Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

PR Should Supplement (Not Replace) Your Advertising

By Shari VanZant

Up until the last couple of decades, industrial marketing meant placing print ads in trade magazines and periodically sending direct mailings to reinforce the message. Then along came the internet and the entire direct mail/PR process was completely revamped.

Standard practice previously involved sending press kits through the mail and then waiting for an appearance in print several months later. In this digital age, PR is sent by email and regularly appears the same day we send it – making PR a more valuable tool than ever.

While it is important to remember that PR should always be used as a supplement to advertising, and never in its place, it is a very effective way of increasing your company and product awareness.

At Bernard & Company, our PR program goes a step further. After a press release is sent, our team regularly searches for our clients’ PR appearances, both online and in print magazines and tracks each one that is found. An archive is built and presented to the client at the end of every quarter with a dollar value assigned to it as if it were paid advertising space, with most clients getting a return of many times the cost spent. This helps show the value of our program, and proves once again, the power of PR.

Continue readingWe’re a full-service, strictly industrial ad/PR agency, started by Fred Bernard in 1975. I joined him shortly thereafter, bought the agency in 1982 and I’m still here. Lots has changed over the years, but one word hasn’t. INDUSTRIAL.

Fred came out of Honeywell and Ryerson Steel, while my background was electrical and automotive. Once, we had a high concentration of pump, valve, filter and controls clients. Today, we have more machine tools, production equipment for discrete manufacturing and the market leader in motion control. Our longest-retained client (62 years!) is the global leader in industrial ovens and furnaces and, this year, we’re celebrating 50 years with the market leader in rubber molding machinery, a client we helped conquer the North American market, in which they had no presence in 1970, when they sold their first two presses to one of Fred’s filter clients.

Today, we remain a full-service, strictly industrial ad/PR agency, but we supply our clients social media, geotargeting, website development, full online marketing services, trade show work, video and our unique Special PR program, which nets our largest guys over a MILLION in equivalent ad space, every year. We create the content AND place it in all the right spots.

Being industrial, we do no broadcast, billboard, newspaper or other consumer advertising and we’re not even B2B, as we do no commercial biz. We are STRICTLY i2i, that is, industrial engineers, designers, manufacturing and production pros, talking to others of the same stripe.

Even our most generic equipment client could conceivably sell to less than 150,000 companies globally. One client has a market universe less than 700 in all of North America.

This means we do pinpoint marketing to the right eyeballs, not mass marketing to the masses.

That’s the distinction with a BIG difference between Bernard & Company and other agencies.

Thanks for reading our agency newsletter,

Tim Daro

Continue reading

CERATIZIT USA has joined forces with several companies to make ventilators. The CERATIZIT Group has extensive experience in the carbide production process, from the powder to the finished cutting tool. Not only does this allow special-purpose tools to be developed for customer-specific applications but it also means that a full range of industry-specific standard tools are held in stock and quickly available. High-precision drilling, reaming, countersinking and boring are specialties of CERATIZIT. Involved in this effort is Staub Precision Machine and the industrial distributor Abrasive Tool.

Staub Precision Machine used CERATIZIT reamers to perform a finishing operation of high-precision holes to size. The reamer was a solid carbide PCD tipped (polycrystalline diamond) with through-tool coolant diameter of .626” +.0005 -.0000. The material cut was aluminum and the production run quantity was 2,500 parts per week. In addition, Staub designed and machined two tombstones as well as collets. There were 33 parts on each of the four sides of the tombstone in the machine and Staub made 132 parts at a time. The machine was running at 4900 RPM (revolutions per minute) and 78 inches per minute feed. The hole was only .250” deep, taking less than a second per hole to ream. In addition, the hole was sized .616” before reaming, leaving .010” of stock allowance. While the hole has a .0005” tolerance, the reamer cuts the same size every time with a high mirrored finish.

Located in Hamburg, New York, Staub Machine Company was founded in 1975 in Tony Staub’s garage. Over the next 43 years, the company developed into an industry leader in precision machining and the precision industry. In 1995, Staub moved into an old Super Duper grocery store located at 206 Lake St. in Hamburg. Tony Staub decided to sell the assets of Staub Machine Company to Staub Precision Machine, Inc. to keep the company intact, innovating and growing. Today, the company supplies high-volume production to match the needs of customers, producing machine component parts for a number of manufacturers across the country, especially in Western New York.

The close collaboration between Staub and CERATIZIT was achieved thanks to Abrasive Tool. Located in Buffalo, New York, the company is a distributor of high quality tooling solutions. Jay Janca, distributor sales engineer, supplied Staub Precision Machine with the reamers, helped process the part and also coordinated delivery of several other parts. He and Tony Staub started this project on a Thursday evening in his garage with a set of drawings and a part he needed to make for a ventilator client. Through Janca, he reached out to Chuck Somerville, CERATIZIT sales engineer and told him about the project. Quickly, Tony, Jay, Chuck and the staff at CERATIZIT worked on confirming details of the tool. CERATIZIT had an approved drawing at the beginning of the week and the reamers were shipped on Friday of the same week and in production the following Monday. This was just over a week after the initial discussion. Staub machines run unattended for maximum productivity 24/7, so CERATIZT worked to make the process as smooth as possible. Tony was very happy with CERATIZT, saying, “I was amazed at how quickly they responded and the reamers produced a beautiful part. I am sure we will continue working with CERATIZIT in the future.”

Another two companies that joined CERATIZIT in the manufacturing of ventilators were Blackhawk Industrial and another manufacturer of precision metal components. As CERATIZIT products are distributed by Blackhawk, the company helped connect CERATIZIT with their customer. Commenting on why CERATIZIT was chosen, sales engineer Mitch Vraja said, “We were asked to provide reamers because they know our quality and we had a quick delivery.” Blackhawk Industrial is an industrial distributor in Brunswick, Ohio. The machining process performed by their customer company involved machining adapters. In order to ensure that the tool holding device could accommodate various types of cutting tools, CERATIZIT reamers were used to create a hole for better positioning. Different cutting tools in the adapter were used on various machines. The tool involved was number 52M.57.0497, known as Fullmax – DBGU – Ø4,97 +4µ. The material cut was stainless steel. The ventilators had to fit in a precise location, thus dowel pins were used to locate the mounting brackets to the mobile unit. In this process, five reamers were used to provide a true position diameter. The tool diameter of the reamed blind hole in stainless steel was .1958 +/- .0005. There were three holes in each bracket and over 10,000 brackets were made.

Blackhawk’s customer blends old world craftsmanship with cutting- edge technology. Capabilities include precision turning, grinding, milling, automated assembly and inspection, semi-automated assembly, manual assembly and wire EDM. Additional capabilities are CNC machining, Swiss machining, machining ranges between 3mm and 66 mm and material neutral machining. The company serves the automotive, hydraulics, sensor, recreational vehicle, plumbing, application, natural gas, firearms, off-road vehicle and medical equipment markets. Within the medical field, the company specializes in manufacturing small diameter components requiring strict tolerances and superior finish.

As an industrial distributor, Blackhawk specializes in metalworking equipment categories such as carbide cutting tools, abrasive, fabrication and machining equipment. In addition, the company has a wide offering of packaging, MRO products and a proven ability to provide custom industrial vending solutions, as well as creative supply chain solutions.

For more information, please contact:

CERATIZIT S.A.

101, Route de Holzem

LU-8232 Mamer, Luxembourg

Tel: +352 31 20 85-854

www.ceratizit.com

CERATIZIT USA, Inc.

Canada, United States

11355 Stephens Road

Warren, MI United States 48089-1833

Tel: +1 586 759 2280 (Toll free: +1 800 783 2280)

www.ceratizit.com

As an industry #ANCATooloftheYear celebrates the knowledge and imagination of cutting tool craftsmen, creating tools with the perfect geometry, profile, and finish that shape and build our world everyday.

Pat Boland, ANCA Co-founder said “All finalists were of a very high standard and demonstrated a deep understanding for tool geometry as well as taking full use of ANCA’s software to design unique and special cutting tools. We congratulate the winner KV Tooling, runner up Eshed Tools and Zakłady Mechaniczne Kazimieruk who we gave a special creativity award for daring Bat Man design.”

“Our entry was a very complex tool with many features incorporated into one tool. We designed the cutting tool to satisfy a customer’s problem, where our one tool replaced a machining requirement that previously required six tools. The customer was very happy with the production gains and for us to submit to ANCA Tool of The Year. We believe winning the competition makes our company more marketable and will give us great exposure and hopefully expand our customer base,” concluded Brian.

Eshed Tools entered the competition to share their special tool manufacturing skill set with ANCA users. Shmulik Arbel, Production Manager commented that they were proud of their expertise that means they can “produce special geometries that are difficult to achieve and save our clients expensive production time.”

Reflecting on coming runners up Shmulik continued, “Taking out this prize creates a great opportunity for global exposure through the Tool of the Year competition. For us ESHED tools as a small and growing tool manufacturer, world wide recognition is important and will help us expand beyond the local market.”

Zakłady Mechaniczne Kazimieruk on winning the ‘Most Creative Tool’ said: “We thought outside the box and were motivated to inspire the grinding community with our entry. During everyday work our team make a lot of customized tools so we wanted to make something fresh and unique – even to us. Furthermore, entering was a great test for our grinding skills. We relished the opportunity of seeing others craftmanship and the entries in the tool of the year competition demonstrated to us the range and type of cutting tools that are possible.”

The competition was based on the passion and the craft of tool making and celebrate our highly skilled tool grinding community. Watch the live announcement of winners at EMO 2019:

Judging Panel

The top five tools were judged on the following criteria:

For further information, please visit:

https://machines.anca.com/Contact

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

Continue readingLeading supplier of fast hole EDMs now offers added features of REALTIME

Beaumont Machine, located in Southwest Ohio, has updated its core fast-hole EDM machine, the FH40, with added features, including a faster response time.

According to company President Ed Beaumont, “Fast-Hole EDM has changed in the past five years from primarily producing cooling holes to the needs on shapes and diffusers. The additional need for a lower recast and virtually no microcracking has become the standard in aerospace. As a result, Beaumont Machine has been working on answers for our customers, focusing on the ability to work REALTIME with our power supply to control interconnection and closed-loop features. Doing so aids in delivering a better overall quality for our process. Other features that improve with the REALTIME process such as micro-pulse technology, breakthrough hole-start technology and blind hole drilling all benefit from this better interconnection between the power supply and control.”

This new design has been incorporated in the company’s mainstay fast hole machine, the FH40. Additional features of this machine include:

For more information, please contact:

Ed Beaumont

President

BEAUMONT MACHINE

4001 Borman Drive

Batavia, OH 45103

Phone: 513-701-0421

Web: www.beaumontmachine.com

Email: beaumach@msn.com

The Absolute Arm 7-axis system delivers tactile probing and laser scanning in a uniquely ergonomic package. It is the best choice for high-end portable measurement applications. The articulating arm offers unparalleled ease of movement and ease of measurement.

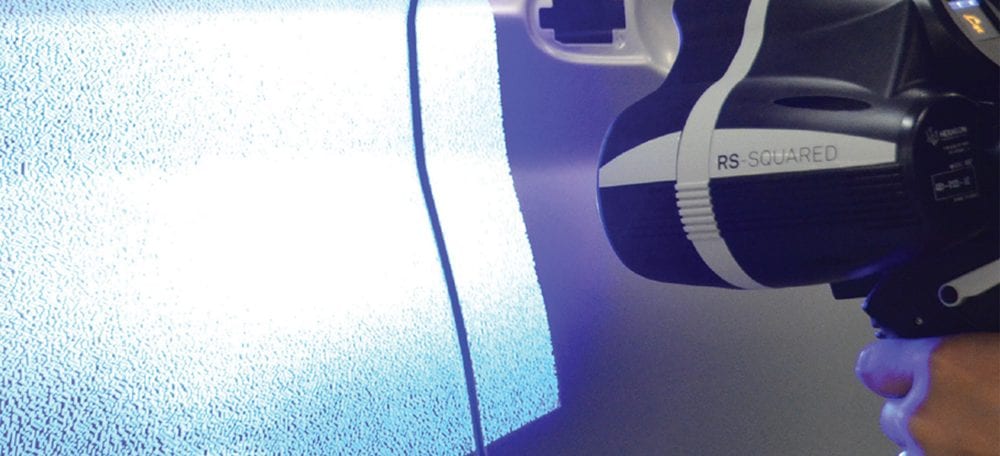

RS-SQUARED is a white light scanner that uses the Absolute Arm system to position large square ‘tiles’ of 3D scan data. This removes the need for time-consuming application of reference markers or spray, or complex mechanical processes such as fringe projection that requires a stable environment. Up to 4 data tiles are captured every second, which combined with minimal set-up time, creates a scanning system capable of generating point cloud data in very little time. As with other Absolute Arm scanners, the RS-SQUARED can be easily removed and remounted without needing time-consuming recalibration processes due to an innovative repeatable mounting system.

The RS-SQUARED area scanner represents a new direction for portable measuring arm technology, embracing the need for high-productivity by incorporating advanced white light scanning technology. Together with the Absolute Arm 7-axis, it offers the ultimate all-around portable measurement solution for medium-to-large sized components.

Exact Metrology is an ISO AS9100 Certified along with being FFL and ITAR Registered.

Exact Metrology, with facilities in Cincinnati, Moline and Milwaukee plus affiliated offices throughout the country, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

For information, please contact:

EXACT METROLOGY, INC.

Dean Solberg

20515 Industry Avenue

Brookfield, WI 53045

Local: 262-533-0800

www.exactmetrology.com

deans@exactmetrology.com

EXACT METROLOGY, INC.

Steve Young

11575 Goldcoast Drive

Cincinnati, OH 45249

Local: 513.831.6620

Toll Free: 866.722.2600

www.exactmetrology.com

stevey@exactmetrology.com

Jason Kleinhenz received a biomedical engineering degree from the University of Cincinnati. He is currently the training and marketing manager at Exact Metrology.

Exact Metrology, a comprehensive metrology service provider, shares helpful safety tips for metrology workers during the COVID-19 pandemic. These tips are courtesy of Jason Kleinhenz, Exact Metrology marketing and training manager.

With much of the workforce operating from home, keeping up with quality inspection and reverse engineering is difficult during this time. However, there are solutions to counteract this problem. Some companies employ several of these tactics daily, but in these trying times they are much more relevant to maintain effective production.

If you are in the workplace, follow all the stated guidelines. These include staying 6 feet away, washing/sanitizing touched surfaces and washing your hands. Also remember to clean the objects you’re working with such as data collection tools and computers.

Only one person should collect the data from the object(s). That person is responsible for handling the objects and the data collection tools. Of course, the designated person also needs to clean and sanitize all objects, tools and surfaces.

Workers must save and upload data sets (and/or workspaces) to the cloud. Due to security threats, a company’s IT team should use a virtual private network (VPN) and/or file transfer protocol (FTP). This reduces the chances of data being hacked or stolen.

Have another person, or a team, work separately to download (receive) the data sets, or workspaces and process them. They will have their own safety procedures in place (essentially the same as the data collector). If possible, the processing person(s) should write programs at the same time the data is collected. This saves time and money as two operations are occurring at the same time. Most likely, this is not possible in reverse engineering projects. However, in quality inspection projects, this is a massive time-saving practice.

Communicating between the collector and processor(s) can be done quickly, and virtually, with online services like Skype and Zoom. The good old-fashioned phone works well for quick conversations too. There are some software packages that allow seamless workspace sharing between different people and teams such as a package through PolyWorks® by InnovMetric.

These techniques and tools can help companies reach their quality and reverse engineering objectives during social distancing. Exact Metrology is available to answer any questions about how to maximize efficiency or help with projects.

Exact Metrology is an ISO AS9100 Certified along with being FFL and ITAR Registered.

Exact Metrology, with facilities in Cincinnati, Moline and Milwaukee plus affiliated offices throughout the country, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

For information, please contact:

EXACT METROLOGY, INC.

11575 Goldcoast Drive

Cincinnati, OH 45249

Local: 513.831.6620

Toll Free: 866.722.2600

www.exactmetrology.com

info@exactmetrology.com

Additional benefits of ordering the pre-defined packages include a price discount, a simplified ordering process and a shortened lead-time. The program is subject to availability and delivery time will depend upon the stock available in Elk Grove Village, IL. Only customers located in the United States with a physical mailing and delivery address are eligible for this program.

“Siemens is bringing the Sinumerik 828D to a highly competitive price point in the US market. The 828D is a compact, panel-based CNC that offers machine tool builders very flexible machine design integration”, says John Meyer, Marketing Communications Manager, Siemens Industry, Inc. He continues, “End-customers will benefit from our highly intuitive and easy-to-use ShopMill and ShopTurn graphical programming interfaces, which increase machine tool usability and shop-floor productivity.”

There are seven pre-defined Sinumerik 828D packages covering the most typical standard milling and turning machines. They include:

With its popular CNC system for milling and turning machines, Siemens is offering the Sinumerik 828D Fast Package program for quick delivery to machine tool builders, system integrators and retrofitters. These pre-defined packages for typical standard milling and turning machines include the CNC, drive, motors and accessories (e.g. cables).

Learn more by visiting our website: http://usa.siemens.com/828-fp

Follow us on Social Media:

www.twitter.com/siemens_cnc_us

www.facebook.com/SiemensCNC

Siemens Digital Industries (DI) is an innovation leader in automation and digitalization. Closely collaborating with partners and customers, DI drives the digital transformation in the process and discrete industries. With its Digital Enterprise portfolio, DI provides companies of all sizes with an end-to-end set of products, solutions and services to integrate and digitalize the entire value chain. Optimized for the specific needs of each industry, DI’s unique portfolio supports customers to achieve greater productivity and flexibility. DI is constantly adding innovations to its portfolio to integrate cutting-edge future technologies. Siemens Digital Industries has its global headquarters in Nuremberg, Germany, and has around 75,000 employees internationally.

Siemens Corporation is a U.S. subsidiary of Siemens AG, a global powerhouse focusing on the areas of power generation and distribution, intelligent infrastructure for buildings and distributed energy systems, and automation and digitalization in the process and manufacturing industries. Through the separately managed company Siemens Mobility, a leading supplier of smart mobility solutions for rail and road transport, Siemens is shaping the world market for passenger and freight services. Due to its majority stakes in the publicly listed companies Siemens Healthineers AG and Siemens Gamesa Renewable Energy, Siemens is also a world-leading supplier of medical technology and digital healthcare services as well as environmentally friendly solutions for onshore and offshore wind power generation. For more than 160 years, the company has innovated and invented technologies to support American industry spanning manufacturing, energy, healthcare and infrastructure. In fiscal 2018, Siemens USA reported revenue of $23.7 billion, including $5.0 billion in exports, and employs approximately 50,000 people throughout all 50 states and Puerto Rico.

Continue reading

Refurbishing Offers a Less Expensive Option During These Uncertain Economic Times

As machinery ages, it begins to decline in performance and consume more replacement parts. Wardwell’s braiding machines are excellent candidates to be refurbished with new parts and updated features. Options can include high-efficiency motors, drives, broken wire detection, empty bobbin detection, core run-out sensors and longitudinal taping systems. The advancements in mechanical and electronic components make retrofit a cost-effective option to improve performance on existing machines.

Wardwell, Central Falls, Rhode Island, began in 1911 as a supplier of braiding machines to the manufacturers of textile products and later developed machinery models for reinforced hose and composite structures. Since the 1970s, the company’s focus has been on specialized braiding machines that serve the wire and cable industry. Today, Wardwell is a global supplier of braiders, winders and payoffs for the wire and cable industry.

For more information, please contact:

Cynthia Chen

Wardwell Braiding Co.

Phone: 401-724-8800 X 183

Fax: 401-723-2690

E-mail: cchen@wardwell.com

Web: www.wardwell.com

Company to sell full line of EDM wires, including brass and coated

All pricing is shown for the products in the GIP Online Store, something unique to the EDM industry, plus all major credit cards are accepted for fast, easy purchasing. In addition, GIP offers trial spools at discounted rates to all participants in the company’s GIP Wire Test Program, which can be engaged at the company’s website, www.gip-edmwire.com.

THE ADVANTAGES OF ONLINE BUYING

For more information, please contact:

Barry Ramsay

General Manager

GLOBAL INNOVATIVE PRODUCTS

7697 Innovation Way

Suite 200

Mason, OH 45050

Phone: 513-701-0441

www.gip-edmwire.com

bramsay@gipintl.com