Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

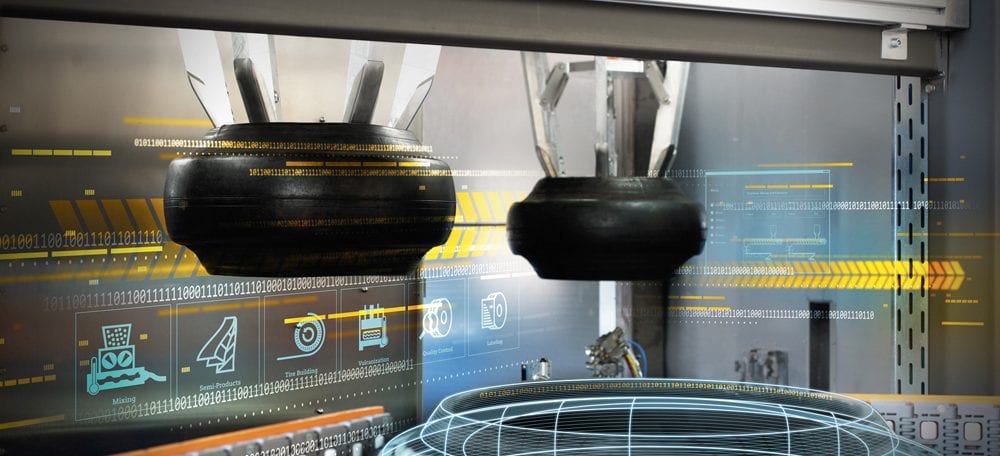

Siemens has developed a complete digital twin of the AUTOLOK® curing press with software in the loop capability (SIL) for McNeil & NRM, a leading builder of tire presses and related equipment.

While the global tire market has experienced significant growth over the years, the industry has undergone several changes lately that are driving a re-focus of the technology. These include e-Mobility and autonomous driving. Competitive tire production needs to be highly flexible and react quickly to volatile market developments, while also meeting today’s high standards of quality, safety and environmental impact issues. Digitalization helps manufacturers remain competitive, as it provides heavy machine builders significantly increased flexibility in design protocols.

In the Siemens strategy, digital twins of the product, the production process and the production facilities, as well as the product’s in-plant performance, are linked to a single integrated data model in the cloud. This creates a complete picture of the manufacturing landscape and a closed loop through the digital world. It enables continuous improvements for best possible results, based on actual production and performance data feedback. The digital twin of a tire press helps turn innovative design into a successful new machine by providing design, simulation and verification, all in the digital environment. The entire production process is planned, simulated and optimized under virtual working conditions, before the press build starts. Furthermore, prototyping efforts are reduced considerably, machines can be optimized during development and machine operators can be trained, long before a machine is actually commissioned.

Using the digital twin technology from Siemens, McNeil & NRM can predict the operation of the press and simulate its actual running. The Siemens Mechatronics Concept Designer (MCD) provides the ability to achieve virtual commissioning. Virtual commissioning based on “software in the loop” is based on the TIA Portal, PLCSIM Advanced and the Mechatronics Concept Designer. This is a crucial factor in reducing commissioning times in the real world and preventing costly machine crashes. In addition, McNeil & NRM will be working on applying NX software and Mechatronics Concept Designer tools to accelerate the sharing of information between its mechanical design and control design teams to improve the efficiency of the machine development process. Going forward, mechanical design changes and enhancements will be replicated in the virtual world to provide operational data and design feedback to bring innovations to the production of tires.

Performance and maintenance data from production equipment and entire production lines will be captured and analyzed using Mindsphere, the Siemens cloud based open IoT system. Mindsphere provides analytics and connectivity capabilities, developer tools, applications and services to evaluate and utilize all available data in a meaningful way for the machine builder and end user alike.

Ed Bailey, Vice President of Engineering & Development at McNeil & NRM, also notes, “The Siemens and McNeil & NRM collaboration to create the digital twin of our 63” curing press provides an essential foundation for our product development roadmap. This twin is a prerequisite to accelerate all dimensions of development and collaboration with our customers, including software development, virtual commissioning, training, and press optimization. Further development can enable our customers to virtualize tire production machine cells, complete lines and ultimately the entire plant.”

More information on these developments will be available at the Tire Technology Expo in Hanover, Germany, between February 25 and 27, 2020. It features the world’s most important suppliers to the tire manufacturing industry. Please visit Siemens at booth 8224 and McNeil & NRM at booth 8040 for a demonstration of these cooperative capabilities.

About McNeil & NRM

With a combined total of more than 150 years of experience and expertise, McNeil & NRM, Inc. stands at the cutting edge of the global tire industry. With its technology base in Akron, Ohio and high-quality manufacturing plant in Bucharest, Romania, McNeil & NRM, Inc. is positioned to remain a pillar in machinery supply to the industry. This can be seen in its dedication to manufacturing excellence, their commitment to engineering and aftermarket sales support and their pursuit of total customer satisfaction.

McNeil & NRM, Inc. stands to meet the future head-on by designing, manufacturing and servicing a new generation of tire production equipment to meet the most stringent processing requirements. This is backed up by its global footprint in North America and Europe which is supported by their international network in other regions.

About Siemens Industry, Inc.

The Siemens Operating Company Digital Industries (DI) is an innovation leader in automation and digitalization. Closely collaborating with partners and customers, DI drives the digital transformation in the process and discrete industries. With its Digital Enterprise portfolio, DI provides companies of all sizes with an end-to-end set of products, solutions and services to integrate and digitalize the entire value chain. Optimized for the specific needs of each industry, DI’s unique portfolio supports customers to achieve greater productivity and flexibility. DI is constantly adding innovations to its portfolio to integrate cutting-edge future technologies. Siemens Digital Industries has its global headquarters in Nuremberg, Germany, and has around 78,000 employees internationally.

Continue reading

For over 55 years, Guill Tool has been providing tooling for the aerospace, extrusion, medical, consumer and commercial, defense, wind, oil and energy industries. Due to its years of experience, the company has a highly skilled team of expert machinists engineers trained in the latest CAD, CAM, CFD and FEA programs. Besides being experts in extrusion tooling, Guill is a major industrial manufacturer who can provide customers with one-stop shopping for their tooling and other select machine shop needs.

The Guill high quality standards are evidenced by the company’s many certifications, including ISO 9001:2015. Defense certifications include AS9100:2016 (aerospace manufacturing), MIL-I-45208A (inspection system), MIL-STD-45662A (calibration system), JCP Certified (government contracting), ITAR Registered (export compliant), NIST SP800-171 (cyber security) and others.

As part of this new medical machining program, Guill offers 5-axis machining centers, high precision machining, and full wire EDM capabilities with a .008” hole popper. Guill machines super alloys and exotic metals to close tolerances.

Machining capabilities range from small hole machining to .008” in diameter and machining material measuring up to 15 inches in all axes.

For more information, please contact:

Matt Christofaro

Extrusion Sales

Guill Tool & Engineering

10 Pike Street

West Warwick, RI 02893

USA

Office: 401-828-7600

https://www.guill.com/industries/medical/

Guill, a global leader in extrusion tooling, now offers its substantial machine shop capabilities as an independent service to customers.

Continue reading

This Grieve jumbo walk-in oven features 4” thick insulated walls, removable top-mounted heat chamber (shown in the right foreground of the attached photo), aluminized steel interior and exterior, door seals eliminated and doors equipped with drag seals, plus the unit was constructed to split into four sections for shipment to the customer’s location.

Oven controls on No. 976 include a 13,500CFM powered forced exhauster (shown in the left foreground of the attached photo) and other safety equipment required to handle up to two gallons of flammable solvent at 370ºF (~188ºC). Also onboard are a digital programming temperature controller, SCR power controller and motorized dampers on the intake and exhaust for accelerated cooling and rapid purging. This Grieve jumbo walk-in was built to NEMA 12/NFPA 79 electrical standards.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

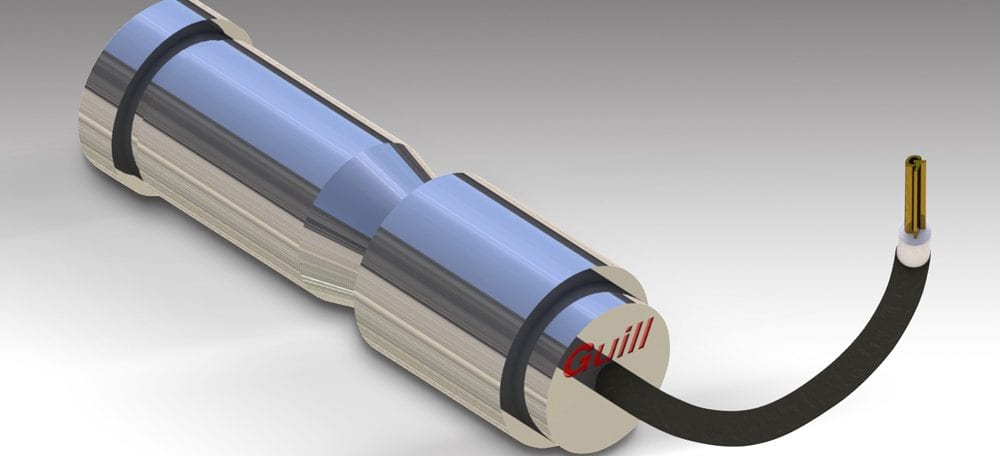

A typical Guill extrusion tip and coating wire eligible for the new 10-day delivery program.

Guill Tool & Engineering, a global manufacturer of extrusion crossheads, tips and dies, has announced its new 10-day tooling program. This program applies to eligible tips and dies that will be shipped within 10 business days of receiving the purchase order from the customer.

The company’s quality precision tips and dies have been manufactured in the U.S. for 55 years. All Guill extrusion tools are produced using certified and documented quality steel material specifically qualified for the polymer to be extruded. Furthermore, Guill designs tips and dies for any application the customer needs. These feature multi-lumen, stripe, multiple stripe, wire and cable, hose, pipe, tube, fiber optic, blown film, corrugated tube and profile. Dies include face seal, shouldered, snap together, floating die plates, interchangeable die plate and custom dies. Available tips include single and multi-lumen, threaded style, snap together, fixed center shoulder, profile, tapered style and custom. To find out which tools are eligible for the program, customers can check with any sales representative. For all other parts, company personnel will review the customer’s drawing to determine if it is eligible for the program.

Eligible tips and dies for this program cannot be plated and must have a diameter less than 1.5” and a length less than 4.75.”

Guill proudly manufactures all its products in the U.S. under the quality standards ISO 9001:2015 and AS 9100:2016.

For more information, please visit the website or contact:

Matt Christofaro

Extrusion Sales

Guill Tool & Engineering

10 Pike Street

West Warwick, RI 02893

401-828-7600

www.guill.com

Although Tsuchiya has used 3D software, digital scanning, 3D printing and CNC (Computer Numerical Control) to help create sculptures in the past, the Florence project was the first time digital scans of actual people were used to create a sculpture.

Tsuchiya planned the general pose of the firefighter, the public service worker and the police officer with a little girl, using a 3D design program. He asked Matthew Martin, the Division Manager of Exact Metrology, and Scott Menne to digitally scan actual employees from the City of Florence, Kentucky. The firefighter in gear was scanned at the fire station, while the police officer and Martin’s daughter were scanned at the Florence city headquarters. A friend of the City of Florence posed as the public service worker.

After Tsuchiya finished the sculpting, the clay/foam/wood statues were delivered to the Sincerus Bronze foundry in Indianapolis to cast them in bronze. The whole process, from concept to bronze finishing, took four to five months for each sculpture.

For more information, please contact:

Steve Young

Exact Metrology, Inc.

11575 Goldcoast Drive

Cincinnati, OH 45249

Phone: 614-264-8587

Local: 513-831-6620

www.exactmetrology.com

stevey@exactmetrology.com

Exact Metrology is an ISO 9001:2008, AS9100, FFL and ITAR Certified Company.

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

Continue reading

Previously, the farm used only conventional slope screens for their primary separation which removed the coarse material. The farm had to dredge their 200 acre-foot waste lagoon once a year.

Bettencourt Dairy needed to process and meet their nutrient management plan when they added cross vents and vacuum trucks to move the manure from the barns. In 2018, they decided to add a Centrisys CS26-4DT dewatering centrifuge to remove the fines from the manure.

“We saw the Centrisys centrifuge as the only piece of equipment that was going to be able to get the solids out of our water,” Don Brand, Bettencourt Dairy Operations Manager of Equipment and Buildings. “The centrifuge seemed like the only piece of equipment that would be able to grow and expand with the operation.”

“The Centrisys centrifuge was the first piece of equipment that we bought for manure processing that worked from the beginning the exact way it was promised,” Brand said.

Centrisys/CNP supports global sustainability through its resource intensification portfolio with water and wastewater equipment and processes. Our systems are simple. They are designed to use less energy, less chemicals and less space. Centrisys is a U.S.A. manufacturer of dewatering centrifuges, sludge thickeners and also provides global service, repair and parts for all centrifuge brands. CNP, a division of Centrisys, designs and supplies nutrient recovery and biosolids treatment optimization systems.

For more information, please contact:

Centrisys/CNP

9586 58th Place

Kenosha, WI 53144

262-654-6006

Michele Whitfield or Jessie Jones

Email: marketing@centrisys-cnp.com

Website: www.centrisys-cnp.com

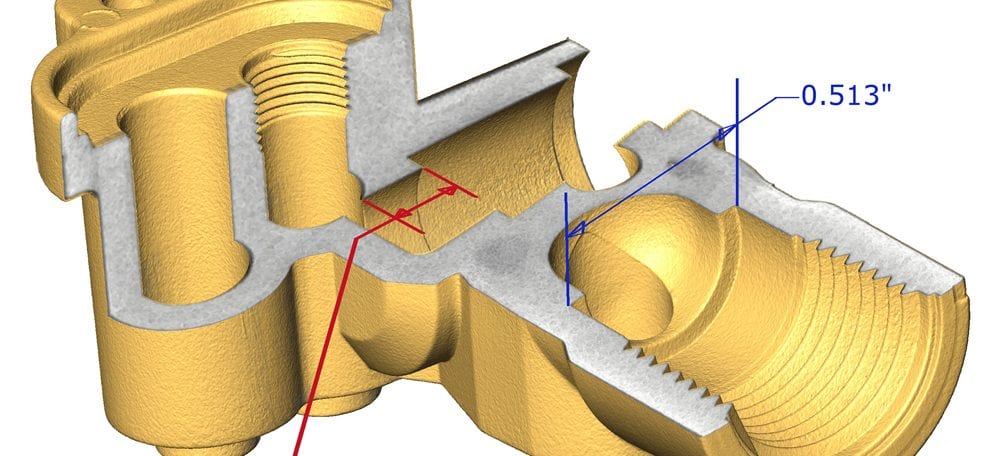

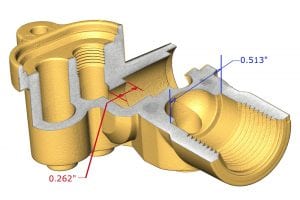

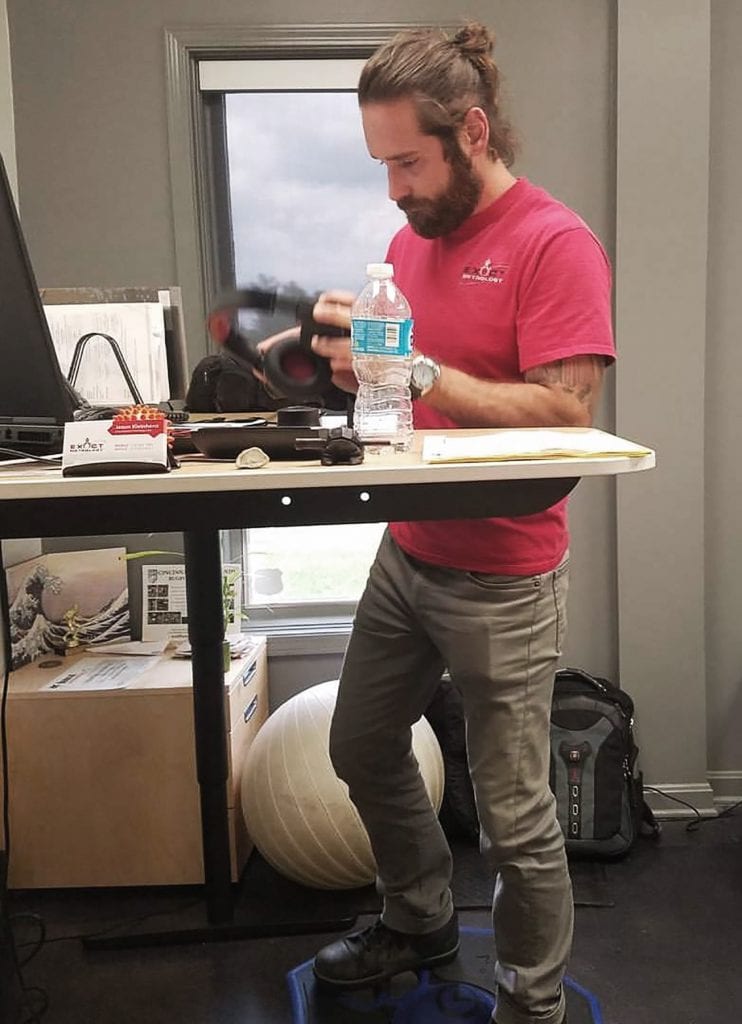

Exact Metrology will be exhibiting at the upcoming show. Their main technologies featured will be CT scanning, Geomagic Design X and Polyworks Inspector™ software. In addition, Exact Metrology will discuss structured light. According to Jason Kleinhenz, an engineer and trainer at the company, “CT scanning in combination with Design X (for reverse engineering ) and/or Polyworks (for quality inspection) creates opportunities for reverse engineering and quality inspection of internal components, very accurately, not possible through any other tool. Structured light systems allow highly accurate 3D data collection via line-of-sight.”

CT scanners permit the exploration of the interior of parts without any harm or destruction to the parts themselves. This technology takes multiple readings from various angles and converts the CT grey scales images into voxel-based 3D point clouds. After the CT scanner generates the point cloud data, Exact Metrology generates a CAD-to-part comparison map, dimension the part or reverse engineer it.

Geomagic Design X allows provides an easy path from creating editable, feature-based CAD models from a 3D scanner to integrating them into existing engineering design workflow. Furthermore, the software allows users to re-use existing designs without having to manually update old drawings or re-measure and rebuild a model in CAD. Finally, Geomagic Design X is easy to learn and use.

Polyworks Inspector™ uses high-density point clouds and contract-probe datasets to control the quality of parts and tools at every manufacturing process phase. Using this software, users can acquire and control tool and parts dimensions, prevent manufacturing and assembly issues, guide assembly building and oversee the quality of assembled products.

Structured light, commonly known as blue light scanning, describes the use of 3D light-based scanners. Generally, structured light-based scanners offer the most accurate and highest resolution data. “Blue” refers to the color of the LED bulb in the projector.

Josh Schradin and John Legleu from Exact Metrology, will be there to answer any questions attendees may have. Schradin is head of the CT department, while Legleu is a technical salesperson.

Please stop by Exact Metrology at booth 51415 SUP during the show.

Exact Metrology is an ISO Certified, AS9100, FFL and ITAR Certified Company.

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D scanning, reverse engineering, quality inspection, product development CT scanning and services and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

For more information, please contact:

EXACT METROLOGY, INC.

Steve Young

11575 Goldcoast Drive

Cincinnati, OH 45249

Local: 513.831.6620

Toll Free: 866.722.2600

www.exactmetrology.com

stevey@exactmetrology.com

Dean Solberg

Exact Metrology, Inc.

20515 Industry Avenue

Brookfield, WI 53045

Local: 262.533.0800

www.exactmetrology.com

deans@exactmetrology.com

Centrisys/CNP has signed an exclusive U.S. distributor agreement with LIPP America Tank Systems, LLC for water, sludge and digester tanks. LIPP has a patented stainless steel digester system that allows digesters to be built on-site in less than two months. The short construction period and patented digester building system allow Centrisys/CNP to offer its clients cost-effective, high-quality digesters with a long life cycle. The LIPP product line compliments Centrisys/CNPs product portfolio by offering its customers solutions for resource intensification and resource recovery.

“Like Centrisys/CNP, LIPP is a highly innovative, privately-owned company. This partnership allows us to customize digesters and storage tanks with short delivery times and attractive costs,” said Gerhard Forstner, CNP President. “The distributor agreement enables Centrisys/CNP to retrofit even small wastewater treatment plants and convert them to resource recovery centers by recovering water, energy and nutrients.”

“We at LIPP America Tank Systems are honored and extremely excited to be a new partner with the Centrisys/CNP team,” said Al Lettinga, President/C.E.O. “We are confident that working together, we can make tremendous penetration within the municipal bioenergy and waste treatment market with our special LIPP double-fold tank technology. At LIPP America, as in the world markets, we stand out as a high quality and very unique tank technology. The LIPP double-fold and dual stainless plating system are a one-of-its-kind in the entire world market. Therefore, we are set apart against any liquid storage system in the market today.’

LIPP recently built a municipal anaerobic digester in Ohio and three more are currently being built in Michigan.

Centrisys/CNP supports global sustainability through its resource intensification portfolio with water and wastewater equipment and processes. Our systems are designed for simple operation using less energy, less space and fewer chemicals. Centrisys Corporation is a U.S.A. manufacturer of dewatering centrifuges, sludge thickeners and complete dewatering systems for municipal and industrial water and wastewater. Centrisys’ service department is a leader in global service, repair and parts for all centrifuge brands. CNP – Technology Water and Biosolids Corporation designs and supplies nutrient recovery and biosolids treatment optimization systems. CNPs key technologies are AirPrex® and CalPrex™, phosphorus recovery technologies that produce struvite and brushite fertilizers, and PONDUS, a Thermo-Chemical Hydrolysis Process (TCHP) which increases biogas production and digester capacity and reduces sludge volume and polymer consumption. CNP is a U.S. distributor for digester and storage tanks and hydrograv® adapt Variable Inlet System.

For more information, please contact:

Centrisys/CNP

9586 58th Place

Kenosha, WI 53144

262-654-6006

marketing@centrisys.com

www.centrisys-cnp.com

No. 942 is a 350°F (177°C), special walk-in oven from Grieve, currently used for curing epoxy at the customer’s facility. Workspace dimensions of this oven measure 84” W x 144” D x 108” H. 400,000 BTU/hour are installed in a modulating natural gas burner, while a 12,000 CFM total are provided by two (2) 5-HP recirculating blowers providing combination airflow to the workload.

This Grieve oven features 4” insulated walls, aluminized steel interior and exterior and three (3) independent doors for access to workspace on front with standard double doors on rear. Additional features include 2” insulated floor with three (3) pairs of truck wheel guide tracks. The oven is raised above factory floor level on 6” I-beams.

The oven features all safety equipment required by IRI, FM and National Fire Protection Association Standard 86 for gas heated equipment, including a 325 CFM, 1/3-HP powered forced exhauster.

Controls on the No. 942 include a digital programming temperature controller and 10” diameter circular chart recorder.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

Jason Kleinhenz is one of many Exact Metrology employees at the company’s Cincinnati office, located at 11575 Goldcoast Drive. While he does not have an official job title at the company, Kleinhenz describes himself both as an engineer and as a trainer. His job duties include managing and performing training, as well as marketing and creating content for Exact Metrology.

His first work experience came at age 12, when he and his brother started their own lawn care business. To support himself during his time at the University of Cincinnati, he recalled working “almost every food/beverage position possible.” This included employment at the famous French restaurant Jean-Robert at Pigall’s. Kleinhenz also worked in the university’s Nanomedicine Development Center. As a paid intern, he built RNA nano-motors that would attach to cancer cells and inject healthy DNA. He further broadened his experience with a job at General Electric in Japan, working in the environmental health and safety department. After graduating with a degree in biomedical engineering, Kleinhenz remained at the University of Cincinnati performing research on the female pelvic floor for the Biomedical Engineering Department.

Kleinhenz started working in metrology in 2011, but had a 2-year hiatus. During that time, he worked as a Solutions Engineer at MHI Inc, a specialized heating manufacturer. He started working at Exact Metrology in 2015 as an applications engineer. Next, he took over the position of sales coordinator before handling his current tasks. According to Kleinhenz, “The best part of working in metrology is that one day you might be working on a rocket and the next day on a beautiful piece of art (and everything in between).” Regarding his most memorable experience at Exact Metrology, he mentioned his trip to Peru this past summer. During two weeks, he helped scan Peruvian artifacts for preservation and deliver school supplies to a rural community. “My mission in life is to relay joy, love and enrichment. Peru was a great experience because I was able to check the box of each of those, and the relationships and communities formed are invaluable.”

Besides his work at Exact, Jason started 2 companies. One delivers fresh cooked meals weekly while the other operates as a non-profit to raise money and “do good” for local area parks and communities through a hockey league. He also built and operates 2 donation-based services; a podcast studio and a gym.

Exact Metrology is an ISO Certified, AS9100, FFL and ITAR Certified Company.

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

For more information, please contact:

Jason Kleinhenz

Exact Metrology, Inc.

11575 Goldcoast Drive

Cincinnati, OH 45249

Phone: 513-813-4221

Mobile: 513-262-7097

www.exactmetrology.com

jasonk@exactmetrology.com