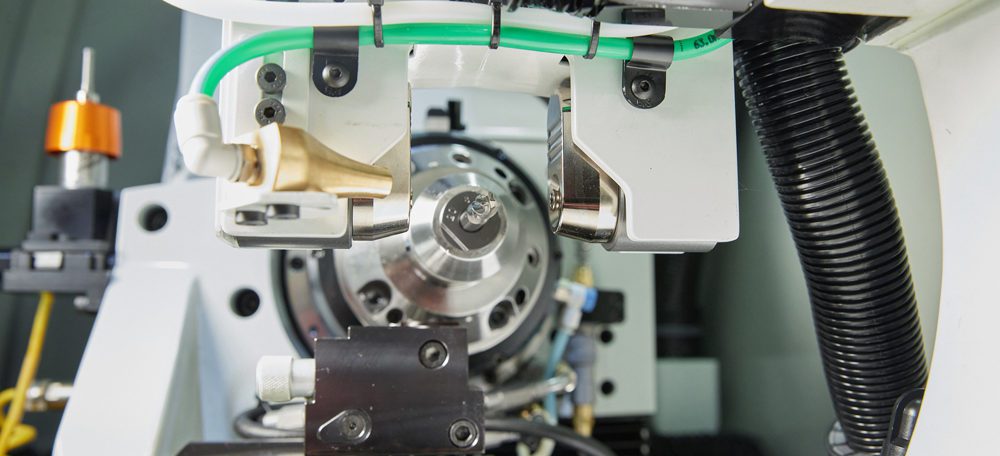

PRESENTING THE CPX IN-PROCESS OD MEASUREMENT SYSTEM

The CPX in-process OD measurement system is a quality control system that monitors and controls the OD of ground blanks within a batch production.

Batch grinding on a CPX with high material removal rates and to tight tolerances is a basic function of the machine, the OD measurement system takes it further by utilizing the Statistical Process Control (SPC) feature that comes standard with the OD measurement software. SPC is user defined, the tolerances along with the Cp and CpK values are constantly monitored, controlled, and reported to the user.

The OD measurement system is permanently mounted inside the machine and only called upon when required, based on the set tolerances and the frequency of measurement, an accurate in-process measurement and compensation is applied to maintain the blank OD to the nominal diameter.

The system is flexible with the ability to handle multiple diameters in one setup, making it perfect for complex blank geometries/shapes and longer batch runs.

AUTOMARKX: ANCA’S AUTOMATIC LASER MARKING STATION

AutoMarkX is an automatic stand-alone laser marking station replacing manual and labor-intensive processes. It is AIMS Ready, which means it can be used as a standalone machine but could be easily integrated to your lights out, unmanned AIMS manufacturing cell with automatic pallet transfer using AutoFetch robot.

The AutoMarkX eliminates the need for manual laser marking which is a repetitive and labor-intensive job which could be automated and therefore saving you money. By avoiding manual handling, tool quality is protected by eliminating risk of chipping.

AutoMarkX accepts up to two full pallets of tools, which means you can mark a large batch of tools unmanned. Flexible marking means the message could be etched on a single side of the shank or, using the AMX’s new rotary workholding on opposite sides of the shank as well as at the end of tool. This new feature will be demonstrated for the first time at IMTS. This latest laser marking option is particularly useful for applications where a unique tool identification code (e.g. Datamatrix) needs to be etched on the tool. Codes like Datamatrix are usually etched on the shank where they risk the exposure to excessive surface wear, rendering them unreadable. The end of tool is the best location to etch this type of code to overcome this issue.

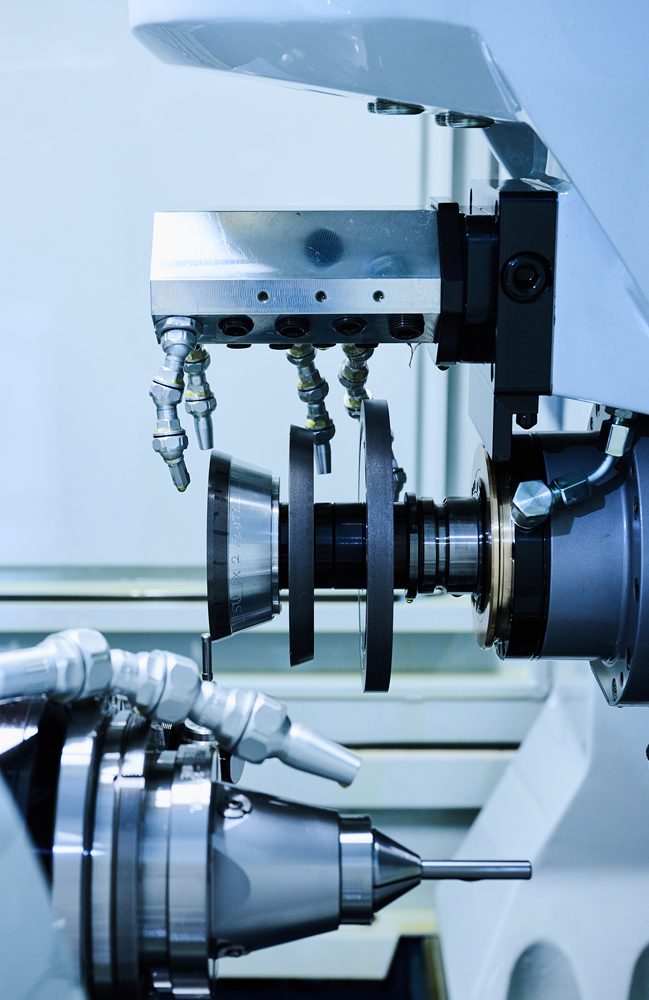

GCX LINEAR: GEAR UP FOR THE EV REVOLUTION

Driven by the automotive industry’s electrification and the general rise of e-mobility, the demand for skiving cutters has seen 30% year on year growth. The GCX Linear provides a complete solution for customers to tap into this rapidly developing market, including the ability to produce skiving cutters, shaper cutters and regrinding of hobs. It offers advanced stand-alone software to design and optimize the tool, neatly interfaced with the gear tool package inside ANCA’s renowned ToolRoom software.

The machine is designed for accuracy with features including all axes with LinX linear motors and an enhanced headstock. GCX Linear boasts a series of technologies: AEMS dressing, MTC on grinding spindle and dresser spindle, integrated gear tool measurement and direct compensation – setting the new standard for producing skiving tools that achieve the highest DIN AA quality class.

ANCA has developed a world-first integrated gear tool measurement system, which enables all the grinding-measuring-compensation to be done in the machine. This is the only practical closed-loop solution in the market and will be on display at IMTS as part of the skiving cutter production process on GCX Linear.

NEW TOOLROOM RN35 AND CIM3D PREVIEW

Besides demonstrations on ANCA’s industry leading ToolRoom and CIM3D software, visitors will have a special preview of the upcoming RN35 release.

ToolRoom RN35 focuses on productivity and cycle time improvements especially machine running costs. New process optimization features help to enable reduction in cycle time which in return provides better quality tools and wheel life. This includes automated reduction in air grinding time and gaps calculated based on tool simulation models. Some of the major enhancements include:

• Feedrate optimization – Integration of Q-Prime feature in ToolRoom software to achieve constant Material Removal Rate (MRR) based on wheel manufacturers specifications. This is done by calculating and controlling non-constant feedrate where applicable to achieve better cycle time and extended wheel life.

• Airtime Reduction – Automated reduction in airtime by optimizing gaps based on tool simulation models and wheel shapes.

• Statistical Process Control (SPC) – Gives control of your production process during high volume manufacturing by monitoring the variations due to wheel wear and other process-controlled activities. Process capability data can be graphically displayed or stored for future QC purposes or further evaluation. It also helps customers to control critical tool dimensions like diameter by updating wheels at regular intervals.

• Profile Fluting – Gives the ability to control and maintain hook/rake angle along the trajectory of the cutting edge on a given profile. Increases cutting performance and life of the tool due to uniform hook/rake angle along the edge.

Other features include in-process measurement of tool geometries, enhancement to profile software as well as several more.

FX7 RFID and LASERULTRA

The FX7 is fitted with ANCA’s Dynamic Tool Loading System, which is ideal for customers manufacturing or regrinding a wide and varied range of tools in small to medium size batches. The tool management system with RFID links unique tool programs to the correct tool in a loader pallet. This works in conjunction with automated Schunk collet changing to allow unattended grinding of random tool diameters and types.

The FX7 robot loader also changes wheel packs based on the individual tool grinding program linked to the RFID coding. With a six-station wheel changer and the ability to change collets the ANCA FX7 with RFID is the ultimate automation package.

The FX7 is additionally fitted with new LaserUltra, for automated post process tool measurement within the grinding machine itself. Measuring cutter profile and diameter to +/-0.002mm, LaserUltra can provide compensation feedback to ensure accuracy and consistency with unattended tool grinding operations.

Visit ANCA at IMTS at Booth 237406.

About ANCA

ANCA is a thriving business with over 1,200 employees and a world leading manufacturer of CNC grinding machines, motion controls and sheet metal solutions.

It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

For further information, please contact:

Johanna Boland

Group Corporate Communications Manager

M: +61 407799779

Johanna.Boland@anca.com

“It’s an honor to be part of this competition and I hope it can help raise awareness about the benefits of a well-designed and executed cutting tool.” John Saunders, ANCA Tool of the Year Judge

ANCA’s Tool of the Year contest is once again underway for the fifth year in a row. The prestigious, global competition opened for entries on May 17, 2022 and will close on August 8, 2022. The competition is based on the passion and the craft of tool making and celebrates the highly skilled tool grinding community. This year the panel of judges will include John Saunders, Saunders Machine Works, among a select group of industry experts.

John Saunders, President of Saunders Machine Works (SMW) and founder of YouTube channel NYC CNC, is excited to be a part of the selected panel. Saunders started his business about 15 years ago when he was trying to bring a product to market as a young entrepreneur. Admittedly not knowing anything about machining or even manufacturing, he ended up purchasing a benchtop CNC machine while living in New York city. At the time, his sole goal was to try to understand what machining was and how it worked. He was not planning on making parts himself, but wanted to be able to better communicate with engineers and machine shops on what parts they needed and ended up falling in love with the industry. This led to him documenting his journey on his well-known YouTube channel, called NYC CNC.

Saunders passion for “making stuff” was once again invigorated. Fast forward about 7 years into that journey, Saunders left New York city and moved back to central Ohio where he grew up. It was there, in Zanesville, Ohio, he started Saunders Machine Works as a “proper” brick and mortar business.

In the early years, the company did some job shop work and other projects, but now focuses on their line of Fixture Plates, as well as accessories, like the Mod Vise. The Mod Vise is a very popular, modular workholding system that allows one to hold small parts, big parts, dual station parts, etc. In addition to that, SMW continues to publish a lot of YouTube videos and offers hands-on CNC training classes where folks can learn CAM and how to operate CNC Machines.

Known widely through the manufacturing field for his YouTube channel, Saunders feels the biggest development in the machine tool industry, and the part he cares about most, said Saunders, is “the knowledge one can now gain from YouTube and other online resources, and how that learning may be enough to actually prepare them to take the next step; to buy a machine or start a side business, or a young person who’s interested can get guidance on whether they go into a trade or an engineering program, and that’s something I care greatly about and I think it’s absolutely awesome and I think that’s only going to continue.”

Saunders first became familiar with ANCA while on a shop tour for NYC CNC in a facility using ANCA machinery. He is excited to attend IMTS 2022 and for his role as a judge in ANCA’s Tool of the Year contest. He says competitions are important to the industry because “they bring a sense of community and a community bonding,” plus, he feels, “It’s really about having fun and showing off what you can do.”

The winner of #MadeonANCA receives $10,000 AUD worth of ANCA innovations for parts, accessories or software that fit the winner’s grinding needs or a trip to ANCA’s headquarters in Melbourne, Australia. This amazing prize further includes access as an ANCA VIP to exclusive opportunities with our ANCA tool experts. The winner of the most innovative virtual tool will receive a full CIM software package.

To enter the ANCA Tool of the Year contest, please see: https://machines.anca.com/Tool-Of-The-Year

NYC CNC, a leading CNC Machining YouTube channel, has over 420,000 subscribers. It has published over 1,000 videos which all together add up to more than 78.9 million views. NYC CNC regularly posts new videos on CNC machining and manufacturing entrepreneurship.

To see NYC CNC, please visit:

For further information, please contact:

Johanna Boland

Group Corporate Communications Manager

M: +61 407799779

Johanna.Boland@anca.com

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia, where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA, as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

Continue reading

Exact Metrology: A Division of In-Place Machining Company, a comprehensive 3D metrology service provider and hardware sales company, recently hosted Technology Fairs at their facilities in Brookfield, Wisconsin and Moline, Illinois.

Each event drew over 100 people from the surrounding areas who were interested in learning more about the industrial benefits of innovative and highly accurate 3-dimensional scanning technologies and software. Attendees included quality assurance and quality control engineers, manufacturing and production personnel, and other supervisors and technicians from a variety of industries including power generation, automotive, off-highway, consumer durables, and others.

Dimensional metrology instruments displayed included the latest scanners from Artec, Hexagon Manufacturing Intelligence, GOM CT, Romer, and more. In addition, demonstrations were provided showing the advanced functions of PolyWorks and Geomagic 3D software. At the Moline facility, attendees witnessed the precision measuring and dimensional layout capabilities of that locations in-house large-scale Coordinate Measuring Machine (CMM). The Technology Fairs in both locations featured hands-on scanning and data capture demonstrations as well as educational training sessions in breakout rooms. Discussions were led by Dean Solberg, Vice President, Greg Goth, Division Manager, technology partner personnel, and other Exact Metrology engineers.

Among the hot topics discussed by attendees during the luncheon and demonstrations were technology trends – including robotics, the benefits of reverse engineering parts and components, and long-range scanning of complete process lines and equipment.

In-Place Machining Company: On-Site Machining Solutions In-Place, Any Place in the World.

In-Place Machining Company, with facilities in Wisconsin, Washington, Virginia, Ohio, and Ontario, Canada, is the premier provider of high-precision engineered on-site machining, metrology, and large scale cutting & drilling services for a wide range of renewable energy, aerospace, industrial, and military customers throughout the world.

Exact Metrology: A Division of In-Place Machining Company, is ISO9001, AS9100 Certified as well as ITAR Registered.

Exact Metrology: A Division of In-Place Machining Company, with facilities in Cincinnati, Ohio, Moline, Illinois and Milwaukee, Wisconsin, plus affiliated offices throughout the country, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

OASIS Alignment Services: A Division of In-Place Machining Company

OASIS Alignment Services: A Division of In-Place Machining Company, provides 3-Dimensional Metrology Services, Precision Alignment Inspections and Diagnostics and Mechanical Services across a wide range of industries including aerospace, automotive, power generation, shipbuilding, pulp and paper, converting, printing, plastics, textiles and more. OASIS has completed thousands of successful projects since its inception in 1982 and continues to set industry standards in alignment procedures, specialized tooling and reporting techniques. OASIS operates service centers in New Hampshire, North Carolina, Florida, Ohio, Wisconsin, California, Washington, and Ontario and Québec, Canada. For more visit www.oasisalignment.com

For more information, please contact:

Exact Metrology: A Division of In-Place Machining Company

Dean Solberg

20515 Industry Avenue

Brookfield, WI 53045

Local: 262-533-0800

www.exactmetrology.com

deans@exactmetrology.com

The future of optimized cutting tool production, AIMS, connects sequential tool production processes – see it at IMTS, Chicago in September

Once again ANCA is on the forefront of innovation with AIMS – ANCA Integrated Manufacturing System. An Industry 4.0 factory wide integration, AIMS is ANCA’s solution for considering the factory as a single machine. Rather than separating workflow into many different elements of design, blank preparation, grinding, laser marking, washing, packing and shipment – AIMS streamlines the entire tool manufacturing process and complementary technologies.

An interactive and fully operating AIMS cell will be on display at IMTS in Chicago, September 12-17, 2022. The demo showcases the main modules of the AIMS system – an AutoSet job preparation station, AutoLine for pallet and tool transfer as well as AutoFetch – a robot responsible for material transfer between processes — pallet and individual tools between job preparation, grinding and tool measurement on ZOLLER measuring machine.

With AIMS, ANCA is responding to common challenges in the tool manufacturing sector of labor cost and availability, as well as safety and production efficiencies. Access to skilled staff and the need for elimination of simple, repeatable tasks which could be easily automated – AIMS maximizes grinders’ productivity and, in general, improves Overall Equipment Effectiveness. Integration with ERP systems to streamline workflows is also one of the important AIMS features.

The principles of the AIMS system are flexibility and modularity. This means each system can be tailored to an individual customer’s needs using the right building blocks – or modules. It can scale from a purely software-based monitoring solution to a fully automated manufacturing cell.

AIMS is not a single product but rather a suite or ecosystem of interconnected building blocks which can be configured to satisfy an individual customer’s requirements. Manufacturers can build their AIMS system gradually using standalone AIMS Ready components, which can be easily upgraded to fully automatic when required. Customers can tackle their most pressing issues first and stagger implementation over a period of time. This staggered option makes AIMS a feasible solution for customers as they invest in this revolutionary technology and realize the potential for their business.

Jan Irzyk, AIMS Product Manager said: “We are delighted to present a physical, working model of AIMS for customers to understand the powerful potential of truly integrated manufacturing.”

“AIMS can be configured in many ways, the IMTS cell demonstrates an unattended manufacturing workflow of two varieties of endmills on one ANCA MX7 machine. An important part of this workflow is closed loop measurement and compensation process using ZOLLER Genius as a measurement station. Depending on an individual customer’s requirements, our system can automatically transfer a tool from the ground batch, clean it, measure required geometries and transfer the results to the respective grinder where grinding parameter compensation is taking place to achieve required dimensional tolerance of the batch.”

Visitors to ANCA’s booth at IMTS (Booth 237406, North Building, Level 3) can see:

Jan concluded, “In the not-too-distant future we will be able to demonstrate the AIMS capability in a production environment, which is very exciting – so watch this space, there’s much more to come!”

For further information, please contact:

Johanna Boland

Group Corporate Communications Manager

M: +61 407799779

Johanna.Boland@anca.com

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia, where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA, as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

Continue reading