Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

No. 979 is a 850ºF (454ºC), electrically-heated, universal style oven from Grieve, currently used for various machine shop heat treating operations at the customer’s facility. Workspace dimensions of this oven measure 36” W x 36” D x 36” H in each of the two compartments. 24 kW (12kW per zone) are installed in Incoloy-sheathed tubular elements to heat the dual oven chambers, while a 600 CFM, ½-HP recirculating blower provides front-to-back universal airflow to the workload in each compartment.

This Grieve universal oven features 6” insulated walls, aluminized steel exterior with enamel finish, Type 304 stainless steel interior, double doors, three roller shelves rated for 200 lb. loading, five nickel plated, 100 lb. capacity shelves in the top chamber, three nickel plated, 100 lb. capacity shelves in the bottom chamber and an integral leg stand.

No. 979 controls include a digital indicating temperature controller for each compartment, recirculating blower airflow safety switches, a 10” diameter circular chart recorder for each compartment to record part temperature and manual reset excess temperature controllers with separate contactors.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

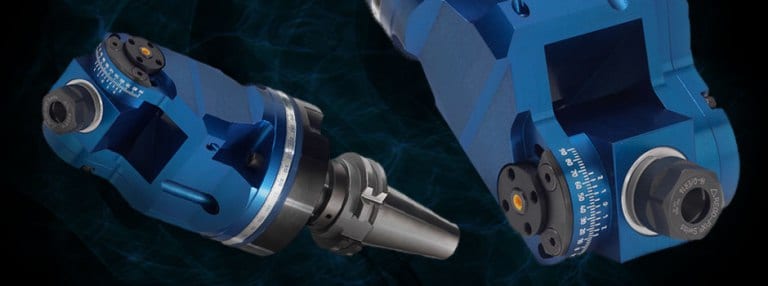

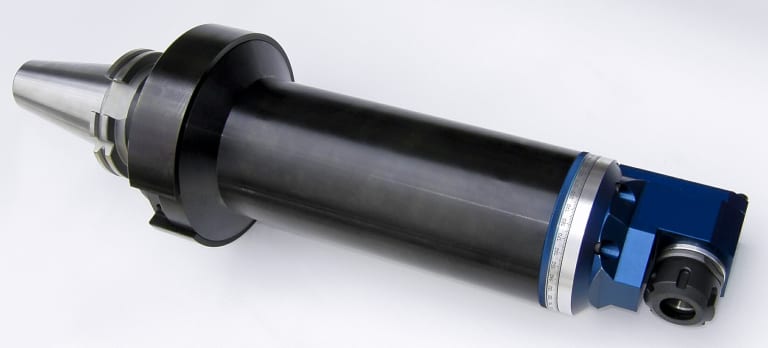

For best results in the machining of multiple material layers, cutting parameters must be applied for each different material. The new L-MAX, a portable drilling unit from SOMEX (a member of the SUHNER group of companies) can perform all of these functions in automatic mode.

Multiple material layers, also referred as Stacks, can be composed of completely different materials, stacked up in layers of, for ex ample: Titanium, Carbon or Aluminum. In order to achieve optimal machining results, each material layer must be programmed with its own cutting parameters- ideally for each layer automatically. The spindle speed and feed rate must be adapted for each material transition to the next.

In the past, aluminum was the primary choice of materials used in the aircraft industry and portable, handheld pneumatic-driven drilling units were used as a common tool in this industry.

The application of these conventional pneumatic drilling units in today’s modern and innovative aircraft industry necessitates extreme compromises. In addition to large air consumption combined with high noise emissions, pneumatic-driven drilling units cannot perform feed and speed variations as required for different stack materials.

Consequently, only a portable, handheld NC-programmable drill unit is capable to deliver optimal results and high efficiency, since the aircraft industry imposes rigid quality standards including:

– Concentricity / position between holes ≤ 40 μm

– Surface quality between Ra 1.6 und Ra 3.2

– Circularity / Hole quality for rivets ≤ H8

– Other requirements such as avoidance of delamination.

Working principle for a portable, handheld

NC-programmable L-MAX drilling unit

An L-MAX concept integrates 2 servo motors: The larger motor drives the spindle and the smaller servo regulates the feed. The feed rate is determined by the speed difference between ball screw and ball screw nut or, in other words:

– If the speed (rpm) of the feed servo motor is higher than the spindle motor speed (rpm), then the L-MAX spindle will advance.

– If the speed (rpm) of the feed servo motor is lower than the spindle motor speed (rpm), then the L-MAX spindle will retract.

Both servo motors are controlled by the control system IDM. It allows the user to regulate spindle speed and feed at any position of the total travel.

Furthermore, an adaptive drilling mode can be selected to help improve and optimize a drilling cycle. In this mode, the drill unit recognizes the transition from one layer to the next, automatically. Irregular material thickness of layers at any position are detected and matched with the correct cutting parameters. This way, cycle times can be minimized and machining quality and results optimized.

The control system includes a Minimum Quantity Lubrication (MQL) system, which is directly mounted to the mobile platform.

– Programmable spindle speed and spindle feed

– Work cycles such as chip brake cycle and peck feed cycle Spindle speed range from 3,000 rpm up to 5,000 rpm

– Drilling capacity from 4.76 mm (3/16”) up to 11.11 mm (7/16”)

– Integrated Minimum Quantity Lubrication (MQL)

– Light weight, depending on drilling capacity, from 5.5 kg (12lbs)

– Quiet operation up to 65 dBA

– Option: Adaptive drilling mode

SUHNER INDUSTRIAL PRODUCTS, CORP.

Hwy 411 S./Suhner Drive

P.O. Box 1234

Rome, GA 30162

Phone: 706-235-8046

Fax: 706-235-8045

Attention: Lee Coleman, Automation Division

www.suhner.com

automation.usa@suhner.com

Text and pictures files can be found and down loaded at:

www.suhner-press.com

Ann Arbor, Michigan – GMTA (German Machine Tools of America) represents various top-quality German metalworking machine builders, including Wera Profilator, K + G, Pittler, Praewema and WMZ, as well as Arnold lasers. These machines are sold to the North American market exclusively by GMTA, primarily for gear and spline production, as well as other power transmission and various metalworking applications. The company’s target markets include automotive, off-highway, energy and other heavy equipment manufacturing. Machines are provided for gear honing, gear grinding, the patented Scudding® process for gearmaking, polygon milling, turning, gear tooth pointing and multi-task machining operations, as well as various laser operations or laser line integration and parts washing. This newsletter is provided to our friends in the media to keep you and your readers updated on News of Note at GMTA.

In the news…

-GMTA participated in the annual Auto Show Charity Preview in Detroit and a good time was had by all.

-GMTA is running at “light speed” with their new Arnold laser work cells. Available as single or double work cells, the Arnold systems are offered as CO2 or fiber lasers, with full integration into a machining line, either by means of robotic part articulation or other automated transfer mechanisms, most of which are being supplied to customers by GMTA engineering. Leads from IMTS and the company’s aggressive ad program are already being developed into serious opportunities for the company, often in tandem with other machine tool lines and the Rosink parts washers now offered by GMTA.

-Recently, a Diskus vertical double-disc grinder was sold to Hoergiger Fine Stamping in Canada. The DDS 600 machine feature two vertically arranged motor spindles, each equipped with 600mm grinding wheels used for simultaneous two-sided grinding of shims. The machine has a rotary through-feed system and an integral post-process measuring system, all developed by Diskus engineering and provided to the customer by the GMTA teams from Ann Arbor.

-The Mexico office of GMTA is reporting brisk activity, owing to the substantial procurement authority in-country now. According to VP Scott Knoy, “This contrasts with bygone days, when the decision-making and purchasing were largely centered in America and specifically in Detroit. It’s a whole new ballgame with the Mexican market today and we believe our new location (Queretaro) there is well positioned to serve this dynamic manufacturing environment.” GMTA already has a substantial installed base of machines in Mexico from all their partner companies.

-GMTA management will be attending EMO in Milan with its partners, then exhibiting at Gear Expo, being held this year in Detroit, October 20-22.

-The alliance with Star, through which GMTA is sourcing tooling locally, continues to prosper and mutually benefit both companies.

-GMTA was featured prominently in a recent article in Manufacturing Engineering magazine, covering the subject of gear making for the energy sector.

-Now available from GMTA, the Präwema SynchroFine 205 HS gear honing machine features direct-driven, digitally controlled spindles for the tool and the workpiece, enabling precise, rigid synchronization. The Präwema Honing gear finishing process produces quality comparable to grinding results for spur and helical gears, as well as shafts. The machine’s software checks the stock allowance and workpiece runout and then optimizes the X-axis approach distance. Measuring the workpiece does not affect the cycle time and the process can reduce overall cycle times by 3 to 5 sec.

For more information on this announcement, please contact:

GMTA (German Machine Tools of America)

4630 Freedom Drive

Ann Arbor, MI 48108

Phone: 734-973-7800

Fax: 734-973-3053

Web: www.gmtamerica.com

Email: scott@gmtamerica.com

Attention: Scott Knoy, VP

Connect with GMTA online:

Large parts and one-off runs present particular challenges; common CNC platform offers many benefits to busy York, PA shop

Despite the large, heavy workpieces and frequent one-off production, Voith Hydro maintains a steady flow of work for its machining, typically holding +/- 0.002” tolerances on various carbon and stainless steels. Workpieces here often exceed 25’ in diameter.

Voith Hydro in York, Pennsylvania is a major manufacturer of hydroelectric power generation equipment, especially the intricate turbines used in such operations, supplying hydroelectric generating companies and municipalities throughout North America. Over 12,000 units have been commissioned in the field with more than 65,000 MW of installed capacity, plus Voith Hydro has also upgraded over 600 existing power generation units. As a turnkey supplier to the industry, the company manages all phases of power plant projects, from analysis and planning, design and implementation, to commissioning and operation. Voith Hydro is ISO 9001 and ISO 14001 Certified.

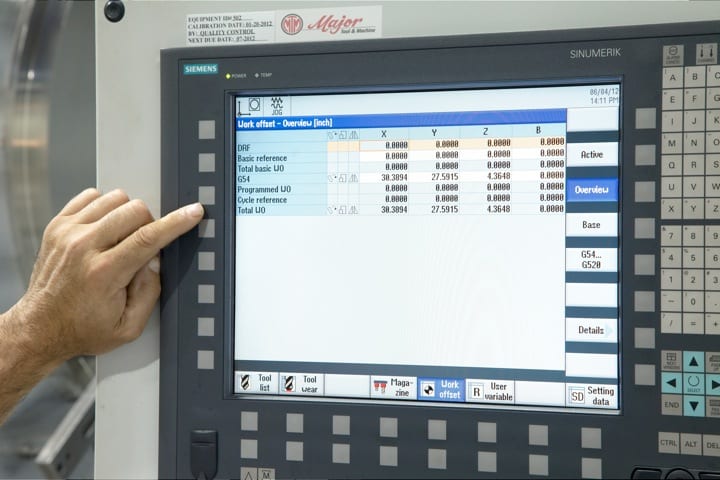

Milling, line boring and turning operations are performed on large multi-axis machine tools, most equipped with Siemens SINUMERIK 840D CNC onboard to control all axes of motion.

At the York facility, very large multi-axis machining centers produce carbon and stainless steel work pieces, most often in a one-off mode and at sizes frequently exceeding 35’ in diameter. Adam Ward, the manager of maintenance & facilities at Voith Hydro, says the machining done typically holds +/- 0.002” tolerances here, nonetheless. “We do turning, line boring and milling on extremely large and heavy work pieces that often challenge us to design the optimum machining cycle. Our long cycles can frequently result in heat distortion on material surfaces and so we take great care in looking for problems before they occur.”

Voith Hydro maintains an impressive array of machine tools and multi-axis machining centers here. Despite a variety of builder brands, the majority of the machines have one common component, namely, the Siemens SINUMERIK 840D CNC onboard.

Remote condition monitoring is performed between Voith Hydro and many of its machine tool builders to troubleshoot and resolve issues in real time, using the CNC on the machine.

As Ward notes, “Our operators are quite comfortable with the CNC from Siemens and they use it for all motion control, plus the operator interface has the ability to afford us great troubleshooting capability and something else we value greatly, the commonality of the HMI on the control. That fact allows us to do a great deal of cross-training and that’s very important to us. We need to be highly flexible, given the one-off nature of our work here.” Most of the operators at Voith Hydro are capable of running multiple machines, while the maintenance personnel on his team can more easily service the machining equipment in the facility, adds Ward. He credits his machine builders and the Siemens team led by Howard Weinstein and Robert Stiefel for this ongoing flexibility.

Part designs are run through the company’s CAM system and simulated offline to preserve machine uptime.

Voith typically takes a customer design, runs it through their CAM system and simulates the cycle offline, in order to preserve valuable machine uptime. Since the work here involves highly complex geometries on the turbine sections, the simulation must be equally complex and account for all machine motions and collision avoidance. Once the program is finally determined for a part, it is fed over the Voith Hydro network to the appropriate machine tool or machining center for scheduling and production startup.

During production, a system of real-time remote condition monitoring is available through the CNC for troubleshooting by both the Voith Hydro maintenance personnel and, when required, machine builder personnel, working offsite.

Large Ingersoll milling machine was retrofit recently, with all new Siemens CNC, motors, drives and other hardware.

Ward cites one example where an Ingersoll milling machine was completely retrofitted both mechanically and electrically by a Siemens Solution Partner, with a new CNC, motors, drives, encoders, other hardware and software. “Working with the builder and Siemens support personnel, we were able to resolve issues and implement changes to the programming, right on the CNC of the machine…and all done remotely, in a very short time period.”

Voith Hydro in York, PA produces a wide variety of power generation components for various machine builders and municipalities across America.

Voith Hydro boasts machining capabilities on workpieces over 42’ diameter and 350 tons at the York facility. Surface finishes are typically 250 and 125 Ra, though occasionally 64 or 32 Ra is required. The finishes are achieved through both machining and secondary finishing operations, according to company sources.

Adam Ward further notes that, on most new machines required at Voith Hydro, “The cross-training capability of the CNC, the standardization of the HMI on various types of machines, the support provided and the previous successes our operators and maintenance personnel have realized, all combine to make specifying Siemens as our control of choice an easy decision.”

Howard Weinstein, business development manager for the power industry manufacturing sector at Siemens, comments on the relationship with Voith, “We’re a proud partner to Voith Hydro in York, Pennsylvania. Their facility is a great showcase for our flagship CNC, the SINUMERIK 840D, as used on an array of multi-axis machining centers to produce large, complex geometry parts for the hydroelectric power industry.”

For more information on this story, please contact:

SIEMENS INDUSTRY, INC.

DRIVE TECHNOLOGIES – MOTION CONTROL (MACHINE TOOL BUSINESS)

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/cnc

Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communication

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

Others involved in this story may also be contacted:

Voith Hydro

760 East Berlin Road

York, PA 17408-8701

Phone: 717-792-7512

Web: www.voith.com

Email: adam.ward@voith.com

Adam Ward, Manager of Maintenance & Facilities

Workspace dimensions inside this unit measure 24” wide x 36” deep x 24” high. 24kW power is installed in Incoloy sheathed tubular heating elements. A 1000 CFM, 3/4 HP recirculating blower provides a front-to-back horizontal “universal” airflow to completely surround the workload.

This Grieve oven features 8” thick insulated walls, an aluminized steel interior and exterior, plus inner and outer door gaskets. The inner gasket seals directly against the door plug, while the other gasket seals directly against the front face of the oven for optimum seal integrity. The unit accommodates up to seven shelves on 3” centers.

Standard equipment includes a digital indicating temperature controller, manual reset excess temperature controller with separate heating element control contactors, a recirculating blower airflow safety switch and a UL Listed control panel, top-mounted to minimize floor space requirements.

All standard universal ovens by Grieve meet the requirements of National Fire Protection Association Standard 86, Industrial Risk Insurers, Factory Mutual and OSHA Standards.

This unit was entirely designed, engineered, built and full tested by Grieve.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

Guill Tool, a West Warwick, RI designer and builder of extrusion tooling, offers an assortment of literature for machine builders and extruders at its website, www.guill.com.

Individual brochures are offered, depicting the wide array of tooling possibilities…straight inline heads, rotary heads and crosshead dies…available to suit any extrusion machine built anywhere in the world, running all types of compounds.

Guill provides tooling for plastic, rubber, TPE and other material extrusions, with end products ranging from extremely thin-walled, multi-lumen medical tubing and catheter balloon tubings up to multi-layer wire & cable jacketing and 20” diameter pipe for industrial applications and agricultural drip lines. Guill also provides tooling for film, sheet and profile extrusions.

The company designs, engineers, machines, assembles, tests and delivers all tooling to its worldwide customer base in all the consuming industries for extrusions. The company also offers tooling carts and disassembly/cleaning stations for easier line integration.

According to company sources, the utilization of properly designed and engineered tooling can result in substantial material savings for extruders of all types.

NOTE: Guill will attend MD&M West in February, NPE in March and Interwire in April, 2015.

Please visit www.guill.com to request a quotation or obtain company literature.

For further information, please contact:

GUILL TOOL & ENGINEERING CO., INC.

10 Pike Street

West Warwick, RI 02893

Phone: 401-828-7600

Web: www.guill.com

Email: sales@guill.com

Attention: Bill Conley

Connect with Guill Tool online:

Longtime market leader in all-electric injection presses NIIGATA will introduce two new machines to the market at the upcoming NPE in Orlando, March 23-27.

Visit NIIGATA at NPE Orlando, Booth W-1363, March 23rd-27th with a free guest pass.

NEW: NIIGATA all-electric MDVR110S7000 (Vertical IMM with 2-station rotary table)

NIIGATA introduced the world’s first all-electric vertical IMM in 1996 and its latest model, the S7000, capitalizes on NIIGATA’s long history and 100% focus on making all-electric machines.

Highlights of the new MDVR110S7000 include:

~While many vertical machines have high table heights, forcing the customer to build a work platform around the machine, the NIIGATA patented vertical toggle system allows lowering the table height on this 110-ton model to just 3.4 feet from the ground, including leveling pads.

~The machine has a wider table than standard verticals, allowing larger molds to be placed on the platen. The MDVR110S7000 boasts a mold size capacity of 500mm x 500mm (33.64” x 33.64”).

~Fast table rotation of under 1 second.

~Ultra low-speed injection can be beneficial in molding thicker walled insert jobs. NIIGATA boasts an ultra low-speed capability of just .01 mm/sec injection speed.

~With a 2-station machine running separate “A” and “B” mold halves, a molder can often encounter problems with differences in mold halves causing part variations. With the NIIGATA Vertical, two completely independent injection profiles can be set for the “A” and “B” halves, allowing the molder to finish the job without making expensive and time consuming mold repairs or adjustments.

NEW: NIIGATA MD110S7000 horizontal all-electric IMM

Having introduced our first fully-electric machine at the Japan Plastics Fair in 1984, NIIGATA has devoted 100% of its R&D resources toward improving all-electric molding machine technology. Using the Japanese Kaizen system, we are now introducing our 7th generation of the all-electric machine, built entirely in Japan to tough quality standards.

A few NEW features of the MD110S7000 all-electric IMM include:

~Elimination of moving platen’s lower side tie bar bushings to improve the cleanliness of the part drop area.

~Addition of an FDA-approved grease supply system that allows medical cleanroom and food grade applications with fewer worries about part contamination.

~NIIGATA’s standard high nozzle touch force, similar to that of the hydraulic machines, can now be dialed down when the application allows, to promote longer sprue bushing life.

~Fully automatic and adjustable mold clamping force is continuously monitored by tie bar sensors.

~NIIGATA’s horizontal machines boast the industry’s shortest footprint, but heaviest overall weight to provide superior machine durability.

Also in the Niigata booth…

NIIGATA MD385W6000 all-electric IMM:

NIIGATA’s “workhorse machine”, the MD385 is being exhibited running a drink cup mold provided by a customer, together with an impressive IN-MOLD LABELING SYSTEM manufactured by Campetella of Italy. See and learn more about the MD385 HERE and at the show!

Also running during the show…

NIIGATA MD55S6000 all-electric IMM:

NIIGATA’s small size all-electric press will be exhibited at the booth of LUBE Corp. USA ( #W-2389). This machine will have clear covers, highlighting the automatic lube system of the machine. ( http://lube-global.com/english/)

Don’t forget! NPE, Booth W-1363

For more information on all these developments, please contact:

Peter Gardner

Vice President Sales and General Manager

NIIGATA Operations North America

DJA Global Group

939 AEC Drive

Wood Dale, IL 60191

Phone: 630.875.0202

Fax: 630.361.6060

E-mail: peter.gardner@niigata-us.com

Website: niigata-us.com

Connect with NIIGATA online:

No. 975 is a 1250ºF (676ºC), electrically-heated cabinet oven from Grieve, currently used for heating metal parts to remove deposits at the customer’s facility. Workspace dimensions of this oven measure 50” W x 50” D x 50” H. 160 kW are installed in Incoloy-sheathed tubular elements to heat the oven chamber, while a 6000 CFM, 5 HP recirculating blower provides horizontal airflow to the workload.

This Grieve cabinet oven features 10” insulated walls comprising 2” of 1900ºF block insulation and 8” of 10 lb/cf density rockwool insulation, top-mounted heating chamber, aluminized steel exterior, Type 304, 2B stainless steel interior and all safety equipment required for handling flammable solvents, including explosion-venting door hardware. The insulated floor of the oven is reinforced for 1000 lb. loading with a 1/4” thick, Type 304 stainless steel plate.

No. 975 controls include a digital indicating temperature controller and manual reset excess temperature controller with separate contactors.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

Major Tool & Machine, Inc. retrofitted two of their machining centers in 2010 changing to a CNC technology platform that was completely new to the company. Ten more such large-scale retrofits have followed, bringing increased enthusiasm, momentum and productivity.

Major Tool & Machine has been on track to retrofit over a dozen of its giant milling and turning machines within just two years, all supported by a new Siemens CNC platform. MTM’s management says the process has been an empowering experience for the company.

CNC upgrade enhances performance and precision

Major Tool & Machine (MTM) is a large job shop, producing precision milled and turned hardware throughout the company’s 500,000 square foot Indiana facility. Performance is essential, because MTM contracts with aerospace, energy, nuclear and defense companies on many mission-critical, one-off projects. Owner and CEO Steve Weyreter will tell you openly, MTM is more competitive by way of a significant CNC technology change, starting with an aggressive retrofit strategy.

Günther Zimmermann, CNC Controls Engineer at MTM, says the company’s retrofit program and the decision to change to the Siemens SINUMERIK CNC platform have brought a new enthusiasm and momentum to the company. Over the last two years the change has also brought significant time and cost reductions, especially in the areas of programming, maintenance engineering, and machine operations.

“The initial goal in early 2010 was to retrofit two Cincinnati U5 Gantry machines,” Zimmermann recounts. “We evaluated two CNC technology platforms and after considerable analysis our CEO Steve Weyreter announced that Siemens would best support the company’s future.”

The decision to reduce costs by moving to a single CNC platform was the least difficult decision for the company to make, Zimmermann explains. The larger challenge for MTM was the integration of a new CNC technology platform that was new to the company.

Bill Henderson, MTM’s manager of large machining and maintenance, agrees that the decision to change to a Siemens CNC platform integrated with advanced part and tool probing was critical, because the shop manages constant changeovers from one complex job to the next, making setup times a critical time/cost constraint for the company. Another big advantage is the increased flexibility by only having to train machinists and maintenance personnel on one type of control.

Henderson went on to say “the decision to change to a new control has signaled higher expectations for the company, along with new challenges for those who program, operate and maintain the company’s big machines.

Naturally, there’s a resistance to change,” Henderson says. “People are comfortable with what they normally run, but after our discussions with the people on the plant floor, they understood the overall objective. Our retrofit program is not finished, yet it’s already showing tremendous benefits.”

An advantage MTM gained by its retrofit strategy has been the ability to interchange heads and rotary tables from machine to machine. Easy-to- use head storage and tool management programming provided by the Siemens CNC platform support the new interchange capability.

Retrofitter Doug Huber says having Siemens as a new CNC technology partner has made a difference for Major Tool & Machine, but it’s also been an evolutionary uplift for his own retrofitting company, Indiana Automation.

“Indiana Automation has increasingly retrofit using Siemens controls in recent years, Huber explains. “On a retrofit, we always try to exceed what the original machine could do, and that’s just kind of inherent when you put on a Siemens 840D. Major Tool’s first retrofits were the Cincinnati U5 machines, a bridge model and two gantry models. These are five-axis machines and five-axis is the 840D’s forte. The processing power of the control is so much better, that it just whips through the blocks faster. So right off, cycle time is a major performance enhancement.”

Huber says something else happened this time. As his firm finished retrofitting the first three giant machines with Siemens five-axis controls, drives and motors, the reaction within the company was not just that the machines were now predictably more efficient, but that they performed as very different machines. A new advantage is the ability to interchange machining heads from machine-to-machine, and all driven by the Siemens CNC platform.

Central to MTM’s retrofit program has been the Siemens SINUMERIK 840D sl control, which features the SINUMERIK Operate interface. The highly intuitive interface enables both programmers and operators to easily capitalize on the broad capabilities of the control.

“On many of the U5 machines, the axes come off with the heads,” Huber explains, “and we rebuilt these machines to accept any one of three different heads. That’s one of Major Tool’s key strategies. They insist on having flexible machine capabilities, so that they can run all kinds of different parts. They have straight heads for serious metal cutting, contour heads for five-axis work and finesse work. They have 90-degree heads for more flexibility than a straight head, but it’s also not as fragile as the contour head. And they wanted to interchange all of these heads to automatically go pick up a head out of the shuttle and, on the fly, reconfigure the axes and the zero positions. To do this, the compensation tables all had to be updated. Everything needed to be done with the macro program so that each head came on ready to run.”

The interchangeable head strategy was a challenge, Huber says, because the machines were not originally capable of sharing heads. But with support from Siemens, the strategy has worked, including the ability to interchange rotary tables as well as heads. “Each head or rotary table has a configuration file that has all the settings and compensations and travels with it from machine to machine. So now when you mount that head the control just runs the configuration file that goes with it and its all set up for you. We also incorporated Siemens Tool Management for each machine’s 60-pocket tool chain. We used the feature on these machines to manage all the different tooling MTM uses, both in the automatic tool changer as well as the ones manually loaded.”

Huber says, “MTM’s ability to smoothly transition to more advanced CNC is largely due to the HMI’s ease of use. The Operate interface is a huge help to us and to Major Tool. The HMI helps make better parts. And it didn’t take very long for the operators to fall in love with it.”

Programming as easy as 1-2-3: Using the SINUMERIK Operate interface, a machinist can turn on coolant flow by 1) pressing Cycle Stop to stop the machine, 2) Coolant On, and 3) Restart.

“I had never used a Siemens control before,” admits MTM machinist Mike Burthay. “I have extensive knowledge of G-code and CNC controls and I would say the Siemens 840D sl with the Operate interface is the easiest one I’ve ever run. It’s user friendly, that’s exactly the words for it.”

Burthay reports several ways in which the Siemens SINUMERIK Operate interface has made his life easier. “There’s not as much G-code,” he says. “The control does it all for you as long as you put in the parameters as to size, length, width. Then once you’re in Job Mode, there’s a screen where you can tool change or jog the machine around to certain positions, or turn the spindle on, turn the coolant on, anything that traditionally required G-code. So now you can push a cycle stop button to pause the machine, enter a change such as turning coolant on, then restart the program.

“Another function I love is Block Search, which allows me to start or restart right in the middle of a program. Say you’re finishing a pocket and you have to run the tool two or three times to get a tight tolerance, I can enter in a line number and hit Block Search, the control picks up every line before that, restarts the spindle and everything for you.”

Burthay says the Siemens control also enables him to program parts right on the machine whenever necessary, using a simple yet robust program called ShopMill. “I can go into ShopMill, type in some parameters and it will kick out that G-code program for me automatically. Say I want to drill a hole two inches deep. I open ShopMill, pick my tool, tell it the depth and these steps are all interactive on the screen. It even shows me 3D motion images of the tool path, confirms the drill going down as expected into the part. So I hit go and it puts a drill cycle into the program for me.”

Programmed for collaborative growth

Lead Programmer, Tim Hayden, has from the beginning conducted all processor setups for the newly retrofitted machines. Hayden says integrating the Siemens CNC platform has been an empowering experience he had not expected, given the fact that he had never before set up a post processor to run a Siemens control, nor had he ever before operated a Siemens control.

“Now, when I look at the Siemens control, I think man, it would have been so much better to have had it all along,” Hayden says, “because the other control I’ve been using is just a lot more cryptic. The Siemens control with the SINUMERIK Operate interface is more powerful for writing macros and the language seems modern, whereas the other control seems like it is still based on an old FORTRAN type language.”

Work offsets for compound angles can be scaled and rotated using the Frames function of the Siemens SINUMERIK Operate interface. Many advanced machining operations can be managed simply, without the use of time-intensive manual G-code programming.

Hayden points to the Frames coordinate and offset programming function of the Siemens interface as an example of improved programming convenience.

“We do a lot of work on compound angles,” Hayden explains, “and with the Siemens Frames function, you can scale and rotate your coordinate system on the control, just plug it in with your work offsets. Whereas, on the other control you will see a G54 request, you’ve got to enter G-code. You can’t just plug it into your work offsets like you can with the Siemens control.”

Hayden says the SINUMERIK Operate interface brings greater programming flexibility. The HMI enables him to enter G-code using a comparatively more advanced manual data entry (MDI) function; however the HMI has all but eliminated the need for G-code entry by way of its intuitive design and evolved capabilities.

Another example of such HMI evolution is in the area of data management.

“When we post a program, we no longer have to use a G-code based MDI,” Hayden explains. “We no longer need to type in T= and enter a nine digit number and then enter M6 to make a tool change. With the Operate HMI, you pick your tool off a screen and hit cycle start. It’s just as easy to program going to a position. Instead of doing things the old way by typing G0X0Y0Z0 into the MDI, you open the Operate interface, click position, then click how you want to wrap it and then you just type the numbers into those fields. So it’s a lot more user friendly.”

Hayden says the Siemens CNC platform has supported greater collaboration at MTM between him and the machinists, and this is helping the company find ways to increase performance and efficiency. He agrees with his coworkers’ assessments that shorter setup times and greater operator freedom are making a significant difference.

“One of our production bottlenecks has been programming,” Hayden says. “The machinists that run our machines are professionals, they’re not button pushers, and with the SINUMERIK Operate interface, we can now rely on them to control and program certain parts right on their machines, while we programmers work on the more complex projects.”

“Siemens was the best fit for all of us,” Hayden concludes. “Siemens CNC is set up as an open control, and with that kind of flexibility, it seems anything is possible.”

For more information on Siemens SINUMERIK CNC, visit www.usa.siemens.com/cnc.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Remember when IMTS 2014 announced their photo contest and we submitted this scrumptious morsel of photography?? For #TBT, I’d like to pay tribute to this delicious day in Bernard & Company history: “Chicago’s Favorites” featuring Bernard & Company, IMTS, Portillo’s Chicago-Style Hot Dogs/Fries and Italian Beef Sandwiches, Lou Malnati’s Deep Dish Pizza and Garrett’s Chicago Mix Popcorn.

(Original Tweet here)

(Original Tweet here)

Keep warm and keep having fun, manufacturing world!

– n

Continue reading