Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Procon X-RAY GmBH, a leader in custom-designed industrial CT scanners, will be available in USA through Exact Metrology

November 30, 2015 – Exact Metrology announced today the signing of an agreement with ProCon X-Ray for exclusive rights to distribute the company’s product line throughout the USA.

ProCon, located in Germany, has been developing x-ray systems for non-destructive testing since 2004. The company is a state-of-the-art manufacturer of x-ray and CT (computed tomography) systems designed specifically for industrial applications.

ProCon offers several standard models, ranging from portable units and desktop models to full-size, stand-alone systems. Each of the company’s standard units can be customized to meet customer specific job requirements. The systems are all offered with high-resolution focus x-ray technology.

ProCon works directly with customers to determine the scope of requirements, then develops and designs a unit to meet the individual application needs. Units can be designed with multiple x-ray sources and multiple detector set-ups. This process results in customers obtaining exactly the type of metrology equipment required, without any unnecessary features. Turnaround time in production of the equipment is thereby reduced to a minimum. ProCon systems are also user-friendly and easy to use in operation, according to Exact VP Steve Young.

Exact Metrology offers a complete line of portable scanning and measurement technologies, as well as contract measurement for 2 and 3D laser scanning services, reverse engineering services, non-contact inspection, metrology services, 3D digitizing and training, plus its recently announced CT scanning services, usable by all types of manufacturing, packaging and product integrity concerns.

For more information on this agreement, please contact:

Steve Young, VP

Exact Metrology, Inc.

11575 Goldcoast Drive

Cincinnati, OH 45249

Local 513.831.6620

Toll Free 866.722.2600

www.exactmetrology.com

stevey@exactmetrology.com

Exact Metrology is an ISO 9001:2008 Certified Company.

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

Pomona, California (November 30, 2015)… NOARK Electric, a leading low-voltage electrical product manufacturer, announces the latest edition to the B1N miniature circuit breaker family: the UL 489 B1NQT. This recyclable, quick-connect breaker is available in three curves (B, C and D), ranges from 0.5 to 63 A and has an optional detachable shield to make it faster and easier for the installer.

NOARK Electric provides reliable products, improves profitability and maintains the highest performance levels. The NOARK B1N breaker series is suited for a host of industrial applications, including HVAC equipment and other component sub-assembly designs. NOARK offers exceptional value with local support and inventory for a wide range of UL 508A panel designs, all backed by the industry’s first 5-year limited warranty.

NOARK Electric will display this new product and its full line in booth #1379 at the upcoming AHR 2016 show in Orlando, Florida. Additionally, NOARK will present a brief session to the HVACR industry, covering the B1NQT and additional NOARK product lines on Tuesday, January 26 at 4:00 p.m. in Theatre C, room N320G. Free AHR show passes can be obtained by contacting NOARK.

NOARK Electric (North America), located in Pomona, CA, is a global electrical component and intelligent control system supplier. The company is establishing a representative and distribution network to serve its primary markets, which include the building trades and electric panel board builders in various industries. As a global supplier, NOARK currently operates four R&D centers, three distribution centers, 15 office locations and employs over 1,000 associates. Sales currently exceed $2 billion worldwide.

For more information on this product, consult your local sales representative or email: nasales@noark-electric.com

Contact:

Jessie Jones, Marketing Manager

NOARK Electric (North America)

2188 Pomona Blvd.

Pomona, CA 91768

Phone: 626-330-7007

Website: na.noark-electric.com

Email: nasales@noark-electric.com

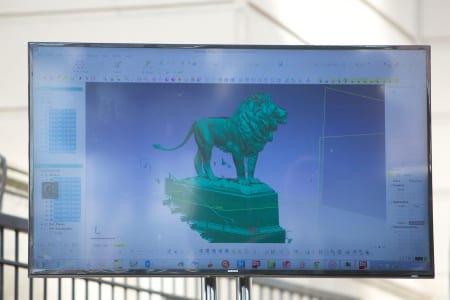

Scans to be used by Met-L-Flo to make miniature 3D printed models for FABTECH

The South Lion, named Attitude of Defiance, was

As Dean Solberg remarked, “We’re creating a file with millions of 3D data points that would allow the program to accurately recreate the lion at almost any size, whether on a conventional CNC machine tool or in the new 3D printing method being used by Carl (Dekker) and his team at Met-L-Flo. Dekker noted that 3D printing of one of the seven additive manufacturing techniques his company currently employs to make not only prototypes but also functional short run production parts.

Exact Metrology will be exhibiting its various metrology equipment and services, including robotic articulation and its new CT scanning technology that allows precision examination of internal structures, during FABTECH.

Exact Metrology is an ISO 9001:2008 Certified Company.

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

Click the link to view a video of the press conference: https://www.youtube.com/watch?v=K0qPVAI5z8Y

For more information on this event or to arrange a demonstration, please contact:

EXACT METROLOGY, INC.

Dean Solberg

20515 Industry Avenue

Brookfield, WI 53045

Phone: 262-533-0800

Local: 866-722-2600

www.exactmetrology.com

deans@exactmetrology.com

Connect with Exact Metrology online:

—

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

Continue readingEvent will feature speakers from Exact Metrology, FABTECH and Met-L-Flo to discuss the art of manufacturing and other innovative technology showcased at FABTECH 2015

WHAT: FABTECH 2015, North America’s largest collaboration of technology, equipment and knowledge in the metal forming, fabricating, welding and finishing industry, will bring 3D scanning technology to the steps of the Art Institute of Chicago on Sept. 16. Exact Metrology, a 3D scanning solutions company, will use its Surphaser technology – known for its high accuracy and scan data quality – to 3D scan the museum’s south lion by Edward L. Kemeys (1843-1907). The guardian lions have flanked the Art Institute’s iconic Michigan Avenue entrance for more than 100 years and have become a symbol of the museum and of the city.

Attendees will have the opportunity to witness Exact Metrology’s scanning technology firsthand and hear from industry leaders as they discuss the process and benefits of 3D scanning and printing. Additionally, speakers will provide a look at what other advanced manufacturing technology will be showcased at FABTECH 2015, taking place at Chicago’s McCormick Place, Nov. 9-12.

After the scan data is captured, Met-L-Flo will use it to print approximately 300 small-scale replicas of the lion, which will be on display and used as giveaways at FABTECH.

Following the brief press conference, representatives from FABTECH, the Art Institute, Exact Metrology and Met-L-Flo, Inc., will be available for interviews.

WHO: Dean Solberg, vice president, Exact Metrology

Ed Youdell, president and CEO (FMA), FABTECH

Carl Dekker, president, Met-L-Flo, Inc.

WHEN: Wednesday, Sept. 16

9 a.m. – Press to arrive; photo opportunities

9:20 a.m. – Press conference

WHERE: The Art Institute of Chicago

111 South Michigan Ave.

Chicago, Il 60603-6110

Note: Press conference to take place on steps near the south lion, located in front of the Art Institute.

About Exact Metrology

Exact Metrology is an ISO 9001: 2008 certified company that offers contract measurement & scanning services, metrology equipment solutions, and hardware & software rentals. Its goal is to provide customers with a specifically tailored solution to their measuring needs. To accomplish this, it offers more options, more products and more experience.

About FABTECH

FABTECH is North America’s largest collaboration of technology, equipment and knowledge in the metal forming, fabricating, welding and finishing industry. The event provides a powerfully aligned hands-on, face-to-face business growth experience, attracting more than 1,500 exhibitors and 40,000 attendees. The event is made possible by its five co-sponsors, all of whom representing the varied and diverse makeup of the manufacturing industry. They include SME, the American Welding Society (AWS), the Fabricators & Manufacturers Association, International (FMA), the Precision Metalforming Association (PMA), and the Chemical Coaters Association International (CCAI). Read more about FABTECH’s co-sponsors here.

About the Art Institute of Chicago

The Art Institute of Chicago collects, preserves and interprets works of art of the highest quality, representing the world’s diverse artistic traditions, for the inspiration and education of the public and in accordance with our profession’s highest ethical standards and practices.

About Met-L-Flo Inc.

Met-L-Flo, Inc., is a contract manufacturer specializing in 3D Printing and Additive Manufacturing services since 1991. It strives to partner with clients to implement innovative solutions for their product development and low volume production needs. Advanced applications of its technologies enable it to boost clients’ competitiveness and enhance product success. Its commitment to Quality is solidified in the company’s ITAR, ISO 9000 and AS 9100 Rev C Certifications.

As a leader in the industry, it prides itself on creating innovative, unconventional solutions that utilize both tool and tool-less applications. Products may be produced in metal, plastic, silicone, or wax including fiber reinforcement

For more information on the event, please contact:

EXACT METROLOGY, INC.

11575 Goldcoast Drive

Cincinnati, Ohio 45249

Phone: 513-831-6620

Toll Free: 866-722-2600

www.exactmetrology.com

stevey@exactmetrology.com

Steve Young, President

Connect with Exact Metrology online:

—

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

Continue readingFirst application of CT scanning for metrology in America involves aluminum casting

Josh Schradin, one of the 3D Scanning specialists at Exact Metrology’s Cincinnati facility, recently completed a CT Scanning project involving aluminum castings measuring approximately 12” x 6” x 6” and weighing 10 to 15 pounds.

For this particular job, which represents the first use of CT scanning for metrology in America, the client was interested in wall thickness inspection as well as porosity and void analysis. The blue paint visible in some of the images was applied by the customer to indicate stress areas where leaking or breaking was suspected. Josh Schradin performed three stacked scans, each taking only about 30 minutes, to capture the entire casting. The result of the scans revealed the voids (legitimate holes) and highlighted the most serious problem areas in red-to-pink shadings.

In addition to offering the only method to get 3D views inside a part, another primary benefit of the Exact Metrology CT scanning is the true dimensional data provided in a non-destructive test manner, i.e. without cutting up or otherwise destroying the test object.

The workpiece (casting) was rotated 360 degrees in the x-ray beam’s path, with multiple readings from various angles being taken. Once the CT grey scale images were converted into voxel-based 3D point clouds, Schradin was able to generate a CAD-to-Part comparison for the customer.

If interested parties have a need for Internal Defect Analysis/3D Quantitative Porosity Analysis, Materials Structure Analysis or Assembly Control, CT Scanning (Industrial X-ray), Exact Metrology invites inquiries for immediate assistance.

Exact Metrology is an ISO 9001:2008 Certified Company.

To see videos on this new scanner’s capabilities, please visit:

VG GE casting analysis with CT hi-res at Exact Metrology

v | tome | x m CT scanner at Exact Metrology

For more information on this new system or to arrange a demonstration, please contact:

EXACT METROLOGY, INC.

11575 Goldcoast Drive

Cincinnati, Ohio 45249

Phone: 513-831-6620

Toll Free: 866-722-2600

www.exactmetrology.com

stevey@exactmetrology.com

Steve Young, President

Connect with Exact Metrology online:

—

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

Continue readingLarge parts and one-off runs present particular challenges; common CNC platform offers many benefits to busy York, PA shop

Despite the large, heavy workpieces and frequent one-off production, Voith Hydro maintains a steady flow of work for its machining, typically holding +/- 0.002” tolerances on various carbon and stainless steels. Workpieces here often exceed 25’ in diameter.

Voith Hydro in York, Pennsylvania is a major manufacturer of hydroelectric power generation equipment, especially the intricate turbines used in such operations, supplying hydroelectric generating companies and municipalities throughout North America. Over 12,000 units have been commissioned in the field with more than 65,000 MW of installed capacity, plus Voith Hydro has also upgraded over 600 existing power generation units. As a turnkey supplier to the industry, the company manages all phases of power plant projects, from analysis and planning, design and implementation, to commissioning and operation. Voith Hydro is ISO 9001 and ISO 14001 Certified.

Milling, line boring and turning operations are performed on large multi-axis machine tools, most equipped with Siemens SINUMERIK 840D CNC onboard to control all axes of motion.

At the York facility, very large multi-axis machining centers produce carbon and stainless steel work pieces, most often in a one-off mode and at sizes frequently exceeding 35’ in diameter. Adam Ward, the manager of maintenance & facilities at Voith Hydro, says the machining done typically holds +/- 0.002” tolerances here, nonetheless. “We do turning, line boring and milling on extremely large and heavy work pieces that often challenge us to design the optimum machining cycle. Our long cycles can frequently result in heat distortion on material surfaces and so we take great care in looking for problems before they occur.”

Voith Hydro maintains an impressive array of machine tools and multi-axis machining centers here. Despite a variety of builder brands, the majority of the machines have one common component, namely, the Siemens SINUMERIK 840D CNC onboard.

Remote condition monitoring is performed between Voith Hydro and many of its machine tool builders to troubleshoot and resolve issues in real time, using the CNC on the machine.

As Ward notes, “Our operators are quite comfortable with the CNC from Siemens and they use it for all motion control, plus the operator interface has the ability to afford us great troubleshooting capability and something else we value greatly, the commonality of the HMI on the control. That fact allows us to do a great deal of cross-training and that’s very important to us. We need to be highly flexible, given the one-off nature of our work here.” Most of the operators at Voith Hydro are capable of running multiple machines, while the maintenance personnel on his team can more easily service the machining equipment in the facility, adds Ward. He credits his machine builders and the Siemens team led by Howard Weinstein and Robert Stiefel for this ongoing flexibility.

Part designs are run through the company’s CAM system and simulated offline to preserve machine uptime.

Voith typically takes a customer design, runs it through their CAM system and simulates the cycle offline, in order to preserve valuable machine uptime. Since the work here involves highly complex geometries on the turbine sections, the simulation must be equally complex and account for all machine motions and collision avoidance. Once the program is finally determined for a part, it is fed over the Voith Hydro network to the appropriate machine tool or machining center for scheduling and production startup.

During production, a system of real-time remote condition monitoring is available through the CNC for troubleshooting by both the Voith Hydro maintenance personnel and, when required, machine builder personnel, working offsite.

Large Ingersoll milling machine was retrofit recently, with all new Siemens CNC, motors, drives and other hardware.

Ward cites one example where an Ingersoll milling machine was completely retrofitted both mechanically and electrically by a Siemens Solution Partner, with a new CNC, motors, drives, encoders, other hardware and software. “Working with the builder and Siemens support personnel, we were able to resolve issues and implement changes to the programming, right on the CNC of the machine…and all done remotely, in a very short time period.”

Voith Hydro in York, PA produces a wide variety of power generation components for various machine builders and municipalities across America.

Voith Hydro boasts machining capabilities on workpieces over 42’ diameter and 350 tons at the York facility. Surface finishes are typically 250 and 125 Ra, though occasionally 64 or 32 Ra is required. The finishes are achieved through both machining and secondary finishing operations, according to company sources.

Adam Ward further notes that, on most new machines required at Voith Hydro, “The cross-training capability of the CNC, the standardization of the HMI on various types of machines, the support provided and the previous successes our operators and maintenance personnel have realized, all combine to make specifying Siemens as our control of choice an easy decision.”

Howard Weinstein, business development manager for the power industry manufacturing sector at Siemens, comments on the relationship with Voith, “We’re a proud partner to Voith Hydro in York, Pennsylvania. Their facility is a great showcase for our flagship CNC, the SINUMERIK 840D, as used on an array of multi-axis machining centers to produce large, complex geometry parts for the hydroelectric power industry.”

For more information on this story, please contact:

SIEMENS INDUSTRY, INC.

DRIVE TECHNOLOGIES – MOTION CONTROL (MACHINE TOOL BUSINESS)

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/cnc

Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communication

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

Others involved in this story may also be contacted:

Voith Hydro

760 East Berlin Road

York, PA 17408-8701

Phone: 717-792-7512

Web: www.voith.com

Email: adam.ward@voith.com

Adam Ward, Manager of Maintenance & Facilities

Guill Tool, a West Warwick, RI designer and builder of extrusion tooling, offers an assortment of literature for machine builders and extruders at its website, www.guill.com.

Individual brochures are offered, depicting the wide array of tooling possibilities…straight inline heads, rotary heads and crosshead dies…available to suit any extrusion machine built anywhere in the world, running all types of compounds.

Guill provides tooling for plastic, rubber, TPE and other material extrusions, with end products ranging from extremely thin-walled, multi-lumen medical tubing and catheter balloon tubings up to multi-layer wire & cable jacketing and 20” diameter pipe for industrial applications and agricultural drip lines. Guill also provides tooling for film, sheet and profile extrusions.

The company designs, engineers, machines, assembles, tests and delivers all tooling to its worldwide customer base in all the consuming industries for extrusions. The company also offers tooling carts and disassembly/cleaning stations for easier line integration.

According to company sources, the utilization of properly designed and engineered tooling can result in substantial material savings for extruders of all types.

NOTE: Guill will attend MD&M West in February, NPE in March and Interwire in April, 2015.

Please visit www.guill.com to request a quotation or obtain company literature.

For further information, please contact:

GUILL TOOL & ENGINEERING CO., INC.

10 Pike Street

West Warwick, RI 02893

Phone: 401-828-7600

Web: www.guill.com

Email: sales@guill.com

Attention: Bill Conley

Connect with Guill Tool online:

Available from German Machine Tools of America, the Präwema SynchroFine 205 HS gear honing machine features direct-driven, digitally controlled spindles for the tool and the workpiece, enabling precise, rigid synchronization

Ann Arbor, Michigan – Now available from German Machine Tools of America (GMTA), the Präwema SynchroFine 205 HS gear honing machine features direct-driven, digitally controlled spindles for the tool and the workpiece, enabling precise, rigid synchronization. The Präwema Honing gear finishing process produces quality comparable to grinding results for spur and helical gears, as well as shafts. The machine’s software checks the stock allowance and workpiece runout and then optimizes the X-axis approach distance. Measuring the workpiece does not affect the cycle time and the process can reduce cycle times by 3 to 5 sec.

The machine features a pick-up design to enable automation. The workpieces and dressing tools are loaded and unloaded by the workpiece spindle. The large X-axis travel enables placement of additional stations adjacent to the loading/unloading station inside the machine, such as a two-flank roll-checking device. External robots and conveyor systems can also be integrated by GMTA engineering.

The honing machine is constructed on a natural granite bed to promote stability and control thermal fluctuations. The X and Z axes are equipped with linear motor drives. The cutting tool is clamped with a hydraulically operated system and the tool spindle can be swiveled into a vertical position, enabling easy access. Additional options are available for machining over-sized drive shafts as long as 850 mm and the Präwema SynchroFine 205 HS-D model, equipped with two spindles, is offered for further reduction of cycle times.

For more information on this announcement, please contact:

GMTA (German Machine Tools of America)

4630 Freedom Drive

Ann Arbor, MI 48108

Phone: 734-973-7800

Fax: 734-973-3053

Web: www.gmtamerica.com

Email: scott@gmtamerica.com

Attention: Scott Knoy, VP

Connect with GMTA online:

The objective of this new development was the integration of the latest servo drive and control technology from Bosch Rexroth. Software developed additionally allows the user to program six different basic cycles without prior knowledge of CNC.

By visualizing these six cycles – drilling – combined drilling (drilling and thread cutting with the one tool) – thread cutting – drilling with chip removal – drilling with jump function – undercutting, the unit has become extremely easy to program.

Plus, should the required machining cycle not be found among the standard selections or prove more complex, the unit can be switched to sentence programming.

The BEA 16 machining unit itself is a precision device from the SUHNER spindle machining unit series that has been designed for gruelling continuous use in multiple shift operations. The BEA 16 has a drilling capacity of 16 mm Æ in 450 N/mm2 steel. The max feed path is 140 mm, and the max speed is 500 rpm.

Today, rising production piece numbers and greater workpiece complexity with all-round machining are leading to a renaissance of the so-called special machine. However, today’s special machines are being used no longer as purely single-purpose solutions, but rather for whole part families.

These require different machining cycles, feed speeds, feed paths and rotating speeds, and, of course, must allow fast retooling. And it is these requirements exactly that the BEA 16 will meet to the full.

SUHNER INDUSTRIAL PRODUCTS, CORP.

Hwy 411 S./Suhner Drive

P.O. Box 1234

Rome, GA 30162

Phone: 706-235-8046

Fax: 706-235-8045

Attention: Lee Coleman, Automation Division

www.suhner.com

automation.usa@suhner.com

Text and pictures files can be found and down loaded at:

www.suhner-press.com

Sinumerik CNC ensures high-quality guitar craftsmanship

Fryer Machine Systems supplies an American guitar builder with milling machines for the production of high-quality guitars. Right-angle head compensation is essential to the accurate, repeatable milling of guitar necks — an easy task for the Sinumerik 840D CNC on board Fryer machines.

The challenge of repeatable product performance is not new to C.F. Martin & Company. Six generations ago, company founder C. F. Martin Sr. was confronted with managing a guitar-making enterprise that was producing totally handcrafted guitars, one by one, with little means for standardization. Since those days, guitar legends such as Gene Autry, Eric Clapton, John Mayer and new-comers Ed Sheeran and Hunter Hayes have relied on the consistently distinctive tone, treble and bass specific to Martin acoustic guitars. When Martin learned that its previous machine tool builder had exited the market, the company turned to Fryer Machine Systems for new machines to cover a production increase and seized the opportunity to upgrade the control technology with Sinumerik CNCs.

Larry Fryer (left) and Mark Bickert from Martin Guitar are satisfied with Siemens CNC technology, service and part quality.

Hands-on support in customizing the CNC

“We use right-angle head aggregates in our CNCs,” explains Mark Bickert, engineering project manager at Martin. “We needed to find a machine builder that could give us right-angle head aggregate capability in conjunction with right-angle head compensation and a high-rpm spindle.” Fryer Machine Systems has earned a reputation for building reliable production machines that come with unexpectedly advanced features and functionality. The company happens to be the largest purchaser of Siemens controls in the United States, and the customizable aspects of a Fryer machine can often be attributed to the versatility of the Siemens controls on board. This time, however, Martin needed to be certain that the new Fryer machines would perform as expected.

“Anyone can sell you a machine with a controller on it and say, ‘Here you go,’” Bickert says. “But that’s not what happened this time. We were buying a machine through a Fryer dealership, and the machine had a Siemens control. Siemens invested their time in us during our transition and set-up. They really excelled.”

Bickert says a potential constraint to the transition was that all-new milling programs might need to be written for the Fryer machines, including the right-angle head cutter compensation programs, which were essential. “Siemens not only gave us the right-angle head cutter compensation we wanted and the ability to do it properly, they also helped write the programs,” Bickert says. “They took the programs that we already had for cutting parts on our existing machines and reconfigured them to work in the Fryer machine with the Siemens controller.”

Guitar body castings now also machined in-house

Having made a smooth transition to the company’s new Fryer-built machines last year, Martin has not skipped a beat in its ability to perform right-angle compensation milling. Martin now has eight Fryer/Siemens machines, utilizing one for the guitar maker’s tooling and machinery operations and seven for various other guitar production operations. It is here, behind the scenes, that the company’s machinists reside and modern CNC technology and Old World craftsmanship come together to create the fixtures, tools and wherewithal that contribute to the mastery of Martin guitar making. It is also here that Martin found a way to bring previously outsourced operations in-house, a step that has improved repeatable production quality while reducing production costs. “The machining of our castings had been another hurdle for us,” says Terry Kline, Martin’s manager of tooling and machinery. Until the company invested in the Fryer machines with the Siemens controls, Martin had outsourced the machining of its guitar body castings, with inconsistent results. “Now we’re holding close tolerances on our guitar body castings,” Kline says. “The quality of the castings is consistently accurate.”

CNC technology meets craftsmanship

On a daily basis at Martin, Kline sees what is possible when CNC technology and craftsmanship work together. “Without CNC technology, we’d be still carving out all our necks by hand, and that’s just not efficient enough to compete in today’s world,” he says. The intersection of technology and craftsmanship has come naturally for this 180-year-old guitar company, without one side compromising the other. “I think every manufacturing company needs to embrace technology,” says Kline. “Technology and craftsmanship go hand-in-hand. People are amazed by how much handwork still goes into our guitars. We’ll build a neck and a body and then assemble the two elements together, which makes that guitar come to life.”

Right-angle head compensation is essential to the accurate milling of guitar neck components. The function requires the sophisticated Sinumerik 840D sl CNC and ShopMill software from Siemens. Guitar image courtesy of C.F. Martin & Company.

For more information on this story, please contact:

SIEMENS INDUSTRY, INC.

DRIVE TECHNOLOGIES – MOTION CONTROL (MACHINE TOOL BUSINESS)

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/cnc

Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communication

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

–

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.