Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

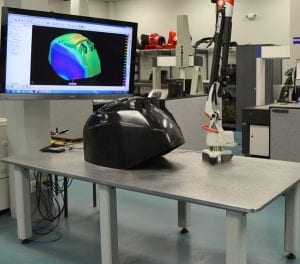

The Absolute Arm 7-axis system delivers tactile probing and laser scanning in a uniquely ergonomic package. It is the best choice for high-end portable measurement applications. The articulating arm offers unparalleled ease of movement and ease of measurement.

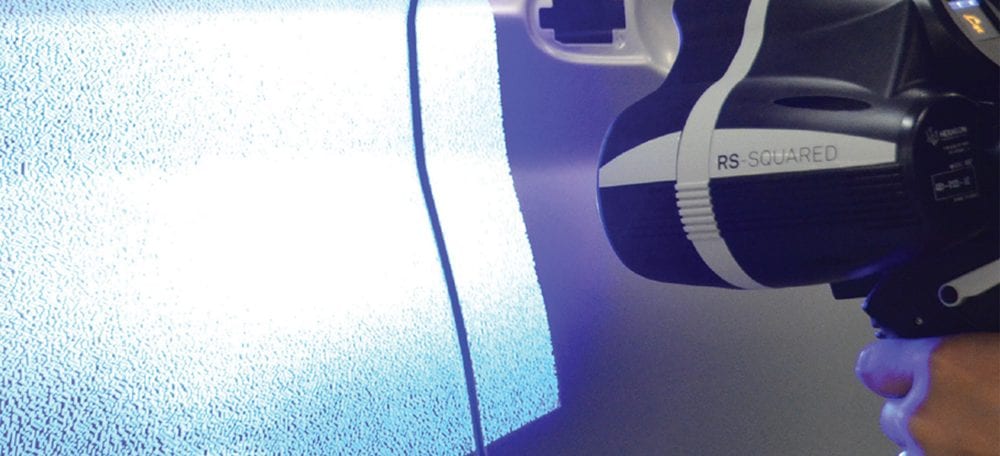

RS-SQUARED is a white light scanner that uses the Absolute Arm system to position large square ‘tiles’ of 3D scan data. This removes the need for time-consuming application of reference markers or spray, or complex mechanical processes such as fringe projection that requires a stable environment. Up to 4 data tiles are captured every second, which combined with minimal set-up time, creates a scanning system capable of generating point cloud data in very little time. As with other Absolute Arm scanners, the RS-SQUARED can be easily removed and remounted without needing time-consuming recalibration processes due to an innovative repeatable mounting system.

The RS-SQUARED area scanner represents a new direction for portable measuring arm technology, embracing the need for high-productivity by incorporating advanced white light scanning technology. Together with the Absolute Arm 7-axis, it offers the ultimate all-around portable measurement solution for medium-to-large sized components.

Exact Metrology is an ISO AS9100 Certified along with being FFL and ITAR Registered.

Exact Metrology, with facilities in Cincinnati, Moline and Milwaukee plus affiliated offices throughout the country, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

For information, please contact:

EXACT METROLOGY, INC.

Dean Solberg

20515 Industry Avenue

Brookfield, WI 53045

Local: 262-533-0800

www.exactmetrology.com

deans@exactmetrology.com

EXACT METROLOGY, INC.

Steve Young

11575 Goldcoast Drive

Cincinnati, OH 45249

Local: 513.831.6620

Toll Free: 866.722.2600

www.exactmetrology.com

stevey@exactmetrology.com

Jason Kleinhenz received a biomedical engineering degree from the University of Cincinnati. He is currently the training and marketing manager at Exact Metrology.

Exact Metrology, a comprehensive metrology service provider, shares helpful safety tips for metrology workers during the COVID-19 pandemic. These tips are courtesy of Jason Kleinhenz, Exact Metrology marketing and training manager.

With much of the workforce operating from home, keeping up with quality inspection and reverse engineering is difficult during this time. However, there are solutions to counteract this problem. Some companies employ several of these tactics daily, but in these trying times they are much more relevant to maintain effective production.

If you are in the workplace, follow all the stated guidelines. These include staying 6 feet away, washing/sanitizing touched surfaces and washing your hands. Also remember to clean the objects you’re working with such as data collection tools and computers.

Only one person should collect the data from the object(s). That person is responsible for handling the objects and the data collection tools. Of course, the designated person also needs to clean and sanitize all objects, tools and surfaces.

Workers must save and upload data sets (and/or workspaces) to the cloud. Due to security threats, a company’s IT team should use a virtual private network (VPN) and/or file transfer protocol (FTP). This reduces the chances of data being hacked or stolen.

Have another person, or a team, work separately to download (receive) the data sets, or workspaces and process them. They will have their own safety procedures in place (essentially the same as the data collector). If possible, the processing person(s) should write programs at the same time the data is collected. This saves time and money as two operations are occurring at the same time. Most likely, this is not possible in reverse engineering projects. However, in quality inspection projects, this is a massive time-saving practice.

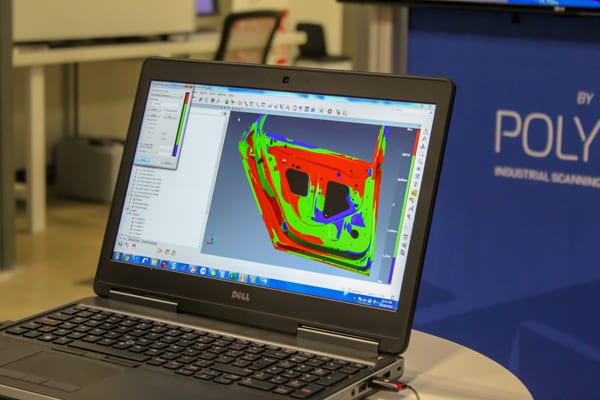

Communicating between the collector and processor(s) can be done quickly, and virtually, with online services like Skype and Zoom. The good old-fashioned phone works well for quick conversations too. There are some software packages that allow seamless workspace sharing between different people and teams such as a package through PolyWorks® by InnovMetric.

These techniques and tools can help companies reach their quality and reverse engineering objectives during social distancing. Exact Metrology is available to answer any questions about how to maximize efficiency or help with projects.

Exact Metrology is an ISO AS9100 Certified along with being FFL and ITAR Registered.

Exact Metrology, with facilities in Cincinnati, Moline and Milwaukee plus affiliated offices throughout the country, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

For information, please contact:

EXACT METROLOGY, INC.

11575 Goldcoast Drive

Cincinnati, OH 45249

Local: 513.831.6620

Toll Free: 866.722.2600

www.exactmetrology.com

info@exactmetrology.com

Scanner features Leica Cyclone Field 360 and Leica Cyclone REGISTER 360

3D reality capture is a process of scanning and capturing any site, for example, factories, buildings, crashes and crime scenes, in a 3D digital model, combining measurements and imagery. The model can be used for design and comparison purposes in various situations, capturing every detail with to-the-millimeter accuracy. This technology combines one-touch operation with portability and speed to deliver high levels of accuracy, automation and the ability to create 3D environments in a matter of minutes.

Thanks to 3D reality capture, Building Information Modeling (BIM) experts save time and money as BIM processes become more efficient, from the accuracy of construction documentation to design and build quality assurance. The latest laser scanning technological developments improve understanding and documentation of the build environment through the use of millimeter-accurate laser scanning and High-Dynamic Range (HDR) imagery. By using 3D reality capture, previews of data and imagery are viewable onsite directly from a tablet, enabling scans to be checked and verified before going to the office.

With a measuring rate up to 2 million points per second, automated targetless field registration (based on VIS technology) and automated transfer of data from site to office, the device and software greatly reduce time spent in the field and maximize productivity.

The scanner’s portable design and collapsible tripod fit into most backpacks. Low noise data allows for better images, resulting in crisp, high-quality scans that can be used in a variety of applications.

As part of the RTC360 solution, the Cyclone FIELD 360 links the 3D data acquisition in the field with the laser scanner and data registration in the office with Cyclone REGISTER 360. The user can automatically capture, register and examine scan and image data.

Exact Metrology is ISO, AS9100 Certified as well as FFL and ITAR Registered.

Exact Metrology, with facilities in Cincinnati, Moline and Milwaukee plus affiliated offices throughout the country, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

For information, please contact:

EXACT METROLOGY, INC.

Dean Solberg

20515 Industry Avenue

Brookfield, WI 53045

Local: 262-533-0800

www.exactmetrology.com

deans@exactmetrology.com

EXACT METROLOGY, INC.

Steve Young

11575 Goldcoast Drive

Cincinnati, OH 45249

Local: 513.831.6620

Toll Free: 866.722.2600

www.exactmetrology.com

stevey@exactmetrology.com

Exact Metrology, a comprehensive metrology service provider, participated in a webinar on February 20, 2020. The general subject involved testing and inspecting parts that are 3D printed. Josh Schradin, a project manager at Exact Metrology, gave a presentation on industrial CT (Computed Tomography) for additive manufacturing.

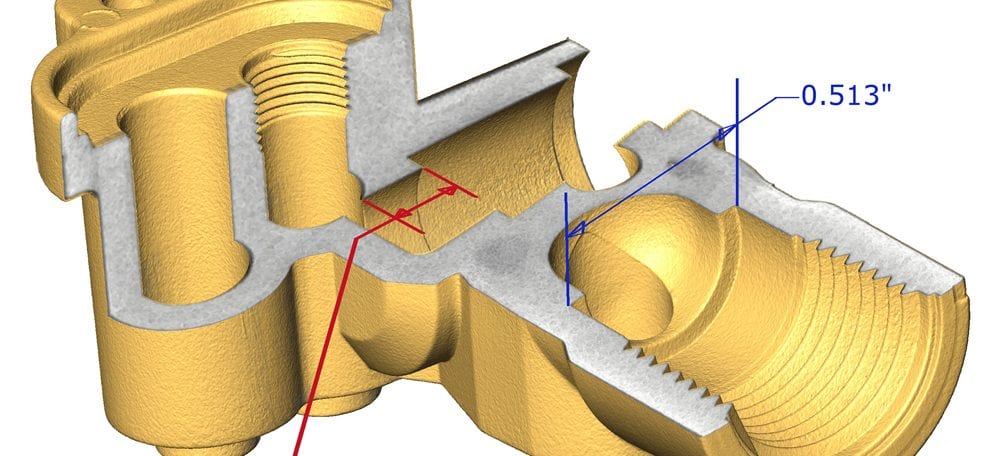

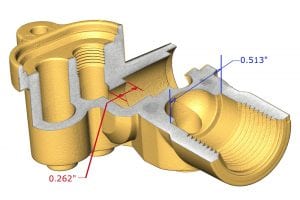

A CT scan, also known as an X-ray Computed Tomography (X-ray CT) or a Computerized Axial Tomography scan (CAT scan) uses computer-processed combinations of several X-ray images taken from different angles to produce cross-sectional (tomographic) images or “virtual slices” of specific areas of a scanned object. This allows the user to see inside the object without cutting or damaging it. The basic components of a CT system are its X-ray source, the sample on a rotary table and a detector (see image 1).

Magnification is also an important part of CT scanning. Moving the object closer to the X-ray source provides a larger shadow, optimizing the resolution of the final image, while having an object closer to the detector provides a smaller shadow that decreases the final resolution.

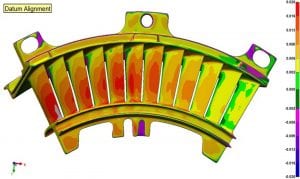

Trapped powder can be located during the printing process either by magnification or using a color map that shows deviation to the nominal model (see image 8).

Product content positon allows manufacturers to audit their products and determine if embedded objects are placed properly.

Exact Metrology is an ISO AS9100 Certified along with being FFL and ITAR Registered.

Exact Metrology, with facilities in Cincinnati, Ohio, Milwaukee, Wisconsin and Moline, Illinois and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

For more information, please contact:

For information, please contact:

EXACT METROLOGY, INC.

Dean Solberg

20515 Industry Avenue

Brookfield, WI 53045

Local: 262-533-0800

www.exactmetrology.com

deans@exactmetrology.com

Steve Young

Exact Metrology, Inc.

11575 Goldcoast Drive

Cincinnati, OH 45249

Toll Free: 866-722-2600

Local: 513-831-6620

www.exactmetrology.com

stevey@exactmetrology.com

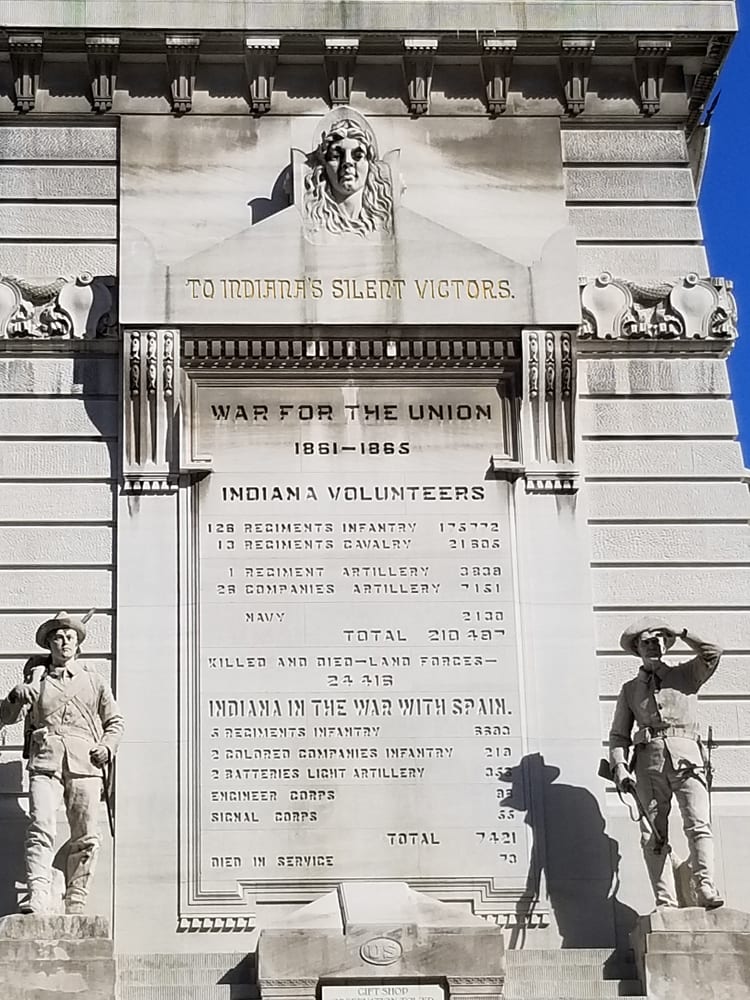

Innovative, an ad agency in Indianapolis, was contacted by Downtown Indy Inc. to create a light projection at Monument Circle for Veterans Day. Located in the heart of downtown Indianapolis, it features the Soldiers & Sailors Monument and the Colonel Eli Lilly Civil War Museum. Downtown Indy Inc., the city’s nonprofit organization, received a grant from the Lilly Endowment for the show and the goal of the ad agency was to produce a projection show that will be image mapped on two buildings in the circle’s southwest quadrant. To accomplish this, Innovative became the creative content provider for Exact Metrology.

Greg Hoeting, the application specialist at Exact Metrology, used a Leica P40 to collect point cloud data. Leica ScanStation P-Series 3D laser scanners are ideal for capturing 3D geometry of civil infrastructure, creating an as-built representation of large industry complexes, reconstructing crime scenes or generating 3D data for integration into Building Information Modeling (BIM). In addition, these laser scanners offer unsurpassed range and angular accuracy with low-range noise and survey-grade dual-axis compensation that form 3D color point clouds mapped realistically.

Next, Hoeting used Polyworks® to mesh the data and export a .stl file. The Polyworks® software suite maximizes productivity, quality and profit when integrating 3D measurement devices into the industrial manufacturing process. The software interfaces directly with major brands and technologies of single- point and point cloud 3D models through plug-in extension models. Furthermore, Polyworks® supports a wide array of native point cloud and polygonal model file formats.

Lastly, Hoeting used Leica Cyclone to align the color texture with a center point at the base of the monument. This point cloud processing software provides the widest range of options for 3D laser scanning projects in engineering, surveying, construction and related applications.

Exact Metrology scanned around the monument and several buildings such as: Novel Coworking Circle Tower, IPL, Guaranty Building, Salesforce Tower (Chase Tower portion).

Exact Metrology is an ISO AS9100 Certified along with being FFL and ITAR Registered.

Exact Metrology, with facilities in Cincinnati, Ohio, Milwaukee, Wisconsin and Moline, Illinois and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

For more information, please contact:

Steve Young

Exact Metrology, Inc.

11575 Goldcoast Drive

Cincinnati, OH 45249

Toll Free: 866-722-2600

Local: 513-831-6620

www.exactmetrology.com

stevey@exactmetrology.com

This location will serve as a training, support, contract measurement and sales center. Training will be provided on software packages such as: PolyWorks®, Geomagic and PC-DMIS. The Polyworks® software suite maximizes productivity, quality, and profit, while integrating 3D measurement technologies into an industrial manufacturing process. Geomagic is a leading provider of 3D software that creates digital models of physical objects for industries like aerospace, archeology, medical, dental, tooling and foundry. Provided by Exact Metrology through Hexagon

Commenting on the importance of this opening, Joe Wright of Exact Metrology said, “Exact Metrology can add support and service to our customers in western Illinois and Iowa. We hope to keep growing the customer base in this area.”

Exact Metrology is an ISO AS9100 Certified along with being FFL and ITAR Registered.

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

For information, please contact:

EXACT METROLOGY, INC.

Dean Solberg

20515 Industry Avenue

Brookfield, WI 53045

Local: 262-533-0800

www.exactmetrology.com

deans@exactmetrology.com

Although Tsuchiya has used 3D software, digital scanning, 3D printing and CNC (Computer Numerical Control) to help create sculptures in the past, the Florence project was the first time digital scans of actual people were used to create a sculpture.

Tsuchiya planned the general pose of the firefighter, the public service worker and the police officer with a little girl, using a 3D design program. He asked Matthew Martin, the Division Manager of Exact Metrology, and Scott Menne to digitally scan actual employees from the City of Florence, Kentucky. The firefighter in gear was scanned at the fire station, while the police officer and Martin’s daughter were scanned at the Florence city headquarters. A friend of the City of Florence posed as the public service worker.

After Tsuchiya finished the sculpting, the clay/foam/wood statues were delivered to the Sincerus Bronze foundry in Indianapolis to cast them in bronze. The whole process, from concept to bronze finishing, took four to five months for each sculpture.

For more information, please contact:

Steve Young

Exact Metrology, Inc.

11575 Goldcoast Drive

Cincinnati, OH 45249

Phone: 614-264-8587

Local: 513-831-6620

www.exactmetrology.com

stevey@exactmetrology.com

Exact Metrology is an ISO 9001:2008, AS9100, FFL and ITAR Certified Company.

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

Continue reading

Exact Metrology will be exhibiting at the upcoming show. Their main technologies featured will be CT scanning, Geomagic Design X and Polyworks Inspector™ software. In addition, Exact Metrology will discuss structured light. According to Jason Kleinhenz, an engineer and trainer at the company, “CT scanning in combination with Design X (for reverse engineering ) and/or Polyworks (for quality inspection) creates opportunities for reverse engineering and quality inspection of internal components, very accurately, not possible through any other tool. Structured light systems allow highly accurate 3D data collection via line-of-sight.”

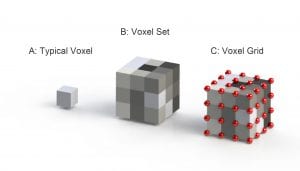

CT scanners permit the exploration of the interior of parts without any harm or destruction to the parts themselves. This technology takes multiple readings from various angles and converts the CT grey scales images into voxel-based 3D point clouds. After the CT scanner generates the point cloud data, Exact Metrology generates a CAD-to-part comparison map, dimension the part or reverse engineer it.

Geomagic Design X allows provides an easy path from creating editable, feature-based CAD models from a 3D scanner to integrating them into existing engineering design workflow. Furthermore, the software allows users to re-use existing designs without having to manually update old drawings or re-measure and rebuild a model in CAD. Finally, Geomagic Design X is easy to learn and use.

Polyworks Inspector™ uses high-density point clouds and contract-probe datasets to control the quality of parts and tools at every manufacturing process phase. Using this software, users can acquire and control tool and parts dimensions, prevent manufacturing and assembly issues, guide assembly building and oversee the quality of assembled products.

Structured light, commonly known as blue light scanning, describes the use of 3D light-based scanners. Generally, structured light-based scanners offer the most accurate and highest resolution data. “Blue” refers to the color of the LED bulb in the projector.

Josh Schradin and John Legleu from Exact Metrology, will be there to answer any questions attendees may have. Schradin is head of the CT department, while Legleu is a technical salesperson.

Please stop by Exact Metrology at booth 51415 SUP during the show.

Exact Metrology is an ISO Certified, AS9100, FFL and ITAR Certified Company.

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D scanning, reverse engineering, quality inspection, product development CT scanning and services and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

For more information, please contact:

EXACT METROLOGY, INC.

Steve Young

11575 Goldcoast Drive

Cincinnati, OH 45249

Local: 513.831.6620

Toll Free: 866.722.2600

www.exactmetrology.com

stevey@exactmetrology.com

Dean Solberg

Exact Metrology, Inc.

20515 Industry Avenue

Brookfield, WI 53045

Local: 262.533.0800

www.exactmetrology.com

deans@exactmetrology.com

Daniel Fernandez-Davila has made this trip for 21 years, accompanied by his students and residents from Wayland, Massachusetts. Besides Kleinhenz, the team included Antonia Hieronymous, Rachel Lorenc and Nick Ciorogan. Daniel and Antonia started a non-profit called Loose Change. Based in Wayland, Massachusetts, Loose Change organizes an annual week-long event to gather donations from the community. As the name implies, residents donate their spare change to the organization. All of the funds are used to buy books and educational materials for Peruvian schoolchildren. In addition to providing school supplies, the non-profit also builds/renovates schools. In addition, Fernandez-Davila made it his mission to scan a South American monolith and several artifacts, so that the information could be used in archeological research and also in presentations for museums. Lorenc participated on behalf of her mentor, Dr. Lisa DeLeonardris at Johns Hopkins. Dr. DeLeonardris said that “The purpose of this trip was first and foremost to document the artifacts (shaman vessels and monolith) with hopes of better presenting and/or publishing iconographic analysis.” Ciorogan, a professional photographer and videographer, completed filming for the movie “My Teacher.” With a release date of 2020, the movie focuses on Fernandez-Davila’s work in the Peruvian jungle.

Artec 3D, a world-renowned developer and manufacturer of professional 3D scanners and software, provided a Space Spider and Exact Metrology brought an Eva scanner. The Space Spider is a high-resolution 3D scanner based on blue light technology. It is ideal for capturing small objects or intricate details of large industrial objects in high resolution and with great accuracy. Also supplied by Artec 3D, Eva is used for making a quick, textured and accurate 3D model of medium sized objects. It scans quickly, capturing precise measurements in high resolution. Not only does it capture almost any type of object (including black and shiny surfaces), but it is used in numerous industries including quality control, heritage preservation, forensics, automotive, medical, aerospace and prosthetics.

The data was processed in Artec Studio 14 and 10 by Exact Metrology personnel, namely Chris Lafferty, Greg Hoeting and Jason Kleinhenz. Then, the information was given to Chris Catlett at 3D Systems. The company supplies the best range of 3D printers, materials and application expertise. 3D Systems was used to turn 3D data into PDFs, CAD files and short movies. To complete this task, Exact Metrology employed Geomagic, their leading 3D software for digital reconstruction of the ruins.

Through this project, Exact Metrology showed that they can scan anything, anywhere for educational and research purposes, as well as build partnerships with the local community. The right side of the scanned monolith was dated between 400 BC and 200 AD, while the left side was estimated to date between 700 and 14700 AD. The artifacts are estimated to be between 500 BC and 100 AD. Exact Metrology plans to turn the data into solids by possibly 3D printing a few, turn the solids/meshes into user-friendly interactive tools or turn them into short videos. Furthermore, the company is preparing to present two scientific papers with Johns Hopkins at the 60th Annual Andean Studies Meeting in Berkeley, California in 2020. The videos will be supplied to museums in Peru.

To sum up the experience, Kleinhenz said, “The true value from this project came from the struggle, relationships built and the communities engaged. We’re excited to partner with great people and organizations to further the archeological research and philanthropic work. The community growing from this endeavor is really passionate and driven to deliver results – from my perspective, I’m grateful that I get to be a part of that movement, show Exact Metrology’s capabilities and partner with great people.”

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

Artec 3D is an international company, headquartered in Luxembourg, with subsidiaries in the United States (Santa Clara, California) and Russia (Moscow). Artec develops and produces innovative 3D solutions and products. Artec has a team of professional experts in the collection and processing of 3D surfaces as well as biometric facial recognition. Artec’s products and services can be used in many industries, such as in engineering, medicine, media and design, entertainment, fashion, historic preservation, security technology and more.

For more information, please contact:

Steve Young

Exact Metrology, Inc.

11575 Goldcoast Drive

Cincinnati, OH 45249

Phone: 614-264-8587

Local: 513-831-6620

www.exactmetrology.com

stevey@exactmetrology.com

Exact Metrology, a leading metrology services provider, offers customers and interested parties information on 3D scanning services, CT scanning, metrology equipment and software solutions on their website at www.exactmetrology.com

The company’s 3D scanning includes inspection scanning, CT scanning, reverse engineering, long range scanning and scan to CAD.

CT scanning (computed tomography) is used in aerospace, archeology, automotive, castings, die cast, electronics, food, molds, personal products and plastics. Confident in its ability to obtain 3D views from inside a part, Exact Metrology issued a GOM CT challenge. It invited users to send scanned data they’ve obtained from other technologies. If the results obtained from GOM CT weren’t superior, the company would send the user $100 with no strings attached. In addition, Exact Metrology is a representative and seller in North America of Procon X-ray GmbH, a German developer of x-ray inspection equipment for industrial applications and university/scientific research.

Besides GOM and Procon, Exact Metrology features various leading manufacturers such as: Artec 3D, Geomagic Capture, Hexagon, InspecVision Planar, Leica Geosystems, Leica HDS, Polyrix, Raytech and Surphaser.

Along with its equipment, Exact Metrology offers several software options to complement their offering. This includes Artec Studio, Leica Geosystems Cyclone, Hexagon, Geomagic, GOM Inspect, Polyworks, Volume Graphics and 3D Reshaper.

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

For more information, please contact:

Steve Young

Exact Metrology, Inc.

11575 Goldcoast Drive

Cincinnati, OH 45249

Phone: 614-264-8587

Local: 513-831-6620

www.exactmetrology.com

stevey@exactmetrology.com

Dean Solberg

Exact Metrology, Inc.

20515 Industry Avenue

Brookfield, WI 53045

Phone: 262-533-0800

Local: 866-722-2600

www.exactmetrology.com

deans@exactmetrology.com