Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Event will feature speakers from Exact Metrology, FABTECH and Met-L-Flo to discuss the art of manufacturing and other innovative technology showcased at FABTECH 2015

WHAT: FABTECH 2015, North America’s largest collaboration of technology, equipment and knowledge in the metal forming, fabricating, welding and finishing industry, will bring 3D scanning technology to the steps of the Art Institute of Chicago on Sept. 16. Exact Metrology, a 3D scanning solutions company, will use its Surphaser technology – known for its high accuracy and scan data quality – to 3D scan the museum’s south lion by Edward L. Kemeys (1843-1907). The guardian lions have flanked the Art Institute’s iconic Michigan Avenue entrance for more than 100 years and have become a symbol of the museum and of the city.

Attendees will have the opportunity to witness Exact Metrology’s scanning technology firsthand and hear from industry leaders as they discuss the process and benefits of 3D scanning and printing. Additionally, speakers will provide a look at what other advanced manufacturing technology will be showcased at FABTECH 2015, taking place at Chicago’s McCormick Place, Nov. 9-12.

After the scan data is captured, Met-L-Flo will use it to print approximately 300 small-scale replicas of the lion, which will be on display and used as giveaways at FABTECH.

Following the brief press conference, representatives from FABTECH, the Art Institute, Exact Metrology and Met-L-Flo, Inc., will be available for interviews.

WHO: Dean Solberg, vice president, Exact Metrology

Ed Youdell, president and CEO (FMA), FABTECH

Carl Dekker, president, Met-L-Flo, Inc.

WHEN: Wednesday, Sept. 16

9 a.m. – Press to arrive; photo opportunities

9:20 a.m. – Press conference

WHERE: The Art Institute of Chicago

111 South Michigan Ave.

Chicago, Il 60603-6110

Note: Press conference to take place on steps near the south lion, located in front of the Art Institute.

About Exact Metrology

Exact Metrology is an ISO 9001: 2008 certified company that offers contract measurement & scanning services, metrology equipment solutions, and hardware & software rentals. Its goal is to provide customers with a specifically tailored solution to their measuring needs. To accomplish this, it offers more options, more products and more experience.

About FABTECH

FABTECH is North America’s largest collaboration of technology, equipment and knowledge in the metal forming, fabricating, welding and finishing industry. The event provides a powerfully aligned hands-on, face-to-face business growth experience, attracting more than 1,500 exhibitors and 40,000 attendees. The event is made possible by its five co-sponsors, all of whom representing the varied and diverse makeup of the manufacturing industry. They include SME, the American Welding Society (AWS), the Fabricators & Manufacturers Association, International (FMA), the Precision Metalforming Association (PMA), and the Chemical Coaters Association International (CCAI). Read more about FABTECH’s co-sponsors here.

About the Art Institute of Chicago

The Art Institute of Chicago collects, preserves and interprets works of art of the highest quality, representing the world’s diverse artistic traditions, for the inspiration and education of the public and in accordance with our profession’s highest ethical standards and practices.

About Met-L-Flo Inc.

Met-L-Flo, Inc., is a contract manufacturer specializing in 3D Printing and Additive Manufacturing services since 1991. It strives to partner with clients to implement innovative solutions for their product development and low volume production needs. Advanced applications of its technologies enable it to boost clients’ competitiveness and enhance product success. Its commitment to Quality is solidified in the company’s ITAR, ISO 9000 and AS 9100 Rev C Certifications.

As a leader in the industry, it prides itself on creating innovative, unconventional solutions that utilize both tool and tool-less applications. Products may be produced in metal, plastic, silicone, or wax including fiber reinforcement

For more information on the event, please contact:

EXACT METROLOGY, INC.

11575 Goldcoast Drive

Cincinnati, Ohio 45249

Phone: 513-831-6620

Toll Free: 866-722-2600

www.exactmetrology.com

stevey@exactmetrology.com

Steve Young, President

Connect with Exact Metrology online:

—

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

Continue readingAluminum profiles are produced in all shapes and sizes.

Often, these profiles can be very difficult to machine, because of the various shapes, sizes, number of operations required and cycle times needed. When a profile shape will not allow the holes to be punched and cycle time makes producing the parts on machining centers impractical, Suhner, with its modular design and broad assortment of spindle options, can now offer processors an ideal solution to their machining needs.

Suhner’s line of spindles for Profile Machining includes the popular MONOmaster Electric Driven, Pneumatic Feed Units, ranging in size from the smallest BEM-3 unit, capable of drilling up to a 3mm hole in mild steel, up to the BEM-28 unit, capable of drilling up to 28mm in mild steel and having 200mm of controlled stroke. Many of the units in the MONOmaster line are available with other options, such as inline, direct drive units for the BEM-6 and 12S, as well as 1:4 speed increasers for the BEM-6 &6D units capable of speeds up to 14,400 RPMs @ 60 Hz. With the larger BEM12 & 12D units, the option of 4:1, or 16:1 gear reduction is available, giving RPM speeds as slow as 40 RPMs @ 60 Hz.

Suhner also offers the MULTImaster line of flexible shaft driven units, a feature not currently offered by any other spindle manufacturer. These units are driven by Suhner flexible shafts and are ideal in areas where spacing is a critical concern. The smaller BEW-3 unit allows spacing as close as 48mm center to center. The BEW-6 unit, as close as 55mm center to center and the larger BEW-12 unit, as close as 75mm center to center, are also available. Using these units with Suhner’s VG System, users can drive up to (8) spindles with a single motor.

For high precision, tough applications, Suhner offers the POWERmaster line of spindles. This includes the BEX-15 & BEX-35 machining units, capable of running at speeds up to 23,000 RPM’s. These are block units, capable of milling, drilling and sawing operations. Suhner also offers a complete line of slide products to provide the feed movement for the block spindles. These slides are available in pneumatic or ball screw feed design, for either servo or gear motors.

Also very popular in the machining of aluminum profiles is Suhner’s line of adjustable and fixed spindle multi-heads for drilling special hole patterns or hole spacing where spindles are too large to fit into the required spacing for the center to center distances needed. Suhner’s line of special fixed spindle multi-heads is built in Rome, Georgia and often can be built to spec in less than six weeks.

A typical machine used by a major automotive roof rack manufacturer incorporates many of these Suhner items to produce the long bars for a Ford Escape roof rack.

This machine uses Suhner BEW-6 units to drill 6mm holes from the front and back side of the part, where electric spindles will not fit. BEM-12 motorized units, with special fixed spindle multi-heads are being used to produce 8mm diameter holes that are too close for even the smallest spindles to produce, when mounted side by side. Suhner’s BEX-35 PowerMaster units are used at each end of the part to saw the part to length (Under Yellow Covers). All these operations are ongoing at the same time to produce complete machined parts in seconds, a feat impossible to do on any conventional CNC machining center.

With Suhner’s modular spindle design and machining capabilities, most every need of the aluminum profile industry can be met in every market segment, whether automotive, industrial, solar, aerospace, military or commercial aviation.

SUHNER INDUSTRIAL PRODUCTS, CORP.

Hwy 411 S./Suhner Drive

P.O. Box 1234

Rome, GA 30162

Phone: 706-235-8046

Fax: 706-235-8045

Attention: Lee Coleman, Automation Division

www.suhner.com

automation.usa@suhner.com

Text and pictures files can be found and down loaded at:

www.suhner-press.com

At FABTECH 2015, Suhner will demonstrate its Somex® machining tools, featuring automatic tool clamping and tool release via pneumatic cylinder, designed for heavy-duty sheet and plate cutting to 2“. These tools are typically integrated with laser, plasma and waterjet machines. Thru-tool coolant is standard, along with spindle tapers of ISO/CAT 40. These rugged yet precision tools offer spindle concentricity to 0.01mm (0.0004“).

Adapters for servomotor mounting are onboard these Somex® tools, which also feature a timing belt drive system, max. speeds up to 6000 RPM, max. spindle torque to 400 Nm (275 lbs-ft). The tool without the motor weighs 55 kg (121 lbs).

Options include HSK63 spindle taper, servomotors to 7.5 HP, spindle position sensors and tool release via hydraulic cylinder.

These tools are available with linear ball screw slide assemblies with travel to 480 mm (18.9 in) and thrust of 5500 Nm (1236 lbf).

Many other Suhner drilling units for production and OEM machine integration will be on display, as well.

SUHNER INDUSTRIAL PRODUCTS, CORP.

Hwy 411 S./Suhner Drive

P.O. Box 1234

Rome, GA 30162

Phone: 706-235-8046

Fax: 706-235-8045

Attention: Lee Coleman, Automation Division

www.suhner.com

automation.usa@suhner.com

Text and pictures files can be found and down loaded at:

www.suhner-press.com

The oven travel comprises a 3’ long open belt loading zone, 18’ long insulated heat zone with recirculated airflow, 3’ long open belt unloading zone and a 30” wide, Type 304 stainless steel woven wire conveyor belt with 3” high flex plate edges, driven by a ½-HP motor v-belt drive, variable from 1-19 IPM.

This Grieve belt conveyor oven features 7” thick insulated walls, aluminized steel exterior and interior, exhaust hoods over each end equipped with a 12” diameter tubeaxial fan, driven by a ½-HP motor, plus all safety equipment required by IRI, FM and NFPA Standard 86 for gas-heated equipment, including a 650 CFM, ½-HP powered forced exhauster.

Controls on No. 867 include a digital indicating temperature controller and 10” diameter circular chart recorder.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

Siemens announces the enhancement of its popular Sinamics® S120 drive system with an integrated web server to facilitate more efficient diagnostic and maintenance functionality for end-users, integrators and system designers alike.

Sinamics integrated web server allows remote or local area maintenance checks at any time on various drive models in the Siemens drive family.

With this drive improvement, a user may access the Sinamics S120 with any PC with a browser capable of internet connectivity through a standard Ethernet interface to execute a variety of functions. If a wireless LAN (WLAN) router is networked, web pages can be viewed using other web-capable devices such as tablets and smart phones.

Among the functions possible with this integrated web server on Sinamics S120 drive systems are the ability to download a plant configuration, commission a drive from anywhere, perform firmware updates, access an immediate status overview on the drive, check and assess all alarm and fault messages. In addition, users can monitor and adapt all process or line parameter settings, archive machine documentation, including all notes taken, create customized server pages, set-up user administration and access level for operator and service personnel, plus perform virtually all drive diagnostics and remote maintenance actions. This combination of service possibilities results in significant reductions in machine or line downtimes due to faster, more efficient diagnostic and maintenance procedures.

Connectivity of the Siemens Sinamics drive system to the Internet for full web browsing, access and maintenance capability.

This Sinamics S120 drive system enhancement ideally suits applications where no special software or model version dependencies are desired. Series commissioning on a line is possible and the web server is compatible with all system security measures, such as a firewall. An up-to-date internet browser is sufficient for access. This web server capability is integral on Sinamics S120 drive firmware V4.6 or greater.

For more information about the Sinamics S120 web server, please visit: www.usa.siemens.com/sinamics-webserver-pr

—

Siemens Industry, Inc.

John Meyer

(847) 640-1595

john.meyer@siemens.com

Siemens Industry, Inc.

Hollie Davis

(770) 751-4882

hollie.davis@siemens.com

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: mc.us@siemens.com

Continue readingFranklin, Georgia Tier One automotive supplier realizes up to 70% greater output from its internally designed production equipment, utilizing Suhner advanced drilling technology

See the video here!

JAC Products (Franklin, Georgia) puts 30-40 million holes into approximately 6 million pieces of extruded and formed aluminum each year. The products made at this facility are used as roof rack rails on nearly every major automobile, mini-van and truck brand. This fact translates into a majority share of the North American vehicle market for JAC.

As Mike Traylor, the JAC tool room & die shop manager notes, “We build and maintain nearly all our own machinery here in our factory. That means the whole team must keep striving to find greater efficiencies and new ideas.” As a vertically integrated manufacturer, JAC operates hundreds of drilling stations in its Franklin factory, located on the banks of the Chattahoochee River in southeastern Georgia. In the company’s extrusion department, millions of pounds of aluminum are extruded annually from 6061, 6063 and 6463 alloys. The extruded shapes then move to the fabrication department, where they are formed and drilled on highly automated equipment to produce the finished products. Following a decorative and wear-resistant finishing operation, JAC performs the final assembly of the products and ships directly to the customer’s assembly line.

A tour of this facility strikes the visitor in several ways. First, there is a steady flow of material between departments and very little wasted motion, as every station at JAC is a dedicated operation producing an average of 100,000-200,000 left- and right-side rail sets per year for each specific automobile model.

Another point of note is the openness of the machinery. That condition results, according to Traylor, from one very important supplier to JAC, one that has been a partner to this Tier One for nearly 20 years. Suhner Automation Division, based in nearby Rome, Georgia, supplies an assortment of flex shaft and direct motor-driven drilling units to JAC, where Traylor’s team of mechanical specialists incorporates them into the company’s internally-designed production equipment. Owing to the flex shaft design on many drills, the drive motors are removed from the cutting area, making accessibility much better not only for operators and maintenance personnel. This configuration also improves access to other equipment such as laser trackers and position sensors. “The bottom line, as they say, is that we get upwards of 60-70% more output from our equipment since we began using the Suhner solutions for our drilling,” notes Traylor. The previous drills used here were also prone to breakdowns and service problems, which caused unacceptable delays in production, especially as the industry transitioned to the just-in-time philosophy. As Mike comments, “If JAC was going to keep up with JIT, we needed a more reliable supplier and better ergonomics on our equipment to improve the output.” He contacted an associate from a previous company relationship, Charles Stitcher, the regional marketing manager from Suhner, who presented his company’s solutions in flex shaft and related drilling devices. “It was a light bulb moment for our company,” says Traylor, “because we knew we’d found an answer to a lot of our challenges.”

By taking the motors out of the drilling area, the JAC operators could have much freer access to the work product, while the maintenance personnel could access a single manifold in many cases to do repairs, routine maintenance or replace components. Most of the machines designed here are dedicated pieces of equipment, used to produce a single rail set for a particular model, then retrofitted or rebuilt for the next generation, next model year design, or a completely different vehicle by Traylor’s team. The flex shaft design gave the machine building and maintenance group at JAC a significant advantage and it has continued to benefit the company in many ways, according to Traylor. “We can now use a more compact work area concept, which saves operator steps. Seems like a little thing, but when you do the math and the motion study, it represents a huge annual savings for our company, without sacrificing any safety considerations for our workforce.”

As one might guess, JAC understands the fabrication process for putting holes into aluminum, whether for roof mounting, rivet placement, or trim assembly. Often, the angle of the drill must be oriented to the surface of the workpiece, rather than in a typical x-y planar arrangement. Here again, the flex shaft design of the Suhner drills pays big dividends for the machine designers at JAC, as it allows them to position the drilling mechanisms in various configurations and tighter proximities. This allows the required accuracies, secondary counterbore operations or other processing steps to occur. After working on nearly 500 machine builds at JAC, Mike Traylor says he’s been very impressed with the flex shaft drill and its adaptability on a wide variety of applications.

“On one rail set for a Ford vehicle and another for a Toyota vehicle, the old way would have involved one operator performing all the drilling, one step at a time. Today, we have up to 11 drills and a cutoff operation, all performed at once. The savings in setup time alone are off the chart.” He cites another job where the output was previously 1200 sets per day and is currently 1200 per hour.

Not all of the drilling here is done with flex shaft models, however. On several dedicated machining operations, various Suhner motor-mounted drills are utilized, including a specially designed system for sawing.

Senior Launch Manager at JAC, Alberto Blanco, comments, “We need to hold +/- 0.1-0.2mm tolerances on the drilling and +/- 0.5mm on our cutoff lengths for our customers, so the Suhner equipment capability has been very favorable in helping us deliver our value proposition to customers.” Traylor adds that the drills are used virtually non-stop, so wear is inevitable, further noting the availability of Suhner rebuild kits, including o-rings and seals, makes maintenance much easier for his team.

Finally, Jeff Cavalier, the JAC engineering & facilities manager notes, “With the support we get from Suhner, we know Mike and his team can make it happen, every day, creating and maintaining the machines that get the job done for our customers. That’s a nice feeling.”

SUHNER INDUSTRIAL PRODUCTS, CORP.

Hwy 411 S./Suhner Drive

P.O. Box 1234

Rome, GA 30162

Phone: 706-235-8046

Fax: 706-235-8045

Attention: Lee Coleman, Automation Division

www.suhner.com

automation.usa@suhner.com

Text and pictures files can be found and down loaded at:

www.suhner-press.com

New force measuring instruments need to have more functions and features, be smaller and offer more value for the money. PENKO responds to this challenge with its new product range, Type 1020-FMD. These instruments are suitable for automatic as well non- automatic applications. They are an ideal interface between load cells with an integrated controller to the system for data processing.

The unique PENKO way of measuring with high-speed of 1600 conversions/sec and high internal resolution, 24 bit, guarantees a fast and accurate data transfer and/or cut-off. These characteristics allow application of the instruments for static and dynamic force measurement as well as destructive material tests. These applications are supported with zero adjustment, track recording, hold/peak, hold/valley, hold and overload protection.

As a standard, all Type 1020-FMD models are provided with USB to facilitate set-up and back-up functions. Additional models include RS232, RS485/422, Ethernet, CANBUS and Profibus. The range is completed with an analog output, 0/4 – 20/24 mA. Easy and fast calibration is done digitally. The force is displayed by means of a bright 2.8” TFT screen with 13 mm high figures, plus a color bar.

Choose from two enclosures, a compact panel model and stainless steel housing.

• The panel meter has a front of 150 x 76 mm and a depth of only 82 mm;

• The stainless steel enclosure size including the swivel bar is 180 mm x 145 mm x 153 mm (W x H x D).

For easy selection, a free brochure is available: 1020 Series Brochure.

Contact:

Susanne Krause, Marketing Director

Penko Engineering B.V.

Schutterweg 35

Ede, The Netherlands

Phone: +31 (0)318 525 630

www.penko.com

skrause@penko.com

In the United States:

Karl Cornelius, National Sales Manager

Powerforce LLC

229 Dunavant Road

Rockford, TN 37853

Phone: 865-318-5532

www.powerforceusa.com

karl@powerforceusa.com

Operations for the prep on tubings and pipes generally require multiple manufacturing steps such as cutting, chamfering, face-off, turning and tapping including thread milling or thread forming.

Higher part quantities usually combined with the need for different manufacturing steps demand efficient and time saving production methods to help reduce time and cost. Special purpose machines such as rotary & linear transfer machines, offer the best solutions to help obtain shorter overall part cycle times.

The machining of tubings begins from bar stock length

The transfer machine performs OD and ID turning incl. chamfering oerations followed by thread rolling.

An extensive background of experience with operations on transfer machines allows SUHNER to optimize a manufacturing process with standard or custom solutions for each machining application. One specific application is for large & long OD threads. These operations are extremely difficult and challenging for manufacturers, when trying to obtain shorter cycle times, simply because an OD threading operation by itself will dictate the overall machine cycle time.

SUHNER, in cooperation with WAGNER, a German manufacturer for OD thread rolling heads, has developed a special process, which allows threading operations in very short cycle times. A pneumatic cylinder-activated system is used to open and close the thread rolling head, which is equipped with multiple thread cutting or forming inserts.

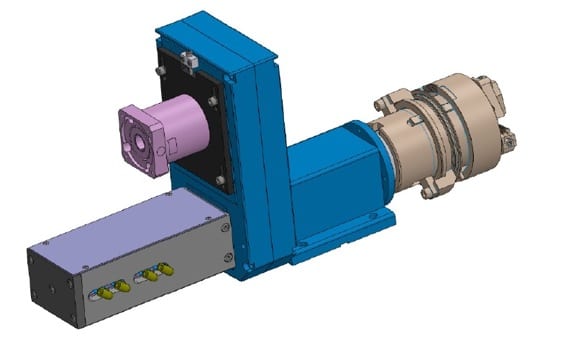

Special unit BEX35 ISO40 equipped with WAGNER Z27-2 thread rolling head allows optimized OD thread rolling operations and shortened machine cyle times

The work piece is fed from bar stock material. After a cut to length operation, it is machined by (3) Suhner BEX15 machining units with special Weldon tool holders. Operations include OD & ID and face turning. All units are equipped with a 1.5kW motor and high precision angular contact spindle bearings.

The most interesting station on this machine is the one for an OD threading operation, which is accomplished with a BEX35-ISO40 machining unit equipped with a WAGNER Z27-2 thread rolling head. In this operation, the thread rolling head is rotating and the work piece is stationary. The feed motion for this station is done with a CNC slide unit. In order to synchronize the thread pitch, both the BEX35 spindle and CNC slide are servo motor driven.

As soon as the threading operation is finished, the WAGNER thread rolling head with integrated inserts opens quickly to allow a fast return to the home position.

Opening and closing action of the head is accomplished by an internal BEX35 drawbar, controlled by a 3-position pneumatic cylinder.

This pneumatic cylinder is designed to make an additional stroke of 10mm. This allows for head and insert adjustments or replacements, depending on thread size.

Depending on length, a typical OD thread rolling cycle time ranges between 6 -10 seconds. Illustrated work pieces are steel tubings as used in the HVAC product industry. There are 7 part variations, each with a different thread size, pitch and length requirement. Thanks to the application of CNC servo driven spindle and slide components, customers can achieve very short changeover time, as well.

SUHNER INDUSTRIAL PRODUCTS, CORP.

Hwy 411 S./Suhner Drive

P.O. Box 1234

Rome, GA 30162

Phone: 706-235-8046

Fax: 706-235-8045

Attention: Lee Coleman, Automation Division

www.suhner.com

automation.usa@suhner.com

Text and pictures files can be found and down loaded at:

www.suhner-press.com

First application of CT scanning for metrology in America involves aluminum casting

Josh Schradin, one of the 3D Scanning specialists at Exact Metrology’s Cincinnati facility, recently completed a CT Scanning project involving aluminum castings measuring approximately 12” x 6” x 6” and weighing 10 to 15 pounds.

For this particular job, which represents the first use of CT scanning for metrology in America, the client was interested in wall thickness inspection as well as porosity and void analysis. The blue paint visible in some of the images was applied by the customer to indicate stress areas where leaking or breaking was suspected. Josh Schradin performed three stacked scans, each taking only about 30 minutes, to capture the entire casting. The result of the scans revealed the voids (legitimate holes) and highlighted the most serious problem areas in red-to-pink shadings.

In addition to offering the only method to get 3D views inside a part, another primary benefit of the Exact Metrology CT scanning is the true dimensional data provided in a non-destructive test manner, i.e. without cutting up or otherwise destroying the test object.

The workpiece (casting) was rotated 360 degrees in the x-ray beam’s path, with multiple readings from various angles being taken. Once the CT grey scale images were converted into voxel-based 3D point clouds, Schradin was able to generate a CAD-to-Part comparison for the customer.

If interested parties have a need for Internal Defect Analysis/3D Quantitative Porosity Analysis, Materials Structure Analysis or Assembly Control, CT Scanning (Industrial X-ray), Exact Metrology invites inquiries for immediate assistance.

Exact Metrology is an ISO 9001:2008 Certified Company.

To see videos on this new scanner’s capabilities, please visit:

VG GE casting analysis with CT hi-res at Exact Metrology

v | tome | x m CT scanner at Exact Metrology

For more information on this new system or to arrange a demonstration, please contact:

EXACT METROLOGY, INC.

11575 Goldcoast Drive

Cincinnati, Ohio 45249

Phone: 513-831-6620

Toll Free: 866-722-2600

www.exactmetrology.com

stevey@exactmetrology.com

Steve Young, President

Connect with Exact Metrology online:

—

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

Continue readingNo. 980 is a 500ºF (260ºC), electrically-heated universal style oven from Grieve, currently used for post curing fabric-coated silicone rubber gaskets at the customer’s facility. Workspace dimensions of this oven measure 30” W x 144” D x 30” H. 24 kW are installed in Nichrome wire elements to heat the oven chamber, while a 4200 CFM, 3-HP recirculating blower provides front-to-rear universal airflow to the workload.

This Grieve universal oven features 4” thick insulated walls, aluminized steel exterior, Type 304, 2B finish stainless steel interior, plus an integral oven leg stand and one pair of truck wheel guide tracks installed on the top of the floor to accept the customer’s wheeled fixture.

No. 980 includes all safety equipment required for flammable solvent processing, including explosion-venting door hardware and powered forced exhauster.

Controls on this oven include a digital indicating temperature controller.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP