Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

The process-oriented approach of SIGMASOFT® makes it possible to use injection molding simulation of elastomer applications not only for filling or cooling times, but also the non-productive times between each process phase. When the process is simulated considering the influence of operational times occurring between the main process stages, the accuracy of the simulation is dramatically improved.

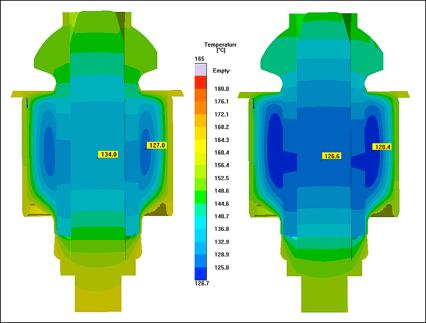

Temperature distribution in a metallic component overmolded with elastomer. Left: without consideration of the mold opening time; right: considering a mold opening time of 60s.

Schaumburg, IL, September 7, 2012 – Even though it is not necessary to include them to complete an injection molding simulation, the non-productive times have a major influence on the process and on part quality. Process Simulation Software SIGMASOFT®, from SIGMA®, can include non-productive times in the simulation enabling substantial improvement in the accuracy of the results to be achieved.

Taking into consideration the times in which the mold opens and closes, the times in which it is heated up or cleaned, as well as handling times when the inserts are placed simulation makes it possible to accurately analyze the process cycle. The interaction between all mold components has to be considered and cycle times have to be predicted accurately. That way even factors that influence the part quality, such as the curing degree, can be predicted by the simulation.

An example is presented in Figure 1. In this case the mold temperature decreases during the time period when the mold stays open. If this time is not considered in the simulation, the prediction of the whole cycle time, as well as the prediction of the cooling time or curing degree, will be erroneous. Besides, the predicted quality of the parts produced can deviate from reality.

In SIGMASOFT®, such non-productive times can be defined and varied separately in the simulation. Therefore, besides calculating the whole cycle, it is also possible to perform trouble-shooting of problems at each of the production stages. Through the utilization of simulation it is possible to decide if changes in the process definition are enough to solve production problems, or if the mold has to be reworked to achieve the desired quality and productivity goals.

—

SIGMA® (www.sigmasoft.de) is 100% owned by MAGMA® (www.magmasoft.de), the world market leader in casting process simulation technology based in Aachen, Germany. Our SIGMASOFT® process simulation solution optimizes the manufacturing process for injection molded plastic components. SIGMASOFT® combines the 3D geometry of the parts and runners with the complete mold assembly and temperature control system and incorporates the actual production process to develop a turnkey injection mold with an optimized process.

At SIGMA® and MAGMA®, our goal is to help our customers achieve required part quality during the first trial. The two product lines – injection molded polymers and metal castings – share the same 3D simulation technologies focused on the simultaneous optimization of design and process. SIGMASOFT® thus includes a variety of process-specific models and 3D simulation methods developed, validated and constantly improved for over 25 years. A process-driven simulation tool, SIGMASOFT®, with its comprehensive simulation approach, provides a tremendous benefit to production facilities. Imagine your business when every mold you build produces required quality the first time, every time. That is our goal. This technology cannot be compared to any other conventional “Design” simulation approach employed in plastics injection molding.

New product success requires a different communication between designs, materials, and processes that design simulation is not meant for. SIGMASOFT® provides this communication. SIGMA® support engineers, with 450 years of combined technical education and practical experience, can support your engineering goals with applications specific solutions. SIGMA® offers direct sales, engineering, training, implementation, and support, by plastics engineers worldwide.

For more information:

Christof Heisser or Matt Proske

SIGMA Plastic Services, Inc.

10 N. Martingale Road, Suite 425

Schaumburg, IL 60173

Phone: 847-558-5600

Email: contact@3dsigma.com

Web: www.3dsigma.com

Continue readingWith the process-oriented approach of SIGMASOFT®, the injection molding simulation for elastomers is no longer limited to predicting the cavity filling while designing the part or to answer questions regarding a balanced filling. Based on an accurate simulation of the curing reaction (vulcanization), it can be used for designing the mold, identifying process windows and troubleshooting during production.

The process-oriented approach of the Injection Molding Simulation Software SIGMASOFT® allows for the easy and exact consideration of all relevant information regarding mold and process into the calculation, beyond the part and runner geometry.

Schaumburg, IL, July 25, 2012 – At the recent DKT Conference in Nuremburg, Germany, SIGMA Engineering GmbH, Aachen, presented the latest functionality expansions of its 3D Injection Molding Simulation Software SIGMASOFT®. The focus of the presentation was the software’s ability to reduce development and production costs through new developments in process simulation.

Many factors in elastomer injection molding have an influence on product quality and costs. To ensure a competitive advantage, the whole manufacturing process must be considered. Since the design stage has the largest influence over the total costs of a part, this is where the savings start with SIGMASOFT®.

By using process simulation, feasibility and rough process parameters can be evaluated. Parting line and venting channels can be worked out, as well as the optimal type and positioning of the injection drop point. Where are weld-lines acceptable? Where do they need to be avoided? Do inserts need pre-heating? Which level of vulcanization should be reached and how much time and what temperature are needed to achieve this level? Important factors regarding part quality are optimized in this way, through the algorithms in the software.

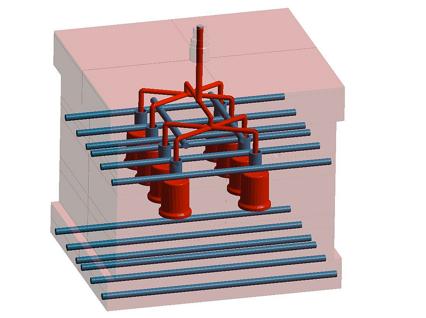

A mold, which will be used for producing the part, can now be developed. Decisions must be made at this point, which can incur substantial costs: How many cavities can be designed in the mold (clamping force and required pressure)? How should the runner system be designed to obtain balanced cavity filling and the same compound quality in every cavity? Is there need for a cold runner? What heat-output is needed and how must the heating system be configured? Are the heated clamping plates adequate? Where should control points for the tempering be positioned?

The simulation is able to answer all these questions and allows reaching the desired quality with minimal effort (time and energy). In this way, the process stability is guaranteed before the mold is even built. Costs can be reduced significantly during development and existing processes can continue to be improved. This is all accomplished while substantially reducing rejects and material waste, thereby getting to the first good part much faster.

The latest developments in the software’s thermal solver allows for the exact integration of all mold components. As a result, an accurate reproduction of the real temperature profile in the mold is possible, even over multiple injection molding cycles. The simulation definition is optimized for the requirements of process engineers, so that complex detail questions can be examined from a practical perspective without requiring extensive knowledge of simulation software. For example, it can be determined how heating cartridges influence mold temperature and part quality, simulating them with their respective electric power and control.

—

SIGMA® (www.sigmasoft.de) is 100% owned by MAGMA® (www.magmasoft.de), the world market leader in casting process simulation technology based in Aachen, Germany. Our SIGMASOFT® process simulation solution optimizes the manufacturing process for injection molded plastic components. SIGMASOFT® combines the 3D geometry of the parts and runners with the complete mold assembly and temperature control system and incorporates the actual production process to develop a turnkey injection mold with an optimized process.

At SIGMA® and MAGMA®, our goal is to help our customers achieve required part quality during the first trial. The two product lines – injection molded polymers and metal castings – share the same 3D simulation technologies focused on the simultaneous optimization of design and process. SIGMASOFT® thus includes a variety of process-specific models and 3D simulation methods developed, validated and constantly improved for over 25 years. A process-driven simulation tool, SIGMASOFT®, with its comprehensive simulation approach, provides a tremendous benefit to production facilities. Imagine your business when every mold you build produces required quality the first time, every time. That is our goal. This technology cannot be compared to any other conventional “Design” simulation approach employed in plastics injection molding.

New product success requires a different communication between designs, materials, and processes that design simulation is not meant for. SIGMASOFT® provides this communication. SIGMA® support engineers, with 450 years of combined technical education and practical experience, can support your engineering goals with applications specific solutions. SIGMA® offers direct sales, engineering, training, implementation, and support, by plastics engineers worldwide.

For more information:

Christof Heisser or Matt Proske

SIGMA Plastic Services, Inc.

10 N. Martingale Road, Suite 425

Schaumburg, IL 60173

Phone: 847-558-5600

Email: contact@3dsigma.com

Web: www.3dsigma.com

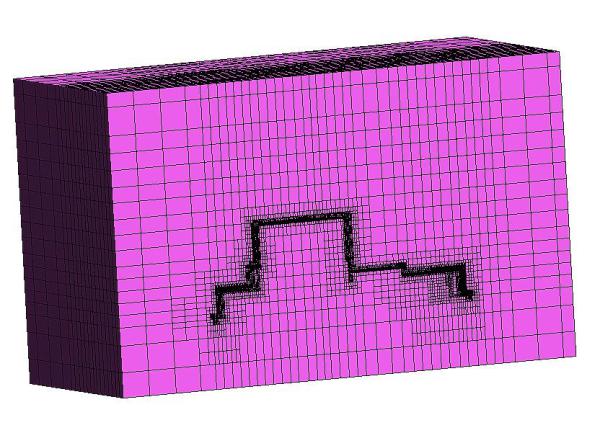

Continue readingThanks to a completely reengineered solver technology and a revolutionary meshing concept, with SIGMASOFT® Version 5.0, the simulation time required in elastomer applications can be reduced by up to 80%. With this dramatic speed-up, simulation can now be integrated in the elastomer processing on a daily-basis, both for part design and process troubleshooting.

Figure 1 –With the new solver technology and the use of “unstructured meshes,” SIGMASOFT® Version 5.0 reduces the calculation time by up to 80% in the simulation of elastomer injection applications.

Schaumburg, IL, July 25, 2012 – At the DKT conference in Nuremberg, Sigma Engineering GmbH, Aachen, presented SIGMASOFT® Version 5.0, the latest release of its process-oriented simulation software. With a completely reengineered solver technology and a new meshing concept, calculation times have been dramatically reduced, while keeping all the advantages of accuracy and user friendliness of a complete 3D-simulation approach.

“With SIGMASOFT® Version 5.0, we have achieved a major breakthrough in injection molding simulation,” explains Dr. Marco Thornagel, Executive Manager at Sigma. “Some years ago, users had to wait sometimes days to get the results of a simulation. It was not viable to use simulation to support every-day production activities, or to quickly optimize products. Now, however, simulation can be part of the daily production tools used in the mold shop or in the production floor, to deliver reliable and profitable answers both to design new products and to optimize existing molds.”

SIGMASOFT® is still the only option available in the market to seamlessly integrate all elements in the mold within the simulation. Thanks to the implementation of “Finite Volume” numerical methods, not only can the cavity be considered in the simulation, but also the complete real mold configuration, including tempering channels, heating elements and inserts. SIGMASOFT® is and has always been based exclusively in 3D technology, developed over a quarter century. The mesh required to conduct the simulation is generated effortlessly by the user in only minutes, without requiring any manual optimization.

The new meshing technique in the latest version of the software uses “unstructured meshes.” These are basically “intelligent meshes,” which can automatically mesh finer regions where complex thermal and flow phenomena take place, such as part boundaries, thin walls or complex runner systems. It also can save mesh elements in regions where fewer interactions take place, such as mold boundaries. The calculation effort is reduced and the productivity of the software increases.

Through parallelization, the new solver architecture makes it possible to exploit the complete potential of multi-core technology in state-of-the-technology computers. Beyond a significant reduction in computational time, the technology now allows users to simulate more complicated injection molding processes. This will be now the focus of further developments in the software, according to Sigma sources.

For further information on this story, please contact:

Matt Proske

SIGMA Plastic Services, Inc.

10 N. Martingale Road, Suite 425

Schaumburg, IL 60173

Phone: 847-558-5600

Email: contact@3dsigma.com

Web: www.3dsigma.com

Continue reading

Getting started with live tools…

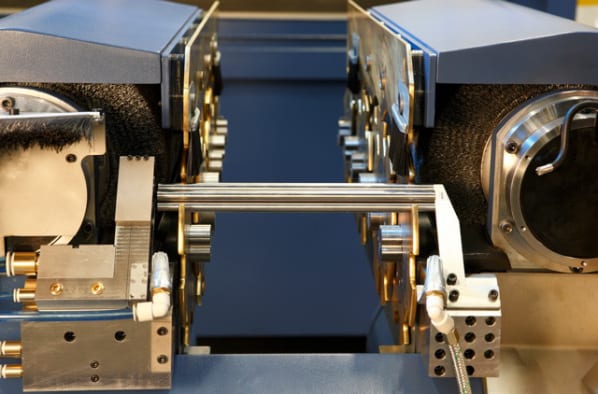

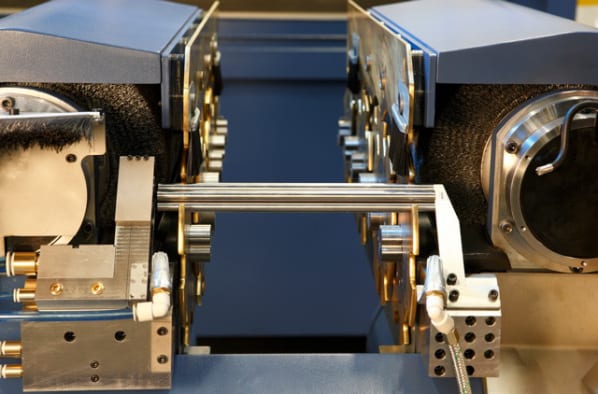

A flexible tool adapter system can be a big time and money saver, if properly utilized and properly designed for maximum power transmission and accuracy in alignment.

When any metalworking manufacturing facility, whether captive or job shop, makes the substantial investment in a new lathe, they are often looking for ways to streamline the manufacturing process. The smarter you are when choosing the live tools for your job, the more efficient the machine becomes. Finding a supplier of live tools who offers high-quality, high-performance products that will allow you more flexibility on the first big job and into the future in your operation is the key.

The first tool feature to consider is the output needed. Standard ER output or quick-change? Do you need coolant through the tool capabilities? Does the tool meet your requirements for precision and performance, including the necessary torque output to complement the machine? Are the tools designed according to the specifications of the lathe manufacturer?

When you look at an ER output, does it give you enough flexibility or do you need a more flexible machining system that will allow you to use the same tool for different applications. If more flexibility is required, then you may want to consider tooling with a system that features adapters for a variety of tools without the cost of new complete toolholder assemblies for each tool needed. However, when you look at such systems, be sure they feature a rigid polygon drive system design to prevent power transmission and alignment issues. Such systems seem appealing, because the live tool stays in place and only the adapter and collet get changed out with each new tool. However, less sophisticated though inexpensive systems will compromise the accuracy of your work. At that point, the few dollars saved will mean very little, compared to the scrap and downtime resulting.

If changeover time is critical, such as when working on a “family of parts,” the option of a true “quick- change system” might be more

A true quick-change system can be set offline and quickly installed, but it must be considered in light of today’s AND tomorrow’s workload.

beneficial. Adapters can be set offline and ready to go for minimal changeover time.

When coolant-thru tools are selected, it is imperative you first check the machine specifications to be sure your tool is capable of handling the coolant pressure of the machine. In general, your internal coolant live tools should be able to handle 1000 psi or more.

If your live tool is constructed with large, high accuracy bearings, the tool will have excellent rigidity and premium cutting performance, with minimal runout. (0.0002” or 0.006mm is a desirable goal.) The bearings, combined with ground, paired and high accuracy gears, make for tools that are consistent and long lasting. Bore tolerance is absolutely key in maintaining proper bearing load and this factor should never be compromised.

In addition, you should consider the many applications that can be accomplished with the proper live tool. You can purchase speed increasers for higher rpm, gear reducers for added torque, adjustable angle tools for compound angles, multiple-spindle tools for additional capacity, or gear hobbing tools for spline or gear cutting. Most of those items are standard catalog devices, but one more piece of advice: never shy away from the custom tool, when appropriate and justified by the job you have in-shop today, as well as the ones you might have tomorrow. A good tooling supplier will work with you to produce custom tools at reasonable prices, but the supplier must be very reliable, so look for one with grinding, finishing and perhaps even heat treating in-house or very closely monitored, to do such work. Additionally, be certain the supplier has local support and tools can be repaired or reworked quickly and correctly.

The workpiece materials are always a driver. Those of you doing medical machining know this well. Buying a less expensive or lower featured tool to work cobalt chromium and titanium is a really bad idea, to be blunt.

Custom tools, though usually dedicated to a particular application, can be the best solution, IF the design and construction of the tool is solid and the application engineering and after-sale support is available locally to service it.

On a practical level, always check the supplier for inventory and source of supply. Today, when your customers are demanding faster response times and more cost off-loading, you can expect the same from your tooling supplier. Likewise, application and engineering assistance should be available from local sources to support your tool choices.

The bottom line is the bottom line for most of us today. However, always consider the future jobs when purchasing tooling systems for your new and existing lathes. What might seem a bargain might not be, after the first big job is completed.

DIN and ABEC standards are the norm in industry and your supplier should be willing to supply all necessary documentation on request. Shortcuts on quality are never, repeat never, worth the short-term savings.

I hope this short primer on tooling will assist you in equipping your next machines.

For addition information or inquiries, please contact:

Preben Hansen, President

HEIMATEC INC.

16 E. Piper Lane Suite 129

Prospect Heights, IL 60070

Phone: 847-749-0633

Fax: 847-749-2445

Email: info@heimatecinc.com

Website: www.heimatecinc.com

—

Heimatec is an international tooling manufacturer, based in Renchen, Germany. Its experienced staff is dedicated to providing customers the most innovative tooling technology possible. In 2010, the company opened Heimatec Inc. in Prospect Heights, IL, near Chicago, to serve its growing North American customer base with sales and service, plus an extensive inventory of products. Heimatec serves the auto, aero, medical, off-highway, rail, energy, woodworking, composites and other industries, as well as an ever-increasing number of machine tool OEM’s worldwide.

Continue readingNew Heimatec system reduces downtime, eliminates costly changeover; ideal for the busy job shop or production department

HT Series quick-change tool adapter system from Heimatec requires only a single clamping bolt turn for changeover. Click the image to view the animation.

Heimatec, a world leader in live tools, angle heads and multi-spindle drill heads, announces immediate availability of its newest development, the HT Series quick-change tool adapter system. With the HT Series onboard, users do not need to change tooling, only the adapter and that action is accomplished with a single clamping bolt. In this way, collet assemblies can be preset outside the machine tool, then simply swapped out as needed.

Whether a one-off job shop or long run production department, downtime on any machine tool is costly and the HT Series reduces changeover from an average of 15-20 minutes down to about that many seconds. The tool head stays in the machine, so less probing is needed after the changeover, as well.

HT Series offers users a lower initial investment, minimized tooling time, reductions of tooling quantities and related costs, plus considerably lower inventories. Further savings are realized by the high degree of flexibility in the system, the shortest gauge line of any system on the market, meaning no additional tool length consumed, standard coolant-through design, exceptional repeatability to 0.0002” and easier handling of the components, resulting in lower setup costs.

This new quick-change system is available from Heimatec with all common outputs, including collet, extended collet, collet with tension and expansion for tapping, weld-on, weld-on extended, arbor, hydro-chuck, indexable insert holder, shrink fit and blank/plug design.

Interested parties can see the HT Series in action on youtube at:

http://www.youtube.com/watch?v=Wl7_978FQ94&NR=1

For further information and literature on this new product, please contact:

Preben Hansen, President

HEIMATEC INC.

16 E. Piper Lane Suite 129

Prospect Heights, IL 60070

Phone: 847-749-0633

Fax: 847-749-2445

Email: info@heimatecinc.com

Website: www.heimatecinc.com

—

Heimatec is an international tooling manufacturer, based in Renchen, Germany. Its experienced staff is dedicated to providing customers the most innovative tooling technology possible. In 2010, the company opened Heimatec Inc. in Prospect Heights, IL, near Chicago, to serve its growing North American customer base with sales and service, plus an extensive inventory of products. Heimatec serves the auto, aero, medical, off-highway, rail, energy, woodworking, composites and other industries, as well as an ever-increasing number of machine tool OEM’s worldwide.

Continue reading

This Grieve cabinet oven has 6” insulated walls, aluminized steel exterior, Inconel 600 interior with continuously backwelded seams and special exterior paint. The oven also features full inert atmosphere construction, including pressure regulator, flow meter, pressure gauge, internal high-temperature gasket, all-welded expansion connection in the doorway throat, air jacket on inner oven for cooling, ½” thick cellular silicone rubber atmosphere seal, blower shaft seal, positive latching door hardware, adjustable offset door hinges, outlet with pressure relief, interior seams welded gas-tight and all wall penetrations fitted with compression fittings.

No. 873 has a 650 CFM blower to pull air through the air jacket on the inner oven for cooling, plus automatic dampers. A hinged door jacket with 4” diameter connector to allow the jacket to be ventilated is also provided.

Sixteen pairs of shelf supports to support thirty-two Inconel 600 pans, with two pans on each level, plus loading truck tracks on the floor of the workspace, are built into this Grieve oven.

Controls on this inert atmosphere cabinet oven include a programming temperature controller, manual reset excess temperature controller, SCR power controller and fused disconnect switch.

To everything, there is a REASON…turn, turn, turn…

Here’s your best reason to stop by our booth:

At this year’s IMTS, Heimatec will display its live tooling in a unique way…a live demo on a rotating machine tool turret. Come and see the show!

Heimatec, a world leader in live tools, angle heads and multi-spindle drill heads, today announced immediate availability of its newest development, recently unveiled for IMTS.

U-tec is the company’s patented flexible tool adapter system that allows a standard ER output live tool to accept various adapters for different applications. This allows users the ability to have quick changeover of tools on almost any lathe, using a single live tool, without having to commit to a quick-change system on the initial purchase. A facemill adapter, for example, can be quickly positioned into the standard holder, without the need for a completely new base being installed. This significantly reduces inventory costs as well as changeover time, for the busy shop.

The U-tec system, according to Heimatec Inc. President Preben Hansen, “…represents a real improvement in lathe and mill/turn tooling design. U-tec allows great user flexibility, while a polygonal drive system ensures extremely high power transmission stability and faster set-up with absolutely no loss in performance or accuracy, because the live tool base remains in position and only the adapter and collet get swapped.”

He went on to explain the unique collet nuts on the U-tec system have internal threading for rigid mounting and that this new tool adapter system enables the actual cutting tool to be brought into closer proximity to the bearing, thus further improving performance in use. This benefit results from the short and compact tool length design. Internal coolant up to 2000 psi(140 bar) is provided standard.

Every adapter in the U-tec system comes complete with any necessary clamping nuts and adapters are immediately available in face mill style, ER extensions, side lock, shrink fit, hydraulic and blank.

The U-tec system is available for all major turning machines on the market today. Heimatec currently manufactures over 10,000 live tool types.

For further information and literature on this new product, please contact:

Preben Hansen, President

HEIMATEC INC.

16 E. Piper Lane Suite 129

Prospect Heights, IL 60070

Phone: 847-749-0633

Fax: 847-749-2445

Email: info@heimatecinc.com

Website: www.heimatecinc.com

—

Heimatec is an international tooling manufacturer, based in Renchen, Germany. Its experienced staff is dedicated to providing customers the most innovative tooling technology possible. In 2010, the company opened Heimatec Inc. in Prospect Heights, IL, near Chicago, to serve its growing North American customer base with sales and service, plus an extensive inventory of products. Heimatec serves the auto, aero, medical, off-highway, rail, energy, woodworking, composites and other industries, as well as an ever-increasing number of machine tool OEM’s worldwide.

Continue readingAdvanced Machine & Engineering Co. (AME) Rockford, IL announces their return to IMTS 2012. As in the past, they will have two booths to showcase their products and services.

Visit Booth W-2405 to learn about precision machine components, featuring:

Visit Booth E-5714, for additional AME products such

Our sister company, Hennig, Inc., will have their complete line of products in Booth E-5714 and W-2405.

Advanced Machine & Engineering Co., is a manufacturer located in Rockford, IL, serving the Machine Tool Industry with precision components and accessories, including spindle interface components, workholding devices, and, through our sister company, Hennig, machine enclosures, chip removal and filtration systems. The Fluid Power – Safety markets are served with cylinder rod locks and safety catcher devises; and the Production Saw market with our Amsaw carbide saw machines and Speedcut blade products. AME has manufacturing partners and customers around the world and across the U.S. To learn more, visit www.ame.com.

For more information, contact:

Tim Waterman

ADVANCED MACHINE & ENGINEERING CO.

2500 Latham St.

Rockford, IL 61103

Phone: 815-316-5277

Fax: 815-962-6483

E-mail: info@ame.com

Connect with AME online:

Integrated Sawing and Machining Center Sets New Industry Standard

The ACS Sawing Machine is the new industry standard for cold saws. It utilizes a proprietary sawing algorithm with servo motor controlled feed to continuously adjust critical sawing parameters during each cut. The results are the fastest sawing times, best surface finish and longest blade life available on the market.

The CFMcurve machining center is a patented Rattunde process that

Precision parts are made in one continuous process with no operator intervention. Bundles of mill length stock, up to 16.5 meters (54’) long, are placed in an automatic loader, individually separated and fed to the sawing process. Cut parts are then transferred to the CFMcurve machine for precise finishing. Utilizing advanced CNC controls, linear ball screws and servo motors, all mechanical motion is seamlessly integrated into the machine design for full process control.

The operator interface saves part files for instant recall when changing parts. Servo motors move all cutting and machining tools to their exact positions and implement saved parameters. No tooling change is required in the ACS Saw within a diameter range of 10mm; there is a 5mm diameter range in the CFMcurve. Tooling change for the complete system takes less than 20 minutes, when necessary.

All critical sawing and machining parameters are monitored and controlled. Clamping forces and position, saw blade torque and vibration, plus machining insert torque are continuously displayed and monitored. Operating limits are set and machine functions stop when they are not met. Saw blade and tooling insert wear is predictable and consistent. Key data for each part produced are stored in memory for statistical evaluation. All guesswork is removed for the operator.

Additional processes, engineered and manufactured by Rattunde, are easily integrated with the ACS + CFMcurve, including: part inspection stations, washing and drying, automatic packaging and automatic container changing, all available to further automate customer manufacturing. The system being exhibited at IMTS will include part inspection and automatic packaging.

The ACS + CFMcurve is available in three models with diameter ranges from 10mm to 102mm, 10mm to 136mm and 10mm to 169mm, with finished part lengths from 10mm to 3500 mm. All material types can be processed.

You can watch the machine in action at:

http://www.rattunde-corp.com/tube-sawing-video.htm

For further information, please contact:

Rattunde Corporation

4980 Kendrick St. SE

Grand Rapids, MI 49512

616-940-3340

Alec Banish

IMTS PRE-SHOW NEWS…BOOTH N-6737

No. 1022 is a 550ºF, electrically-heated, two-zone, dual belt conveyor oven from Grieve, currently used for encapsulation curing of large electrical coils in fixtures at the customer’s facility. Workspace dimensions of this oven measure 8’ W x 40’ D x 18” H. 480KW (240KW per zone) are installed in Incoloy-sheathed tubular elements to heat the oven chambers, while two 20-HP recirculating blowers provide a 49,000 CFM vertical downward airflow to the workload.

This Grieve conveyor oven comprises a 2’ long open belt loading zone and 3’ long insulated, unheated entrance vestibule, two 20’ long insulated heat zones with independent recirculated airflow and temperature control, 3’ long insulated unheated exit vestibule and finally a 2’ long open unloading zone for the workpieces.

No. 1022 has 6” insulated walls throughout, aluminized steel interior/exterior and is split into two sections for shipping. Side doors along the length of the oven permit access to the workload and heating chambers. This Grieve conveyor oven is built with all safety equipment required for handling flammable solvents and is constructed to NFPA 79/NEMA 12 electrical standards.

The oven further features two 3’ wide, 1-3/16” diameter cross bar conveyor belts with 1-HP motor drive, variable from 0.5 to 9 ipm. The conveyor belt drive is used in either index or continuous mode. Removable drip pans are provided below the conveyor assembly.

Controls on the oven include separate power and control panels, plus photo eyes at the unload station to signal an alarm, if the workpiece unloading is not cleared before conveyor indexing, SCR power controller for each zone and a tower light to indicate oven status. All control functions are accessed through a touch screen HMI connected to the onboard PLC.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart

Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-

9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank

Calabrese.

Continue reading