Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

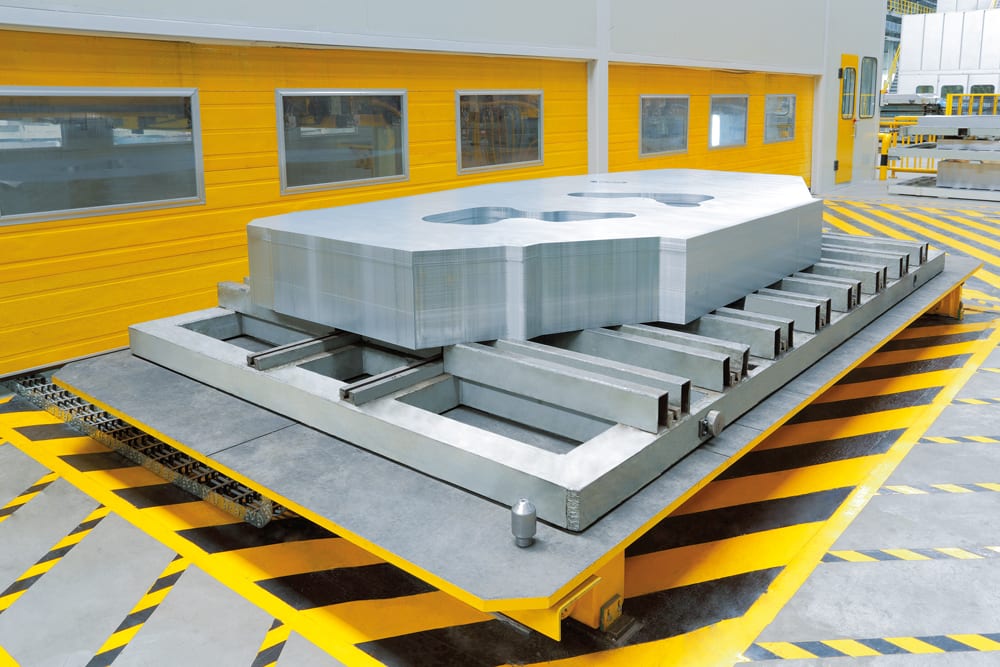

Canton, Michigan, December 2, 2019 – Customers from Germany, the US and China have already invested in laser blanking lines from Schuler. Recently, Schuler received another order from the People’s Republic—this one by one of the largest Chinese steel producers for a plant in Tianjin, as well as an order from a customer in South Africa. Around 50 visitors took advantage of Schuler’s invitation to learn about the benefits offered by the technology during two days in Heßdorf, Germany. They also had a chance to look at the actual system that will be delivered to China.

South African automotive supplier VM Automotive is expected to begin producing blanks for the plant of a high-end German automaker in South Africa (among other jobs) on a Laser Blanking Line 2.18 in the fall of 2020. The newly established blanking operations will handle the full scope of material logistics for the car manufacturer, thereby increasing the value in South Africa. By investing in this highly flexible laser blanking line, VM Automotive was able to gain the upper hand over competitors that use conventional blanking systems. Additional logistics centers are planned for other auto manufacturers in South Africa.

In 2014, a high-end German automaker ordered one of two laser blanking lines for mass production, and the equipment began producing two years later. “Our customer no longer has any dies for these blanks,” noted Martin Liebel, who manages the Schuler site in Heßdorf, a town located in the vicinity of Nuremberg. A highly flexible laser beam now performs the work formerly handled by the dies. This laser beam makes it possible to alter the blanking shape at the push of a button, whereas altering a blanking die can take several months, not to mention the accompanying costs for storage and maintenance. And when the set up time is taken into consideration, the overall equipment effectiveness (OEE) climbs to 80% for the laser blanking line, compared to just 65% for conventional press blanking lines.

With the system’s DynamicFlow Technology, a laser blanking line is up to 70% as productive as a modern servo blanking line with a press. “Output actually significantly exceeded our expectations,” said Liebel, adding that it had been possible to regularly increase output by a few percentage points with the help of a number of smaller measures. A proven cleaning process ensures that the system produces high-quality blanks which are also spotless—an important requirement for critical body shell parts. The same German carmaker went on to order two additional high-tech lines in 2017.

At roughly the same time, Schuler began developing a new concept featuring two laser heads instead of three. “We needed a basic machine that would also deliver solid, acceptable performance for the rest of the world,” said Liebel. The decision proved to be the right one, as evidenced by the orders for one Laser Blanking Line 2.18 each from China and South Africa this year. “The systems are becoming more and more dynamic, and the concept will win out in the end,” said a confident Liebel.

One of the things that makes these systems so dynamic is the distance control for the lasers. This control maintains a distance of 0.7 to 0.9 mm from the continuously moving coil and, where necessary, corrects the distance within fractions of a second to ensure that any residual surface irregularities in the sheet metal do not damage the heads. Liebel explained, “This axis is critical to the line’s output. Each coil contains residual waves. If I’m looking to blank at a rate of 100 meters per minute, I need to be able to respond extremely dynamically.”

Larger surface irregularities are eliminated by the straightener. “The straightening result is a key ingredient to a stable process, especially for the laser blanking line,” added Regional Sales Manager Justine Fonteyne. “To make this happen, we use the ‘Check2Flat’ system, which adjusts the crowning on the straightener rollers.” Either the visualization system makes a recommendation based on the adjustment system, which the operator must then review, or the straightener itself can provide a fully automated control. “It’s important to remove as much of the tension from the material as possible so that the metal doesn’t pop up during blanking. These types of systems help to ensure process stability.”

According to Liebel, another increasingly important aspect for carmakers is the intelligent capacity utilization of production facilities across the globe. “But it’s difficult to make a product somewhere else on short notice if you’re using a press blanking line. To do so, our customers first have to move the die, prepare it for shipment and then send it off.” If a supplier is producing the blanks, the scrap chutes or something else may not fit. “With laser blanking lines in the production network, all I have to do is send a data set for the desired part and make sure that the coil material is available on-site. If the system has available capacity, production can start one or two hours later. It’s really a huge advantage.”

Fonteyne’s coworker Berthold Jüttner offered another example: “One of our customer’s plant managers had a problem with a blanking press and had asked another plant manager if he would be able to cut a few blanks for him on the latter’s laser blanking line. He then immediately sent the drawings and had the coils brought to the site. Blanking began the next day.”

In addition to the newly achieved blank programming freedom, Jüttner saw another advantage in the line’s excellent dimensional accuracy, reproducibility and surface quality. “There are no burrs and the amount of cuttings is significantly less than in conventional blanking.” The so-called “angel’s hair” phenomenon is especially prevalent where blanks are cut from aluminum coils, and is also the reason why blanking presses regularly need to stop so that the dies can be cleaned. “This is no longer an issue with the laser blanking line.”

Laser blanking also makes it possible to support the material across its entire surface area. “We can nest the parts edge-to-edge on the coil and no longer need the 8 to 10 mm dividers required when using the blanking dies. For small cutouts, we can briefly open the belts and the scrap can drop into the scrap chute. On the new lines, the scrap and the usable parts are no longer separated using robots, but rather by an intelligent sorting system. This provides an additional boost in output.”

The growing amount of high strength steels used in automobiles is increasingly pushing blanking presses closer and closer to their maximum mechanical loads, adds Liebel, who noted: “When it comes to yield strengths, there are no limits in laser blanking. We have performed many tests and high-strength steels are no problem.” As Jüttner added, “The laser doesn’t care at all what’s under it.”

According to Liebel,” The bundled beam of light darts across the metal coil at speeds of up to 100 meters per minute and a thickness between 0.7 and 2.5 mm.” Before the year 2000, it was only possible to achieve blanking speeds of 4 or 5 meters per minute using CO2 lasers. Then the fiber laser made its triumphant entrance and opened up the possibility of laser blanking for the first time. This development wouldn’t have been possible with conventional gas lasers.”

In addition, noise emissions are much lower than with blanking presses. “If sound protection is installed on the laser blanking line, you’ll have to look very carefully to see whether the line is running or not,” Jüttner commented. He added that a person can have a completely normal conversation, as long as a press isn’t running next to them. The investment cost is also significantly lower, since the laser line is not as tall and also does not require an elaborate press foundation. “That’s a huge cost factor,” concluded Jüttner. The loop for the material buffer is also routed above ground. However, the laser line’s energy requirements are comparable to those of a press blanking line.

Schuler has developed a software package, the LBL Studio, designed to greatly reduce the operator workload required to program the laser cutting movement. “All you have to do is upload the drawing data and the program will calculate the best-possible contours, the possible nesting options and the optimum level of laser utilization,” Fonteyne said as she listed the software’s benefits. “This means that users can already define the laser movement contours and configure the transitions offline. The binding output quantities can also be predicted. After that, the data can be transferred to the control system, and production can be run exactly as configured.”

www.schulergroup.com/Laserblanking

About the Schuler Group – www.schulergroup.com

Schuler offers customer-specific cutting-edge technology in all areas of forming technology – from networked presses to press shop planning. In addition to presses, the product portfolio also includes automation and software solutions, dies, process know-how and service for the entire metalworking industry. Our customers include automobile manufacturers and automotive suppliers, as well as companies from the forging, household appliance and electronics industries. Presses from the Schuler Group mint coins for more than 180 countries. As a provider of innovative system solutions, we support our customers worldwide in the digital transformation of forming technology. In the 2018 fiscal year, Schuler generated sales of € 1 212 billion. Schuler AG, founded in 1839 at its headquarters in Göppingen (Germany), has approx. 6 600 employees at production sites in Europe, China and America as well as service companies in over 40 countries. The company is majority-owned by the Austrian ANDRITZ Group.

Schuler in Heßdorf was founded in 1962 as Hermann Schleicher GmbH, with the original headquarters in Erlangen, before joining the Schuler Group in 1990. The facility’s product portfolio includes automation solutions ranging from coil loading to end-of-line destacking. The most important areas it serves are the auto manufacturing, automotive supplier, and household appliance industries. The location employs approximately 350 people.

For further information on Schuler Inc., North America, please contact:

Guido Broder, Vice President of Sales & Marketing

Schuler Incorporated

7145 Commerce Blvd.

Canton, MI 48187 USA

734-207-7200

Guido.Broder@schulergroup.com

GMTA, the North American distributor of Profilator, has added new machines using the process modules it already supplies. Profilator is suitable when customers require complex machining processes to be carried out effectively, efficiently and with high precision.

Today, an operator working on a modern machine expects a flexible manufacturing process, short cycle times, reduced investment and running costs. With these requirements in mind, Profilator offers polygon & face slot machining, gear tooth pointing, chamfering and deburring, gear and spline cutting, shifter stop machining and Scudding®.

The polygon turning unit is used for castle teeth machining on automotive gearbox parts. The rotating cutterhead is synchronized with the workplace spindle and a front face coupling is produced with the carbide insert arrangement and the transmission ratio. With additional inserts on the same cutter head, the part can be deburred. In gear tooth pointing, the pointing tower can be used in both rotative and indexing modes. Settings and corrections are made through the new Ergo Control SIMPS® (Profilator Simplified Integrated Machine Programming System). For the chamfering and deburring of splines, gear wheels and shafts, Profilator uses the ZEM series gear deburring machines. This vertical, single spindle gear deburring machine offers clear advantages over conventional deburring machines. Gear cutting is used both for the Profilator rotative gear cutting with inserts and for hobbing. Through the application of Schlagzahn tools and carbide inserts, customers achieve the most economical manufacture of splines, gears, involute gears and front face gears. The shifter stop is synchronized so that the tool machines each tool flank. Lastly, Scudding® can be used for a wide range of symmetrical gear applications as well as non-symmetrical gear or profile applications such as belt pulleys and synchronize gears. The same machine can be used for internal and external Scudding® applications.

Profilator developed the S-type machine. This is a compactly and modularly designed, vertical single spindle pick-up gear cutting machine. Machines in the S Series are better than broaching and most applications feature a dry machining process. All machine components are designed for especially high static stiffness and optimal dynamic behavior. Furthermore, the machine’s twin spindle arrangement speeds up the process considerably. A control panel and a media container are installed on the rear of the machine bed. The workplace flow direction is variable. S-type machines are available in three sizes, namely Profilator S-150, Profilator S-250 and Profilator S-500. Profilator S-150 has a part diameter up to 150 mm, while Profilator S-250 and S-500 have a part diameter up to 250 mm and 500 mm, respectively.

For more information, please contact:

Walter Friedrich

President

GMTA

4630 Freedom Drive

Ann Arbor, MI 48108

+1-734-973-7800

walter@gmtamerica.com

www.gmtamerica.com

GMTA is the exclusive distributor for a number of top-quality German and other metalworking machine builders companies including Arnold, BvL, K+G, Praewema, Profilator, Rasoma, Samag and WEMA Glauchau. The company’s headquarters is located in Ann Arbor, Michigan with a subsidiary in Queretaro, Mexico.

Continue reading

A statue honoring Cincinnati civil rights activist Marian Spencer is underway. While Cincinnati already has several mythical representations of women, this would be the first statue of a real woman. Spencer was the first African American woman elected to Cincinnati City Council (1983) and the first female president of the Cincinnati Chapter of the NAACP (1981). She led the campaign to desegregate Coney Island swimming pools in the 1950s when her children were denied entry based on their skin color. Her subsequent lawsuit lead to integration. In addition, Spencer also fought to desegregate Cincinnati public schools. Spencer passed away this year at 99.

Earlier this year, Alicia Schneider, the Committee Chair of the Women’s City Club, approached Spencer’s friend and biographer, Dot Christensen and asked her if Spencer would like to have a statue made in her honor. Marian Spencer supported the idea. The Women’s City Club set up a Spencer Statue Fund at Fifth Third Bank. The group hopes to raise $125,000.

Local Cincinnati sculptor Tom Tsuchiya was commissioned to make the statue. Tsuchiya is known for the statues of Reds players featured outside the Great American Ball Park. The statue will be a life-size rendition of her during her city council days with arms outstretched and two portrayals of modern children. Tsuchiya wanted to depict Marian in an authentic way. He said, “I decided against a single figure. That kind of statue is mounted high and it’s meant to be imposing, looking down on everyone. Marian wasn’t like that. She was a person of the people.” He added, “It’s also 2/3 of a circle with the figures’ hands outstretched so that people can walk up to it and complete the circle.”

Noah Branscum, from Exact Metrology, scanned the clay model of the figures using the GOM ATOS Triple Scanner. The ATOS triple scan is a high resolution, optical digitizer that delivers rapid and precise 3D measuring data for the optimization of design processes. Thus, it improves industrial production processes. ATOS sensors are used in several industries for the inspection of parts such as: sheet metals, tools and dies, turbine blades, prototypes and injection molded and pressure die cast parts. It offers advantages in measuring reflective surfaces or objects with complex indentations. The software of the sensor is continuously monitoring the calibration status, the transformation accuracy, environmental changes and part movement to ensure the quality of the measuring data.

Ronnie Hensley used Geomagic Wrap to make the scan data (mesh file .stl) water-tight and scale it to actual size. Geomagic Wrap enables users to transfer point cloud data, probe data and import 3D formats into 3D polygon meshes for use in manufacturing, design, entertainment, archeology and analysis. The software intelligently processes complex point cloud data to revolutionize the way digital design and manufacturing is performed. It also revolutionized 3D printing, prototyping, and engineering. Tom then took the files from Exact Metrology and supplied them to other shops to build the statues.

The statue will be located in the Women’s Committee Garden of Smale Park. Spencer will be facing due south, looking at the John A. Roebling Suspension Bridge. The National Underground Railroad Freedom Center is right behind the statue and a playground in located to the west. The statue is expected to be presented June 28, 2020 on what would have been Marian Spencer’s 100th birthday.

Exact Metrology is an ISO Certified, AS9100, FFL and ITAR Certified Company.

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D scanning, reverse engineering, quality inspection, product development CT scanning and services and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

GOM GmbH

GOM develops, produces and distributes software, machines and systems for 3D coordinate measuring technology, 3D computed tomography and 3D testing based on latest research results and innovative technologies. With more than 60 sites globally and more than 1,000 metrology specialists, GOM guarantees professional advice as well as support and service. More than 14,000 system installations improve the product quality and manufacturing processes in the automotive, aerospace and consumer goods industries.

For more information, please contact:

EXACT METROLOGY, INC.

Steve Young

11575 Goldcoast Drive

Cincinnati, OH 45249

Telephone:

Local: 513.831.6620

Toll Free: 855.727.9226

www.exactmetrology.com

stevey@exactmetrology.com

This Grieve oven features 10” thick insulated walls comprised of 2” 2000°F ceramic blanket and 8” of 10 lb/cf density rockwool. Features include a top mounted heat chamber, aluminized steel exterior and Type 304, 2B finish stainless steel interior. Additional features include a rear door for access to workspace and heat chamber, exhaust hood over drawers and motorized dampers on intake and exhaust for accelerated cooling.

The oven includes all safety equipment required by IRI, FM and National Fire Protection Association Standard 86 for gas-heated equipment, including 1800 CFM stainless steel powered forced exhauster. It also meets AMS2750, Class 2 (±10F), Type C (survey thermocouple at hottest and coldest location).

Controls on the No. 1049 include a digital indicating temperature controller, two digital shutdown timers, one for burner and one for oven and a circuit breaker disconnect switch.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, Illinois 60073-2835

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese

Presentations were given by company personnel on September 13, 2019 in Ravensburg, Germany.

The company was founded in 1919 as a mechanical workshop by Anton Arnold. At the time, the company was considered a special welding plant for cast iron and aluminum. From 1950, under the leadership of Karl Arnold, the company developed contract turning for automatic turning parts. From 1969, the focus shifted to equipment construction and special machines for various industries. In 1985, the first laser system was built for ZF Friedrichshafen.

While competitors need to adjust beam guidance after every mirror change, the change was a matter of a few minutes for Arnold and production could be continued immediately. This production-oriented thinking has continued with the company’s machine designs. All important components were geometrically overdetermined and could only be installed with proper production.

In the first years, Arnold focused purely on welding machines. The aim was always to build a single block machine, possibly supplemented by conveyor belts for component supply and removal.

Even though there were isolated laser projects parallel to the classic special machine construction of the first few years, the main focus of the company since the 1990s has been the construction of laser systems. The first few laser applications were used in gear wheels, heat exchangers, shaft welding with induction and starter contacts for incandescent lamps.

New technology developed by Arnold features systems for rotary parts such as a double station and the M800/1500 units. In addition, the company offers new concepts of 3D systems used for welding, cutting, powder application welding, hardening and polishing. The newest flex cell and gantry systems feature up to 7 axes working simultaneously. Lastly, the company developed two extreme expansion stages of gear wheel welding systems. These are fully automated systems.

Functional extensions on the current machines include robots, conveyors, press stations, additional axes, induction preheating, UMH preheating, brushing stations, runout test stations and ultrasonic testing.

Current projects include Melato (manufacture of pressing tools from layered, laser-cut sheets), POLAR (laser polishing), KLASSE (laser cutting and solidification with an optic in a gantry system) and GeKoWig (titanium powder application welding in a protective gas atmosphere).

Together with IWS, Arnold has developed Remoweld Optic, a high-frequency optic scanner. With this scanner, copper, aluminum and mixed compounds can be welded virtually splash-free. With IWS, the company exhibited the optic scanner at various trade shows. The response has been very positive and several interested parties have approached IWS with potential applications.

In conclusion, Arnold has undergone many transformative changes in the past 100 years and it continues to expand its capabilities to better serve its customers.

For more information, please contact:

Walter Friedrich

President

GMTA

4630 Freedom Drive

Ann Arbor, MI 48108

1-734-973-7800

walter@gmtamerica.com

GMTA is the exclusive distributor for a number of top-quality German and other metalworking machine builders companies including Arnold, BvL, K+G, Praewema, Profilator, Rasoma, Samag and WEMA Glauchau. The company’s headquarters is located in Ann Arbor, Michigan with a subsidiary in Queretaro, Mexico.

Continue reading

Exact Metrology featured their new hot product, the GOM CT Scanner, which provides 3D data of internal and external component geometries in exceptionally high resolution. The Leica Absolute Scanner and Absolute Tracker were also featured in the booth as was the Hexagon Absolute Arm. Exact experts spoke with attendees about their onsite scanning and measurement services including 3D scanning, reverse engineering and CT scanning. Exact offers testing, including onsite, plus equipment sales to the fab industries and others.

Schuler, a press manufacturer, attracted visitors to their booth with a hydroformed Harley Davidson motorcycle frame on display. Hot topics included IIOT solutions, automated smart presses, hydroforming and metal stamping applications and press lines for lightweight materials.

Siemens displayed their new SINUMERIK Motion Controller (MC), which is the perfect platform for the fabrication industry in regards to laser cutting, water jetting, plasma cutting plus wood routing and stone cutting. The booth also featured the SINUMERIK 840D sl CNC and a SIMATIC PLC for various motion control requirements in the fab industry. Other topics included Mindsphere, digital twins and additive manufacturing.

Suhner had an eye-catching display complete with sparks flying, which showcased ROBOT tools grinding, polishing, tube polishing and filing. On display, Suhner had two files, a narrow and a broad belt grinder. They also had air spindles and an electro spindle. The booth also featured the MONOmaster drill unit made in Switzerland and the ECONOmaster made in Rome, GA. Among those machine tools were POLYdrills which are multi head drills that perform anywhere from 2 to 32 drilling applications at one time and deep hole drills that can drill from 200 millimeters to 500 millimeters and 800 millimeters. Suhner also provides the industry a full range of abrasive hand tools and pads.

All booths were crowded with considerable traffic over the course of the show. Another successful Fabtech in Chicago! See you in Vegas next year!

-Maureen Lepke, Social Media Director

Continue reading

Daniel Fernandez-Davila has made this trip for 21 years, accompanied by his students and residents from Wayland, Massachusetts. Besides Kleinhenz, the team included Antonia Hieronymous, Rachel Lorenc and Nick Ciorogan. Daniel and Antonia started a non-profit called Loose Change. Based in Wayland, Massachusetts, Loose Change organizes an annual week-long event to gather donations from the community. As the name implies, residents donate their spare change to the organization. All of the funds are used to buy books and educational materials for Peruvian schoolchildren. In addition to providing school supplies, the non-profit also builds/renovates schools. In addition, Fernandez-Davila made it his mission to scan a South American monolith and several artifacts, so that the information could be used in archeological research and also in presentations for museums. Lorenc participated on behalf of her mentor, Dr. Lisa DeLeonardris at Johns Hopkins. Dr. DeLeonardris said that “The purpose of this trip was first and foremost to document the artifacts (shaman vessels and monolith) with hopes of better presenting and/or publishing iconographic analysis.” Ciorogan, a professional photographer and videographer, completed filming for the movie “My Teacher.” With a release date of 2020, the movie focuses on Fernandez-Davila’s work in the Peruvian jungle.

Artec 3D, a world-renowned developer and manufacturer of professional 3D scanners and software, provided a Space Spider and Exact Metrology brought an Eva scanner. The Space Spider is a high-resolution 3D scanner based on blue light technology. It is ideal for capturing small objects or intricate details of large industrial objects in high resolution and with great accuracy. Also supplied by Artec 3D, Eva is used for making a quick, textured and accurate 3D model of medium sized objects. It scans quickly, capturing precise measurements in high resolution. Not only does it capture almost any type of object (including black and shiny surfaces), but it is used in numerous industries including quality control, heritage preservation, forensics, automotive, medical, aerospace and prosthetics.

The data was processed in Artec Studio 14 and 10 by Exact Metrology personnel, namely Chris Lafferty, Greg Hoeting and Jason Kleinhenz. Then, the information was given to Chris Catlett at 3D Systems. The company supplies the best range of 3D printers, materials and application expertise. 3D Systems was used to turn 3D data into PDFs, CAD files and short movies. To complete this task, Exact Metrology employed Geomagic, their leading 3D software for digital reconstruction of the ruins.

Through this project, Exact Metrology showed that they can scan anything, anywhere for educational and research purposes, as well as build partnerships with the local community. The right side of the scanned monolith was dated between 400 BC and 200 AD, while the left side was estimated to date between 700 and 14700 AD. The artifacts are estimated to be between 500 BC and 100 AD. Exact Metrology plans to turn the data into solids by possibly 3D printing a few, turn the solids/meshes into user-friendly interactive tools or turn them into short videos. Furthermore, the company is preparing to present two scientific papers with Johns Hopkins at the 60th Annual Andean Studies Meeting in Berkeley, California in 2020. The videos will be supplied to museums in Peru.

To sum up the experience, Kleinhenz said, “The true value from this project came from the struggle, relationships built and the communities engaged. We’re excited to partner with great people and organizations to further the archeological research and philanthropic work. The community growing from this endeavor is really passionate and driven to deliver results – from my perspective, I’m grateful that I get to be a part of that movement, show Exact Metrology’s capabilities and partner with great people.”

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

Artec 3D is an international company, headquartered in Luxembourg, with subsidiaries in the United States (Santa Clara, California) and Russia (Moscow). Artec develops and produces innovative 3D solutions and products. Artec has a team of professional experts in the collection and processing of 3D surfaces as well as biometric facial recognition. Artec’s products and services can be used in many industries, such as in engineering, medicine, media and design, entertainment, fashion, historic preservation, security technology and more.

For more information, please contact:

Steve Young

Exact Metrology, Inc.

11575 Goldcoast Drive

Cincinnati, OH 45249

Phone: 614-264-8587

Local: 513-831-6620

www.exactmetrology.com

stevey@exactmetrology.com

Market leader in high-precision pneumatic valves and other components machines 316SS and other materials, achieving better finish in less time with reduced power and less wire breakage, due to proprietary product from Global Innovative Products

Trevor McCoy, CNC/EDM programmer at Clippard, runs a FANUC wire EDM with the GIP proprietary PLASMA coated brass wire. McCoy states he achieves better finish with 15 to 20% improvement in run time. (machine hood open only for photo purpose)

Clippard (Cincinnati, Ohio) is a world leader in fluid control products and other high-precision components, and the company prides itself on having been vertically integrated for decades, since its founding in 1941. The company operates two ISO certified manufacturing locations in Ohio and does advanced machining of all types to produce its extensive catalog of standard and custom product solutions for a myriad of markets worldwide. At the heart of its machining capabilities are 12-axis CNC Swiss machines, CNC milling centers and CNC wire EDM’s, plus numerous post-finishing operations, including anodizing, EN plating and thermal deburring. Various metal and thermoplastic materials are machined.

Recently, after extensive discussions with a local EDM supply distributor, a proprietary hybrid coated brass wire was presented to the Clippard Director of Operations, Robin Rutschilling and his CNC/EDM Programmer, Trevor McCoy by Barry Ramsay of Global Innovative Products (hereafter GIP), a Mason, Ohio supplier of consumables for EDM shops through their GIP distributor network, who also produces a variety of its own products for need-specific operations in electrical discharge machining. One such product is a PLASMA hybrid coated brass wire, comprising of a gamma-phase intermetallic zinc alloy coated wire with brass core. This proprietary GIP innovation had proven out in numerous lab testings but needed “real world” production validation. Barry Ramsay and GIP application engineer Brad Hansard approached the team at Clippard.

Clippard uses wire EDM for the production of many components, including the tooling used in its conventional machine shops. All EDM work at Clippard is performed for internal production purposes, so one-offs are common, making speed a critical factor for the department.

As the product had been found suitable for all types of wire machines, with excellent auto-threading capability and increased performance, even at conventional brass wire settings, Ramsay felt confident the product would outperform what Clippard was currently using in its EDM shop, including other GIP wire. This new product was being offered in 0.008”, 0.010” and 0.012” (20mm, 25mm and 30mm) diameters, so Ramsay proposed giving the Clippard EDM department a supply for testing on one of its Fanuc wire machines.

Gamma phase brass is a brittle intermetallic alloy (Cu5Zn8) with a high zinc content (approximately 65% Zn) which can also be synthesized by a diffusion anneal. However, when such coatings are wire drawn subsequent to the diffusion anneal, the coating will fracture due to its brittleness and redistribute around the wire circumference creating a discontinuous layer sometimes described as a “porous layer”, which promotes turbulent flow enhancing the flushing of debris. However, it is zinc enrichment created at the surface combined with the elevated melting point of CuZn gamma phase (approximately 800ºC/1472ºF) which are the biggest factors contributing to the performance of Gamma Phase Brass coated wire.

The arrangement between the two companies actually began in a somewhat unconventional manner, as Trevor McCoy relates. “We have an Ocean hole popper (electrode/sinker EDM) and the circuit boards needed repair. Brad was able to do that kind of work, which I knew from previous experiences with him. So, he proposed exchanging the board servicing for the opportunity to test the GIP hybrid PLASMA wire. Seemed reasonable to us, so we agreed.” The FANUC wire EDM in the shop at Clippard seemed an ideal candidate for GIP, as well, as Barry Ramsay notes, “We knew they were running all types of materials and some very high-precision tooling used in their own machine shop for the production of various pneumatic components with very tight tolerances. It seemed a very good place to test our new wire, which had been proven out on our own EDM’s at GIP.” He further says it was a handshake deal, a “classic collaboration between two companies for their mutual benefit,” adding that application engineering supplied by GIP further enhanced the use of the product at Clippard, as the test learning process information was shared without reservation, so both companies benefited.

In this test case, many of the components were being run for the production of special parts being produced by Clippard for robotic arm articulation.

The testing immediately yielded positive results, as McCoy notes they were holding tolerances under a tenth, with a microfinish that was very important for the application. “We do a lot of custom work for our own use, over 50% of my production in EDM. Some of the hard tool steels are difficult to drill and we also run various others. The jobs require a lot of setup time and fixturing, so run time, finish and wire breaks all are critical for us.”

The goals for this proprietary wire testing were three, according to Barry Ramsay. “The characteristics of the PLASMA wire in production on the FANUC machine at Clippard were important, as the flushing of their precision components directly impacts quality. Further, we had our own test results galore but needed an outside house to validate what we were seeing. Lastly, we just wanted to help our friends at Clippard, who had been so cooperative and, in this case, needed our help with those circuit boards. It was a classic win-win for both of us, as all three goals were met.”

Multiple parts were EDM’d during the testing of this PLASMA wire, with full comparative data tracked on the test wire vs. conventional brass. One tool for a medical part was produced, for example, in :56 vs. 1:05 with five skim passes, a 16% improvement in overall production. McCoy notes, “We could apply more power to run faster. The GIP product consistently outperforms premium brass, based on my experience with both now.” He also cited a very practical advantage. “The PLASMA wire is as clean as conventional brass.” Ramsay adds the price point is also competitive, so there’s less of a premium to achieve these enhanced results.

Clippard is a third-generation, family-owned and operated company that has developed many pneumatic components for a variety of applications in industry, commercial and even fun applications. Clippard’s Chief Marketing Officer, Rob Clippard, developed this “air guitar” that operates with the company’s pneumatic valves and cylinders. See it in performance of the classic Pachelbel Canon in D below. A wonderful intersection of music’s magic with the technology of one very creative company!

Chris Agricola, Advertising Manager at Clippard, also contributed to this story.

For more information, please contact:

Robin Rutschilling

Director of Operations

CLIPPARD

7390 Colerain Avenue

Cincinnati, OH 45239

Phone: 513-521-4261

www.clippard.com

r.rutschilling@clippard.com

Or

Barry Ramsay

General Manager

GLOBAL INNOVATIVE PRODUCTS

7697 Innovation Way

Suite 200

Mason, OH 45050

Phone: 513-701-0441

www.gipintl.com

bramsay@gipintl.com

Exact Metrology, a leading metrology services provider, offers customers and interested parties information on 3D scanning services, CT scanning, metrology equipment and software solutions on their website at www.exactmetrology.com

The company’s 3D scanning includes inspection scanning, CT scanning, reverse engineering, long range scanning and scan to CAD.

CT scanning (computed tomography) is used in aerospace, archeology, automotive, castings, die cast, electronics, food, molds, personal products and plastics. Confident in its ability to obtain 3D views from inside a part, Exact Metrology issued a GOM CT challenge. It invited users to send scanned data they’ve obtained from other technologies. If the results obtained from GOM CT weren’t superior, the company would send the user $100 with no strings attached. In addition, Exact Metrology is a representative and seller in North America of Procon X-ray GmbH, a German developer of x-ray inspection equipment for industrial applications and university/scientific research.

Besides GOM and Procon, Exact Metrology features various leading manufacturers such as: Artec 3D, Geomagic Capture, Hexagon, InspecVision Planar, Leica Geosystems, Leica HDS, Polyrix, Raytech and Surphaser.

Along with its equipment, Exact Metrology offers several software options to complement their offering. This includes Artec Studio, Leica Geosystems Cyclone, Hexagon, Geomagic, GOM Inspect, Polyworks, Volume Graphics and 3D Reshaper.

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

For more information, please contact:

Steve Young

Exact Metrology, Inc.

11575 Goldcoast Drive

Cincinnati, OH 45249

Phone: 614-264-8587

Local: 513-831-6620

www.exactmetrology.com

stevey@exactmetrology.com

Dean Solberg

Exact Metrology, Inc.

20515 Industry Avenue

Brookfield, WI 53045

Phone: 262-533-0800

Local: 866-722-2600

www.exactmetrology.com

deans@exactmetrology.com

This Grieve oven features 2” insulated walls, six (6) point vacuum manifold with individual shut-off valves, vacuum gauge and quick disconnect. Additional features include an aluminized steel exterior, Type 304, 2B finish stainless steel interior and an 80 CFM powered forced exhauster.

Controls on the No. 1050 include a digital programming temperature controller, manual reset excess temperature interlock with separate contactors and a recirculating blower airflow safety switch.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, Illinois 60073-2835

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese