Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Standard and custom styles offered for all common tapers, including CAT, HSK and BT

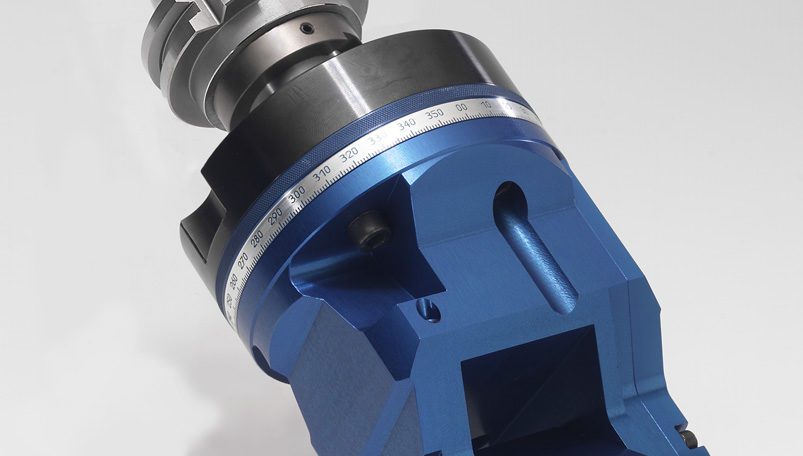

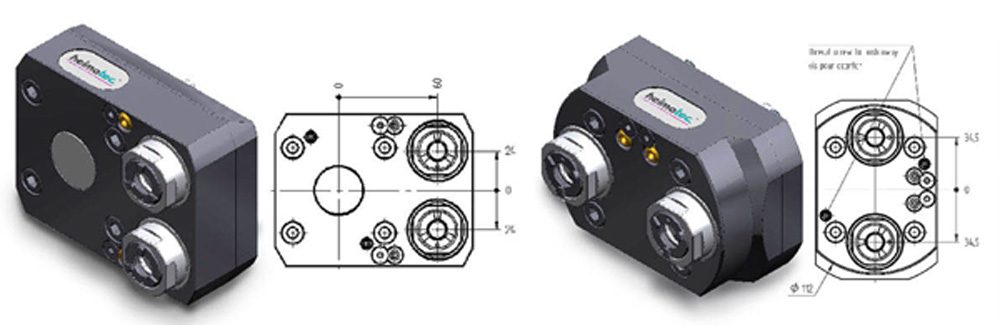

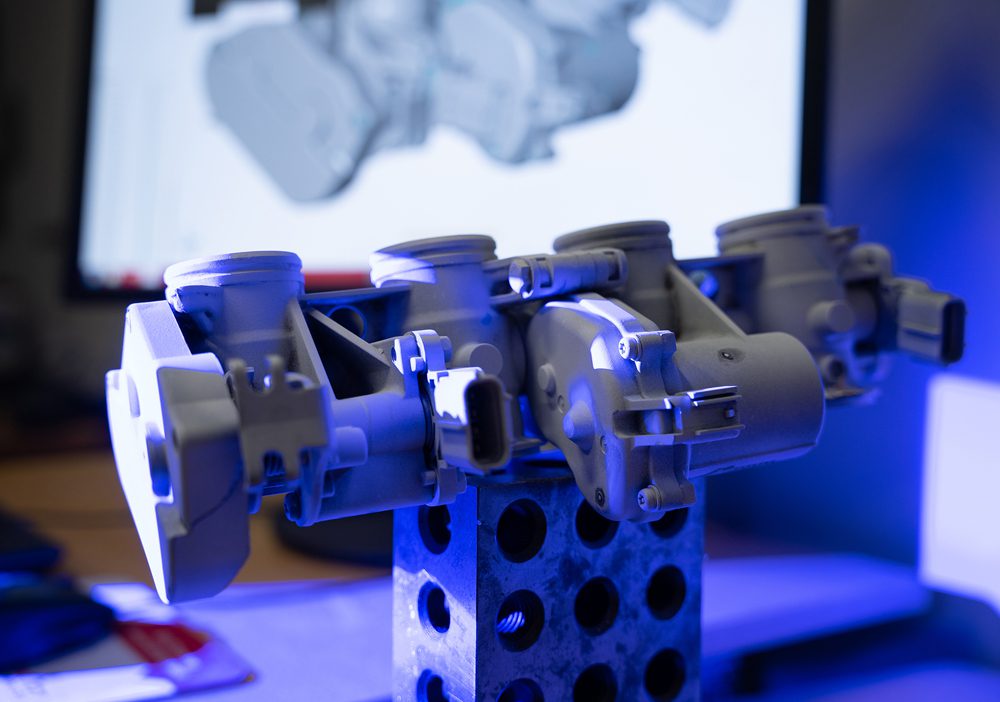

Platinum Tooling, the exclusive importer of Heimatec live tools and angle heads, is pleased to announce the expansion of their current angle head inventory with many styles available for immediate delivery from stock at their Illinois headquarters. These newly designed standard and custom angle heads offer superior performance in comparison to other brands in the marketplace. Heimatec angle heads are available in all popular sizes and styles suitable for today’s CNC machining centers.

Included in Platinum Tooling’s wide offering, there are several designs under 12 pounds that can be used in all automatic tool changers. Angle heads with compact, extended reach features, slim line for working in small places, dual output tools for added productivity and universal adjustable tools for compound angles are also available. In addition, the Heimatec line includes tools for heavy milling, deep drilling and tapping operations. Most of the angle heads are designed with Heimatec’s patented u-tec® changing system which allows for greater flexibility.

Heimatec angle heads are made from high-tensile strength aluminum. High-precision spindle bearings maintain the highest possible spindle concentricity. All the gears on these angle heads have inclined teeth made from high-resistance gear steel and have been specially hardened, ground and lapped in sets to provide the smoothest transmission output possible.

Full 360º body rotation with positive compression locking, 90º incremental repositioning without indicating, maximum torque to 150 Nm, gear ratio 1:1 standard with others available, spindle speeds to 24,000 rpm and interchangeable torque arms are other standard features of this line from Heimatec.

Heimatec tools are offered in North America by exclusive importer, Platinum Tooling Technologies, Inc.

For further information and literature, or to arrange a demo on this new line, please contact:

Preben Hansen, President

PLATINUM TOOLING TECHNOLOGIES, INC.

16 E. Piper Lane

Suite 128

Prospect Heights, IL 60070

Phone: 847-749-0633

Fax: 847-749-2445

Email: phansen@platinumtooling.com

Platinum Tooling Technologies, Inc. in Prospect Heights, IL, near Chicago, serves its growing North American customer base with an extensive inventory of machine tool accessories. Its experienced staff is dedicated to providing the most innovative tooling and technology. Platinum Tooling Technologies, Inc. serves the auto, aero, medical, woodworking, composites and other industries, as well as an ever-increasing number of machine tool OEMs worldwide, through its network of manufacturers’ representatives. Platinum Tooling is the importer of Heimatec, Henninger, Tecnicrafts, and AMF Tooling for North America.

Continue readingNew technology has enabled F.O. Select to easily achieve greater quality, efficiency and durability of their cutting tools

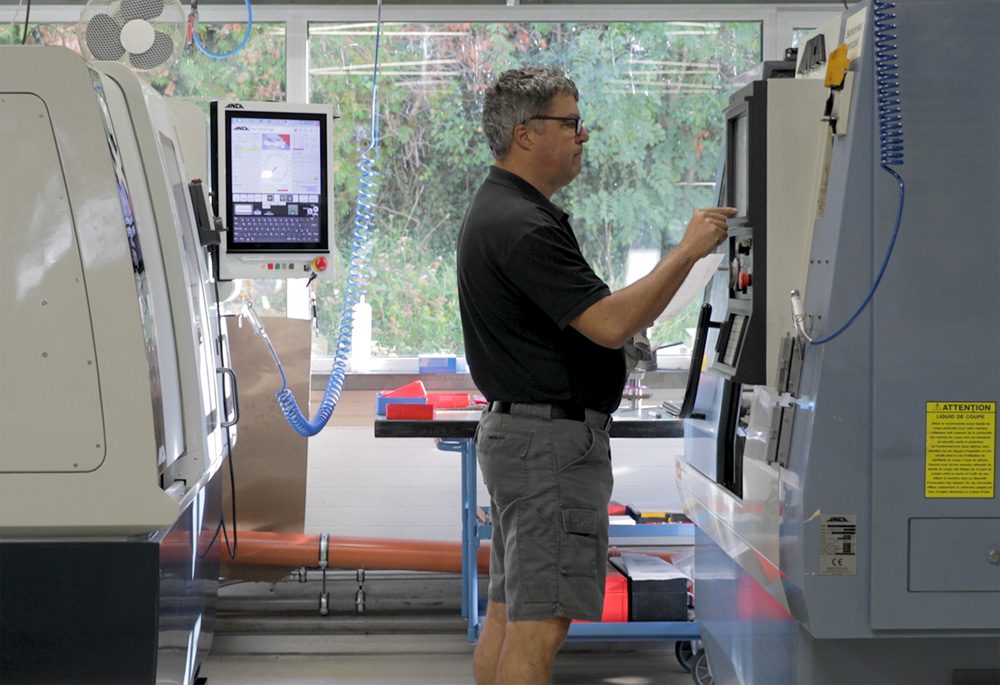

Loïc Jacot, 5th Generation family member of F.O. Select said, “Our business was founded in 1886 by my Great Great Grandfather when he started manufacturing razor blades. At the beginning of the 20th century, the multinational company “Gillette” entered the European market and Arnold Schumacher decided to diversify the production with different cutting tools.”

“Our customers like the fact that we are still a family business. We have 130 years of experience in the production of tools. In general, we can say that we work with all main key cutting machine producers on the market. Since all people in the world use keys you need to cut millions and millions of keys every day. The market is niche but worldwide.”

F.O. Select has the utmost respect for legendary Swiss quality. They specialize in the manufacture of key cutters, cutter wheels and fine tooth cutters. Their dynamism and expertise has led the business to strive constantly for innovative performance and quality assurance. Production wise, the company has leading-edge technology that combines traditional craftsmanship with today’s modern manufacturing methods.

Loïc continues “We produce all our products in-house so we have a control over the whole production process. We produce about 100,000 pieces a year and export our products in 75 different countries with a very short lead time of 48 hours. Keys are becoming more complex because people want more security. Since the market is shifting towards precision we needed more precise machines to manufacture the keys.”

“In Switzerland, if we want to be competitive, we have to be automated, because in Switzerland everything is very expensive. We looked for the best solution for our production needs, understanding that cost reductions could be achieved with better efficiency and productivity. Investing in capital equipment is expensive and we needed to calculate if we should buy a new machinery. We looked at how the ANCA FX5 grinding machine would help us in the production process in terms of productivity through automated solutions. Quality is also very important to our business.”

“We have achieved these savings by investing in equipment that can run without human intervention, or ‘lights out’. This means they can run, producing tools, after office hours – during the night and weekends unattended.”

“In fact, since we installed our FX5 ANCA grinding machine we have been working 24 hours seven days a week.”

“New technology is very important because they bring efficiency, reliability, and precision. Our new ANCA machine is very precise, automated; and thanks to the laser we can measure the pieces on the machine and the machine will, by itself, change the software to make the measurement correct. This is crucial when working unmanned during the night or weekend.”

“The ANCA machine is easy to set up because the software is user friendly. We had no experience how to set up grinding machine producing endmills before our first ANCA machine. And now we have two and in the future maybe more.”

“We received training from ANCA to help set up the machine correctly. The robot is very easy to set up, so in a few minutes, you can change the diameter or you can change the table and the machine will be ready for production. And the good thing also is, I mean, the machine is more compact. I mean in comparison — if we compare our old ANCA machine and the new one, the new one is maybe 30% smaller.”

“We have a bright future because we have modern machines, precise ones, automated. And since we control the whole production process we developed our know-how and we produce more precise and more durable tools,” Loïc Jacot, F.O. Select.

For further information, please contact:

Johanna Boland

Group PR and Communications Manager, ANCA

M: +61 407799779

Johanna.Boland@anca.com

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

Continue reading

Machining center spindle speeders including mechanical, air and electric motor driven

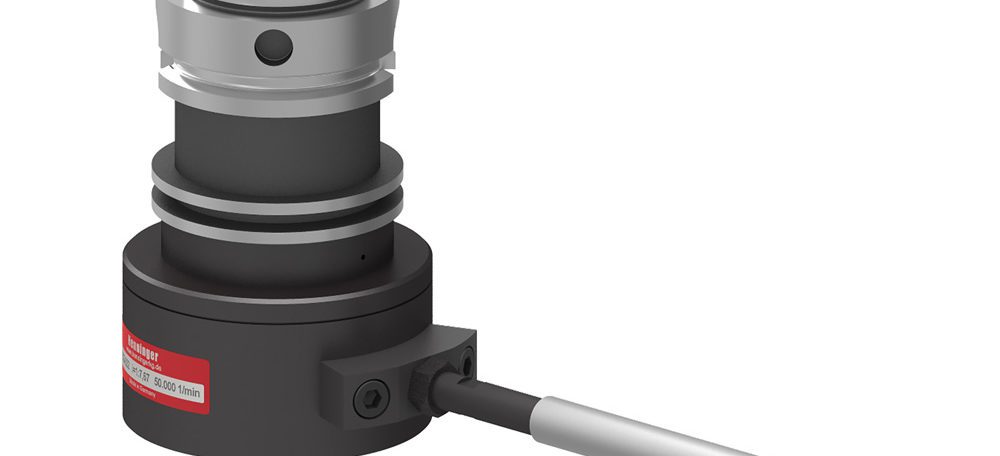

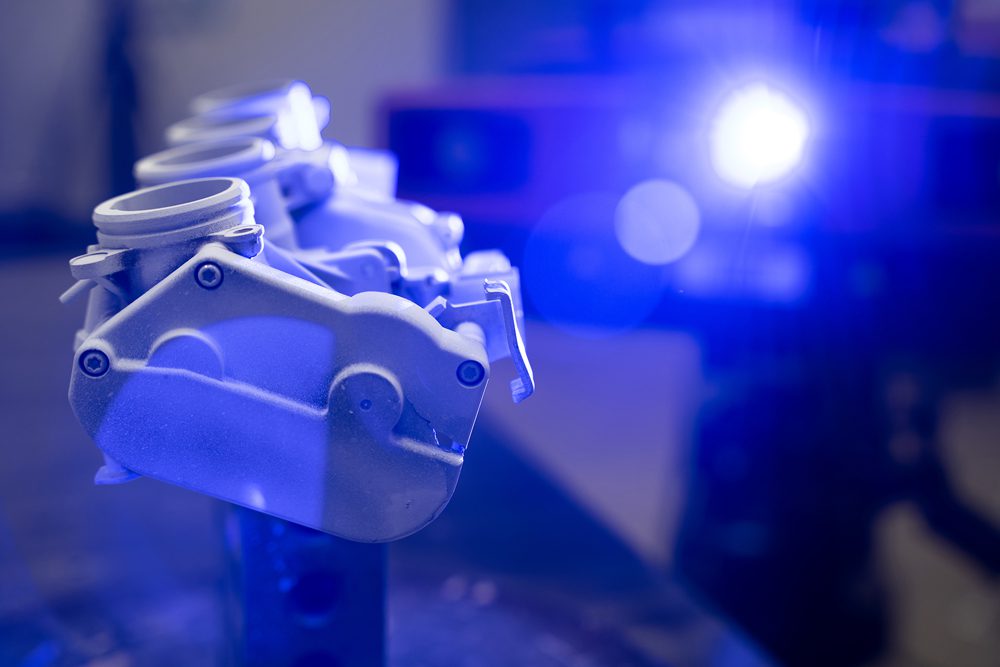

Platinum Tooling, the importer of live tools, angle heads, marking tools, Swiss tools and multiple spindle tools manufactured by various global suppliers, is now importing Henninger Speed Increasers for North America. The announcement was made by company president, Preben Hansen, at headquarters in Prospect Heights, Illinois, near Chicago.

Henninger is a manufacturer of specialized equipment and precision machine tool accessories. Their speed increasers help maximize productivity by achieving a higher spindle rpm that is required for certain applications in today’s marketplace. Small diameter tools require rpms that are sometimes not possible to reach with existing machine tools. In addition, they allow for less wear and tear on the machine’s spindle when it is not required to run at its maximum rpm.

Mechanical speeders are available with up to a 1:8 gear ratio and a maximum speed of 50,000 rpm. Air speeders can run continuously at up to 80,000 rpm and high frequency motor spindles can maintain up to 80,000 rpm with high torque, and have variable speed options.

Many of the speeders have automatic tool change capabilities and are modular in design to offer the customer greater flexibility.

Henninger also manufactures custom angle heads, live centers, face drivers, and live chucks. In addition, Henninger is the premier manufacturer for center grinding machines.

To learn more about these Henninger products as well as the Heimatec, Tecnicrafts, and AMF lines available through Platinum Tooling, please visit the company website.

For more information, please contact:

Preben Hansen, President

Platinum Tooling Technologies, Inc.

16 East Piper Lane, Suite 128

Prospect Heights, IL 60070

847-749-0633

www.platinumtooling.com

phansen@platinumtooling.com

Platinum Tooling Technologies, Inc. in Prospect Heights, IL, near Chicago, serves its growing North American customer base with an extensive inventory of machine tool accessories. Its experienced staff is dedicated to providing the most innovative tooling and technology. Platinum Tooling Technologies, Inc. serves the auto, aero, medical, woodworking, composites and other industries, as well as an ever-increasing number of machine tool OEMs worldwide, through its network of manufacturers’ representatives. Platinum Tooling is the importer of Heimatec, Henninger, Tecnicrafts and AMF tooling for North America.

Continue reading

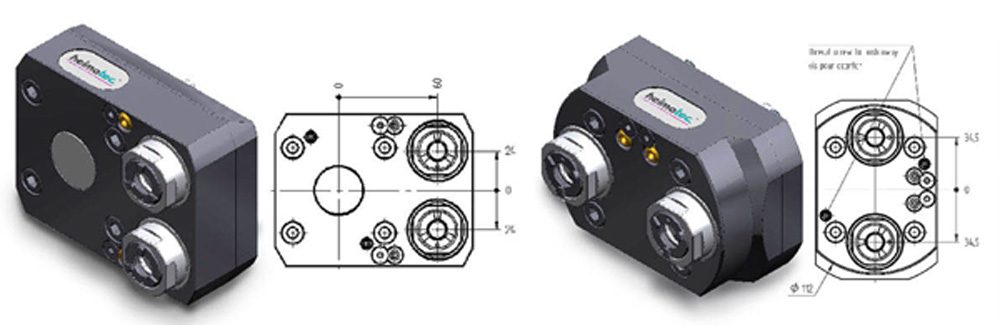

Standard live tools in stock for immediate delivery from Platinum Tooling for DMG Mori, Doosan, Haas, Mazak, Miyano, Nakamura, and many other popular machine brands.

Platinum Tooling, the exclusive North American importer for Heimatec live tools and angle heads, today announces immediate availability of live tooling for most popular turning center models including DMG Mori, Doosan, Haas, Mazak, Miyano and Nakamura. According to Preben Hansen, president of Platinum Tooling Technologies, Inc., “We are now carrying a substantial inventory of live tools for our customers’ machines. It represents a significant financial and warehouse space commitment that we have made to support the North American machine tool market.”

Hansen added that the company will be announcing its in-stock arrangement for many other lines of machine tools, moving forward, including Biglia, Hwacheon, Hyundai, and SMEC. Platinum Tooling Technologies, Inc. serves its North American customers with a full team of manufacturers’ reps, plus its Chicagoland facility provides sales and customer service support, application and engineering advice as well as repair services for the company’s line of live tools.

Literature detailing all the Heimatec products is offered at the company’s website, www.platinumtooling.com. Interested parties may also contact the company directly with inquiries.

For further information and brand-specific literature, or to arrange a demo on any Heimatec tools, please contact:

Preben Hansen, President

PLATINUM TOOLING TECHNOLOGIES, INC.

16 E. Piper Lane

Suite 128

Prospect Heights, IL 60070

Phone: 847-749-0633

Fax: 847-749-2445

Email: phansen@platinumtooling.com

Platinum Tooling Technologies, Inc. in Prospect Heights, IL, near Chicago, serves its growing North American customer base with an extensive inventory of machine tool accessories. Its experienced staff is dedicated to providing the most innovative tooling and technology. Platinum Tooling Technologies, Inc. serves the auto, aero, medical, woodworking, composites and other industries, as well as an ever-increasing number of machine tool OEMs worldwide, through its network of manufacturers’ representatives. Platinum Tooling is the exclusive importer for Heimatec tooling, Henninger speeders, Tecnicrafts Swiss Collets & Guide Bushings, and AMF marking & cleaning tools for North America.

Continue reading

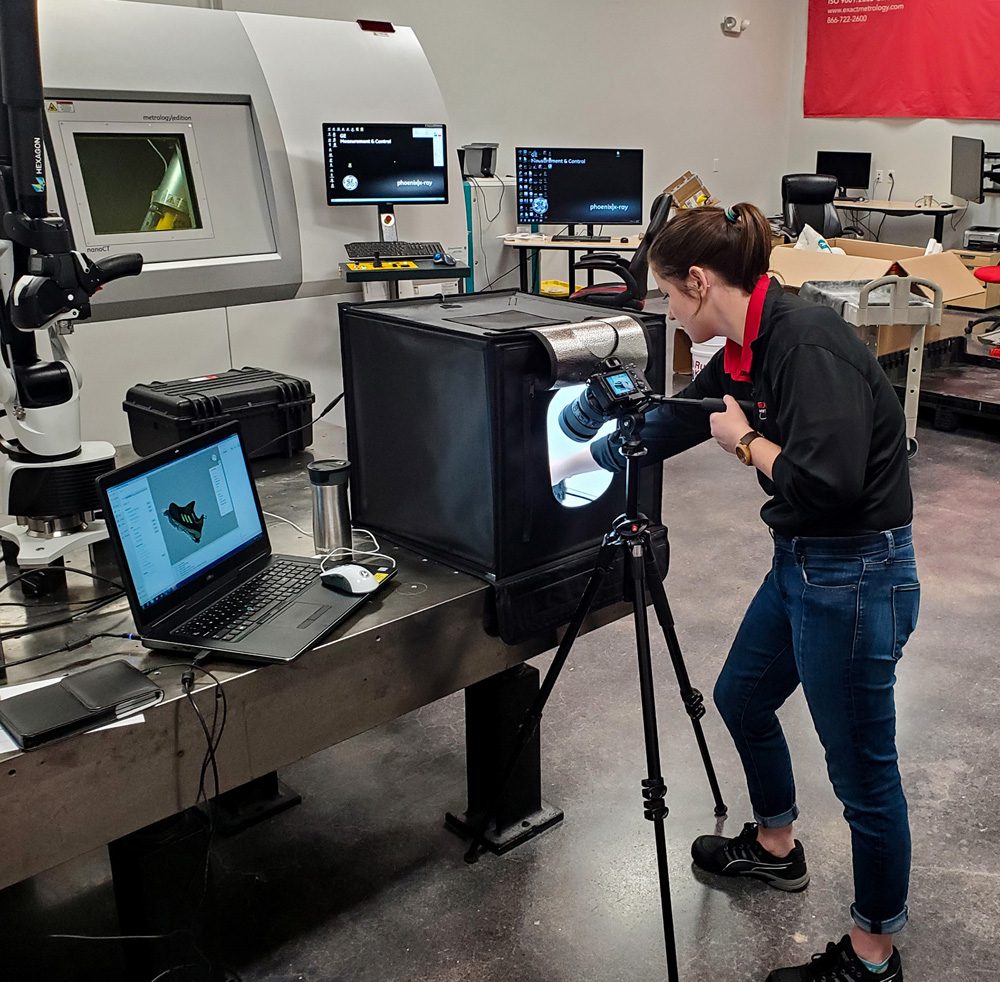

Exact Metrology: A Division of In-Place Machining Company and a comprehensive 3D metrology service provider and hardware sales company, kicked off a new initiative to raise awareness of the capabilities of In-Place Machining Company.

Taking place across the company’s social media platforms each Monday, hence the hashtag #MachiningMonday, this marketing tool will lead to a greater awareness of all the services that (IPM) offers. This concept was developed by Kelly Baldasare, Content Creator at the Exact Metrology Cincinnati, Ohio office. Besides raising awareness, Baldasare hopes that it will “…show the power of what IPM, Exact Metrology, and now the newly acquired OASIS Alignment Services can do together as one team.”

People often ask, “How does metrology work with machining?” The answer is that the possibilities are endless. #MachiningMonday wants to answer this question by showcasing the extensive on-site machining and engineering capabilities of IPM. Baldasare added, “Most people don’t recognize this, but a lot of machining services require metrology and/or precision alignment to make sure accuracy is obtained and to make sure there is no component damage that is being missed before services are performed.” For example, #MachiningMonday recently showcased IPM’s field machining services including lapping and grinding, tapping and reaming, axial, radial and thrust bearing field machining without shaft rotation.

While headed by Baldasare, this initiative is also being driven by Keith Naidl (Creative Services Director of In-Place Machining Company) and Katherine O’Maley (Marketing Manager of OASIS Alignment Services: A Division of In-Place Machining Company). Baldasare is excited to continue bringing new rhetoric to the Exact Metrology discussion. She concluded, “We are all very excited about how our joint capabilities will benefit our customers and we look forward to solving their most challenging issues together as one team.”

Exact Metrology: A Division of In-Place Machining Company, is ISO9001, AS9100 Certified as well as ITAR Registered.

Exact Metrology: A Division of In-Place Machining Company, with facilities in Cincinnati, Ohio, Moline, Illinois and Milwaukee, Wisconsin, plus affiliated offices throughout the country, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

In-Place Machining Company: On-Site Machining Solutions In-Place, Any Place in the World.

In-Place Machining Company, with facilities in Wisconsin, Washington, Virginia, Ohio, California, and Ontario, Canada, is the premier provider of high-precision engineered on-site machining, metrology, and large scale cutting & drilling services for a wide range of renewable energy, aerospace, industrial, and military customers throughout the world.

OASIS Alignment Services: A Division of In-Place Machining Company

OASIS Alignment Services: A Division of In-Place Machining Company, provides 3-Dimensional Metrology Services, Precision Alignment Inspections and Diagnostics and Mechanical Services across a wide range of industries including aerospace, automotive, power generation, shipbuilding, pulp and paper, converting, printing, plastics, textiles and more. OASIS has completed thousands of successful projects since its inception in 1982 and continues to set industry standards in alignment procedures, specialized tooling and reporting techniques. OASIS operates service centers in New Hampshire, North Carolina, Florida, Ohio, Wisconsin, California, Washington, and Ontario and Québec, Canada. For more visit www.oasisalignment.com

Exact Metrology: A Division of In-Place Machining Company

Dean Solberg

20515 Industry Avenue

Brookfield, WI 53045

Local: 262-533-0800

www.exactmetrology.com

deans@exactmetrology.com

Exact Metrology: A Division of In-Place Machining Company

Steve Young

11575 Goldcoast Drive

Cincinnati, OH 45249

Local: 513-831-6620

Toll Free: 866-722-2600

www.exactmetrology.com

stevey@exactmetrology.com

Six ways to make sure your manufacturing business is cyber-secure

By Thomson Mathew—ANCA Software Product Manager

While smart factories are revolutionizing the manufacturing industry through innovation, being connected comes with new risk factors that must be addressed. A Deloitte study revealed that 48% of manufacturers identified operational risks—including cybersecurity—as the greatest danger to their factories.

Manufacturing can be a lucrative ‘get’ for cyberattackers, targeting your intellectual property or blocking production. Businesses risk financial, time and productivity losses if they don’t get the balance right. So, how can you make sure your business is safe?

The cloud offers manufacturers an unprecedented level of flexibility, from lights-out manufacturing to remote real-time data. But this level of connection can expose your business to attack.

While it may be your first concern, the risk isn’t limited to connected machines. Manufacturers can also be vulnerable to phishing attacks, ransomware and internal breaches, among others. This means company phones, email addresses and laptops should all be protected. Relying on supply chains also means manufacturing can be disrupted by attacks on suppliers and distributors. Having a clear picture of risk areas is the first step to creating a secure network.

A false sense of security can be devastating to a manufacturing business if a cyberattack eventuates. Even if you’re on top of what needs to be done, you must ensure everyone in the business understands the risks—human behavior is a significant factor in compromised systems!

Operational technology, including tooling machines, creates endless opportunities for manufacturers. In the past, these machines had no external links to networks and so weren’t vulnerable to digital attacks.

Running machines 24/7 means relying on the network to remain secure even when you’re not there. Because of these risks, ANCA machines have been designed to use whitelisting to ascertain networks can only be accessed by predetermined parties. That means new software and devices must be authorized before they can be added, massively reducing the risk of introducing viruses, malware or weak points. Each piece of software has been thoroughly assessed for vulnerabilities before being whitelisted, so manufacturers can be assured of their machines’ security.

If you’re using a tooling machine, you’re exposing your systems to external third parties. The potential consequences are that you could lose data, you could lose productivity time, or you’ll have ongoing maintenance. You’re putting your machine at risk.

Your manufacturing business isn’t just the machines in your factory. It includes other businesses— like material suppliers, logistics companies and even accountants—and all of their extended networks. Any vulnerability they have can affect your business outcomes.

Speak to each of your stakeholders about what they do to protect their networks. You may not be able to change their approach, but it’ll help you to mitigate the risk at your end, for example, by choosing a more secure supplier or looking into vertical integration.

Even the most secure cloud and digital systems can fail. To ensure your IP is as robust as possible, and to limit the impact on your productivity, you should be performing regular offline backups away from your network.

It’s best to be overcautious. Store multiple backups in different places to better distribute the risk of further data loss—and make sure those locations are secure, too.

Automating this process eliminates the need to remember to do it (often until it’s too late) but performing periodic manual backups will give you the best coverage.

Cybercrime is big business—some reports suggest it’s the equivalent of the world’s third-largest economy, inflicting damages in the trillions of dollars every year. Globally, spending on cybersecurity is expected to grow to almost U.S. $350 billion by 2026.[1], [2]

With so much at stake, the goalposts are constantly changing. New viruses appear in the market every day, with rapid patching and greater security a constant feature. To guarantee your business’s ongoing safety, be ready to respond to new threats by frequently updating all software—not just your antivirus—and deferring to machine experts as situations change.

For further information, please contact:

Johanna Boland

Group PR and Communications Manager, ANCA

M: +61 407799779

Johanna.Boland@anca.com

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

[1] https://cybersecurityventures.com/hackerpocalypse-cybercrime-report-2016/

[2] https://cybersecurityventures.com/cybersecurity-market-report/

Continue readingBy Johanna Boland, Group Strategy and Communications Manager at ANCA CNC Machines

When I moved into the Communications role at ANCA, an Australian manufacturing company, I anticipated our marketing activity would be straightforward, and, if anything, a little bit dull.

I knew I would be working in the technology sector, and that was interesting, but I wasn’t sure how much creativity would be encouraged or needed in a B2B organization.

And to be honest that is what I found. We are a fully privately-owned Australian manufacturer running for over 45 years from Melbourne and export 99 per cent of our product overseas. ANCA is thriving with around 1,000 employees and is a world leading manufacturer of CNC grinding machines, motion controls, sheet metal solutions and components.

We have customers in over 45 countries and facilities in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA as well as a network of representatives and agents worldwide. So as a business ANCA was doing well.

My first job was to benchmark against our competitors, and we were easily meeting the same standards. We had a strong brand, advanced product management process, advertised, participated in the right exhibitions, produced good, printed sales materials and had a passable website. All respectable, solid traditional marketing activities.

But it wasn’t just traditional marketing that enabled us to take the top position in our market. We make a really great product with extraordinary technology backed up by a global sales and service infrastructure. It was a positive customer experience that saw us dominate our market.

We were successful and our customers loved us – so why break what wasn’t broken? Finding my feet, I realized the potential of this opportunity.

With a more progressive marketing strategy we could offer greater customer value and stand out in our market. We wanted to be progressive in channels but also in our approach and content.

Firstly, we considered the customer experience and from reviewing social media, I got a very strong sense of the people behind the machines. These cutting tool manufacturers considered themselves as craftspeople who made objects just as beautiful and refined as a guitar.

Tapping into this passion and profiling the person as well as the technology has differentiated us compared to our competitors. Telling our users’ stories has helped us better engage and inform customers.

We also looked at our channels and digital was the one to tackle first. Our website was old and clunky – but again, against our sector we were not doing badly.

The business wasn’t shouting for a new website, but with dated architecture and visuals the site wasn’t the perfect match for our brand. We boasted technology that could grind to an accuracy of <0.002 millimeters, yet our website was over ten years old, and looked it.

In our new website we have a careers section to highlight how cool ANCA was to work for, video integration for highlighting new products, a news and media section to add value for our customers and it is integrated to our customer relationship management system (CRM) for lead generation and visibility.

Our next step will be to launch an e-commerce platform in a few months – something I am sure our competitors are not ready for and which will further help position us as a progressive business and grow revenue.

Our content marketing not only adds value to the customer but it also profiles our experienced technical experts and reinforces ANCA’s brand as the leader in its field. Social media has also provided important access to the voice of customer and our Product managers regularly use the global Cutting Tool Facebook Forum to seek customer insights and understand what the market is thinking.

We were the first in our industry to really have a go at social media and are now streaks ahead of our competition in both followers and engagement. In fact, our competitors are copying our campaigns in their own social feeds. Thankfully it is much easier to start in front than to catch up.

Posting regular content and engaging with customers’ posts has built a thriving community. We see tons of fantastic user generated content with customers sharing photos of the tools they have produced on our machines every day. Using the hashtag #MadeonANCA, we now have hundreds of mini customer testimonials that give meaningful credibility to our brand.

Going back to the people behind the machine, we prioritized activity to improve the customer experience, rather than selling the product. Our #ToolTipTuesday series has been a hit.

We post a short informative video with tips on how to use our software. These videos have attracted almost 85,000 views on YouTube since launch. A sales person recently had a call from Boeing asking about a machine after seeing a tool tip which piqued their interest.

Given our machines can sell for hundreds of thousands of dollars, this was a cost-effective sales lead. Our #ANCAFlashBackFriday posts spark conversations about past achievements and memories to help reinforce our heritage and brand loyalty. We are also about to launch our own TV show — ANCA Academy — to host on our YouTube channel. What I am most proud of is our Tool of the Year competition, which is now in its fourth year.

The team built a campaign that has attracted over 100 entries from Turkey, India, Italy, France, Thailand, USA, Germany, Poland, China, Russia, Japan, Korea and Malaysia. We livestream the results at the major trade fair of the year and gain significant media coverage to boost our customers’ brands.

Last year there were almost 30 entries received from across the world, achieving 70 media appearances seen by over 80,000 fans and generating over 200,000 engagements on social media.

Awards are not a new concept, but this format was for our industry, especially using social media as part of the campaign. We use our Facebook channel for the community to like the entries and select the finalists, helping grow our own Facebook page and reach a broader audience.

We found an influencer, Alfred Lyon, and asked him to be a judge. Alfred is a customer in the USA who has over 45 thousand followers on Instagram – and I don’t imagine that many people would bother to follow if they weren’t interested in content featuring cutting tools.

At a trade show in Germany when we announced the winner on the stand a customer came up to me and thanked me for giving their industry a platform to be recognized.

Four years into working for ANCA I have seen the value of thinking creatively and bringing new and different ways of building your brand to a business. Traditional marketing remains fundamental, but building a personality around our product, telling a story and considering the person behind the machine has helped us gain a more vibrant and open reputation.

Johanna Boland is Group Strategy and Communications Manager at ANCA CNC Machines.

For further information, please contact:

Johanna Boland

Group PR and Communications Manager, ANCA

M: +61 407799779

Johanna.Boland@anca.com

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

Continue reading

Carbide Grinding Company, Inc, was established in 1974, and developed a reputation as a small, specialist maker of tools, supplying Milwaukee-area manufacturers like Snap-on and Harley-Davidson.

After purchasing the company in 2003 and giving it a new image as Gorilla Mill two years after — its branding is simian-themed, aggressive, fun, and comes with the tagline “Weapons of Mass Production” — Kevin Cranker has set the company on a solid growth path.

They are now up to 48 employees, with 300 distributors worldwide, and a diverse spread of customers.

These include automotive and defense suppliers, aerospace customers including Boeing, and space clients like SpaceX and Blue Origin.

But it’s the support of “mom and pop” shops that Cranker seems happiest about.

“They’re the guys who keep our work up,” he explains.

“When one of the big guys goes away it stings a bit. But then we have a number of small mom and pop job shops that we love doing business with because they’re always there and just always buying.”

Cranker says ANCA CNC Machines has played a large role in Gorilla’s Mills’ progress.

After investing in and being disappointed by a European-made tool and cutter grinding machine early in the millennium, he decided to try an RGX, suitable for re-grinding and low-volume production.

The machine is still part of GM’s collection of ANCA machines, and has been joined by 17 others.

“I’ve been buying a couple a year pretty steady here for the last five or six years. Probably going to need some more here before 2022.”

“We have several RX7s. Several MX7s. A couple of TX7s. We’ve got now a bunch of FX7s. It’s a mix of all different older ones and newer ones. I really, really like the new ones with the linear motors, which work really well.”

Cranker says linear motors made by ANCA Motion offer a “night and day” difference versus ballscrew motion, with greater precision and speeds, and much greater durability in a workshop where a lot of carbide sludge is generated.

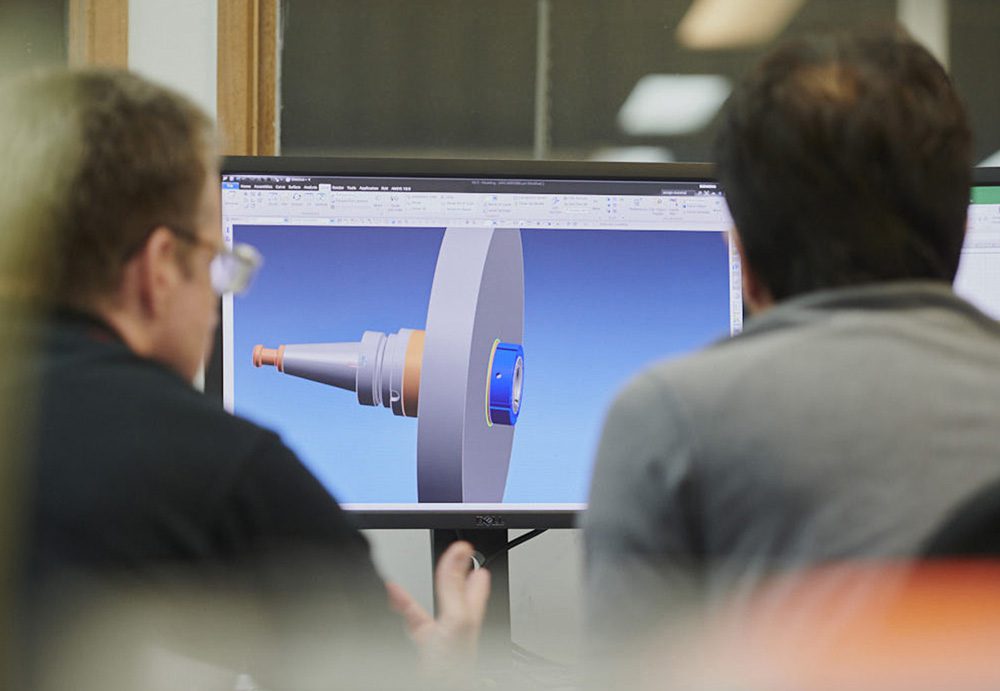

ANCA’s pioneering simulation software was another enabler, and took the “heartache and headache” out of designing the geometries of Gorilla’s patented four-and five-flute mills, which Cranker designed with Mark Greenwood.

The firm adopted simulation with the purchase of its second ANCA machine, and it has proved invaluable ever since.

“The GM Team quickly identified the value in ANCA 3D CIMulation in its assistance to design and develop new tool geometries without actually grinding a physical tool,” says ANCA Inc General Manager, Russell Riddiford.

“Then they take that design to the ANCA machine and get the first tool off the machine perfectly as designed in the 3D CIMulation.”

Cranker adds of tool development that there would be “just no way we could do it” without the 3D CIMulation.

“We were able to mess around with geometries in a virtual space and not waste materials and machine time and everything else,” he says.

“But nowadays the simulator has just gotten so much better with all these new additions and the fact that now you can make blueprint drawings from it and you can just do a whole lot more.”

One software feature that gets regular use is tool balancing, introduced in ToolRoom RN34. This has proven “a huge help,” mainly for single-flute routers, enabling design of tools for high-speed machining that won’t produce noise and chatter and damage workpieces.

Levels of user friendliness and automation options available on ANCA machines have also grown up with Gorilla Mill.

“Cross training” required among the fast-growing workforce is minimal, and most of the workshop’s machines have the same ANCA software.

“Plus, we have all of our machines tapped into a network,” says Cranker.

“We can just manipulate toolpaths and tool programs right in our simulator and then shoot that over to whatever machine they’re needed at.”

Every machine is equipped with a robotic loader — either a pallet-style or a newer AR300 unit — helping make lights out work possible. Daytime is for custom and short-run production. The third shift is unmanned.

As the company grows its staff and revenues — which have risen nearly 900 per cent since the beginning of the Gorilla Mill era — Cranker estimates it will continue to invest in FX and MX machines, as well as robotic options to go with these.

“We currently have the ability to make 3,500 endmills a night if need be, and that’s huge for us, says Cranker, who recalls the company getting started with automation on the old RGX machine.

“It can be tricky if you don’t know how to set things up right, and ANCA’s done a pretty good job of trying to keep complications to a minimum. But we honed our skills, and every time we moved up we bought another loader, because I really want to be able to make tools lights out.”

For further information, please contact:

Johanna Boland

Group PR and Communications Manager, ANCA

M: +61 407799779

Johanna.Boland@anca.com

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

Continue reading

Today, Walter Friedrich, the president and CEO of GMTA (German Machine Tools of America), Ann Arbor, Michigan, has named Marius Braun to the post of Vice President of Sales for the company, effective January 1, 2022. Marius Braun will supervise the North American sales for this powerhouse distributor of various gear making and related lines of machine tools for automotive and other power transmissions, plus cleaning equipment and the newly acquired line of lasers for motor lamination production, Steifelmayer.

Marius Braun has worked in the USA since 2018. He was previously a regional sales manager for Hermle and a Tier One Key Account Manager for Magna.

For GMTA, Marius will oversee the sales of the gear making machine lines sold by the company, most notably PROFILATOR, originators of the patented Scudding® technology for gear generating. In addition, he will supervise the efforts on BvL parts washers, the STIEFELMAYER laser cutting machines for motor laminations, the SAMAG Multi Spindle machining centers, the ARNOLD laser welding machines, and the entire line of RASOMA vertical lathe and special purpose machine.

“GMTA is a leading supplier of gear making machines to the North American market and Marius has many related skills that will allow him to make a strong start for us, as we enter another busy IMTS year,” noted Walter Friedrich.

For more information on this announcement, please contact:

GMTA (GERMAN MACHINE TOOLS OF AMERICA)

4630 Freedom Drive

Ann Arbor, MI 48108

Phone: 734-973-7800

Fax: 734-973-3053

Web: www.gmtamerica.com

Email: sales@gmtamerica.com

Attention: Walter Friedrich, President/CEO

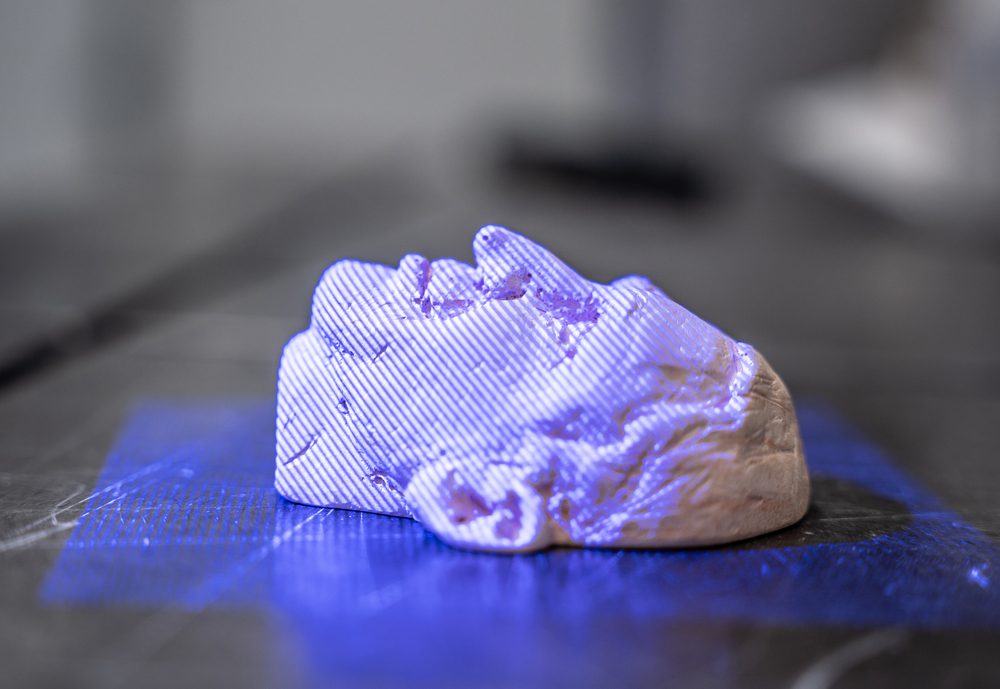

Exact Metrology: A Division of In-Place Machining Company and a comprehensive 3D metrology service provider and hardware sales company, recently used Blue Light Scanning technology to mass produce celebrity-themed soaps. These soaps will be sold by a non-profit for charity.

Blue Light Scanning, a form of structured light scanning technology, operates by using a combination of projector, camera and a lens system. By using a projector, a pattern of light is created and the shadowed, dark areas on the object get measured for data collection. The scanner utilizes optical non-contact technology to capture millions of accurate points in a single fast scan.

Noah Branscum, Exact Metrology Application Engineer for Short Range Scanning, working at the company’s Cincinnati office, completed the soap scan. Steps involved using reference points to help the scanner understand where the carved head is in space. Then, he took a “scan” using the scanner to display the lines of blue light onto the part and had two cameras reading how the lines refracted off the part, producing multiple lines of 3D points in space.” After going around the part to take several scans, Branscum proceeded to use reference points to stitch each scan together. He then created a .stl file of the 3D scan data by way of a “mesh”, using ATOS Professional software. This software is used to operate the sensor head, process the 3D point cloud data and to edit and post-process the data. Besides polygon mesh generation and editing, additional features include sensor control, sectioning and primitive generation.

Discussing the challenges of scanning these famous faces, Branscum commented the scanner was limited in its “line of sight.” “Things like between the eyes and eyelids can be a bit though, or where there’s very sharp valleys like the lips.” Thankfully, ATOS Professional also helps fill in the holes with feature and character line detection.

Asked about future projects like this, Branscum concluded, “We love challenges and this was a fun experience for us. We look forward to working on equally challenging projects in the future.”

Exact Metrology: A Division of In-Place Machining Company, is ISO9001, AS9100 Certified as well as ITAR Registered.

Exact Metrology: A Division of In-Place Machining Company, with facilities in Cincinnati, Ohio, Moline, Illinois and Milwaukee, Wisconsin, plus affiliated offices throughout the country, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

In-Place Machining Company: On-Site Machining Solutions In-Place, Any Place in the World.

In-Place Machining Company, with facilities in Wisconsin, Washington, Virginia, Ohio, California, and Ontario, Canada, is the premier provider of high-precision engineered on-site machining, metrology, and large scale cutting & drilling services for a wide range of renewable energy, aerospace, industrial, and military customers throughout the world.

For more information, please contact:

Exact Metrology: A Division of In-Place Machining Company

Dean Solberg

20515 Industry Avenue

Brookfield, WI 53045

Local: 262-533-0800

www.exactmetrology.com

deans@exactmetrology.com

Exact Metrology: A Division of In-Place Machining Company

Steve Young

11575 Goldcoast Drive

Cincinnati, OH 45249

Local: 513-831-6620

Toll Free: 866-722-2600

www.exactmetrology.com

stevey@exactmetrology.com