Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Different technology modules for different workpieces

This guarantees flexibility in the use of the machine and opens up a wide range of applications, especially as all the technologies can be applied also in combination.

VTC production lines

The VTC 315 DS is ideally suited for complex manufacturing processes. Whether the job includes the high metal removal rates of turning and milling or the gentler grinding process – the VTC series of machines offers the possibility to integrate most of the metal cutting processes. This allows for the creation of complete VTC production lines for soft and hard machining. Turning, milling, drilling, grinding and gear hobbing have already been modularised for this particular machine platform. It provides the VTC with an extensive field of application. “We have already installed complete production lines of VTC machines for the soft machining of crankshafts. Almost all of the operations could be accommodated on machines from the VTC series”, this is how Markus Woitsch, chief of the production team for shaft machines, explains the production line concept of the VTC. Naturally, subjects like spare part stocks and unified machine operation also play a decisive role in the eye of the customer. With a production line that interlinks a number of different VTC machines and utilises different manufacturing technologies, spare part stocks can be drastically reduced, as 80% of the VTC machine components are the same. Only the technology modules change, when a VTC has to be adapted for a new machining requirement.

Complete-machining through technology combination

The VTC 315 DS accommodates turning as well as grinding technologies. For example, the turret carries out all turning operations, while the second station is used for the grinding work. This way, shafts can be complete-machined: the cylindrical bearing seats, the shoulders and the grooves – all machined in a single set-up. “Clamping errors play a particularly important part when it comes to high-performance components. Radial runout can be much reduced when a workpiece does not have to be re-clamped several few times”, elucidates Dr. Guido Hegener on the quality of the machine. To keep downtimes caused by tool changes to a minimum, sister tooling is provided for all turning operations. And the tool life of grinding wheels is so high that the time taken up by a wheel change is of no consequence.

The VTC 315 DS design

A distinguishing feature of the VTC 315 DS is its sturdiness and rigidity. At its heart is the machine base in Mineralit® (polymer granite). The damping properties of this material is 8 times that of grey cast iron, which makes it particularly well suited for hard machining operations like grinding or hard turning. The results are improved tool life and a better surface finish. The vertical design also aids unhindered chip flow. Manual removal of chips is hardly ever necessary. This is particularly important in soft machining, as it often involves volume-intensive chipping operations. The vertical construction is also of advantage where the footprint is concerned. Machines with horizontal spindle and tailstock take up a lot of space width-ways. That raises floor space requirements and costs money. Vertical machines develop upwards, and that – as we know – costs nothing. Automation on the VC 315 DS lies in the turret. A gripper, housed in the turret, collects the raw-part from its storage section and transfers it to the clamping position. Once the workpiece is machined, it is transferred out of the machine the same way. And thus the machine automates itself. The generously dimensioned machine assemblies, such as the work spindle with 330 Nm constant torque, and the grinding spindle with a power rating of 30 kW, have so much reserve capacity that even heavy metal removal work can be carried out on the machine. The control system used is a Siemens 840 D with EMAG grinding software that simplifies programming and operation.

The advantages of the VTC 315 DS:

For more information:

EMAG LLC

38800 Grand River Avenue

Farmington Hills, MI 48335

Tel: (248) 875-0313

Fax: (248) 477-7784

E-mail: info@usa.emag.com

Web: www.emag.com

Attention: Peter Loetzner

Kastalon offers mills and processors highly engineered polyurethane mandrel sleeves, filler plates and filler rings with material hardness and surface options to match customer needs, protecting coils from damage

Kastalon brings 50 years experience in coil processing to the task of engineering a new offering of application-specific, proprietary formulated polyurethane mandrel sleeves, filler rings and filler plates. These products are designed to adapt the mandrel to handle coils with larger ID’s and addresses the problems of damage from creasing, scratching and marring at mills, service centers, toll processors and fabricators alike. Such damage is expensive for any coil handling operation, especially when the metal is prepainted or must maintain optimum cosmetic surface integrity. By the use of Kastalon mandrel sleeves, filler rings or filler plates on the uncoiler or recoiler, the inside wraps on coils are protected from metal to metal contact. More finished material is produced or usable, as a result.

Mandrel sleeves are custom designed with engineered surface hardnesses and grooved or smooth finishes, depending on the particular application. Full sleeves are usually recommended for the recoilers, while filler rings and filler plates are more often utilized for uncoilers.

The design process begins at the company website, where a detailed needs-assessment questionnaire can be completed, followed by a discussion with Kastalon engineering to formulate the proper chemistry, surface and material hardness for the application.

In use, the proprietary chemistry of the Kastalon Polyurethane material withstands the stress caused by the weight of the coil, then reforms when the mandrel is collapsed back to the rest position, owing to the inherent memory of the Kastalon engineered material. With other materials now on the market, sleeves will often sag due to memory loss and the resulting gap can cause significant coil damage. Correspondingly, additional labor and line downtime result from this condition, as realignment of the coil, sleeve and mandrel is needed. Through the true and precise sizing of the mandrel sleeve, combined with the proper material hardness and surface texturing, a Kastalon sleeve can last up to 10 times longer than rubber, fiber or even other commodity type polyurethane products, according to company research, available on request.

Mandrel sleeves, filler rings and filler plates allow coil processing to be accomplished more efficiently, whether on uncoil or recoil reels, at mills, service centers, toll processors and fabricators.

Kastalon mandrel sleeves are non-marring, cut-resistant, abrasion-resistant and offered for friction fit, requiring a separate “keeper”, or bolt-on installation. Company engineers consult customers on the amount of lubricant, cleaning solution or other coating chemistries present in the process, as this will determine the particular formulation selected. Furthermore, Kastalon offers these mandrel sleeves in a wide variety of grooved or soft surface finishes to meet the specific tension and pressure requirements of a processor’s uncoil/recoil apparatus. Special dual-durometer sleeves are also available for mills and processors where “head-in” damage is often encountered.

For most uncoilers, Kastalon filler rings or filler plates can provide the optimum performance for the tension, pressure and metal contact requirements typically present.

The design process for Kastalon mandrel sleeves can begin with a visit to the company’s website, www.kastalon.com, for completion of a needs assessment questionnaire. Detailed information is gathered on this form, allowing the Kastalon engineers to calculate the best sleeve design and chemical composition to suit the job.

For more information on this product, please contact:

KASTALON, INC.

4100 W. 124th Place

Alsip, IL 60803

Phone: 708-389-2210

Fax: 708-389-0432

Web: www.kastalon.com

Email: sales@kastalon.com

Attention: Marty Pokorney

Tessy Plastics uses virtual process development software to simulate the entire injection molding process before production, enabling them to expand their global presence while finding the most cost-effective and high-quality manufacturing solutions.

Tessy Plastics was founded by Henry Beck in 1973 and is headquartered in Central New York with facilities in Virginia and China. Tessy is constantly expanding their global presence in order to find the most cost-effective and high-quality manufacturing solutions. Producing everything from intricate medical devices to everyday consumer items, Tessy strives to engineer, manufacture, assemble and distribute products in the most effective and profitable way possible for their customers. As a family-owned and operated, privately held company, Tessy positions themselves as their customer’s manufacturing partner, taking ownership and a proactive approach on every project they encounter.

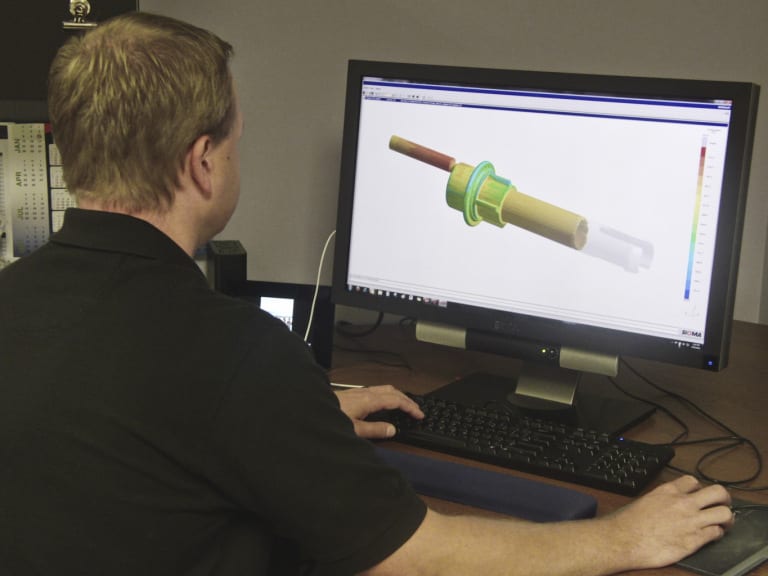

Stafford Frearson, Project Engineer at Tessy Plastics, works on a project using SIGMASOFT at Tessy Plastics in Elbridge, NY.

Servicing the medical, consumer products, business machines, electronic and packaging markets, Tessy partners with their customers from the design stage all the way through product completion. Enabling them to provide their customers a full service experience, Tessy offers additional services including ultrasonic, vibration or laser welding, hot stamp/hot decal, pad printing, laser engraving, or label application printing, manual, semi-automated, fully automated or cleanroom assembly. Finishing options include gluing/bonding, machining/drilling, contact insertion, as well as, high-speed fluid dispensing or ultrasonic dispensing. Tessy also provides leak, burst, dielectric, electric, optical, rheological and spectrophotometer testing. As part of their partnership, Tessy holds themselves 100% accountable for quality assurance.

Proud of their “Commitment to Innovation,” Tessy is in constant evolution creating an atmosphere of growth and discovery. Joe Raffa, VP and General Manager in charge of sales, says, “Using our engineering department, our goal is to continually explore and implement new ways to enable our customers to significantly evolve their business in the most cost effective, lean manner .” Tessy is keeping the injection molding process on the cutting edge of technology by having the capability to evaluate the entire process virtually before sample runs are even attempted on the shop floor. Eric Frearson, VP of Engineering, states, “We have some very complex parts that we manufacture as well as complex molds. Acquiring SIGMASOFT® about two years ago to virtually run the entire mold and process before using production time changed the way we do business. This enables us to understand and find solutions to significant problems that, in some cases, we have been working on for a long time,. We are now pointed in the right direction and shown the precise areas we need to focus on to create a solution, thanks to this process optimization software package.”

At Tessy, the members of the sales team have engineering backgrounds while the engineering team is heavily involved in building, developing and maintaining customer relationships. The sales team boasts trying to commit the engineers to projects that are almost impossible while the engineers welcome the challenge and come up with ways to make them happen. Raffa explains, “With SIGMASOFT® onboard, we are able to commit to these almost impossible jobs. I know that when the customer poses new projects to us, I can go to engineering and talk about warp analysis or filling analysis and whether or not a project is even feasible. Once getting that confirmation after running the process virtually, I have the confidence to commit to a project, knowing that the information we received from the simulated run will reflect reality at least 98% of the time.” Matt Learo, Sales Manager, adds, “We had an existing customer where the materials they were using were discontinued. The customer called and requested that their new material and new tool be run through SIGMASOFT® specifically, to see how the new material was going to behave.” Stafford Frearson, Project Engineer expands, “The more complicated a project is and the more complex a configuration might be, when we are not sure how it might warp or how it might fill, there’s no question we feel more confident in going to the customer and saying, ‘this is what you are going to see’, when we have the report backing us up.” “We use other simulation software, but when the part is complex and on our harder jobs, we always run them through SIGMASOFT®,” Eric Frearson adds.

Tessy has used simulation software for over 20 years but feels adding SIGMASOFT® as one of their resources significantly changed the way they do business. Raffa told of a situation that occurred within the first few months after acquiring the new software. Most new projects Tessy acquires are first-time molded products. In most cases, Tessy helps design the part as well as the molds. Normally, all the components in the assembly are new designs. In one particular instance that Raffa described, the customer wanted to take new components and marry them to old components for a different look in the end product. Tessy learned by examining the way some of the wall thicknesses had to be designed and the way the assembly had to come together through simulation that it wasn’t optimal and the new design would simply not work. The parts that were being received from the prototype molds found warp that Tessy had never seen on these types of projects previously. The customer requested a stress and distortion analysis from an engineering company, costing them thousands of dollars, in addition to taking considerable time. Although the engineering company did provide some results and recommendations, the evidence to support these recommendations was not provided.

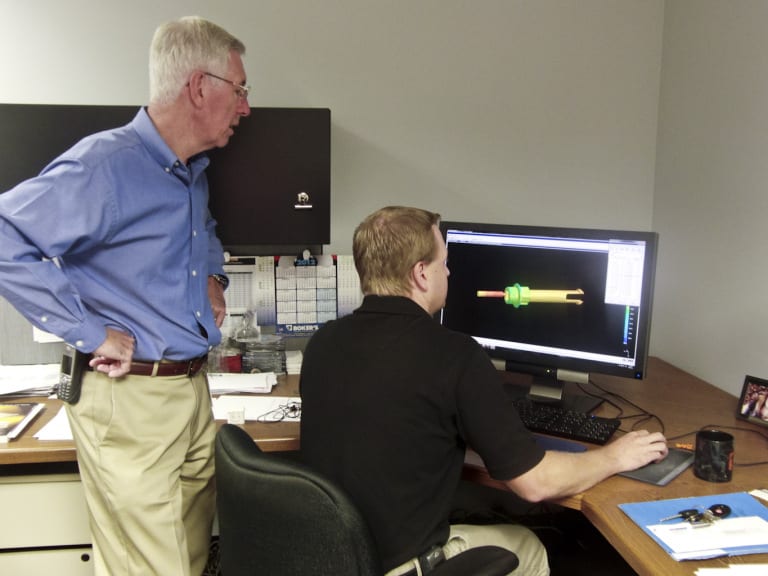

Eric Frearson, Vice President of Engineering, Tessy Plastic (Left) and Stafford Frearson, Project Engineer at Tessy Plastics, discuss a SIGMASOFT screen at Tessy Plastics in Elbridge, NY.

This became the first large project on which Tessy used SIGMASOFT®. By running multiple processes and cooling times and looking at iterations even 24-48 hours later to see how the part was going to react, it was clearly seen when pulling up snapshots and data during certain points through the process what the issue was. Tessy was able to see the part, how it cooled outside of the mold, how it flexed and how it actually got to the state where it was warped. Eric Frearson said, “It gave us evidence to show the customer that no amount of cooling changes or process changes had any effect on the problem. It was purely a design change that was needed to fix the problem. The reports provided by the software gave us the credibility and the client the reassurance to make the changes.” Raffa adds, “It essentially short cut the entire process, we didn’t try running DOEs of all different configurations or measured a ton more parts to chase something that was really not the solution.” Learo also states, “What’s reassuring about this situation was that we hadn’t used SIGMASOFT® for very long at this point and the customer was willing to pay for the stress and distortion analysis from the engineering company and see how the results compared. We found the results long before the engineering company did. When we did receive their findings, they were the same. The difference was, we were able to show why it happened and already had a solution to present our customer.” Eric Frearson adds, “Even the engineer running the analysis at the independent company was impressed. He is an experienced analyst who regularly uses a different product.”

Tessy uses virtual scientific injection molding almost exclusively, enabling their customers to save time, material and money by doing virtual studies in order to predict molding parameters. The addition of this valuable tool enables them to focus on what the final process would be. “We can now say with a very high degree of certainty what the cycle times will be and what issues we might have, before manufacturing ever sees the tool. We weren’t able to say that before having SIGMASOFT®,” Raffa said. Tessy also sees an impact of the software on manufacturing, by helping validate the process before a mold is cut. Learo adds, “We are able to give the process technicians better process parameters before we even see the mold.”

Matt Proske, Vice President, SIGMA Plastic Services (Left) and Stafford Frearson, Project Engineer at Tessy Plastics, have a conversation at Tessy Plastics in Elbridge, NY.

Giving credit to their “Commitment to Innovation,” Tessy is experiencing record growth and expansion in their business, even in these unstable economic times. The implementation of innovative technologies continues to not only ensure profitability, but also contributes to its employees’ ability to further their careers, providing opportunities for advancement on multiple levels. Being part of an industry that is constantly evolving, the leadership at Tessy keeps encouraging their team to reach the highest standards and quality deliverables, which in the market drives all plastic molders to move forward and continue to reach out for new and more efficient ways of serving their customers. It is Tessy’s goal to strive for the most cost-effective, time-saving solutions to ensure quality products for its partners.

For more information, contact:

Matt Proske

Vice President

SIGMA Plastic Services, Inc.

10 N. Martingale Road, Suite 425

Schaumburg, IL 60173

Phone: 847-558-5602

Email: contact@3dsigma.com

Web: www.3dsigma.com

Press Conference for the Americas — EMO Hannover / Hall 25, booth D33

Industrial corporations are facing deep-rooted changes in the world of manufacturing. These changes are taking place alongside increasing integration of product development and production processes with the benefit of innovative software systems and high-performance software — a decisive step on the road toward a new industrial age in manufacturing. “Siemens has invested a lot of work in the integration of automation technology along the entire value chain over a period of many years, and is playing a cutting-edge role in shaping the future of production,” stated Bernd Heuchemer, Vice-President, Global Marketing and Communications, Siemens AG, Drive Technologies Division, Motion Control Systems Business, at a press conference held in the run-up to the EMO 2013 recently. “In the Sinumerik environment in particular, and consequently in the field of CNC production in general, Siemens has been heavily involved for many years already in the area of simulation and the virtual machine, as well as the integration into factory IT systems. Our aim is to drive this process of integration forward to ensure that the field of machine tool construction is also prepared to embrace the next step in the industrial revolution,” continued Heuchemer.

With its Sinumerik family, Siemens offers an integral portfolio of CNC for everything from simple machine tools through standardized machine concepts to modular premium solutions, complete with “smart machine” solutions for the economical manufacture of high-end workpieces. It is working towards the consistent expansion of this CNC technology expertise. “In the future, production models will demand ever greater productivity, flexibility and efficiency, while at the same time expecting simplified machine operation and production sequences. As it continues to develop the Sinumerik CNC portfolio, Siemens is working to satisfy all these expectations,” said Rajas Sukthankar, General Manager, Siemens Industry, Inc., Machine Tool Systems Business. The innovations presented by Siemens at the EMO 2013 will consequently focus on smart function improvements, which will make for greater CNC operating convenience, increase precision at the workpiece and allow greater machining safety across every category of machine, from the compact to the high-end solution. A new function to protect against unwanted component collisions will be showcased by Siemens, for example, alongside improvements to its cohesive Sinumerik Operate user interface, including upgraded simulation options.

The Sinumerik CNC portfolio is additionally playing an increasingly important role in preparing the ground for the next step in the evolution of CNC production, also within the framework of the Siemens Integrated Drive System (IDS). With a view to optimizing the addition of value across the entire process chain through consistent integration, IDS is used to integrate all the components of the drive train consistently into the complete production process environment. This also applies to Sinumerik CNC system solutions.

For every Sinumerik application, ideally coordinated system components such as high-powered Sinamics drives and Simotics motors have always been used as the ideal complements. Alongside horizontal integration of the entire drive train, with Sinumerik Integrate for Production, Siemens is also allowing vertical integration within the control architecture of industrial manufacturing automation. As the example of a leading passenger car manufacturer illustrates, this type of vertical and horizontal integration within the production process can speed up the series start for a new vehicle by up to 50 percent.

The integration across the entire product life cycle can in turn be implemented using suitable Product Lifecyle Management (PLM) software solutions from Siemens. This concept is already being implemented by leading metals processing industries such as the automotive, aerospace and medical technology sectors. This entails the increasing execution of product development and production planning onscreen, before a single machine tool has even been installed. If a modular machine is developed on a virtual basis right from the outset so that it can be fully simulated, time savings up to 40 percent can be achieved. In running operation, productivity increases of 10 percent or more are also made possible by continued simulation and optimization. At this year’s EMO, Siemens will be showcasing the further development of its PLM software, which encompasses scalable solutions for component production and further improved IT integration from the workpiece model through to the machine tool. Siemens will also be revealing the next stage in productivity for NC programming with the further development of its already popular PLM software, NX CAM. Going forward, this software will include special industry-specific machining functions as well as access to a new Manufacturing Resource Library.

For more information on Siemens SINUMERIK CNC, visit www.usa.siemens.com/cnc.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Follow us on Facebook: www.facebook.com/SiemensCNC

or Twitter: www.twitter.com/siemens_cnc_us

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Brazilian steel giant Usiminas recently introduced the new foundry core making simulation software MAGMASOFT® as part of their strategy to establish robust designs and processes for their core production line. The first project on which this software was utilized was already in progress at that time.

The main goal was to optimize the process conditions for the existing tooling layout. This core, called the thin waist core, represents some of the biggest challenges for Usiminas core production: its length (920 mm), substantial changes in the sand flow direction during blowing, the need to fill certain parts of the core through counter-flow and big variations in the cross section within the core.

First trials showed problems with the process, which led to a complete collapse of the lower part of the core. The core blowing and curing steps for the PU coldbox process were analyzed, making it possible to draw preliminary conclusions regarding the existing defects.

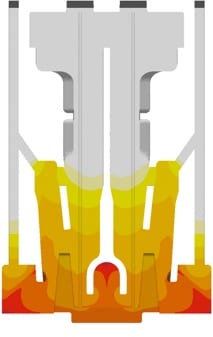

Figure 2. Curing Gas Concentration. The curing gas does not penetrate into the core to the same extent everywhere.

The lack of core strength was related to a poor curing process. The first simulation (Figure 2) already showed that the problematic regions experienced only very low curing gas concentrations during gassing, which was the root cause for the failure.

On the production line, various process conditions such as the curing and purging times and gassing pressure were changed. These attempts provided better results (Figure 3). However, a perfect core could still not be produced. The further analysis with MAGMASOFT® focused on the evaluation of the local concentration of adsorbed curing gas, as it shows the regions where the catalyzing gassing agent cannot activate the chemical reaction. This result clearly demonstrated that only a very small quantity of catalyst was available for accelerating curing in the defect regions (Figure 3).

Figure 3. Core Blown with new parameters in comparison with the local concentration of adsorbed curing gas. The problematic area corresponds exactly with low concentrations in the simulation.

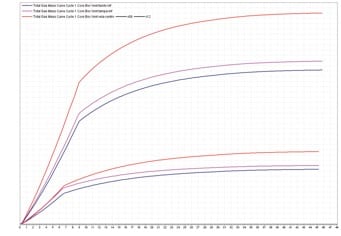

Evaluating simulated curves for the gas mass flow through the vents made it clear that the catalyzing gas was not reaching the critical area. The open venting cross section of the top and central vents was allowing the gas to escape before it reached the bottom of the core.

Instead of making costly modifications to the core box, Usiminas determined that a possible – and simple – solution was to close some vents in the top and center regions, in order to increase the gas concentration in the bottom. However, it was clear that these changes obviously would also influence the core blowing step.

The optimization led to a considerable increase of the curing gas concentration in the lower regions of the core (~36%) (Figure 4). Also, the amount of adsorbed curing gas increased in comparison to the original project. Applying these modifications, Usiminas produced another core, which did not show any gassing defects. Since the venting area was reduced, some filling defects were present, as expected.

Figure 4. Total gas mass flow through the lower vents. The change in mass flow becomes clear. Removing some of the upper and middle vents resulted in a 36% increase in the gas escaping through the lower vents.

Having solved the curing related defects, a further core blowing analysis was carried out. The simulation results showed a very good match between the real defects and areas of low packing density. The flow animation also showed that the problems occurred because these areas had to be filled by a counter flow of the sand (Figure 5).

Another characteristic of the defects was that they all occurred next to the parting line of the core box. Some of the defects showed a smooth surface, indicating that the sand had been removed by a strong air flow. The core blowing simulation results supported the Usiminas conclusion that an improper sealing of the tool was the root cause for these defects. Air could escape with high speed through the parting lines, resulting in the defect formation.

This hypothesis was tested using a silicone rubber band to obtain an improved sealing of the relevant areas of the tool. With this modification, a new core was produced which was absolutely free of any defects.

About software for casting process simulation

Casting process simulation software considers the complete casting process including mold filling, solidification and cooling, and also provides the quantitative prediction of mechanical properties, thermally induced casting stresses and the distortion of cast components. Simulation accurately describes a cast component’s quality upfront before production starts, thus the casting layout can be designed with respect to the required component properties. This results in a reduction in pre-production sampling, but also the precise layout of the complete casting system leads to energy, material and tooling savings for the foundry.

The range of application of MAGMA solutions comprises all cast alloys, from cast iron to aluminum sand casting, permanent mold and die casting up to large steel castings. The software supports the user in component design, the determination of melting practice and casting methodology through to mold making, heat treatment and finishing. This saves costs consequently along the entire casting manufacturing line.

During the last 10 years, the use of casting process simulation has become a valuable business asset for many foundries worldwide. MAGMA5 constantly expands the capabilities of casting process simulation and will further accelerate the acceptance of this technology, in the future.

About Usiminas

With 50 years of operation, Usiminas is the leader in the Brazilian flat steel market and one of the largest steel companies in Latin America. It has a nominal capacity of 9.5 million tons of steel per year. Usiminas Mecânica is a leading provider of capital goods and services to the steel, railway, mining, automotive, energy, petrochemical, marine and infrastructure industries in Brazil. With recent substantial investments, the foundry of Usiminas Mecânica has become one of the largest manufacturers of both small and large steel castings in the country. The yearly production capacity is 30,000 tons, representing about 10% of the projected production in Brazil.

About MAGMA

MAGMA offers comprehensive solutions to the metal casting industry, casting buyers and casting designers worldwide. The MAGMA product and service portfolio includes the powerful modular simulation software MAGMASOFT®,with the newest release MAGMA5, as well as engineering services for casting design and optimization.

Today, MAGMASOFT® is used throughout the metal casting industry, especially for the optimization of cast components in automotive and heavy industry applications.

MAGMA Giessereitechnologie GmbH was founded in 1988 and is headquartered in Aachen, Germany. A global presence and support are guaranteed by offices and subsidiaries in the USA, Singapore, Brazil, Korea, Turkey, India and China. Additionally, more than 30 qualified partners represent MAGMA around the world.

For more information on this release, please contact:

Christof Heisser

President

MAGMA Foundry Technologies, Inc.

10 N. Martingale Road, Suite 425

Schaumburg, IL 60173

Phone: 847-969-1001 ext. 225

Email: cheisser@magmasoft.com

Web: www.magmasoft.com

This Grieve cabinet oven features 6” insulated walls, aluminized steel exterior and interior, plus five levels of dual-lane roller conveyor rated at 300 lbs. per level.

Controls onboard No. 1030 include a digital indicating temperature controller, manual reset excess temperature controller with separate control contactors and a recirculating blower airflow safety switch.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

CAROL STREAM, ILLINOIS – The demand has never been greater for specialized supply chains that deliver medical materials to meet the production demands of OEM’s. These businesses are acutely aware of the need to use quality metals and materials in their products to assure performance, durability and long-term reliability. Due to the recent revisions to ASTM standards F136 and F138, Banner Medical has installed a multi-axis, computer controlled Ultrasonic Inspection System designed and built by Matec Inspection Companies, Inc., for precision ground bars.

ASTM F136 and ASTM F138 are commonly specified standards in the design of titanium and stainless steel surgical implants; and recent revisions to each standard call for ultrasonic testing at final diameter for all centerless ground, or peeled and polished bars, which are greater than or equal to .375” in diameter.

“The decision to purchase this highly versatile inspection system was driven by the current and future needs of our customers. We are experiencing greater demand for ultrasonic testing of medical grade raw materials and the recent changes to ASTM standards F136 and F138 will increase demand even further in the very near term,” said Bob Khin, Vice President of Quality Assurance, Banner Medical.

“We recognize the impact these revisions will have on our customers. Ultrasonic testing at final diameter has the potential to add significant delays and cost to the supply chain. Our new ultrasonic inspection unit allows us to ensure the precision of centerless grinding and testing under one roof. We are providing our customers with a cost effective, time saving solution to the problems which could arise as manufacturers begin to comply with these changes. We will maintain the inventory, production capability, and testing equipment in a medical focused factory,” said Dan Stoettner, Executive Vice President and Chief Operating Officer.

To fully comply with industry testing standards, Banner Medical has hired additional qualified personnel to operate the equipment and implement the proper management systems including Rick Wallen, Director of Technical Services. He will assume full responsibility for the ultrasonic testing program. Rick was employed at Zimmer Inc. for 34 years in various roles and most recently served as Principal Engineer, Quality. He was responsible for all nondestructive testing requirements company-wide.

“We feel very fortunate to have Rick join our team. He is an industry recognized expert in ultrasonic testing and Quality Management Systems, and we are certain he will make an immediate impact within our organization. Rick is an ASTM certified Level III Engineer and an ASQ certified Quality Auditor. He is going to help us provide the very best service to our customers,” said Bob Khin.

###

Banner Medical serves the medical device, implant, and instrument industry with medical-grade metal materials; Banner Medical is ISO 13485 and ISO 9001 certified, and FDA CFR part 820 compliant.

For more information:

BILL NORLANDER

Medical Products Specialist

494 East Lies Road

Carol Stream, IL 60188-9425

P:630.868.1230

F:630.653.7555

E: bnorlander@banner-medical.com

www.banner-medical.com

MIKE HADLEY

Supply Chain Manager

494 East Lies Road

Carol Stream, IL 60188-9425

P:630.868.1229

F:630.653.7555

E: mhadley@banner-medical.com

www.banner-medical.com

This Grieve shelf oven features 4” insulated walls, aluminized steel exterior, Type 304, 2B finish stainless steel interior and six 200 lb. capacity (each) shelves supported by ball slides with shelves extending 30” in front of oven for easy loading/unloading.

Controls onboard No. 1014 include all safety equipment needed for handling flammable solvents, including explosion-venting door hardware, plus a 12-port vacuum manifold with pressure gauge and hand valve at each port, solenoid valve to relieve vacuum and 2-HP rotary vane vacuum pump with pre-filter.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

Advanced Machine & Engineering (AME) provides solutions to run 56 different block sizes at Rockford-area machine shop

In its production of various cylinder and related products for hundreds of customers, TRD Manufacturing, Inc. of Machesney Park, Illinois (near Rockford), a division of Bimba, one of the leaders in actuation devices, was challenged by an ever-increasing variety of sizes, styles and materials in their workpiece blocks. As VP of Operations Kerry Reinhardt explains, “TRD is a fast-paced manufacturer but very dedicated to high quality and fast turnaround on deliveries. We have an established reputation as a solution provider to the fluid power industry.” The company sells through distribution with its end users found in the general manufacturing, automation integration, mining, forestry, medical, food and various mill industries. TRD products are regularly specified as OEM components, plus the company serves the huge MRO marketplace.

To meet the demand for products in an ever-expanding line, complicated by the just-in-time delivery schedules often encountered, as Manufacturing Manager Tom Jensen notes, “TRD was seeking a partner who could develop fixturing to fit our manufacturing business model of quick set-up and the flexibility to run small or large batches of product from a multitude of block sizes.”

TRD turned to a local supplier of various machine tool components, Advanced Machine & Engineering (AME) in Rockford, Illinois. The head of the AME workholding group, Alvin Goellner, observes, “After a few discussions and visits to each other’s plants, we knew TRD would benefit most from our Triag line of modular workholding devices.”

Tom Jensen concurs. “We knew AME had a reputation for building top quality fixturing. Their in-house manufacturing capabilities were very impressive and we knew they could handle a project of this size, based on the other customers they serve and the fact that they are just across town from us, which made it easier to work through the preliminary discussions, quoting and final product delivery.” The horizontal machining center (HMC) used for this particular application at TRD is an Enshu GE480H, with 30” x 30” x 30” travel and a 180-position toolchanger, expandable to 240-position. Workpieces are mounted and handled on a Fastems 10-station pallet changer. Currently, the block sizes run at TRD are 56 in number and run in sizes from 1” x 2” x 2” to 3” x 9-1/2” x 14”. Weights range up to 114 lbs. Final part varieties produced on the machine number over 450, made from 1018 steel and 303 stainless. Lot sizes vary from one-offs to 500, but generally run between 25-50 on average. This machining center set-up runs two shifts per day, with the expectation of running 24/7 during peak demand periods.

The challenge for Alvin Goellner and his team at AME was to design a series of fixtures that was flexible enough to hold 56 different block sizes, offer quick changeover and offer the ability to run different parts on each side or run multiple pallet loads of the same part in high production, when needed. As Goellner notes with a smile, “It was a real one-size-really-can-fit-all situation. We knew the HMC with pallet changer was very costly to run, so keeping downtime to a minimum was essential.”

The solution came in the form of ten Triag custom modular tombstone-style fixtures from AME, who partners with Triag, a major European workholding component supplier, as their exclusive North American distributor. As Jensen notes, “The fixturing in our existing machining cell was fixed, based on block size. AME fixtures use a vise system that quickly adjusts to any size with repeatability, a really key factor in the equation, as it allows all our work shifts to be pre-taught the process. We normally have the fixtures set for specific part sizes but this AME solution now allows us to run any size part on any pallet very quickly for high-volume jobs.” He also observed there was a very short start-up time in the TRD shop, as the flexibility of the tombstone design and the fixturing mechanisms were relatively easy to learn for the operators.

Jensen continues, “We met with Alvin Goellner and brainstormed the improvements needed on our current fixturing system. AME laid out a concept and provided drawings for each fixture, which we then reviewed and approved, based on our current production schedules and anticipated workloads, going forward. All the fixtures ordered arrived on-time or ahead of schedule, a very refreshing experience.” Goellner was the lead man for AME on the project, bringing his 20+ years of fixture design and build experience to the task. Because all aspects of this project’s customized manufacturing, assembly and test of the Triag tombstone fixures were done in-house at AME, there was little delay in the processing of the project and all design changes were quickly accommodated, according to Jensen.

Reinhardt further commented, “The overall experience was excellent and the results have been outstanding for TRD. The project went well and all our expectations were met.” He estimates the improvement percentage in production on the Enshu HMC to be over 40%, after several months in operation.

—

TRD combines 27 years of precision machining and engineering with an unmatched selection of options and modifications to deliver the highest quality customizable NFPA (National Fluid Power Association) cylinders on the market today. At TRD, the customer’s specials are their specialty.

Advanced Machine & Engineering Co., is a manufacturer located in Rockford, IL, serving the Machine Tool Industry with precision components and accessories, including spindle interface components, workholding devices, and, through our sister company, Hennig, machine enclosures, chip removal and filtration systems. The Fluid Power – Safety markets are served with cylinder rod locks and safety catcher devices; and the Production Saw market with our AMSAW® carbide saw machines and Speedcut blade products. AME has manufacturing partners and customers around the world and across the U.S. To learn more, visit www.ame.com.

Hennig, Inc. designs and produces custom machine protection and chip/coolant management products for state-of-the-art machine tools, production lines, power generators and other equipment. Hennig products are designed to protect against corrosion, debris and common workplace contaminants. Manufacturing facilities are located in the U.S., Germany, Brazil, India, Japan, France and South Korea. Repair centers are located in Machesney Park, IL; Chandler, OK; Livonia, MI; Blue Ash, OH; Mexico City, Mexico and Saltillo, Mexico. To learn more, visit www.hennigworldwide.com.

For more information on this story, please contact:

Kerry Reinhart

TRD MANUFACTURING, INC.

A Bimba Company

10914 North Second Street

Machesney Park, IL 61115

Phone: 815-654-7775

Fax: 815-654-7783

Email: reinhartk@trdmfg.com

Web: www.trdmfg.com

OR

Alvin Goellner

ADVANCED MACHINE & ENGINEERING CO.

2500 Latham Street

Rockford, IL 61103

Phone: 815-962-6076

Fax: 815-963-4703

Email: info@ame.com

Website: www.ame.com

The International Monetary Fund (IMF) estimates that the world economy will grow by 3.5 percent this year, with the impetus coming less from Europe and more from dynamic, newly industrialized countries. One example is the automotive industry. According to the association for the German automotive industry (VDA), China’s share of the market in passenger cars increased by 59% and that of Brazil by 18% during the first few months of 2013. The same market is also growing in India and Russia. For a long time, new production facilities have been planned and are under construction, providing great opportunities for the machine tool industry – as the example of EMAG proves. Specialists are developing turnkey manufacturing systems that are tailor-made to suit specific market conditions, with the new production facilities in particular gaining substantially from this increased market activity.

VL 2: Highly effective, truly outstanding space saver

VT 2-4: For demanding shaft production

Central project management

For more information, please contact:

Kristal Kilgore

EMAG LLC

38800 Grand River Avenue

Farmington Hills, MI 48335

Tel: (248) 875-0313

Fax: (248) 477-7784

E-mail: kkilgore@emag.com

Web: www.emag.com